Purpose:

Figure 1: Krell CD-1 player, serial number 99209281 - photo taken August 2023.

Figure 2: Krell CD-1 remote control unit - photo taken after repairing, August 2023.

Background:

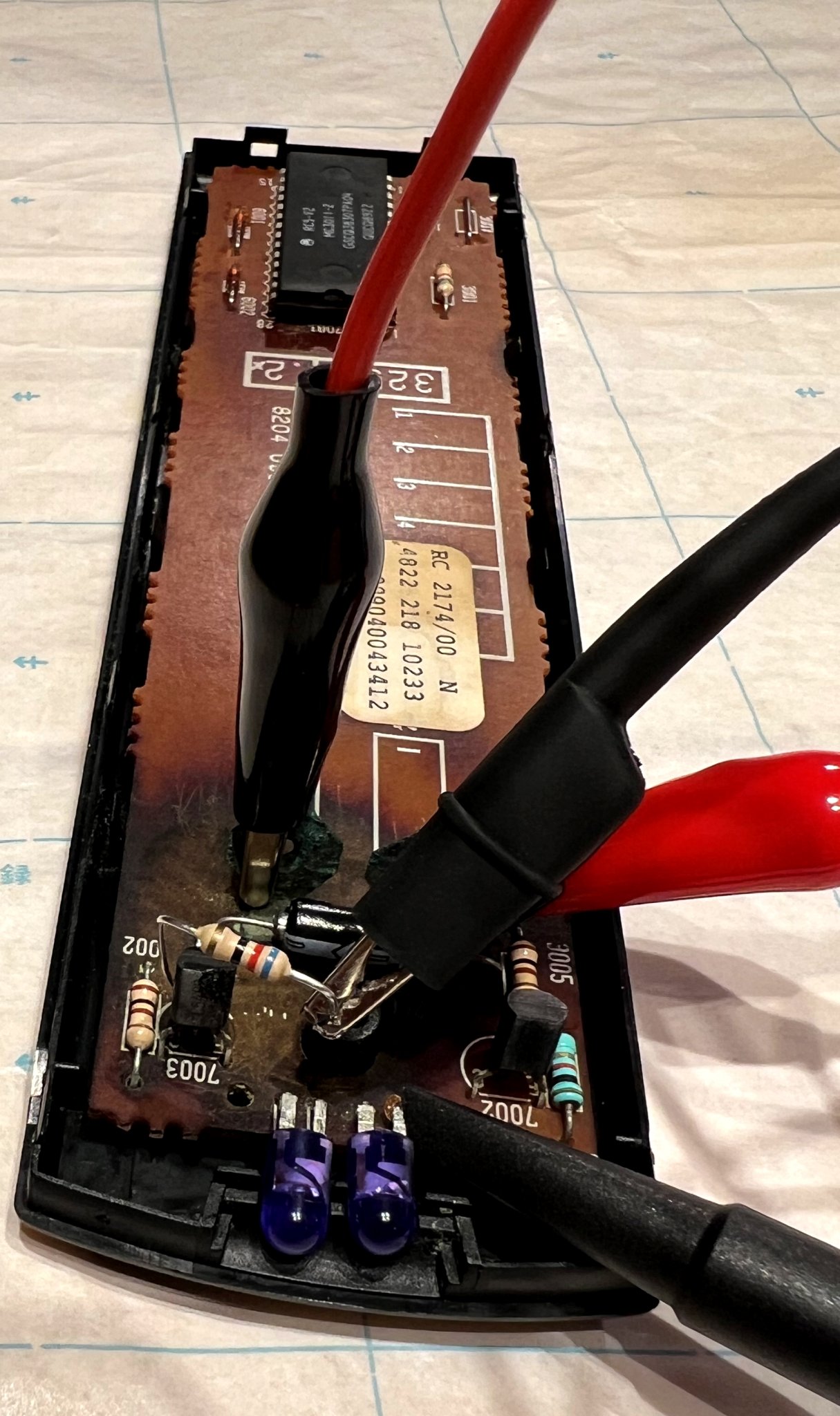

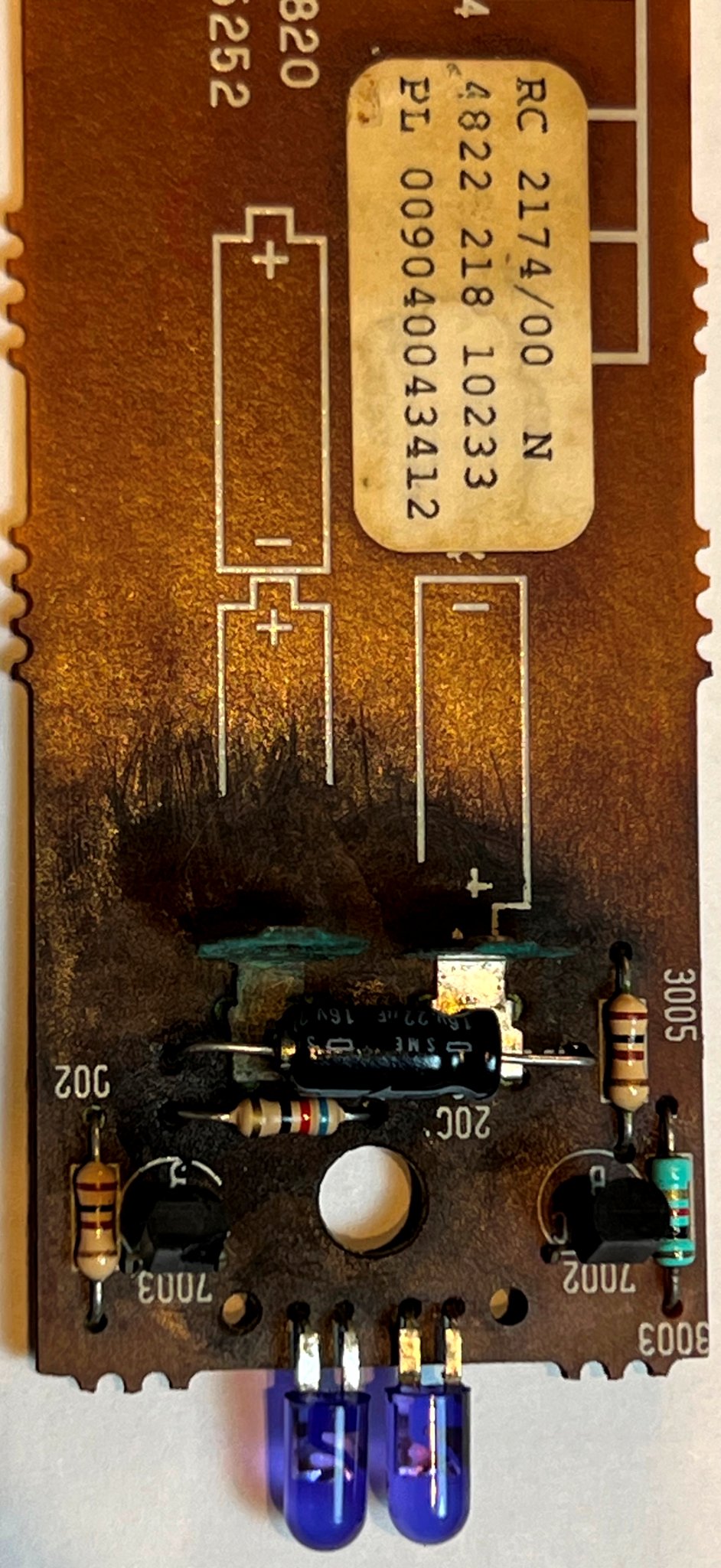

