I need bandpass length of around 20-25cm to get f-3 at 45hz since it's closed back...yet reduced port surface to 85cm² to set velocity around 13m/s max. Since it's a 12" (so 30cm diameter), i will have to verify if configured like that i can contourn the speaker to connect the horn, but i doubt it...

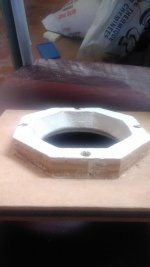

So, things changes a bit. First prototype foam destructed with butil caulking... I redid the horn 50 to 1600cm² from 3mm cardbord cutting by hand 8 petal tulip from hornresp export tool file sizes.

I remesured real final size, and it's just perfect ! Now i'll have to cut opening for the mid-woofer, and it all 1st order electric crossovers 🙂

I will put now a 8" TB w8-740q woofer filler driver. The 12" driver bandpass will be out of the horn, so it will be 4 ways bullet tweeter+w4+w8+12", with minidsp for delay/filter.

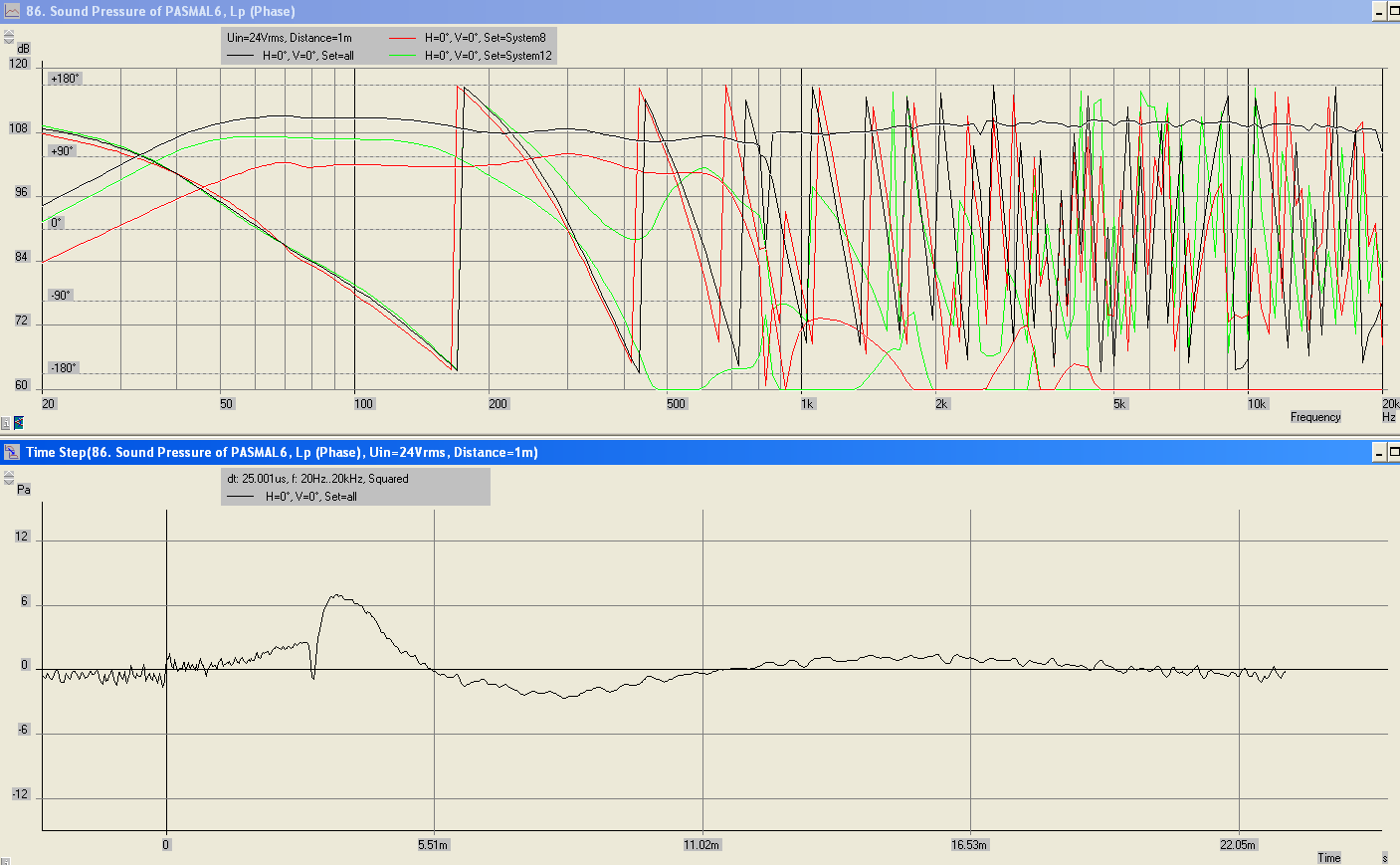

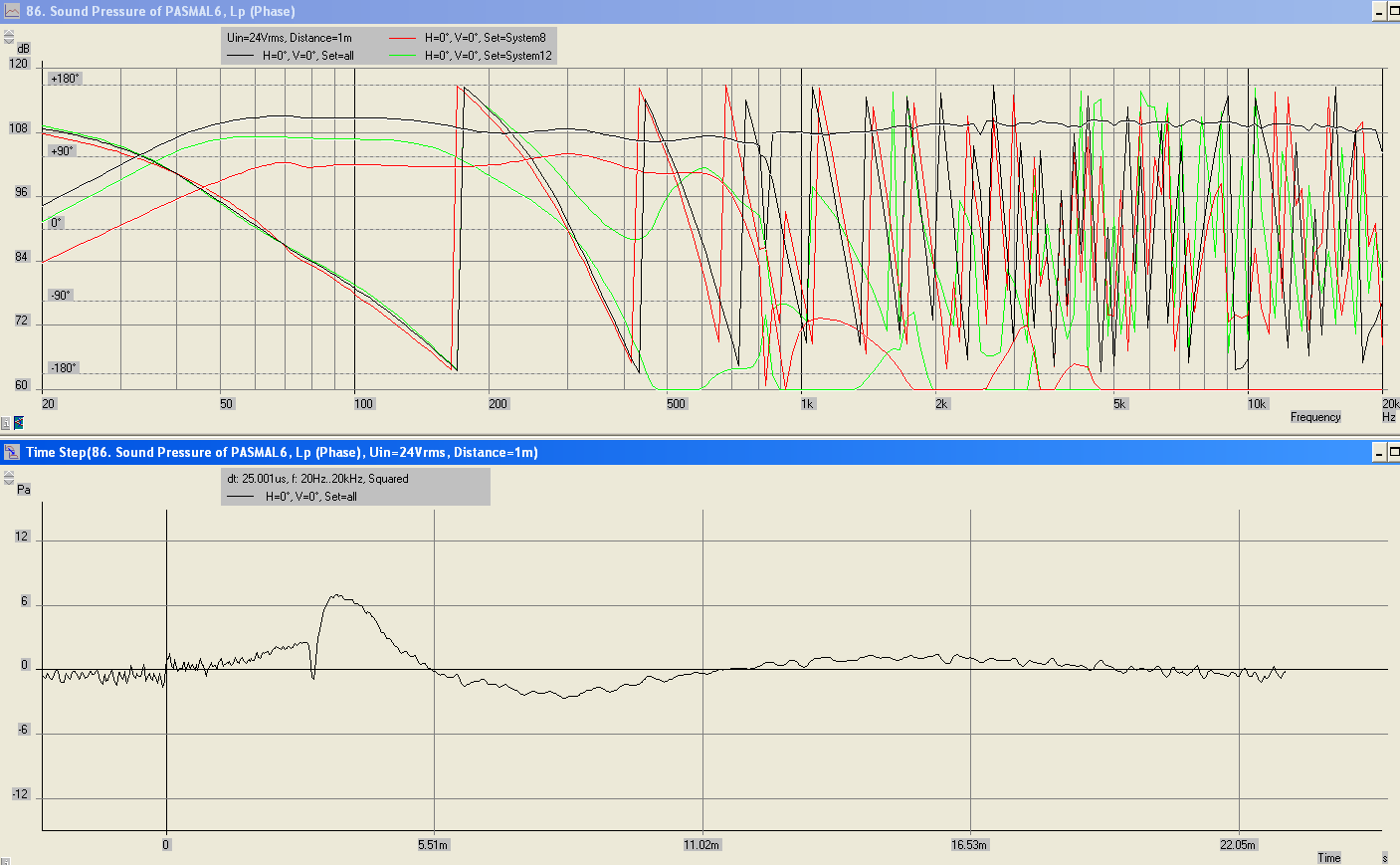

I simulate in akabak as conical, but it's exponential. In hornresp, the exponential profil make it flatter in the 300-1khz range.

