The KEF Carlton III (1983) speakers are now more than three decades old. After the long years, the T33 tweeters may suffer from performance degradation due to the thickening of the ferrofluid in the voice coil gap. Replacing the T33 tweeters or cleaning the voice coil on several pairs of Carlton (II & III) yielded no real benefits. The T33s weren’t particularly impressive tweeters to start with. The T33s may had put an end to most Carltons’ serviceability, perhaps already so in the 90s. It could have been a major factor to the Carlton’s short product life span.

The Carlton III is the continuation of the very successful KEF 104 aB design. But it did not surpass the predecessor. The cabinets were more solidly built, with better damping. The layout of the drivers reduced edge diffractions. The new B200 units were computer designed and have better consistency. (And yes, these drivers are still going strong until today.) The crossovers employ the acoustic Butterworth design, and the snubber circuit took into consideration the spread of resonance frequency (+/-100 Hz) of the tweeter units at 900 Hz. Still, the Carlton III did not enjoy a better fame than the 104s. I still put the blame on the T33 SP1074 fabric dome tweeter. If this problem did not exist, then Carlton III may very well enjoy a bigger fame than the 104s. Sadly, I know of many of them been mutilated for parts to be sold in the second used market.

The modern speaker manufacturers do offer a vast number of tweeter units, but it is not easy to find a good replacement for the Carlton. Cost is a factor, more so are electrical characteristics and facet dimensions. Most amateurs would look for a drop in unit without any work done on the crossover. This could be mission impossible because the crossover was built to suit a particular tweeter, and no two tweeters were built the same, electrically and mechanically, even by the same manufacturer. Unless, we are talking about very cheap crossovers that use only first order filtering. As such, to revive the Carlton III, a complete redesign/reconsideration of the crossover is absolutely necessary after the choice of the replacement tweeter.

My plan was to redo the Carlton III such that it has the high frequency performance of the alloy dome T27a found on the KEF 104 aB. Not using the T27a, as it does have some particular "ringi-ness" or undesirable irritation. Also, it is impossible to find a good pair of T27a these days. The tweeter may be able to fit into the rectangular recess onto the speaker facet without much modification. The sound should retain the smoothness of the fabric dome, and yet able to play cymbals nicely and crisp like the 3/4" metal dome tweeter. The Carlton III should live on.

I started off with the Hiquphon OW-1 tweeters, and a number of other popular choices, but eventually I finalized my choice with the Seas 22TAF/G. This is a hybrid dome tweeter that has a 3/4" alloy dome supported by very large fabric skirt. It turned out to be the best sounding tweeter, and able to blend into the KEF’s sound characteristic seamlessly. Do not let the price fool the judgment; the 22TAF/G is an excellent performer.

Original Crossver

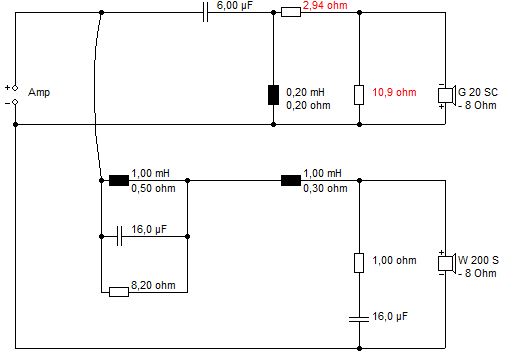

The Carlton III’s high pass section uses the similar 3rd order Butterworth design as the 104aB. The snubbing circuit uses a resistor to slightly widen the snubbing frequency range around 900 Hz, without sacrificing the deepness (effectiveness) of the notch. A Zobel circuit tames the tweeter’s rising impedance above 15 kHz.

The low pass section consists of a RLC resonance that provides a peak near ~2 kHz and also determines the Q of the system. The 600uf capacitor not only isolates the speaker from the danger of DC from the older transistor amplifier, it provides a peak at 100 Hz to give a deeper and quality bass.

Consistent with most KEF’s 70s/80s products, the crossover components were adequate but never overkill. The inductor sizes were modest, and the capacitors were from Alcap. Although the passive components still measure fine after 30 years in service, the capacitor performances degrade over the years. The PCB tracks became slightly corroded, partly due to remnant flux from soldering (?). Many Carlton III sounded as if it could only produce mid range after all these years.

One particular concern was the choice of a single 600uF 50V NP capacitor. It seems too small for the job, and on most Carlton III crossovers the capacitors show signs of fatigue, as most look bloated at the ends. In some cases, the speakers became totally mute because the caps had become open circuit. (many who tried to measure the Carlton III’s impedance usually would have a shock ; ) OC? anyway…).

New Crossover

The 22T/AF has lower impedance than the T33 and has a higher sensitivity of 93dB. The snubber circuit in the high pass is necessary to produce the smooth KEF sound. This simple KEF specialty is not found in most modern HF designs. Many DIY speaker builders using 22T/AF may be surprised how important this snubber is, even if they cross the tweeter way above the 1.05 kHz resonance F.

Using the same crossover F point, the notch filter RC was adjusted to match the same roll off. The sensitivity matching is provided by the simple R pad network. The attenuation network table can be found on the internet for both 4 and 8 ohms speakers. The value of 6 ohms unit can be derived by interpolation of 4 and 8 ohms values. To match the sensitivity of the B200B unit, the tweeter was attenuated from 93db down to about 88db. Although the R values are somewhat awkward, they can be formed by series parallel resistors of standard values. There is no need to add a bypass cap on the series attenuation R (verified by SPICE and listening), but the R should be non-inductive in nature. Zobel is best included to provide good response way above 15 kHz.

There is no need for the high pass section to go thru the series 600uf cap at the input terminals because the cap is basically an AC short circuit. As such, the high pass can tap directly from the input, leaving the 600uf to do the low pass job only. Simulation confirms there are no phase issues.

The following is the SPICE simulation showing how the modified crossover mimics the original design by KEF. The simulated frequency sweep results closely match the measured SPL below 15khz. The knees of the original circuit went away. The tweeter is capable of frequencies above 20 kHz, an important capability when playing LP.