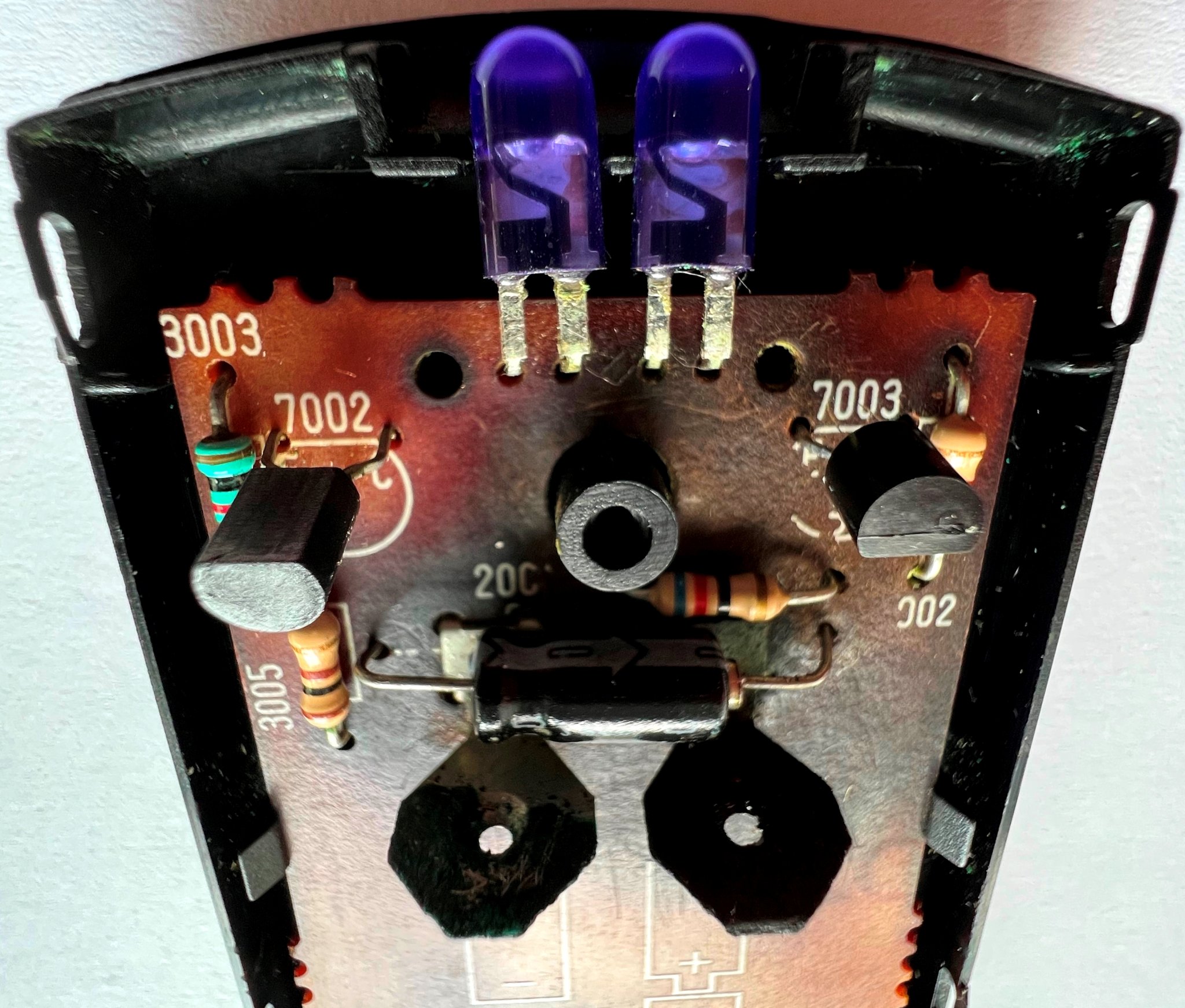

Figure 3: Remote control unit circuit board showing corroded, broken components.