About construction, I added multiple layer both strengh and damping :

=>200g polyester+glass fiber

=>2-3mm silicone caulcking

=>5mm foam

=>2-3mm silicone caulcking

=>5mm foam

=>200g epoxy+glass fiber

+ 1layer inside silicone since surface paper of the 3mm cardboard seemed me noisy.

Total 3kg with more than half the weight of silicone. Inner/outer glass fiber sandwich make it hard, but knocking it, it is ultra damped ^^ Only small and really little low freq resonance.

Attached some construction steps :

1=> fullrange transition masking half the surround

2=> transition from round to octogonal

3=> adding polyester/glassfiber layer

4=> adding first layer silicone/foam

5=> side view without outer/inner silicone layers.

I remesured real final size, and it's just perfect ! Now i'll have to cut opening for the mid-woofer, and it all 1st order electric crossovers 🙂

I will put now a 8" TB w8-740q woofer filler driver. The 12" driver bandpass will be out of the horn, so it will be 4 ways bullet tweeter+w4+w8+12", with minidsp for delay/filter.

I simulate in akabak as conical, but it's exponential. In hornresp, the exponential profil make it flatter in the 300-1khz range.

About construction, I added multiple layer both strengh and damping :

=>200g polyester+glass fiber

=>2-3mm silicone caulcking

=>5mm foam

=>2-3mm silicone caulcking

=>5mm foam

=>200g epoxy+glass fiber

+ 1layer inside silicone since surface paper of the 3mm cardboard seemed me noisy.

Total 3kg with more than half the weight of silicone. Inner/outer glass fiber sandwich make it hard, but knocking it, it is ultra damped ^^ Only small and really little low freq resonance.

Attached some construction steps :

1=> fullrange transition masking half the surround

2=> transition from round to octogonal

3=> adding polyester/glassfiber layer

4=> adding first layer silicone/foam

5=> side view without outer/inner silicone layers.

Attachments

Last edited:

Nice work! The sims look very good indeed - mounting the woofers might be tricky of the horn is not able to support weight of woofer.

Good luck!

Good luck!

The woofer filler should be front monted in it own 10 L box inside the total enclosure. So that i only have to fix this box in the enclosure so that it will be firing to the horn port.

As i explained, i reduce the 12" bandwith, so it act more as a sub now, and no more need it to output inside the horn. The 4" driver excursion is now only 0.4mm/3mm on sims ! And both 12" and 8" will benefit from bandpass harmonic reduction (see explained by Danley somewhere on forums at least 2 times ).

Small Syns is the evident inspiration with it midrange filler. It made me trying siming something adding the only speaker that i got laying around ^^

And...moreover... I used as much glass fiber woven as it needed to drink the 400g of resin, and so built as composite sandwich, thickness make stiffness as shown below, with 3+4.8kg of drivers on it without apperent flexion ^^

As i explained, i reduce the 12" bandwith, so it act more as a sub now, and no more need it to output inside the horn. The 4" driver excursion is now only 0.4mm/3mm on sims ! And both 12" and 8" will benefit from bandpass harmonic reduction (see explained by Danley somewhere on forums at least 2 times ).

Small Syns is the evident inspiration with it midrange filler. It made me trying siming something adding the only speaker that i got laying around ^^

And...moreover... I used as much glass fiber woven as it needed to drink the 400g of resin, and so built as composite sandwich, thickness make stiffness as shown below, with 3+4.8kg of drivers on it without apperent flexion ^^

Attachments

Last edited:

First measurement set loaded with the fullrange done in really poor condition, gives me nice thd at -50db from either 95db to 109db (1meter calibrated mic), 109db +/-flat from 280-1khz. Some ringing at 6khz that diseapear off-axis.

It's really conform to hornresp 0° acoustic pressure (bellow in red), so i'll need some kind of trick to eq it flat with high loose passive component.

Sorry, I don't attach measurement for the moment, they're done in too much poor condition, would need lot of explanation, and it will need as said lot of passive correction.

Passive component ordered.

Now I start working of the 8" woofer plug & port.

It's really conform to hornresp 0° acoustic pressure (bellow in red), so i'll need some kind of trick to eq it flat with high loose passive component.

Sorry, I don't attach measurement for the moment, they're done in too much poor condition, would need lot of explanation, and it will need as said lot of passive correction.

Passive component ordered.

Now I start working of the 8" woofer plug & port.

Try a simple -6dB falloff high pass cap to flatten response. I remember Kees52 got almost a perfect flat response with the Trynergy and a 6uF cap in series.

- Status

- Not open for further replies.