I have a dumb question but after 6 months of trying to learn all I can about LCD projectors I have never seen this one come up. Has anyone ever tried using 4 150W bulbs in the back of a mdf projection box to provide a more uniform light output through the rear frensel? I think having 4 bulbs would provide an even light pattern and should put out over 500w of output minus losses. Would this bee too much light? Could it wash out a 15inch panel? I was thinking about using this light source with the lumen lab lenses and the 135mm triplet. Could this kind of light output help me achieve a 120" diagonal screen?

Thanks for your input,

John

Thanks for your input,

John

We use one lamp to put out light and a fresnel lense to collimate it, to produce an even flow of parallel light rays perpendicular to the LCD over its surface.

Directing light like this is not the same as getting an even reflection on a surface, as in lighting a wall. It's not even in the somewhat more difficult arena of backlighting an LCD. All the light possible has to go in a predefined direction.

With four lamps like you describe, you would achieve four different images each projected (because of the size of the resulting assembly) on different sides of the inside of the box. The lamps would be too far apart to correct using the triplet.

All this is summarized in the statement "we need a point source."

Plenty of people have done 120" diagonal screens, btw. A decent image requires your own box, and a very intense metal halide lamp - 400w is the most proven wattage, resulting in the images you can see on, say, Lumenlab's gallery page.

I've been trying to prove that a 1000w halide lamp would work without washing out (which is what everyone says), but have been set back for the time being because of money issues.

Directing light like this is not the same as getting an even reflection on a surface, as in lighting a wall. It's not even in the somewhat more difficult arena of backlighting an LCD. All the light possible has to go in a predefined direction.

With four lamps like you describe, you would achieve four different images each projected (because of the size of the resulting assembly) on different sides of the inside of the box. The lamps would be too far apart to correct using the triplet.

All this is summarized in the statement "we need a point source."

Plenty of people have done 120" diagonal screens, btw. A decent image requires your own box, and a very intense metal halide lamp - 400w is the most proven wattage, resulting in the images you can see on, say, Lumenlab's gallery page.

I've been trying to prove that a 1000w halide lamp would work without washing out (which is what everyone says), but have been set back for the time being because of money issues.

Ahh the old money issues, is happening to me right now also. I have some of the parts but I need all the optics and lighting. I had previously thought that the pre-lcd frensel would gather light and then output it through the lcd in a straight pattern, then the after lcd frensel would focus the image and at the focal point of that triangle is where the triplet would go. I think a 1000w light would work as well as some of the 400W light setups I have seen on lumenlab are somewhat dim at the corners or around the edges. The edges seem to be the hardest area to light properly and get focused, this is why I thought the 4 lights would work to provide an even light over the entire surface of the lcd. Mabey with the 1000w bulb it would be posible to provide even corner to corner lighting.

hello, guys

can i put a 250w HQI ampole in a 400w ballaste kit?

The 15'' LCD panel doesn’t get damage (lose quality) with the time use, with HQI bulbs?

The 400hqi gives more damage to LCD than 250HQI?

cheers, paspo

can i put a 250w HQI ampole in a 400w ballaste kit?

The 15'' LCD panel doesn’t get damage (lose quality) with the time use, with HQI bulbs?

The 400hqi gives more damage to LCD than 250HQI?

cheers, paspo

250 Watt lamp & 400 Watt ballast

NO! The ballast is a power-limiting autotransformer, or a power-limiting electronic circuit. If you plug a 250 Watt lamp into a 400 Watt ballast it will very quickly overheat and explode.

All Metal Halide lamps use mercury vapor as the conductive medium for the discharge arc. The different colors and brightness are made by small amounts of different halides and nobel gases in the mixture. All mercury vapor arc lamps make lots of UV light. This will bleach the color filters and damage the liquid crystal material in your LCD. You must use a UV filter to protect the LCD. Even the lamps that claim to have a UV filter in the outer glass, only remove 90% of the UV. You can use a piece of Lexan-XL10 or a special UV filter sheet from one of the DIY projector shops. Those are as cheap as $5 US.

The other issue is heat: Any of these lamps will put out lots of heat, both as hot air around the lamp, and as IR light. You need a fan to remove the hot air around the lamp. It should pull or push that hot air out of the box, so it does not mix with the rest of the air in the box. You can also use an IR filter to keep IR energy away from the LCD and fresnels.

NO! The ballast is a power-limiting autotransformer, or a power-limiting electronic circuit. If you plug a 250 Watt lamp into a 400 Watt ballast it will very quickly overheat and explode.