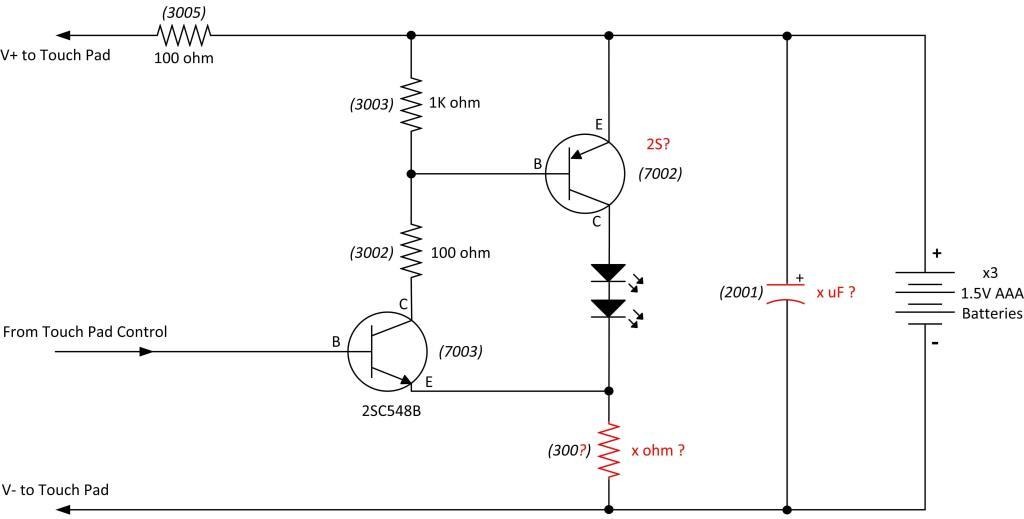

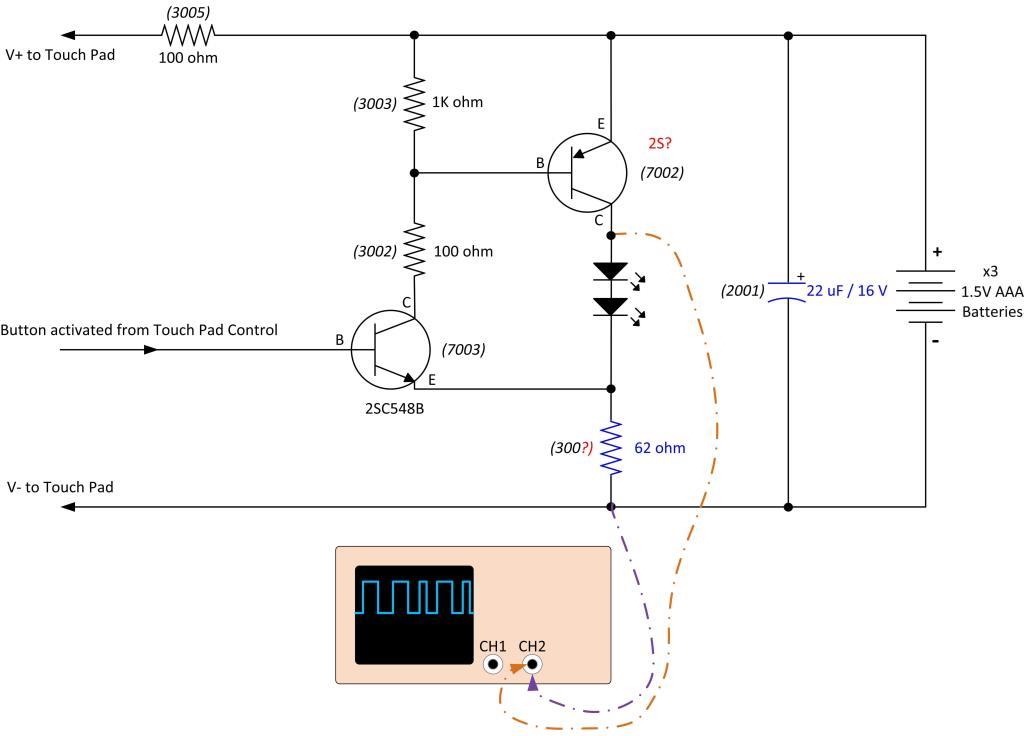

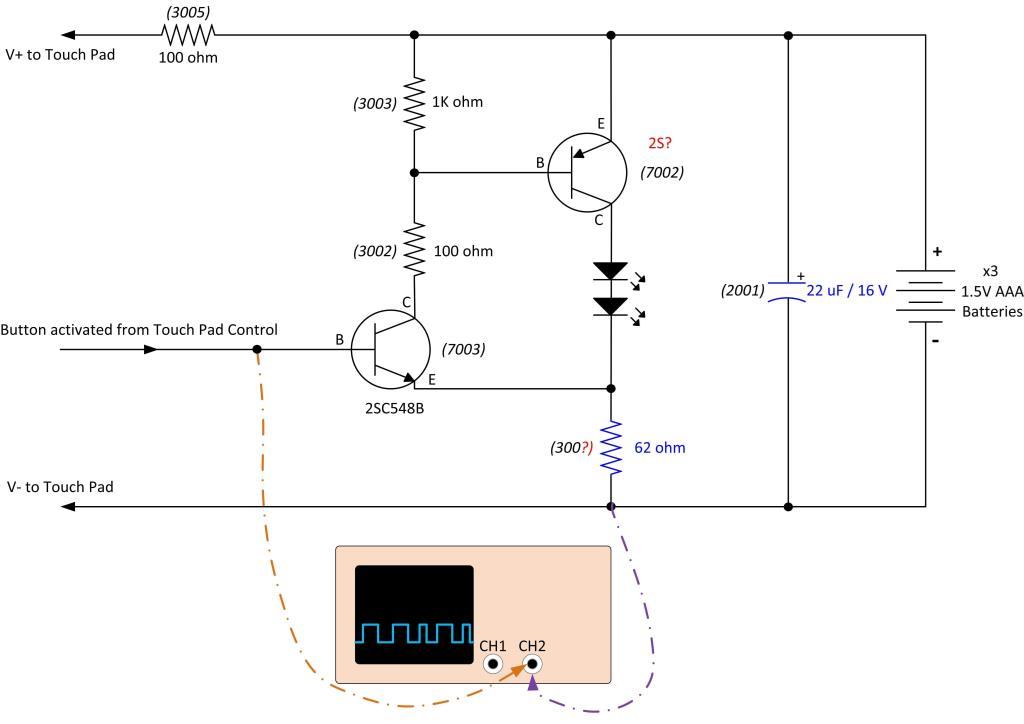

Figure 4. Presumed circuitry (broken) of Krell CD-1 remote control - infra-red transmitter section only.

