Thi was " in the air" a few years ago...

http://www.newwayairbearings.com/Fa...shingsCat1Name=Products&Cat2Name=Air Bushings

😉

http://www.newwayairbearings.com/Fa...shingsCat1Name=Products&Cat2Name=Air Bushings

😉

for tubing I was commenting on...

... the actual metal tubes , as per the post made by AuroraB

eg:

1/4"OD to fit into 5/16" ID.

of course the link made by AuroraB is a complete solved solution. I wonder if any have had an idea o check the costs...

stew

... the actual metal tubes , as per the post made by AuroraB

eg:

1/4"OD to fit into 5/16" ID.

of course the link made by AuroraB is a complete solved solution. I wonder if any have had an idea o check the costs...

stew

The Ladegaard looks like an elegant solution, bearing in mind that DIY can also look this way:

An externally hosted image should be here but it was not working when we last tested it.

For those interested, - the price mentioned earlier, was appx 240$ for the air bearing combo.

It is discussed in this post

http://www.diyaudio.com/forums/showthread.php?postid=153583#post153583

It is discussed in this post

http://www.diyaudio.com/forums/showthread.php?postid=153583#post153583

AFAIK, that TT in acrylic was at a high end show in Munich (can you imagine moving that thing!) and uses a linear tracking arm that floats in a bath of water. To adjust VTA, you add more or less water!

Actually seems like a pretty neat idea!

Fran

Actually seems like a pretty neat idea!

Fran

Yes. I own that model, Clearaudio Tangent, and I've been thinking about it just for kicks, not that I need to.

FWIW, I've never had a problem since owning it years back.

FWIW, I've never had a problem since owning it years back.

Another Ladegaard floating

Hi All,

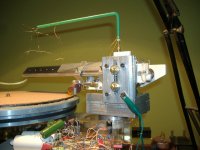

I now have my first prototype arm working! Thanks to Kvap9 for all the advice.

It's just sat next to my TD321 for now, but i have started my own TT based on some leftover walnut for the plinth, the Algar_emi / Mark Kelly dc motor kit and a VPI scout bearing and platter.

First impressions are very good, but i wanted to get some advice on what to try next.

I used some carbon for the tube and a cheap headshell glued to the end, see photo. I soldered the earth wire to the p mount connector on the headshell, but the hum is terrible when connected. What is the correct point to connect earth?

eventually i want to use an arm made from walnut and be one piece.

I was going to use an empty 1ltr plastic bottle for the surge tank, is this ok, or does it need to be very stiff?

Any other advice will be most welcome

Cheers

webby

Hi All,

I now have my first prototype arm working! Thanks to Kvap9 for all the advice.

It's just sat next to my TD321 for now, but i have started my own TT based on some leftover walnut for the plinth, the Algar_emi / Mark Kelly dc motor kit and a VPI scout bearing and platter.

First impressions are very good, but i wanted to get some advice on what to try next.

I used some carbon for the tube and a cheap headshell glued to the end, see photo. I soldered the earth wire to the p mount connector on the headshell, but the hum is terrible when connected. What is the correct point to connect earth?

eventually i want to use an arm made from walnut and be one piece.

I was going to use an empty 1ltr plastic bottle for the surge tank, is this ok, or does it need to be very stiff?

Any other advice will be most welcome

Cheers

webby

Attachments

Any ideas

Hi All,

I have finished the surge tank and this has smoothed the air supply very well.

But now i wanted some ideas on improving the sound quality, the first thing i noticed was a slight reduction in bass weight compared to my linn lvx plus. the prototype has much better channel separation and i love the consistent sound across the whole record.

what should i try first?

Thanks

Hi All,

I have finished the surge tank and this has smoothed the air supply very well.

But now i wanted some ideas on improving the sound quality, the first thing i noticed was a slight reduction in bass weight compared to my linn lvx plus. the prototype has much better channel separation and i love the consistent sound across the whole record.

what should i try first?