All Metal Halide lamps use mercury vapor as the conductive medium for the discharge arc. The different colors and brightness are made by small amounts of different halides and nobel gases in the mixture. All mercury vapor arc lamps make lots of UV light. This will bleach the color filters and damage the liquid crystal material in your LCD. You must use a UV filter to protect the LCD. Even the lamps that claim to have a UV filter in the outer glass, only remove 90% of the UV. You can use a piece of Lexan-XL10 or a special UV filter sheet from one of the DIY projector shops. Those are as cheap as $5 US.

The other issue is heat: Any of these lamps will put out lots of heat, both as hot air around the lamp, and as IR light. You need a fan to remove the hot air around the lamp. It should pull or push that hot air out of the box, so it does not mix with the rest of the air in the box. You can also use an IR filter to keep IR energy away from the LCD and fresnels.

fans 'n' lens's

How should you setup the UV lexan, IR glass or sheet with the fresnels? Could i put he IR glass first alone, than put the UV lexan sandwiched with the 2 fresnels? Do i need to put glass on either side of the fresnels (unsplit design) or just on the side closest to the lamp? Also, is it alot better to use an unsplit design vs. split? Im asking you because i know you will know for sure 🙂 i am planning on doing the unsplit design and angling the screen to compinsate.

Also, i have the lumenlab plans and the one part about the airflow and fans seems like its not enough. I dont want to copy the picture they have and put it in here because of copywrite, but they use 1 120mm fan blowing air out of the PJ and a slot with no fan sucking in. Do you have any pics dranw i guess that show where to put the fans and how many fans. and a picture of the setup of the uv,ir,fresnels alllignment in an unsplit design if thats the way to go. Thanks 🙂

How should you setup the UV lexan, IR glass or sheet with the fresnels? Could i put he IR glass first alone, than put the UV lexan sandwiched with the 2 fresnels? Do i need to put glass on either side of the fresnels (unsplit design) or just on the side closest to the lamp? Also, is it alot better to use an unsplit design vs. split? Im asking you because i know you will know for sure 🙂 i am planning on doing the unsplit design and angling the screen to compinsate.

Also, i have the lumenlab plans and the one part about the airflow and fans seems like its not enough. I dont want to copy the picture they have and put it in here because of copywrite, but they use 1 120mm fan blowing air out of the PJ and a slot with no fan sucking in. Do you have any pics dranw i guess that show where to put the fans and how many fans. and a picture of the setup of the uv,ir,fresnels alllignment in an unsplit design if thats the way to go. Thanks 🙂

were you asking me?

I have an IR filter right after the lamp, since my filter is quite small. I think it could go anywhere before the fresnels. The UV can also damage the acrylic fresnels, so it would be best to put your UV filter before them, too. If you are using a big sheet of IR glass, then you could try a sandwich of IR glass, UV filter, fresnel. But see how hot the IR glass gets. You might need to have an inch or two of space between the IR glass and the fresnels, with some air flowing in there to cool the IR glass.

I used lumenlab's fresnels and they are thin enough that they will sag if you use them horizontal and leave them unsupported. So I have them resting on a piece of Lexan XL10, which also serves as a UV filter. If your fresnels are vertical, then maybe they won't need that much physical support. (Or maybe you will find that they need support on BOTH sides!) Regarding alignment, just make sure the center of each fresnel is on the central axis line from the center of the lamp arc, through the center of the LCD, and then to the center of the projection lens. You can stick a first-surface mirror in there to bend either the light or the image path, but make sure those centers all line up in the mirror reflection.

If you have the right fresnels for your projection lens, and you don't need to do optical keystone correction, then I would use an unsplit design. The image is a bit better that way. If your field fresnel is too short a focal length, then you should try the split design, since that puts it at least 40 mm closer to the projection lens.

I have not seen the lumenlab plans (either legal or pirated) but I use a single 120 mm diameter 120 VAC 65 CFM fan I got at Radio Shack. It sucks air from my light box around the lamp, through a short duct, and dumps it outside the box. The air comes in over and then under my LCD and fresnels, so they get some cool air flow over their surfaces. My fresnels and LCD never get the slightest bit warm! I think a single fan design can work fine, as long as you don't let any of the hot air around the lamp mix with the air in the rest of the box. Keep the air flowing from cool parts (LCD) toward hot parts (IR filter), then the hottest area (the lamp), and then out. Even if the air is 150 degrees F by the time it reaches the lamp, it would still cool the lamp surface (600 F!)