Damaged Capacitor:

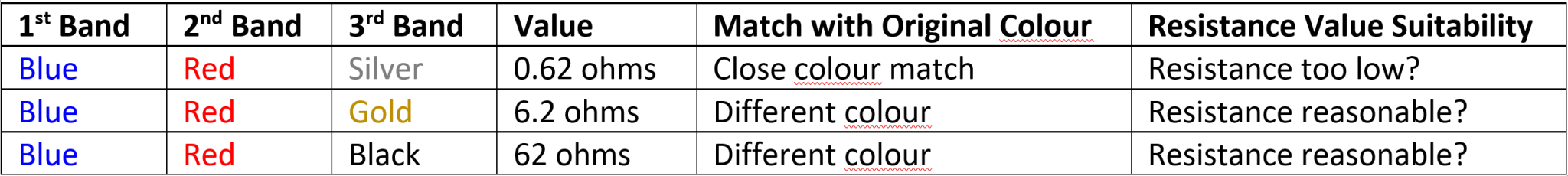

Table 1. Comparison of actual resistors, their resistance values vs. colour codes

Figure 5. Test setup - External 4.5 VDC connected to terminals, oscilloscope connected to battery minus terminal and photodiode's anode.

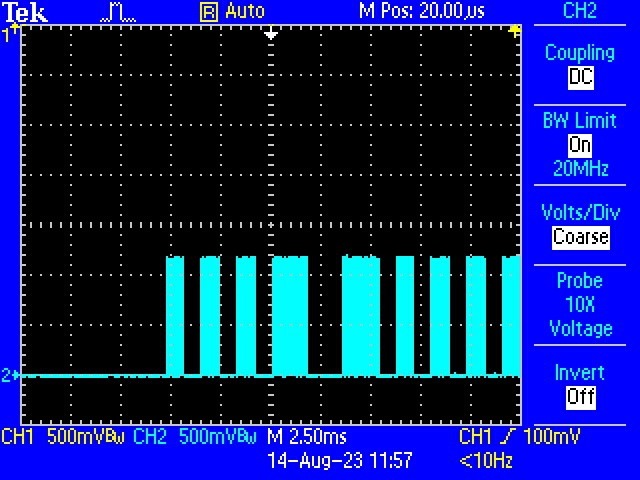

Figure 6. Test of infra-red transmitter section after circuitry repaired.

Figure 7. Zero-signal reference, oscilloscope channel 2 grounded.

Figure 8. Rest condition, touch pad buttons not activated.

Figure 9. Active condition, example of a coded pulse train when touch pad button activated.

Figure 10: Repaired circuit board of remote control unit - note 62-ohm resistor colour coding Blue, Red, Black (not White).

Figure 11. Test of touchpad's control pulses.

Figure 12. Example of control pulses coming from touchpad when button activated - approx. 1.2V amplitude.