SPICE simulation of high pass - green trace Seas red trace KEF

The original inductors for the low pass section may be undersized. Using air cored units has both size and cost penalty, but both are preferred in the pursuit of better sound. The 12 ohms in the RLC resonance circuit may be reduced to 10 ohms to add more mid range, its up to individual.

As the air cored inductors add slight series resistance to the low pass section, this can be compensated by adding more capacitance in the series large valued capacitor to 650uf. The peak is shifted lower to below 100 Hz, thereby pushing up the magnitude of overall response curve near/above 100 Hz.

Using a single large capacitance may not be a good idea as most capacitors, even modern switch mode supply type, cannot withstand too much ripple current. The capacitor will heat up quickly and degrade rapidly. Some may even explode if stressed. The 600uf cap was replaced by 6 paralleled low loss 100uf 100V non polar for audio units, bypassed with 10-50uf of polypropylene fast caps. This combo is a lot more expensive of course. What make sense in mass production may not be welcomed for the end user. Changing this 600uf cap has a greater return than using a much better amplifier in practical terms. By simulation, the ripple current in individual cap is well below 1 A @ max load (I cannot image passing a few amps thru a single small cap). The sound becomes more open, detailed and the bass can go deeper in listening tests.

SPICE simulation of low pass - not much difference

The crossover was built on three perf boards by hard wiring and secured by hot glue. The original crossovers were retained and can be used for comparison if required. Internal wiring was old stock Western Electric tinned solid core copper wire, measuring 1mm in diameter. These cotton sleeved wire sounds amazingly smooth and good than most multi stranded wires with all the fancy names. The speaker terminals were replaced.

All parts were sourced from Jantzen parts of Denmark. Total cost for new crossover parts was about US$200++. The tweeters cost less than US$50 each. A good alternative would be Mundorff parts. For the high pass section, using Solen fast cap did not give a very good return in comparison. (I only use Solen for snubbing). The Jantzen standard or Mundorff white caps are simply better. Alcaps would give a more mellow sound. Those who prefer the Alcaps can by all means do so, its personal choice.

Woodwork

Most KEF speaker cabinets of the 70s/80s were built using chip boards. They do not like water, moisture, and they do not like to be mishandled. Some basic wood working is necessary to improve the overall presentation of the worn cabinet. The recess holding the drivers may become loose or bad, which can be touched up by wood fillers and repainted.

I have sealed the cabinet by applying a layer of polyurethane at the

internals. It turned out to be a nightmare because the oil based polyurethane would continue to smell very badly for weeks and choke any one near the speakers. Even placing the cabinets under the sun did not help much. It took me 3 weeks to totally get rid of the smell, so it is best to apply spray paint or lacquer that is rapid drying.

I have discarded the wool damping materials in the speakers. The internal was reinforced by a layer of hard wood filler and 1 inch noise absorbing materials padded to the walls (just like the instruction found in KEF constructor sheet). This is a time consuming job. KEF in their mass production schedule will have no time for this laborious process of internal damping.

The Seas 22T/AF has a plastic or fiber glass facet that can be easily modified. Just filing off 1mm off each round edge, the speaker would fit nicely onto the speaker cabinet. Certainly, we need to open the insides of the ‘eye’ on the tweeter recess so that the wire terminals may go in smooth.

Still, there are no major works involved on the cabinets. Opening up the speaker recess and work on the tweeters should not take more than 1-2 hours by a novice. The tweeter fits snugly into the cabinet. Using silicone sealant to make a gasket should make it air tight easily.

The completed speakers require at least 50 hours of breaking in. Before that, the bass can be lacking and the high frequency closed in. After 100 hours of running, the speaker performance stabilizes and can allow serious listening.

Final Sound

The Seas 22T/AF on the Carlton III has a similar extension, richness in high frequency range as the T27a, but with none of the harshness. The cymbals sound more refined and delicate, but with no loss in metallic brightness. The sound may not be as ‘exciting’ as the T27. The sound is indeed a cross between a metal dome tweeter and a fabric tweeter, but more towards the metallic characteristics. The tweeter integrates well with the B200 and would not break into two different type of sound as the frequency range change over. Amazingly, it is exceptionally smooth like silk and I guarantee you there will be no fatigue after hours of listening (but on some other speakers that use the 22T/AF, my ears could bleed). Yet, there are no loss in any details whether listening to vocals, jazz or classical music. It is now a class above my pair of overhauled 104aB in terms of high frequency reproduction.

Mid range wise, I was somewhat disappointed because it is not as colored as the 104aB. The newer B200B (5 ohms) is more damped that the B200 SP1039 and has a different characteristics than the SP1039. The Carlton III sounds more blend and less emotional than the 104aB in this area. But still, it is accurate and sound staging is better than the 104aB. The mid range is indeed very open and detailed. The source and amplification would be more a limiting factor.

For the bass section, I was very pleased because the new combo caps indicate a marked improvement. Not only the speakers have better control, the bass went deeper as if a quality sub woofer was added. (I experimented with a 1000uf 50v (polarized) cap in place, and the nice bass was gone). So the combo works. We are still talking about the same cabinet dimensions, slightly improved damping and the same driver units 30 years of age. The air core coil would not saturate as the ferrite types, and that provides a signification improvement in the quality of the voice of any singer. Even the cello never sounded so good before. The speakers may not be very efficiency, by could be driven loud by either a 50W solid state integrated or 5W single ended amplifier.

As the crossovers continue to break in, the sound becomes more and more transparent and open. It comes to a point that some decent recordings can sound as good as live performances. I have finally decided to let this pair of Carlton III take center stage instead of the overhauled KEF104aB (with new drivers and Mundorff parts). I am now contemplating to incorporate the Seas 22T/AF into my second pair of KEF 104aB, instead of using the T27a. That pair of speakers are now under work and I hope to finish before this summer ends. But there would be more work on simulation and measurement. I am confident the work done now elevates the old Carlton III to a level that can rival anything in the market less than GBP1000, or maybe more.