Thanks

What do you think about this idea for a parallel tracking arm:

Take a Damyl fishing line (monofilament, chemically related to teflon) and drill very fine holes into teflon blocks as the counterpart. The Clearaudio Tangent probably uses Dyneema, very stable, but probably to much friction, even in a teflon solution. The Damyl won´t hold its tension so well and will have to be replaced regularly, what rules out this solution for commercial munufacturers, but as we are DIYers here...

Take a Damyl fishing line (monofilament, chemically related to teflon) and drill very fine holes into teflon blocks as the counterpart. The Clearaudio Tangent probably uses Dyneema, very stable, but probably to much friction, even in a teflon solution. The Damyl won´t hold its tension so well and will have to be replaced regularly, what rules out this solution for commercial munufacturers, but as we are DIYers here...

Hello,

Thanks for this thread.

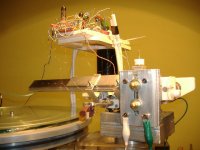

This is my first arm.The most important in construction were cushion and blade rest.Aluminium angles must be mirror polished to get the thinnest air film on them what mean better bass and details.The blade rest must be harder than alu to get better details and 3-D.As allways ,that is my personal experience so check (hear) on your table first but the polish is must for better performance.

Thanks for this thread.

This is my first arm.The most important in construction were cushion and blade rest.Aluminium angles must be mirror polished to get the thinnest air film on them what mean better bass and details.The blade rest must be harder than alu to get better details and 3-D.As allways ,that is my personal experience so check (hear) on your table first but the polish is must for better performance.

Attachments

I'm interested in the path you've taken...including the phono stage...got a link?

I will take photos of the disassembled arm these days as I am going to finish some fine details that I left unfinished because of listening rush.Everything is made on table drill machine without lathe assistance, only machining improvisation and hand saw.Precision of the on the fly VTA is great.The arm elevation is made by excenter screw on lower front nut.The lift is lateral instead of horizontal type so I could place him from the outside of the arm base because I don't like to mess with lift shaft in proximity of cartridge.Today I have placed blade on the glass tubes.Fantastic - another arm compared to alu rest version.I just brushed two miniature fuses on one end for 60° to be able of putting the blade on the end of the fuse.I was afraid that I will loose geometry precision but that didn't happened since the blades are self adjusted on the bottom of the tube because oh arm pivot gravity ant help of fine cosmetic hair oil. Mass of details came out of the records that I didn't ever heard with Morch dp6 and SME 3009.That part of the arm showed the most important necessity of right material choice.

Phono is 12ax7 based pre but I love subminiature sound and near no microfonic characteristic so I putted two 6n17b-v Russian tubes.

Attachments

This is a new step,only 18 cm of 0,01 mm copper diameter to phono stage.Imagine the sound with the phono almost on the cartridge .My turntable enemy friend gave him a chance and listened it and hi said that it sound like a mega$ cd-player but without digititis.He sell every turntable after short period of listening.The wires are from an old MM cartridge and the carrier doesn't see them at all ,no more tension problems.As the wire is so thin I have used a RS-232 connector pins for connections.

Attachments

I'm interested in the path you've taken...including the phono stage...got a link?

I found the link: http://www.angelfire.com/electronic/funwithtubes/Amp-Phono.html

Trans-Fi Terminator

New Trans-Fi armwand and headshell for the Terminator air-bearing tonearm, a Ladegaard inspired creation. It dispenses the blade and uses two point bearing - less contact area, less friction, less mass. And azimuth is adjustable now. It looks cool!

.

New Trans-Fi armwand and headshell for the Terminator air-bearing tonearm, a Ladegaard inspired creation. It dispenses the blade and uses two point bearing - less contact area, less friction, less mass. And azimuth is adjustable now. It looks cool!

.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Ladegaard tonearm - the real DIY winner