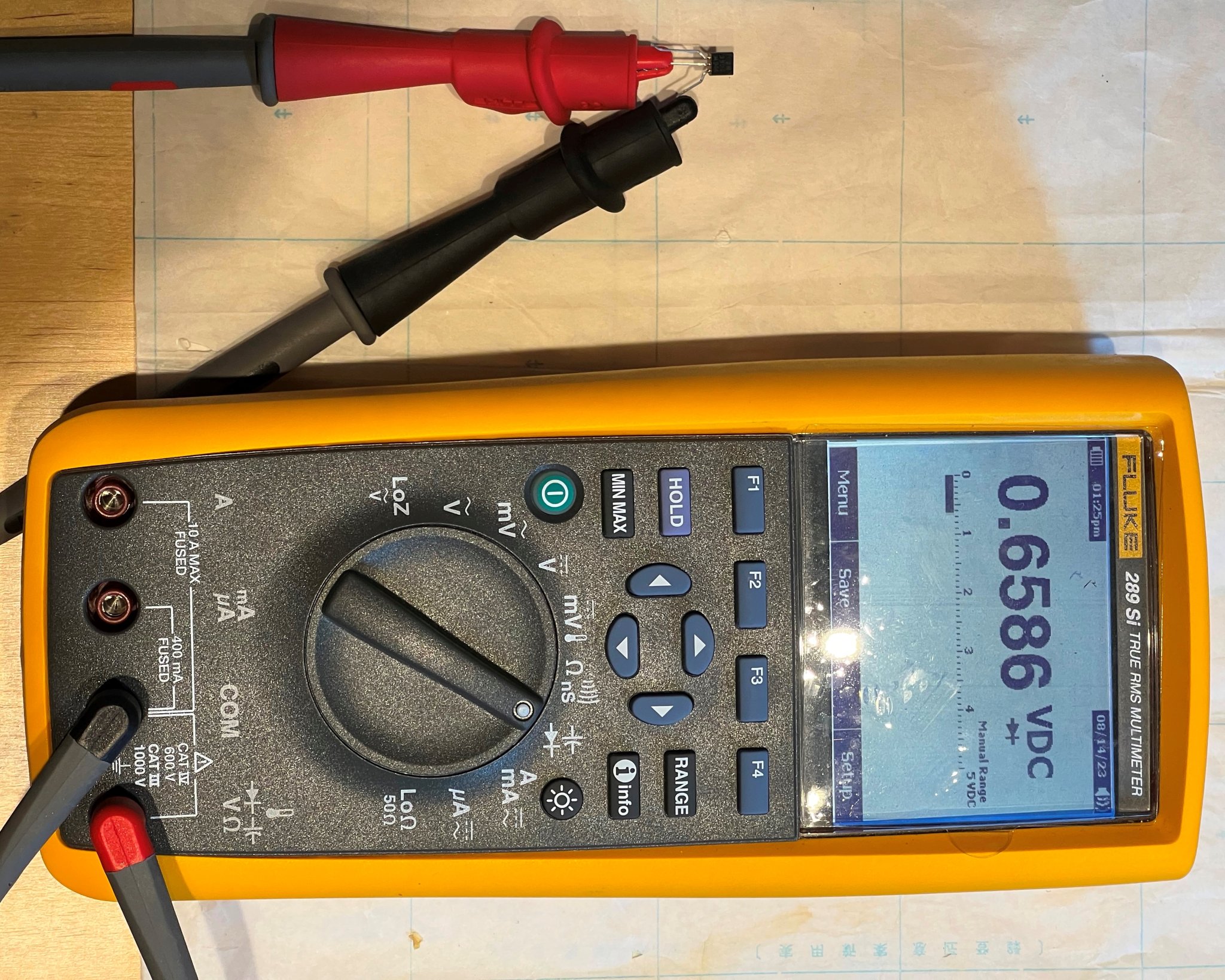

Figure 13. Measured forward bias of original transistor 2SC548B - note unstable voltage with fluctuating final digit.

- The 2SC548 being an obsolete series I replaced it with a spare 2N3904 NPN transistor I had. A check of this transistor's Base-Emitter forward bias showed a typical ~ 0.6 V and stable (Fig. 14).

Figure 14. Measured forward bias of replacement transistor 2N3904 - typical voltage value and stable.

Figure 15. Orientation of transistor at 7002 (left) vs. reversed orientation of replaced transistor at 7003 (right).

Figure 16. Original transistor 2SC548B with broken plastic case.

Final Notes:

- To share my experience repairing a Krell CD-1 player's remote control unit.

- Although this content is relevant to both the Solid State and Digital Source forums, as the primary focus of this report is the identification and replacement of broken components, I felt best to share this content on the Parts forum.

- Krell CD-1 player serial number 99209281 (Fig. 1), supplied with infra-red remote control (Fig. 2).

Figure 1: Krell CD-1 player, serial number 99209281 - photo taken August 2023.

Figure 2: Krell CD-1 remote control unit - photo taken after repairing, August 2023.

Background:

- This Krell CD-1 player I purchased new in 1992 from Loyalty Sound Ltd in Calgary, Canada. Overall, I was very pleased with the performance of this CD player throughout 10 years of worldwide assignments. Although it was in full working condition, sadly I had to put my Krell CD-1 into storage in 2001 due to shortage of living space.

- Unfortunately, during the last international move the remote control unit got packed in a different box from the CD-1 player, with the 3 AAA batteries remaining inside the remote control unit. This led to leakage of the battery's electrolyte, further leading to corrosion and damage to the remote control's internal components rendering it inoperative (Fig. 3). Note corroded battery terminals, damaged electrolytic axial capacitor, broken (missing) resistor - more to come later.

Figure 3: Remote control unit circuit board showing corroded, broken components.

- Other than the Owner's Reference manual that came with my original purchase, I have no access to Krell's circuit diagrams or service instructions, and so contacted Krell customer service to enquire what could be done. Krell's Customer Operations Manager, Timothy Rogers kindly replied that it may be possible to send the unit back to Krell for repair, however with a minimum service charge of 1hr ($125) plus international shipping costs we deemed it probably wasn't worthwhile.

- Although I had no experience with repairing a remote control unit, I decided to investigate and attempt local repair if possible.

- With no circuit diagram, no service instructions and unable to identify the values of the corroded/damaged components presented a challenging puzzle.

- After cleaning as best I could the circuit board (Fig. 3), I then attempted to recreate a circuit diagram by observing and continuity checking each of the circuit board traces. Hopefully, Figure 4 describes a reasonable recreation of the Infra-red transmitter circuitry, with the unidentifiable components labelled in Red.

Figure 4. Presumed circuitry (broken) of Krell CD-1 remote control - infra-red transmitter section only.