If you have a pair of Carlton, stop messing around with replacement T33. Do consider putting in a pair of Seas 22T/AF with the corresponding crossover parts. If you want to keep the original working crossover, include the R attenuation network, change the snubber RC network and the Zobel values. Listen and tell me what you think. Cheers.[/quote]

The Carlton III is the continuation of the very successful KEF 104 aB design. But it did not surpass the predecessor. The cabinets were more solidly built, with better damping. The layout of the drivers reduced edge diffractions. The new B200 units were computer designed and have better consistency. (And yes, these drivers are still going strong until today.) The crossovers employ the acoustic Butterworth design, and the snubber circuit took into consideration the spread of resonance frequency (+/-100 Hz) of the tweeter units at 900 Hz. Still, the Carlton III did not enjoy a better fame than the 104s. I still put the blame on the T33 SP1074 fabric dome tweeter. If this problem did not exist, then Carlton III may very well enjoy a bigger fame than the 104s. Sadly, I know of many of them been mutilated for parts to be sold in the second used market.

The modern speaker manufacturers do offer a vast number of tweeter units, but it is not easy to find a good replacement for the Carlton. Cost is a factor, more so are electrical characteristics and facet dimensions. Most amateurs would look for a drop in unit without any work done on the crossover. This could be mission impossible because the crossover was built to suit a particular tweeter, and no two tweeters were built the same, electrically and mechanically, even by the same manufacturer. Unless, we are talking about very cheap crossovers that use only first order filtering. As such, to revive the Carlton III, a complete redesign/reconsideration of the crossover is absolutely necessary after the choice of the replacement tweeter.

My plan was to redo the Carlton III such that it has the high frequency performance of the alloy dome T27a found on the KEF 104 aB. Not using the T27a, as it does have some particular "ringi-ness" or undesirable irritation. Also, it is impossible to find a good pair of T27a these days. The tweeter may be able to fit into the rectangular recess onto the speaker facet without much modification. The sound should retain the smoothness of the fabric dome, and yet able to play cymbals nicely and crisp like the 3/4" metal dome tweeter. The Carlton III should live on.

I started off with the Hiquphon OW-1 tweeters, and a number of other popular choices, but eventually I finalized my choice with the Seas 22TAF/G. This is a hybrid dome tweeter that has a 3/4" alloy dome supported by very large fabric skirt. It turned out to be the best sounding tweeter, and able to blend into the KEF’s sound characteristic seamlessly. Do not let the price fool the judgment; the 22TAF/G is an excellent performer.

Original Crossver

The Carlton III’s high pass section uses the similar 3rd order Butterworth design as the 104aB. The snubbing circuit uses a resistor to slightly widen the snubbing frequency range around 900 Hz, without sacrificing the deepness (effectiveness) of the notch. A Zobel circuit tames the tweeter’s rising impedance above 15 kHz.

The low pass section consists of a RLC resonance that provides a peak near ~2 kHz and also determines the Q of the system. The 600uf capacitor not only isolates the speaker from the danger of DC from the older transistor amplifier, it provides a peak at 100 Hz to give a deeper and quality bass.

Consistent with most KEF’s 70s/80s products, the crossover components were adequate but never overkill. The inductor sizes were modest, and the capacitors were from Alcap. Although the passive components still measure fine after 30 years in service, the capacitor performances degrade over the years. The PCB tracks became slightly corroded, partly due to remnant flux from soldering (?). Many Carlton III sounded as if it could only produce mid range after all these years.

One particular concern was the choice of a single 600uF 50V NP capacitor. It seems too small for the job, and on most Carlton III crossovers the capacitors show signs of fatigue, as most look bloated at the ends. In some cases, the speakers became totally mute because the caps had become open circuit. (many who tried to measure the Carlton III’s impedance usually would have a shock ; ) OC? anyway…).

New Crossover

The 22T/AF has lower impedance than the T33 and has a higher sensitivity of 93dB. The snubber circuit in the high pass is necessary to produce the smooth KEF sound. This simple KEF specialty is not found in most modern HF designs. Many DIY speaker builders using 22T/AF may be surprised how important this snubber is, even if they cross the tweeter way above the 1.05 kHz resonance F.

Using the same crossover F point, the notch filter RC was adjusted to match the same roll off. The sensitivity matching is provided by the simple R pad network. The attenuation network table can be found on the internet for both 4 and 8 ohms speakers. The value of 6 ohms unit can be derived by interpolation of 4 and 8 ohms values. To match the sensitivity of the B200B unit, the tweeter was attenuated from 93db down to about 88db. Although the R values are somewhat awkward, they can be formed by series parallel resistors of standard values. There is no need to add a bypass cap on the series attenuation R (verified by SPICE and listening), but the R should be non-inductive in nature. Zobel is best included to provide good response way above 15 kHz.

There is no need for the high pass section to go thru the series 600uf cap at the input terminals because the cap is basically an AC short circuit. As such, the high pass can tap directly from the input, leaving the 600uf to do the low pass job only. Simulation confirms there are no phase issues.

The following is the SPICE simulation showing how the modified crossover mimics the original design by KEF. The simulated frequency sweep results closely match the measured SPL below 15khz. The knees of the original circuit went away. The tweeter is capable of frequencies above 20 kHz, an important capability when playing LP.

SPICE simulation of high pass - green trace Seas red trace KEF

The original inductors for the low pass section may be undersized. Using air cored units has both size and cost penalty, but both are preferred in the pursuit of better sound. The 12 ohms in the RLC resonance circuit may be reduced to 10 ohms to add more mid range, its up to individual.

As the air cored inductors add slight series resistance to the low pass section, this can be compensated by adding more capacitance in the series large valued capacitor to 650uf. The peak is shifted lower to below 100 Hz, thereby pushing up the magnitude of overall response curve near/above 100 Hz.

