rabstg said:

PPI woofers? 4 Ohm or 8? Series or Parallel?

Also Vifa Ring Radiator tweeter, is that Vifa mids too?

Electronic or passive cross-overs and what frequency?

Hate to digress from thread but love to talk abut em so here goes 🙂

All drivers are 4 ohm (Vifa P13WH's are two 8 ohms in paralleled to 4 ohm). The PPI Pro12s are 4 ohm each as well. So compounded the PPi may be 2 or 8 ohm depending on amplification.

All 3 driver groups are 91, 91.5 and 92 db/w and have nice flat responses (thats why I chose the Vifa P13WH) and simple XO works well.

XO currently first order 350Hz and 3.5kHz, later active.

Speaking of Digressing, check here for Caps for BrianGT PSU

http://www.diyaudio.com/forums/showthread.php?s=&postid=654482#post654482

Regards

Anthony

http://www.diyaudio.com/forums/showthread.php?s=&postid=654482#post654482

Regards

Anthony

While we're on the topic,

I am in the process of building the enclosures for a 3 way consisting of:

tweeter = Scan Speak 990000 Revelator

Midrange = B&W Kevlar 6.5" from my 805 matrix

woofer = 2 Parts Express 10" aluminum cone woofers

Tweeter and mid passive crossed with 12db/oct from Menicus

Woofer to mid electronically crossed

Krell for the tweeter and mid, Servo controller and Hypex UcD180's for the woofers.

The woofer amps are in the rear of the speakers and I am debating on mounting the KSA-50's on the rear also. Vibration is not a concern.

Anyone else taking that approach?

I could put an 8 - 12" wide heatsink the entire 40" distance of the rear!

I am in the process of building the enclosures for a 3 way consisting of:

tweeter = Scan Speak 990000 Revelator

Midrange = B&W Kevlar 6.5" from my 805 matrix

woofer = 2 Parts Express 10" aluminum cone woofers

Tweeter and mid passive crossed with 12db/oct from Menicus

Woofer to mid electronically crossed

Krell for the tweeter and mid, Servo controller and Hypex UcD180's for the woofers.

The woofer amps are in the rear of the speakers and I am debating on mounting the KSA-50's on the rear also. Vibration is not a concern.

Anyone else taking that approach?

I could put an 8 - 12" wide heatsink the entire 40" distance of the rear!

Re: yup...

I see.... thanks for clarifying...

perhaps I should look into doing a 4 channel of these and simply having a channel per speaker...

water cooling is an idea though... as something can be rigged for fairly cheap (probably a good deal cheaper than doubling all amplifier components)

I'm assuming when you said "yup" you were agreeing that after 50 watts your amp will operate Class B correct?

Stuart Easson said:water cooling might be the way to go if you felt like you had to have one these at full power, but personally, I'd be very scared of the power bill a couple of these would cause, you probably wouldn't want to do the full home theatre 7.1 deal.

...realistically, and you can trust me on this one, the aggregate cooling capability of your sinks, even assuming the fans quadruple the capacity (0.125) is not really adequate for this level of output...

With an ambient temp of 20c, dissipating 1.3kw * 0.125 would give a heatsink temp of 185c...assuming the output transistors stayed alive long enough, they would unsolder themselves...a new method of output protection?

Without fans you'd need one of the heatsinks you mention per output pair, with fans perhaps 2 pairs per sink...somewhere between 8 and 16, per channel...

Stuart

I see.... thanks for clarifying...

perhaps I should look into doing a 4 channel of these and simply having a channel per speaker...

water cooling is an idea though... as something can be rigged for fairly cheap (probably a good deal cheaper than doubling all amplifier components)

I'm assuming when you said "yup" you were agreeing that after 50 watts your amp will operate Class B correct?

yes...

The output is class A to a certain point, thereafter class B. With ~1A idle current you can get ~12w, minimum 16v rails, with ~2A ~50w, 30v rails, 4A 200w min 60v rails and so on...the voltage has to increase as well or the current cannot be driven into the load...hence the idle power becomes prodigious very fast.

Basically because of the total power consumption, some people are making the amps with a switch to choose the level of bias, ergo heat, and the 'amount' of the total output that is 'class A' power...

Stuart

The output is class A to a certain point, thereafter class B. With ~1A idle current you can get ~12w, minimum 16v rails, with ~2A ~50w, 30v rails, 4A 200w min 60v rails and so on...the voltage has to increase as well or the current cannot be driven into the load...hence the idle power becomes prodigious very fast.

Basically because of the total power consumption, some people are making the amps with a switch to choose the level of bias, ergo heat, and the 'amount' of the total output that is 'class A' power...