Damaged Capacitor:

- The only remaining legible markings were the number "10" and the letters "PHIL-". Judging from the blue jacket colour I assumed this to be a Philips electrolytic capacitor, rated 10 V.

- Testing the capacitor out of circuit measured a capacitance of 17.2 uF and an ESR of 8.3 ohms. Presuming this to be a 22 uF, 10 V rated capacitor, the measured capacitance was low and the measured ESR was high, necessitating replacement.

- This was replaced with a fresh 22 uF, 16 V rated electrolytic axial capacitor.

- Before this resistor fell apart and crumbled, I was lucky to observe three colour bands; 1st Blue, 2nd Red and 3rd Silver. This colour band combination equates to a resistance value of 0.62 ohms, which seemed suspiciously low.

- Assuming the 1st and 2nd colour bands of Blue and Red respectively were correct, but unsure what the proper resistance value should be, I inspected the third colour bands of some actual resistors (Table 1).

Table 1. Comparison of actual resistors, their resistance values vs. colour codes

- Side note, I first learned the resistor colour code when I was a teenager in high school, where the Black coloured band signified a blank or non-value.

- However, after researching this I now learned that the colour White can also be used to signify a blank or non-value, which solves the puzzle of the original installed resistor. The 3rd colour band was most likely White, not Silver - shows you can still learn something 50-years after high school!

- So that's what I used, a fresh resistor of 62 ohms having colour bands; 1st Blue, 2nd Red and 3rd Black.

- Still apprehensive whether a 62-ohm resistor was the correct value or not, and with no visible indication to the human eye whether the infra-red photodiodes were transmitting or not, I conducted a test to observe how the circuit performed. Test setup is described in Figures 5 and 6.

- 62-ohm resistor lightly tacked in place for the test.

- External 4.5 VDC supply connected to the battery terminals.

- Oscilloscope connected from the minus battery supply to anode of the two infra-red transmit diodes.

- Touch pad buttons were activated to start signal generation.

Figure 5. Test setup - External 4.5 VDC connected to terminals, oscilloscope connected to battery minus terminal and photodiode's anode.

Figure 6. Test of infra-red transmitter section after circuitry repaired.

- To establish a baseline position of the oscilloscope trace, with no DC power applied the oscilloscope channel 2 input was grounded (Fig. 7).

Figure 7. Zero-signal reference, oscilloscope channel 2 grounded.

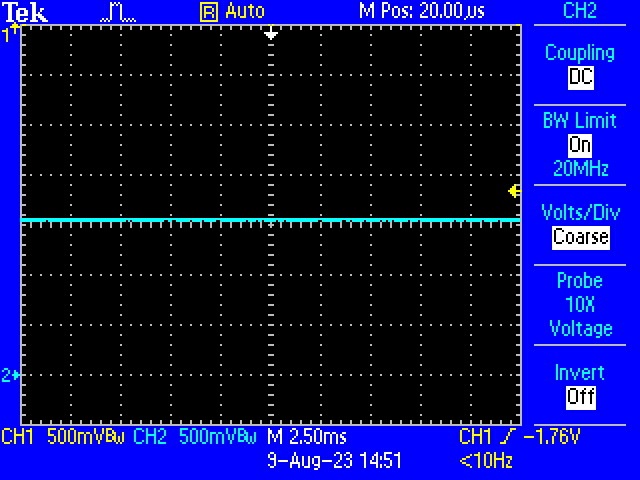

- With the 4.5 VDC supply connected, a stable rest voltage of ~ 1.51 VDC was observed on channel 2 (Fig. 8).

Figure 8. Rest condition, touch pad buttons not activated.

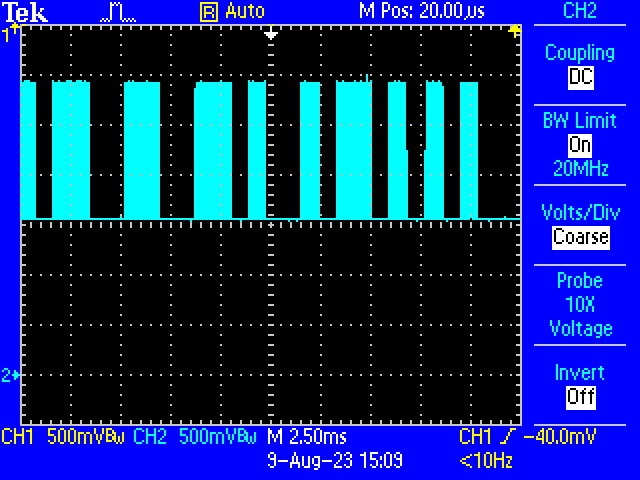

- Finally, when pushing the buttons on the touch pad, different coded pulse trains could be observed. An example of one pulse train captured on the oscilloscope is displayed on channel 2 in Figure 9.