Using a single large capacitance may not be a good idea as most capacitors, even modern switch mode supply type, cannot withstand too much ripple current. The capacitor will heat up quickly and degrade rapidly. Some may even explode if stressed. The 600uf cap was replaced by 6 paralleled low loss 100uf 100V non polar for audio units, bypassed with 10-50uf of polypropylene fast caps. This combo is a lot more expensive of course. What make sense in mass production may not be welcomed for the end user. Changing this 600uf cap has a greater return than using a much better amplifier in practical terms. By simulation, the ripple current in individual cap is well below 1 A @ max load (I cannot image passing a few amps thru a single small cap). The sound becomes more open, detailed and the bass can go deeper in listening tests.

SPICE simulation of low pass - not much difference

The crossover was built on three perf boards by hard wiring and secured by hot glue. The original crossovers were retained and can be used for comparison if required. Internal wiring was old stock Western Electric tinned solid core copper wire, measuring 1mm in diameter. These cotton sleeved wire sounds amazingly smooth and good than most multi stranded wires with all the fancy names. The speaker terminals were replaced.

All parts were sourced from Jantzen parts of Denmark. Total cost for new crossover parts was about US$200++. The tweeters cost less than US$50 each. A good alternative would be Mundorff parts. For the high pass section, using Solen fast cap did not give a very good return in comparison. (I only use Solen for snubbing). The Jantzen standard or Mundorff white caps are simply better. Alcaps would give a more mellow sound. Those who prefer the Alcaps can by all means do so, its personal choice.

Woodwork

Most KEF speaker cabinets of the 70s/80s were built using chip boards. They do not like water, moisture, and they do not like to be mishandled. Some basic wood working is necessary to improve the overall presentation of the worn cabinet. The recess holding the drivers may become loose or bad, which can be touched up by wood fillers and repainted.

I have sealed the cabinet by applying a layer of polyurethane at the

internals. It turned out to be a nightmare because the oil based polyurethane would continue to smell very badly for weeks and choke any one near the speakers. Even placing the cabinets under the sun did not help much. It took me 3 weeks to totally get rid of the smell, so it is best to apply spray paint or lacquer that is rapid drying.

I have discarded the wool damping materials in the speakers. The internal was reinforced by a layer of hard wood filler and 1 inch noise absorbing materials padded to the walls (just like the instruction found in KEF constructor sheet). This is a time consuming job. KEF in their mass production schedule will have no time for this laborious process of internal damping.

The Seas 22T/AF has a plastic or fiber glass facet that can be easily modified. Just filing off 1mm off each round edge, the speaker would fit nicely onto the speaker cabinet. Certainly, we need to open the insides of the ‘eye’ on the tweeter recess so that the wire terminals may go in smooth.

Still, there are no major works involved on the cabinets. Opening up the speaker recess and work on the tweeters should not take more than 1-2 hours by a novice. The tweeter fits snugly into the cabinet. Using silicone sealant to make a gasket should make it air tight easily.

The completed speakers require at least 50 hours of breaking in. Before that, the bass can be lacking and the high frequency closed in. After 100 hours of running, the speaker performance stabilizes and can allow serious listening.

Final Sound

The Seas 22T/AF on the Carlton III has a similar extension, richness in high frequency range as the T27a, but with none of the harshness. The cymbals sound more refined and delicate, but with no loss in metallic brightness. The sound may not be as ‘exciting’ as the T27. The sound is indeed a cross between a metal dome tweeter and a fabric tweeter, but more towards the metallic characteristics. The tweeter integrates well with the B200 and would not break into two different type of sound as the frequency range change over. Amazingly, it is exceptionally smooth like silk and I guarantee you there will be no fatigue after hours of listening (but on some other speakers that use the 22T/AF, my ears could bleed). Yet, there are no loss in any details whether listening to vocals, jazz or classical music. It is now a class above my pair of overhauled 104aB in terms of high frequency reproduction.

Mid range wise, I was somewhat disappointed because it is not as colored as the 104aB. The newer B200B (5 ohms) is more damped that the B200 SP1039 and has a different characteristics than the SP1039. The Carlton III sounds more blend and less emotional than the 104aB in this area. But still, it is accurate and sound staging is better than the 104aB. The mid range is indeed very open and detailed. The source and amplification would be more a limiting factor.

For the bass section, I was very pleased because the new combo caps indicate a marked improvement. Not only the speakers have better control, the bass went deeper as if a quality sub woofer was added. (I experimented with a 1000uf 50v (polarized) cap in place, and the nice bass was gone). So the combo works. We are still talking about the same cabinet dimensions, slightly improved damping and the same driver units 30 years of age. The air core coil would not saturate as the ferrite types, and that provides a signification improvement in the quality of the voice of any singer. Even the cello never sounded so good before. The speakers may not be very efficiency, by could be driven loud by either a 50W solid state integrated or 5W single ended amplifier.

As the crossovers continue to break in, the sound becomes more and more transparent and open. It comes to a point that some decent recordings can sound as good as live performances. I have finally decided to let this pair of Carlton III take center stage instead of the overhauled KEF104aB (with new drivers and Mundorff parts). I am now contemplating to incorporate the Seas 22T/AF into my second pair of KEF 104aB, instead of using the T27a. That pair of speakers are now under work and I hope to finish before this summer ends. But there would be more work on simulation and measurement. I am confident the work done now elevates the old Carlton III to a level that can rival anything in the market less than GBP1000, or maybe more.

If you have a pair of Carlton, stop messing around with replacement T33. Do consider putting in a pair of Seas 22T/AF with the corresponding crossover parts. If you want to keep the original working crossover, include the R attenuation network, change the snubber RC network and the Zobel values. Listen and tell me what you think. Cheers.[/quote]

I have revived a pair of 104ab, Calinda and Carlton III. All 3 are similar designs, sharing a Passive radiator, a B200 variation of woofer and a T27 tweeter on the 104/Calinda and T33 on the Carlton.

May I correct that the T33 SP1074 isn't ferrofluid cooled. There's a special variant on the R107 that is ferrofluid cooled though. And the T27 don't have an alloy dome. It's composite - melinex.