I have an IR filter right after the lamp, since my filter is quite small. I think it could go anywhere before the fresnels. The UV can also damage the acrylic fresnels, so it would be best to put your UV filter before them, too. If you are using a big sheet of IR glass, then you could try a sandwich of IR glass, UV filter, fresnel. But see how hot the IR glass gets. You might need to have an inch or two of space between the IR glass and the fresnels, with some air flowing in there to cool the IR glass.

I used lumenlab's fresnels and they are thin enough that they will sag if you use them horizontal and leave them unsupported. So I have them resting on a piece of Lexan XL10, which also serves as a UV filter. If your fresnels are vertical, then maybe they won't need that much physical support. (Or maybe you will find that they need support on BOTH sides!) Regarding alignment, just make sure the center of each fresnel is on the central axis line from the center of the lamp arc, through the center of the LCD, and then to the center of the projection lens. You can stick a first-surface mirror in there to bend either the light or the image path, but make sure those centers all line up in the mirror reflection.

If you have the right fresnels for your projection lens, and you don't need to do optical keystone correction, then I would use an unsplit design. The image is a bit better that way. If your field fresnel is too short a focal length, then you should try the split design, since that puts it at least 40 mm closer to the projection lens.

I have not seen the lumenlab plans (either legal or pirated) but I use a single 120 mm diameter 120 VAC 65 CFM fan I got at Radio Shack. It sucks air from my light box around the lamp, through a short duct, and dumps it outside the box. The air comes in over and then under my LCD and fresnels, so they get some cool air flow over their surfaces. My fresnels and LCD never get the slightest bit warm! I think a single fan design can work fine, as long as you don't let any of the hot air around the lamp mix with the air in the rest of the box. Keep the air flowing from cool parts (LCD) toward hot parts (IR filter), then the hottest area (the lamp), and then out. Even if the air is 150 degrees F by the time it reaches the lamp, it would still cool the lamp surface (600 F!)

Thanks for the info, very helpful. Ya, i have the 330mm and 220mm fresnels from lumenlab and the 330mm pj lens so illl do the unsplit design. Ill prob buy the 2 pieces of lexan and sanwich the fresnels in there and have the IR glass about an inch or 2 before those. Where could i get IR glass locally and is that the same as tempered glass or heat resistant glass?

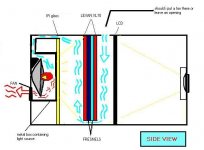

Im having trouble, i think, in understanding the airflow i n the PJ, i tried drawing a diagram of what i think you meant, so tell me if this is correct.

Im having trouble, i think, in understanding the airflow i n the PJ, i tried drawing a diagram of what i think you meant, so tell me if this is correct.

Attachments

airflow

Your drawing has the general idea, with air flowing over the LCD, fresnels, IR glass, but it is not flowing over the lamp surface.

It is a better idea to enclose your lamp with a metal box (where ever possible), so you can push or pull all the airflow through the box right past the lamp surfaces. Of course, you do need a hole for the light to get out, but you can put a pre-condensor lens or IR glass over that hole. The metal box limits light leakage, and heat getting transferred to other parts of the projector. The free air outside the metal box and the high airflow inside the metal box keep it fairly cool. (Don't make the mistake of lining a wooden enclosure with sheet metal: The metal heats up and burns the wood.)

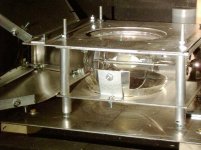

Here is a picture of my light engine, with the front piece of the duct removed. (It would normally cover everything you see.) There is a fan over to the left that pulls the air through the box formed by the top plate, front & back duct pieces, and the plate holding up the reflector. So all of the air flows past the lamp surface. There are multiple layers of metal and free air space between the lamp and the bottom of the wooden enclosure. That is my IR filter right above the lamp. The larger cutout above that is for a pre-condensor lens.

I have seen many light boxes that are much simpler, but they all do the same thing: Hold all the optical parts to keep them aligned, and control the light and heat leakage.

You can look here for IR glass:

http://www.diyprojectorcompany.com/catalog/index.php

Rosco lighting products dealers also have several different IR films and filters. Most theatrical lighting stores and some big camera equipment stores are Rosco retailers.

Your drawing has the general idea, with air flowing over the LCD, fresnels, IR glass, but it is not flowing over the lamp surface.

