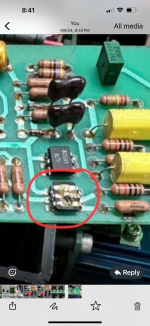

Because of this additional work I found that part of the protection circuit was also damaged after I opened the back panel. Wouldn’t have noticed this if I had not disassemble the back panel

Attachments

Next to derive the power to drive the fans. I chose to drive the 12V fans at a lower voltage to avoid generating too much noise.

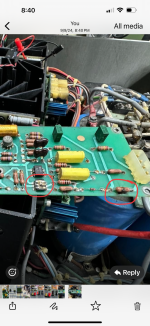

I tapped the power from the auxiliary power to the protection board at the back panel

I tapped the power from the auxiliary power to the protection board at the back panel

Cooling fans installed. The heatsink temp was reduced by significantly from being unable to hold on the heatsink (before) to being able to hold on to it comfortably without having to pull your hands away. Haha. I should have been more scientific and actually measured the temp before and after. Actual use test with the hands is good enough I guessed.

Attachments

Nice writeup. I have a KSA80 that I had completely refurbished -- replacing all caps, reflowed all solder joints and remounting all power transistors. That was a lot of work but I guess I avoided the eventual scenario you started with.

I actually tested all the electrolytic capacitors. All values and ESR were still good after more than 30 years. I did not recommend the owner to replaced.

After repair a listening test showed bass performance were good. If the four big reservoir caps were bad, bass performance would have been affected.

After repair a listening test showed bass performance were good. If the four big reservoir caps were bad, bass performance would have been affected.

I guess it is up to the owner how much to spend. I decided to invest in the caps, particularly the big reservoir caps and the power supply caps on the driver board. I also replaced all the driver transistors pre-emptively. I really like the amp so I figure it is a good long term investment.

Yes. The KSA80 is a very good amplifier considering it is more that 30 years since production. Very authoritative in the lower register and very clear sweet highs.

Here is the thread to my KSA 250 repair. A very unusual failure mechanism. If you are curious have a read.

Thread 'Krell KSA Repair'

https://www.diyaudio.com/community/threads/krell-ksa-repair.402617/

Here is the thread to my KSA 250 repair. A very unusual failure mechanism. If you are curious have a read.

Thread 'Krell KSA Repair'

https://www.diyaudio.com/community/threads/krell-ksa-repair.402617/

Hi @KweeSong Lim .

I would be careful in trusting your driver board repair as shown i #14.

As we talked about in the KSA-250 repair, the burnt (coal like) pcb is probably more or less conducting.

To test this, take your DMM leads, and place them some millimeters apart on the black part of the pcb,

and measure in high ohm setting.

If you measure anything at all in the Kohm- or Mohm range, this is sure to fail again in the long term.

I know, it would be a hazzle to make new pcb´s, but even a Veroboard replacement would be far better...... and safer.

Written with the best regards 😉

I would be careful in trusting your driver board repair as shown i #14.

As we talked about in the KSA-250 repair, the burnt (coal like) pcb is probably more or less conducting.

To test this, take your DMM leads, and place them some millimeters apart on the black part of the pcb,

and measure in high ohm setting.

If you measure anything at all in the Kohm- or Mohm range, this is sure to fail again in the long term.

I know, it would be a hazzle to make new pcb´s, but even a Veroboard replacement would be far better...... and safer.

Written with the best regards 😉

Dear Boydk,

Good point. I should have made a measurement for leakage.

Since amplifier has been returned to the owner I will conduct an experiment by burning another PCB to see if it is partially conducting. If it does I will have to recall the amplifier to prevent future catastrophic failure.

My experience with leaky PCB was with the KSA250 repair. It was suspected to be leaking capacitor electrolyte that caused the leak. It was not a component failure burnt causing the leak.

Thank you for your input. 😊

Good point. I should have made a measurement for leakage.

Since amplifier has been returned to the owner I will conduct an experiment by burning another PCB to see if it is partially conducting. If it does I will have to recall the amplifier to prevent future catastrophic failure.

My experience with leaky PCB was with the KSA250 repair. It was suspected to be leaking capacitor electrolyte that caused the leak. It was not a component failure burnt causing the leak.

Thank you for your input. 😊

- Home

- Amplifiers

- Solid State

- Krell KSA 80 Repair