Regarding the modifications and improvements, I'd like to point out that there are some bitumen sheets attached to the panels of the enclosures internally for damping. These will have gone hard and brittle after 30+ years and they don't perform their task any more. You can have a large imrprovement if you glue fresh bitumen sheets to the back and sides of the enclosure panels.

Bracing is already decent in the enclosure and I wouldn't consider altering it. Damping pads would reduce panel vibration. Additional bracing might move the resonance higher in frequency.

The foam - as you show - applied to the entire box is an improvement in standing wave management but I wouldn't discard the inner filling. It is a matter of fine tuning the resonance and you might even need to increase the fill factor to compensate for extra volume lost to padding and bracing.

One other tweak I found made quite some difference was replacing the sealing flanges under the drivers - except the one for the tweeter. Both the B200 and the B139PR were mounted with inadequate sealing flanges and after 30 years these have deteriorated into almost paper thickness. I used self adhesive polyurethane foam that I cut into 5mm stripes and applied around the insets.

And one final tweak has to do with screws for the drivers (particularly the B200 SP1075. This driver comes with rubber isolating rings through the screw holes. As the sealing flanges do offer an isolation level, I added rubber isolators and bigger spike-nuts (for lack of a better description) to the back of the holes. Using slightly thinner (0.5mm) screws, the combination removes direct contact of the driver or screw to the enclosure and also greatly increases sealing. By careful tuning the screw torque, I have found a level where the vibration from the driver to the enclosure is minimized. I have found that the setting that minimizes vibration measurement also sounds mostly free of boxiness. (The enclosures aren't very thick themselves and tend to resonate at high volume, despite the reduction in vibration offered by the application of bitumen sheets).

I really encourage you to try out the bitumen sheets (on any enclosure) that is 0.75" or less thick, as well as the driver isolation approach.

May I correct that the T33 SP1074 isn't ferrofluid cooled. There's a special variant on the R107 that is ferrofluid cooled though. And the T27 don't have an alloy dome. It's composite - melinex.

Regarding the modifications and improvements, I'd like to point out that there are some bitumen sheets attached to the panels of the enclosures internally for damping. These will have gone hard and brittle after 30+ years and they don't perform their task any more. You can have a large imrprovement if you glue fresh bitumen sheets to the back and sides of the enclosure panels.

Bracing is already decent in the enclosure and I wouldn't consider altering it. Damping pads would reduce panel vibration. Additional bracing might move the resonance higher in frequency.

The foam - as you show - applied to the entire box is an improvement in standing wave management but I wouldn't discard the inner filling. It is a matter of fine tuning the resonance and you might even need to increase the fill factor to compensate for extra volume lost to padding and bracing.

One other tweak I found made quite some difference was replacing the sealing flanges under the drivers - except the one for the tweeter. Both the B200 and the B139PR were mounted with inadequate sealing flanges and after 30 years these have deteriorated into almost paper thickness. I used self adhesive polyurethane foam that I cut into 5mm stripes and applied around the insets.

And one final tweak has to do with screws for the drivers (particularly the B200 SP1075. This driver comes with rubber isolating rings through the screw holes. As the sealing flanges do offer an isolation level, I added rubber isolators and bigger spike-nuts (for lack of a better description) to the back of the holes. Using slightly thinner (0.5mm) screws, the combination removes direct contact of the driver or screw to the enclosure and also greatly increases sealing. By careful tuning the screw torque, I have found a level where the vibration from the driver to the enclosure is minimized. I have found that the setting that minimizes vibration measurement also sounds mostly free of boxiness. (The enclosures aren't very thick themselves and tend to resonate at high volume, despite the reduction in vibration offered by the application of bitumen sheets).

I really encourage you to try out the bitumen sheets (on any enclosure) that is 0.75" or less thick, as well as the driver isolation approach.

Thanks for the comments!

You are right, T27 is composite - melinex. I have revived a number of 104aB. Mainly on improving the cabinet veneer, internal wiring, the crossover and replaced the worn out drivers. The Carlton III posed a lot more challenge because of the T33 tweeters. I hate it.

For the Carlton III, there are no bitumen sheets attached to the panels as in the case of 104aB. I hate working with bitumen and could never find a way to make them 'cling-on' permanently. KEF stapled bitumen sheets directly onto the panels. Yes, the ones on top don't always stay well.

I have not altered the bracing. Just added a layer of wood filler because the chipboard sections were exposed and some bits/pieces were falling off. The wood filler and polyurethane were more to ensure the chip boards continue to stay in one piece. The added rigidity was a bonus.

The internal sound absorbing foams worked out well. The speaker SPL measured ok with no dips or humps, and listening test was ok too. I followed the instructions laid out in KEF's construction series CS5.

The bass now sounds much better controlled and well defined. It sounds as if a sub woofer was added. I shall try out your suggestion on the internal filling. In all of the 104aB, KEF did stuffed the cabinets up completely with blocks of sponges.

You are absolutely right about the T nut screws. I have two problems here. On the B200s and the 22TAF tweeters.

I have improved the sealing between the cabinet and the B200 driver by a thin layer of silicon sealant (allowed to cure before installation). The B200 appears to be 'suspending' on the cabinet via the 3 rubber O rings; there are no rigid connections (?) If I push the driver flange I can see a very slight movement. Due to the hardened wood filler on the cabinet walls, brace, etc, the cabinet rigidity has greatly increased. The speaker cabinet holds up well even when played loud. I shall try out your suggestions on the isolation. The O rings left me perplexed when I tried to torque the screws up.

I have more of a problem on the tweeters. I introduced 4 mm spacers to ensure the tweeter is flushed with the cabinet panel. The tapping screws that hold the Seas 22TAF need to be 'just holding it' else the high frequency will be dulled or sound worse off than the T33 . I tried applying some black tak to fill up the voids on the corners, but that killed the high frequencies too. So I have the tweeter in the way as shown in the picture. I could do more work to improve this (like cut out a hole, etc) but I am happy now.