It is a better idea to enclose your lamp with a metal box (where ever possible), so you can push or pull all the airflow through the box right past the lamp surfaces. Of course, you do need a hole for the light to get out, but you can put a pre-condensor lens or IR glass over that hole. The metal box limits light leakage, and heat getting transferred to other parts of the projector. The free air outside the metal box and the high airflow inside the metal box keep it fairly cool. (Don't make the mistake of lining a wooden enclosure with sheet metal: The metal heats up and burns the wood.)

Here is a picture of my light engine, with the front piece of the duct removed. (It would normally cover everything you see.) There is a fan over to the left that pulls the air through the box formed by the top plate, front & back duct pieces, and the plate holding up the reflector. So all of the air flows past the lamp surface. There are multiple layers of metal and free air space between the lamp and the bottom of the wooden enclosure. That is my IR filter right above the lamp. The larger cutout above that is for a pre-condensor lens.

I have seen many light boxes that are much simpler, but they all do the same thing: Hold all the optical parts to keep them aligned, and control the light and heat leakage.

You can look here for IR glass:

http://www.diyprojectorcompany.com/catalog/index.php

Rosco lighting products dealers also have several different IR films and filters. Most theatrical lighting stores and some big camera equipment stores are Rosco retailers.

Attachments

Ok, i re-did my picture of my airflow setup, tell me if this is better. I know its not accurate but the basic idea is what you have to look at. Any improvements or comments are very much welcomed by anybody.

will using a small double ended 250W bulb with an electronic ballast instead of a 400 or 250W coil,core ballast with a big bulb reduce the heat by much? would it be worth the extra money to spend on it?

will using a small double ended 250W bulb with an electronic ballast instead of a 400 or 250W coil,core ballast with a big bulb reduce the heat by much? would it be worth the extra money to spend on it?

Attachments

new design

That looks better. I suggest you try it with just the one fan, to see if anything gets too warm. Then you can add a pusher fan if you need it. (Fewer fans = less noise.) Like I said, I make do with one 65 CFM fan in my 250 Watt projector with a standard inductive ballast.

The amount of light you need depends on the size of the screen image. If you will have a small image, then a 250 Watt lamp may be enough. With a spherical reflector design, I would not recommend less than 250 Watts. (You can get that in a double-ended shape, if you like.) If you will have anything over 90 inches diagonal, then I suggest a 400 Watt lamp.

Look at the manufacturer's web pages for the lamp data sheets. Some lamps require electronic ballasts, and I think all MH lamps put out a bit more light with a good electronic ballast. The exception to that seems to be the Ushio retrofit lamps, that are designed to work with a High Pressure Sodium lamp ballast. I have read posts claiming trouble running those with electronic ballasts intended for MH lamps.

That looks better. I suggest you try it with just the one fan, to see if anything gets too warm. Then you can add a pusher fan if you need it. (Fewer fans = less noise.) Like I said, I make do with one 65 CFM fan in my 250 Watt projector with a standard inductive ballast.

The amount of light you need depends on the size of the screen image. If you will have a small image, then a 250 Watt lamp may be enough. With a spherical reflector design, I would not recommend less than 250 Watts. (You can get that in a double-ended shape, if you like.) If you will have anything over 90 inches diagonal, then I suggest a 400 Watt lamp.

Look at the manufacturer's web pages for the lamp data sheets. Some lamps require electronic ballasts, and I think all MH lamps put out a bit more light with a good electronic ballast. The exception to that seems to be the Ushio retrofit lamps, that are designed to work with a High Pressure Sodium lamp ballast. I have read posts claiming trouble running those with electronic ballasts intended for MH lamps.

Thanks alot, your advice is very helpfull. All i have to do now is get an IR filter and ballast, bulb. How is this bulb, i can get one very cheap, specs look pretty good but will this type work?

http://donsbulbs.com/cgi-bin/r/b.pl/31973-1.html

Also, i called around at Rosco lighting dealers and a piece of IR glass around 12" x 12" costs about $400 🙂

http://donsbulbs.com/cgi-bin/r/b.pl/31973-1.html

Also, i called around at Rosco lighting dealers and a piece of IR glass around 12" x 12" costs about $400 🙂

cheap bulb

Bulbs like that parabolic reflector one on the webpage you referenced, are difficult to use for a projector. You would have to find one that matches a condensor fresnel's focal length and size. Or add a pre-condensor lens to reshape the cone of light coming from the bulb.

Find one in a T15 or smaller diameter shape, without a reflector. Then add a spherical reflector behind it. Lots of people like the even smaller double-ended bulbs.