Stuart

Re: yes...

I see thanks ....

where is the ideal place to mount sinks for disipation purposes?

Stuart Easson said:The output is class A to a certain point, thereafter class B. With ~1A idle current you can get ~12w, minimum 16v rails, with ~2A ~50w, 30v rails, 4A 200w min 60v rails and so on...the voltage has to increase as well or the current cannot be driven into the load...hence the idle power becomes prodigious very fast.

Basically because of the total power consumption, some people are making the amps with a switch to choose the level of bias, ergo heat, and the 'amount' of the total output that is 'class A' power...

Stuart

I see thanks ....

where is the ideal place to mount sinks for disipation purposes?

I see thanks ....

where is the ideal place to mount sinks for disipation purposes?

wouldn't that be on top since hot air rises above cold, perhaps not the most estetic sulotion, or practical.

Anywhere where it can get adequate ventilation... or was your question around where on the heatsinks should the devices be mounted?

Hi,

heatsinks all the way around the vertical perimeter would be best for passive heatsinking.

The electrical downside is point to point wiring that becomes quite long, but Alephs etc manage this successfully.

heatsinks all the way around the vertical perimeter would be best for passive heatsinking.

The electrical downside is point to point wiring that becomes quite long, but Alephs etc manage this successfully.

PSU boards?

Last I checked, BrianGT was out of stock on psu boards. The WIKI is up to 68 psu requested.

Will psu boards be available?

Last I checked, BrianGT was out of stock on psu boards. The WIKI is up to 68 psu requested.

Will psu boards be available?

NEWSFLASH...............

Today I picked up all the passive parts fomr my local favorte surplus place, so board assembly will begin tonight. Should have them stuffed in a day or so and the semi's will definately be here on Friday. So this weekend is the target to see at least one prototype board up and running.

If the WIKI count for the PSU board cound get a tad bit higher then I will have Brian run another batch of 100 of them just for us KSA builders.

Mark

Today I picked up all the passive parts fomr my local favorte surplus place, so board assembly will begin tonight. Should have them stuffed in a day or so and the semi's will definately be here on Friday. So this weekend is the target to see at least one prototype board up and running.

If the WIKI count for the PSU board cound get a tad bit higher then I will have Brian run another batch of 100 of them just for us KSA builders.

Mark

Heatsink / case concept

I'm looking at M&M Metals profile MK62712 and have attached a first draft with a wood face plate. The face plate would be about an inch thick, angled on each end to complement the "slope" of the fins on the sink. The opening on the end of the face plate I call a "truncated tear drop". (whatever) The opening serves as a reveal of the sink fin behind it. (someone who wanted to bling it up could back-light this) I haven't gotten a price yet & I don't know what colors they make available....several, I hope. It'll be interesting to choose the wood and sink color to complement one another.

I'm looking at M&M Metals profile MK62712 and have attached a first draft with a wood face plate. The face plate would be about an inch thick, angled on each end to complement the "slope" of the fins on the sink. The opening on the end of the face plate I call a "truncated tear drop". (whatever) The opening serves as a reveal of the sink fin behind it. (someone who wanted to bling it up could back-light this) I haven't gotten a price yet & I don't know what colors they make available....several, I hope. It'll be interesting to choose the wood and sink color to complement one another.

Attachments

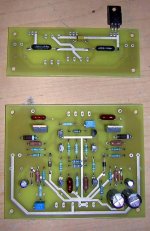

The main board completed...... The NTE in Q-108's position is temporary till the real ones arrive...... There's plenty of room on this board... even if your resistors are the size of the Queen Mary!

The rest of the parts should be here tommrrow.......

Mark

The rest of the parts should be here tommrrow.......

Mark

Attachments

Member

Joined 2002

Member

Joined 2002

Mark A. Gulbrandsen said:Thanks Jason,

Gotta thank Al too....... You should make this your next project!!

Mark

Yeah i just need to order boards 😀

Looking good Mark!

al/ Really,really hoping it doesn't blow up...😉

:edit: Especially as I just looked at the wiki and saw it's up to 150 boards.

al/ Really,really hoping it doesn't blow up...😉

:edit: Especially as I just looked at the wiki and saw it's up to 150 boards.

pinkmouse said:Especially as I just looked at the wiki and saw it's up to 150 boards.

I have this vision of roasted Mouse, Mouse on a stake !

Call me oldfashioned, i enjoy the spaciousness of the components on the boards, nice pics.

jacco vermeulen said:

Call me oldfashioned, i enjoy the spaciousness of the components on the boards, nice pics.

Yes, helps us fat fingered types...

- Home

- Amplifiers

- Solid State

- Krell KSA 50 PCB