I am very pleased with the Carlton III modified with the Seas 22TAF. This is not just a replacement, but a serious upgrade. The speakers are fully broken in and I really enjoy listening to them. Well tweeter technology has come a long way after all these years. Why not you give the 22TAF a try as well 🙂

You are right, T27 is composite - melinex. I have revived a number of 104aB. Mainly on improving the cabinet veneer, internal wiring, the crossover and replaced the worn out drivers. The Carlton III posed a lot more challenge because of the T33 tweeters. I hate it.

For the Carlton III, there are no bitumen sheets attached to the panels as in the case of 104aB. I hate working with bitumen and could never find a way to make them 'cling-on' permanently. KEF stapled bitumen sheets directly onto the panels. Yes, the ones on top don't always stay well.

I have not altered the bracing. Just added a layer of wood filler because the chipboard sections were exposed and some bits/pieces were falling off. The wood filler and polyurethane were more to ensure the chip boards continue to stay in one piece. The added rigidity was a bonus.

The internal sound absorbing foams worked out well. The speaker SPL measured ok with no dips or humps, and listening test was ok too. I followed the instructions laid out in KEF's construction series CS5.

The bass now sounds much better controlled and well defined. It sounds as if a sub woofer was added. I shall try out your suggestion on the internal filling. In all of the 104aB, KEF did stuffed the cabinets up completely with blocks of sponges.

You are absolutely right about the T nut screws. I have two problems here. On the B200s and the 22TAF tweeters.

I have improved the sealing between the cabinet and the B200 driver by a thin layer of silicon sealant (allowed to cure before installation). The B200 appears to be 'suspending' on the cabinet via the 3 rubber O rings; there are no rigid connections (?) If I push the driver flange I can see a very slight movement. Due to the hardened wood filler on the cabinet walls, brace, etc, the cabinet rigidity has greatly increased. The speaker cabinet holds up well even when played loud. I shall try out your suggestions on the isolation. The O rings left me perplexed when I tried to torque the screws up.

I have more of a problem on the tweeters. I introduced 4 mm spacers to ensure the tweeter is flushed with the cabinet panel. The tapping screws that hold the Seas 22TAF need to be 'just holding it' else the high frequency will be dulled or sound worse off than the T33 . I tried applying some black tak to fill up the voids on the corners, but that killed the high frequencies too. So I have the tweeter in the way as shown in the picture. I could do more work to improve this (like cut out a hole, etc) but I am happy now.

I am very pleased with the Carlton III modified with the Seas 22TAF. This is not just a replacement, but a serious upgrade. The speakers are fully broken in and I really enjoy listening to them. Well tweeter technology has come a long way after all these years. Why not you give the 22TAF a try as well 🙂

Last edited:

Hi,

the Seas range of tweeters are invariable above average at least so it's quite possible for the 22TAF to be an improvement over the T33. I might just order a couple of drivers to try out.

It puzzles me that there are no bitumen sheets in the Carlton. There certainly were in the 104 and Calinda. It took me some time to remove them and replace them with fresh.

I use contact adhesive (sold here as "benzene-glue",suitable for leather material) to secure the bitumen sheets. I apply the glue on the bitumen sheet surface, let it cure for several seconds, then spread it like butter using a knife/spatula/whatever. The glue starts to "melt" the bitumen and the two material become one. That's the right moment to place them on the panel. I press it firmly using a roller and apply a few staples to keep it there.

I swear by the use of bitumen. I tried this in a 225lt enclosure (0,5" plywood) and 3 layers around the panels reduced vibration by 12~15dB.

I will certainly add the bitumen sheets to the Carltons myself.

the Seas range of tweeters are invariable above average at least so it's quite possible for the 22TAF to be an improvement over the T33. I might just order a couple of drivers to try out.

It puzzles me that there are no bitumen sheets in the Carlton. There certainly were in the 104 and Calinda. It took me some time to remove them and replace them with fresh.

I use contact adhesive (sold here as "benzene-glue",suitable for leather material) to secure the bitumen sheets. I apply the glue on the bitumen sheet surface, let it cure for several seconds, then spread it like butter using a knife/spatula/whatever. The glue starts to "melt" the bitumen and the two material become one. That's the right moment to place them on the panel. I press it firmly using a roller and apply a few staples to keep it there.

I swear by the use of bitumen. I tried this in a 225lt enclosure (0,5" plywood) and 3 layers around the panels reduced vibration by 12~15dB.

I will certainly add the bitumen sheets to the Carltons myself.

Hello Sasi

Thanks for the great tips!

I have applied bitumen sheets (for car door damping) onto the inner walls of the Carlton III cabinet. To be exact, 7 sheets per cabinet. I hate the smell of glue so I nailed them onto the walls to make a permanent and quick fixation. The bitumen sheets have sticky patches on one side so it helped. Thickness per sheet was just less than 5mm, so it was easy to handle.

I have to thank you for the tips on the B200B. I am still using the same sets of screws, but installed a washer per screw to hold down the flange. The original speaker had the screws tightened all the way in until the screw hits the protruding sleeve. Now I would tighten the screw such that I will stop when the flange do no get pressed in anymore. This certainly helped to decouple the driver from the cabinet somewhat.

Listening tests showed a marked reduction in boxiness. The mid range is more open and clean, and bass is less muddled. As the tweeters breaks in more, the speaker sounds much more like a modern speaker. It is not as fast and as detailed as some Seas metal dome speakers, but it is certainly very musical and sounds better than many modern drivers with paper/doped paper/plastic cone.

I am happy about the Seas 22TAF/G attenuated by 4~5dB and crossed at the same frequency as the original KEF design. The values chosen as shown in the SPICE circuit work very well and further adjustments are not necessary. The timbre is much better than using the T33. This is a good compromise between a silk dome and metallic dome tweeter. (built the Seas 18RLY and Seas 22TAF/G 16 liters compact). You seriously need to try this. But the interface between the tweeter and cabinet needs care.

I have tried driving the speakers with Naim, Pioneer A400 (upgraded) and several tube amplifiers. They all worked very well as sensitivity around 85~86dB 2.8V. The use of low R air cored inductors helped improved the sound significantly.