Figure 9. Active condition, example of a coded pulse train when touch pad button activated.

- Based on this test result (Fig. 9), it showed the remote-control unit to be functioning.

- After removing external DC power, the 62-ohm resistor was fixed properly to the circuit board (Fig. 10).

Figure 10: Repaired circuit board of remote control unit - note 62-ohm resistor colour coding Blue, Red, Black (not White).

- Operating the remote control with the CD-1 player, I was pleased that 17 of the touchpad's 19 pushbuttons functioned properly, the only two inoperative buttons being the "PREV" and "NEXT" buttons. These two buttons are situated closest to the corroded battery terminals and probably became contaminated from the battery's leaking electrolyte. Still, 17 out of 19 working buttons is 90% functional (far better than 0% or having to scrap the remote control).

- After operating reliably for several days, the remote control suddenly stopped working.

- Opening the unit up again found nothing untoward, all replaced components still intact.

- Tracing the signal flow from the touchpad confirmed control pulses of ~ 1.2 V amplitude were flowing to the input of the infra-red transmitter section (Figs. 11, 12).

Figure 11. Test of touchpad's control pulses.

Figure 12. Example of control pulses coming from touchpad when button activated - approx. 1.2V amplitude.

- This test showed the touchpad and its digital circuitry were functioning properly, suggesting something wrong again in the infra-red transmitter circuit.

- Suspecting the input transistor 2SC548B (#7003 in Fig. 11), a check of its Base-Emitter forward bias showed an unstable and strange voltage, > 0.9 V vs. an expected ~ 0.6 V (Fig. 13).

Figure 13. Measured forward bias of original transistor 2SC548B - note unstable voltage with fluctuating final digit.

- The 2SC548 being an obsolete series I replaced it with a spare 2N3904 NPN transistor I had. A check of this transistor's Base-Emitter forward bias showed a typical ~ 0.6 V and stable (Fig. 14).

Figure 14. Measured forward bias of replacement transistor 2N3904 - typical voltage value and stable.

- With the new 2N3904 transistor installed in the circuit board pleased to report the remote control is now operational again!

- Just a minor issue, the physical orientation of the Emitter and Collector leads is flipped between the original 2SC548B and the replacement 2N3904. The easy remedy is to install the replacement transistor 'backwards' to align the Emitter and Collector positions (Fig. 15).

Figure 15. Orientation of transistor at 7002 (left) vs. reversed orientation of replaced transistor at 7003 (right).

- What caused the original 2SC548B transistor to fail? It was only when I gently removed this failed transistor from the circuit board that I noticed its plastic case was broken (Fig. 16). One theory could be the leaked electrolyte from the batteries penetrated the transistor case causing it to weaken and eventually fail.

Figure 16. Original transistor 2SC548B with broken plastic case.

Final Notes:

- The reason for this writing is to share my experience repairing the remote-control unit of a Krell CD-1 player, it's not to bypass factory repairs, just to share what worked for me. Hopefully no more failed components.

- Finally with the circuit board installed back in its case (Fig 2.) and fresh AAA batteries installed, pleased to report the repaired remote-control unit now operates happily with my CD-1 player!

Nice repair work. When I repair a PCB that is damaged by a leaked zinc-carbon battery, I wash it with vinegar, then with sodium bicarbonate solution, then flush it with warm water and dry it with a hairdryer. If there is still any residue, I remove it with a glass fibre brush.

Avoid zinc-carbon batteries!

Avoid zinc-carbon batteries!

Hello lcsaszar,

Thank you for your kind words and for sharing your method of cleaning PCBs damaged from leaking battery electrolyte.

I haven't tried your method of washing by vinegar, sodium bicarbonate solution and warm water, but will make a note of this for next time (to be honest I'm hoping I won't have to do this again).

To share what worked for me cleaning the damaged PCB, I first sprayed contact cleaner and using different sized Q-tips carefully brushed the contact cleaner fluid around the components and board traces to clean as best I could, then after drying cleaning with isopropyl alcohol. I repeated this process several times until all visible residue was removed.

Thanks,

John

Thank you for your kind words and for sharing your method of cleaning PCBs damaged from leaking battery electrolyte.

I haven't tried your method of washing by vinegar, sodium bicarbonate solution and warm water, but will make a note of this for next time (to be honest I'm hoping I won't have to do this again).

To share what worked for me cleaning the damaged PCB, I first sprayed contact cleaner and using different sized Q-tips carefully brushed the contact cleaner fluid around the components and board traces to clean as best I could, then after drying cleaning with isopropyl alcohol. I repeated this process several times until all visible residue was removed.

Thanks,

John