Also, a CRI of 65 is not very good. Look for CRI of >85 and color temp of 5000 - 6000 K.

DIYprojectorCompany has IR glass in the $10-20 range. Rosco has a plastic film product they call Thermashield that is also in that price range. I think either of these should go near the fresnels, so it doesn't get overheated by proximity to the MH lamp.

Bulbs like that parabolic reflector one on the webpage you referenced, are difficult to use for a projector. You would have to find one that matches a condensor fresnel's focal length and size. Or add a pre-condensor lens to reshape the cone of light coming from the bulb.

Find one in a T15 or smaller diameter shape, without a reflector. Then add a spherical reflector behind it. Lots of people like the even smaller double-ended bulbs.

Also, a CRI of 65 is not very good. Look for CRI of >85 and color temp of 5000 - 6000 K.

DIYprojectorCompany has IR glass in the $10-20 range. Rosco has a plastic film product they call Thermashield that is also in that price range. I think either of these should go near the fresnels, so it doesn't get overheated by proximity to the MH lamp.

Ok, thanks. Ya, when i talked to the guy at the rosco place, he had no clue about anything. He had to call rosco and call me back with the $400 price. Ill ask again about the thermashield, see if he knows about that. Also, how is this bulb, sold at a DIY website, but colour temp is over 6000K, is that still ok?

http://www.lightingunlimited.com/lampballastsocket.html

Its almost half way own the page:

Description: "Clean Arc" OUT OF STOCK by Eye Lighting, MT400D/Hor, This lamp has the best color of any lamps we offer. The Clean Arc has a color temp of 6500 and a CRI of 90. I would say this is the best lamp for our projector due to the high color values which = to better color being displayed on your screen. The price $53.99 plus shipping of $5.00. If you are interested in this lamp now, let me know.

http://www.lightingunlimited.com/lampballastsocket.html

Its almost half way own the page:

Description: "Clean Arc" OUT OF STOCK by Eye Lighting, MT400D/Hor, This lamp has the best color of any lamps we offer. The Clean Arc has a color temp of 6500 and a CRI of 90. I would say this is the best lamp for our projector due to the high color values which = to better color being displayed on your screen. The price $53.99 plus shipping of $5.00. If you are interested in this lamp now, let me know.

clean arc lamp

>http://www.lightingunlimited.com/lampballastsocket.html

Yeah, that looks like a good lamp to use. It will just be a tiny bit bluer when you look at a very white image, but daylight can actually have a color temp of 10,000 K. So I think it will look great. Much better than a 4200 K lamp.

His reflector looks pretty nice, and that is a great price for an electronic ballast.

>http://www.lightingunlimited.com/lampballastsocket.html

Yeah, that looks like a good lamp to use. It will just be a tiny bit bluer when you look at a very white image, but daylight can actually have a color temp of 10,000 K. So I think it will look great. Much better than a 4200 K lamp.

His reflector looks pretty nice, and that is a great price for an electronic ballast.

damn, that CLEAN ARC bulb is out of stock and he doesnt know when he will get them again. So theres the EYE bulb with the CRI:65, Colour temp 4200, which seems pretty average. Will that still make a really good image or should i look for something better?

you can do better

https://secure.lumenlab.com/shop/group.php?id=4

lumenlab's online store has Ushio retrofit lamps that are smaller-sized, and have color temp of 5200 K and CRI of 85 (or maybe now 90). These work with a standard High Pressure Sodium ballast, which is pretty easy to find. You can save some money by getting one of these lamps from lumenlab or Atlanta Lightbulbs, and then finding an HPS ballast kit you can pickup locally. (The shipping on magnetic core ballasts is very high, because they are so heavy.)

Another solution is to find a local OSRAM distributor, and get one of their Daylight double-ended MH lamps. I think these need an electronic ballast.

https://secure.lumenlab.com/shop/group.php?id=4

lumenlab's online store has Ushio retrofit lamps that are smaller-sized, and have color temp of 5200 K and CRI of 85 (or maybe now 90). These work with a standard High Pressure Sodium ballast, which is pretty easy to find. You can save some money by getting one of these lamps from lumenlab or Atlanta Lightbulbs, and then finding an HPS ballast kit you can pickup locally. (The shipping on magnetic core ballasts is very high, because they are so heavy.)

Another solution is to find a local OSRAM distributor, and get one of their Daylight double-ended MH lamps. I think these need an electronic ballast.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- Lighting and OHP

- Light Source Question