Thanks for the great tips!

I have applied bitumen sheets (for car door damping) onto the inner walls of the Carlton III cabinet. To be exact, 7 sheets per cabinet. I hate the smell of glue so I nailed them onto the walls to make a permanent and quick fixation. The bitumen sheets have sticky patches on one side so it helped. Thickness per sheet was just less than 5mm, so it was easy to handle.

I have to thank you for the tips on the B200B. I am still using the same sets of screws, but installed a washer per screw to hold down the flange. The original speaker had the screws tightened all the way in until the screw hits the protruding sleeve. Now I would tighten the screw such that I will stop when the flange do no get pressed in anymore. This certainly helped to decouple the driver from the cabinet somewhat.

Listening tests showed a marked reduction in boxiness. The mid range is more open and clean, and bass is less muddled. As the tweeters breaks in more, the speaker sounds much more like a modern speaker. It is not as fast and as detailed as some Seas metal dome speakers, but it is certainly very musical and sounds better than many modern drivers with paper/doped paper/plastic cone.

I am happy about the Seas 22TAF/G attenuated by 4~5dB and crossed at the same frequency as the original KEF design. The values chosen as shown in the SPICE circuit work very well and further adjustments are not necessary. The timbre is much better than using the T33. This is a good compromise between a silk dome and metallic dome tweeter. (built the Seas 18RLY and Seas 22TAF/G 16 liters compact). You seriously need to try this. But the interface between the tweeter and cabinet needs care.

I have tried driving the speakers with Naim, Pioneer A400 (upgraded) and several tube amplifiers. They all worked very well as sensitivity around 85~86dB 2.8V. The use of low R air cored inductors helped improved the sound significantly.

Last edited:

I'm still experimenting with driver mounting techniques. All started by observing the special contraptions devised by KEF for the 105/2 where it was clear they wanted a very tight but decoupled mount.

I'm working under the hypothesis that the driver needs to be decoupled as much as possible from transmitting vibration from the basket to the baffle, while at the same time be stiff and unable to "rattle" under stress.

From then on, the cabinet itself needs to get rid of the energy received by mechanical coupling and the driver backwash.

All in the name of removing the boxiness.

I am setting up an environment where I can try out different things and measure the vibrations by multiple piezo accelerometers secured in multiple locations of the enclosure. I will post a relevant thread sometime in the summer time.

I'm working under the hypothesis that the driver needs to be decoupled as much as possible from transmitting vibration from the basket to the baffle, while at the same time be stiff and unable to "rattle" under stress.

From then on, the cabinet itself needs to get rid of the energy received by mechanical coupling and the driver backwash.

All in the name of removing the boxiness.

I am setting up an environment where I can try out different things and measure the vibrations by multiple piezo accelerometers secured in multiple locations of the enclosure. I will post a relevant thread sometime in the summer time.

HiI,

FWIW a combination of cable grommets, driiled out driver holes and stand

offs, (hollow tubes for mounting circuit boards) and foam sealing tape is

worth investigating if you wand decoupled driver mountings.

Also FWIW Kef after some bad press with decoupled driver mountings,

(allegedly bad dynamics, boring midrange etc) moved the decoupling

from the chassis mounting to the driver magnets, chew on that ....

rgds, sreten.

FWIW a combination of cable grommets, driiled out driver holes and stand

offs, (hollow tubes for mounting circuit boards) and foam sealing tape is

worth investigating if you wand decoupled driver mountings.

Also FWIW Kef after some bad press with decoupled driver mountings,

(allegedly bad dynamics, boring midrange etc) moved the decoupling

from the chassis mounting to the driver magnets, chew on that ....

rgds, sreten.

Hello sreten

Thanks for the information. I have tried various grommets with different elasticity. So far, nothing conclusive as its all subjective listening and I cannot think of how to measure this.

I have taken the design found on the 104 and 104aB, that is to include a support from the back of the panel to the speaker magnet. Its not a 100% contact, but via 1/4inch thick foam. The foam serves as a slight cushion or interface for the driver. This, together with 3 elastic grommets. hold the B200 driver nicely onto the speaker cabinet.

The dynamics of the speaker is excellent. I won't call the mid range boring, but it is pretty accurate now.

There is something about the 104aB cabinet, the sound has a certain overtone.

Also FWIW Kef after some bad press with decoupled driver mountings,

(allegedly bad dynamics, boring midrange etc) moved the decoupling

from the chassis mounting to the driver magnets, chew on that ....

Thanks for the information. I have tried various grommets with different elasticity. So far, nothing conclusive as its all subjective listening and I cannot think of how to measure this.

I have taken the design found on the 104 and 104aB, that is to include a support from the back of the panel to the speaker magnet. Its not a 100% contact, but via 1/4inch thick foam. The foam serves as a slight cushion or interface for the driver. This, together with 3 elastic grommets. hold the B200 driver nicely onto the speaker cabinet.

The dynamics of the speaker is excellent. I won't call the mid range boring, but it is pretty accurate now.

There is something about the 104aB cabinet, the sound has a certain overtone.

Also FWIW Kef after some bad press with decoupled driver mountings,

(allegedly bad dynamics, boring midrange etc) moved the decoupling

from the chassis mounting to the driver magnets, chew on that ....

Last edited:

Wow has been a good 7 years already. The KEF Carlton is still working nicely.

I am onto a Project in doing up a KEF 104aB which was in really bad shape.

Cabinet is now restored. And I have a few options:

1. Use a good pair of T27 or Seas T22?

I already have a good pair of 104aB in working condition. Sound is really transparent. T27 has its charm. Not sure if the T22 is better than T27? T27 has a more definite 'bite' than T22.

2. The B200 is in terrible shape after near 40 years. Use the Monacor SPM205?

The B200 has a large magnet. There is a shop in Singapore called Martin Electronics and they have over 40 years experiences in repairing KEF speakers. (they used to offer KEF construction kits). I had the B200 serviced and checked by them. However, I am tempted to put in a new pair of modern driver the Monacor SPM205. I have not read much reviews of the SPM205, but many sellers state it is a 'good replacement of OEM' for B200. It has a smaller magnet. (The Monacor SPH135 has such good qualities it is replacing many B110.)

I look at the KEF Carlton/ 104aB/ Calinda as Musical Instruments (not a die hard purist in restoration). Any comments most welcomed.

I am onto a Project in doing up a KEF 104aB which was in really bad shape.

Cabinet is now restored. And I have a few options:

1. Use a good pair of T27 or Seas T22?

I already have a good pair of 104aB in working condition. Sound is really transparent. T27 has its charm. Not sure if the T22 is better than T27? T27 has a more definite 'bite' than T22.

2. The B200 is in terrible shape after near 40 years. Use the Monacor SPM205?

The B200 has a large magnet. There is a shop in Singapore called Martin Electronics and they have over 40 years experiences in repairing KEF speakers. (they used to offer KEF construction kits). I had the B200 serviced and checked by them. However, I am tempted to put in a new pair of modern driver the Monacor SPM205. I have not read much reviews of the SPM205, but many sellers state it is a 'good replacement of OEM' for B200. It has a smaller magnet. (The Monacor SPH135 has such good qualities it is replacing many B110.)

I look at the KEF Carlton/ 104aB/ Calinda as Musical Instruments (not a die hard purist in restoration). Any comments most welcomed.

I am interested in what you say in post 3:

"I tried applying some black tak to fill up the voids on the corners, but that killed the high frequencies too."

I know it was a long time ago, but do you have any thoughts as to why the Black Tac had that effect on the sound?

"I tried applying some black tak to fill up the voids on the corners, but that killed the high frequencies too."

I know it was a long time ago, but do you have any thoughts as to why the Black Tac had that effect on the sound?

I wish I can give you an answer backed by measurable data. I suppose it is due to its resonance properties, as in, it is pretty dead. If you put a big blob of blue tak on a violin then the violin won't sing as well.

I avoid using blue tak on the speaker.

I avoid using blue tak on the speaker.

This evening I tried out the 6 pieces of B200 I have at hand. Sadly, out of 6 only 1 is not having any distortion when played loud. I collected the B200 from UK over the years. Well, there must be a reason why they were put on the second hand market. I tried to get a good working pair out of the 6. Since I had spent so much time and effort, everything must be working properly.

I have ordered a pair of Monacor SPM 205/8 from Germany. Back to waiting again. 🙁

I have ordered a pair of Monacor SPM 205/8 from Germany. Back to waiting again. 🙁

I can add a little footnote about when KEF used paper bass, since your Monacor SPM-205/8 is such an animal. IDK if that Qts of 0.7 will be troublesome. Looks like medium inductance and a little more 3kHz breakup than you'd get with a polycone.

KEF Cara, an ABR design. This was bespoke built for a large UK HiFi chain called Laskys in the late 70s, I believe. Nice little old UK Elac bass which I happen to have in a Monitor Audio R300 design, though KEF called it a SP1193. Very nice little driver, widely adopted.

I may have mentioned this before, but followers of the KEF/BBC tradition will find Alan Shaw of Harbeth interesting for the modern evolved take. His newer "Radial" woofers are entirely more rigid than the old polycones.

Harbeth cabinets are interesting too. Still in the lighter ply tradition but now MDF. "Cracked Bell" screw-on front panels sometimes. You actually glue rubbery panel damping to the sides (Carpet adhesive works for me), and twice as thick to the top and bottom. Nothing on front and back. Designed to take the problems lower in frequency where they are less audible. TBH, office carpet rubber-backed floor tiles would probably work as well as anything.

I'm not sure I buy KEFs decoupling ideas. But I can tell you that lightish front panels work better than you might expect. The light ply idea is the vibration moves round the whole box, being damped every time it passes the damped sections. Battening is kept light and rigid so it sings less of its own tunes. There is always going to be an acoustic mismatch between the heavy chassis and the front panel, so why fight it?

Circuits for paper bass might well end up different from polycone circuits, but nothing that can't be fixed. I have seen this clever one used with either type of driver:

That bass section looks familiar to the KEF fans, eh? As it goes I have built an acoustic butterworth 3rd order circuit. I didn't find it very special. 4th order sounds best to me. And simple second order can do the right things sometimes. IMO, it's good to have a shunt coil next to a tweeter to damp the Fs.

Following these restore projects with interest. Knowing your history is always useful with a mature subject like loudspeakers. Very little new under the sun. 🙂

KEF Cara, an ABR design. This was bespoke built for a large UK HiFi chain called Laskys in the late 70s, I believe. Nice little old UK Elac bass which I happen to have in a Monitor Audio R300 design, though KEF called it a SP1193. Very nice little driver, widely adopted.

I may have mentioned this before, but followers of the KEF/BBC tradition will find Alan Shaw of Harbeth interesting for the modern evolved take. His newer "Radial" woofers are entirely more rigid than the old polycones.

Harbeth cabinets are interesting too. Still in the lighter ply tradition but now MDF. "Cracked Bell" screw-on front panels sometimes. You actually glue rubbery panel damping to the sides (Carpet adhesive works for me), and twice as thick to the top and bottom. Nothing on front and back. Designed to take the problems lower in frequency where they are less audible. TBH, office carpet rubber-backed floor tiles would probably work as well as anything.

I'm not sure I buy KEFs decoupling ideas. But I can tell you that lightish front panels work better than you might expect. The light ply idea is the vibration moves round the whole box, being damped every time it passes the damped sections. Battening is kept light and rigid so it sings less of its own tunes. There is always going to be an acoustic mismatch between the heavy chassis and the front panel, so why fight it?

Circuits for paper bass might well end up different from polycone circuits, but nothing that can't be fixed. I have seen this clever one used with either type of driver:

That bass section looks familiar to the KEF fans, eh? As it goes I have built an acoustic butterworth 3rd order circuit. I didn't find it very special. 4th order sounds best to me. And simple second order can do the right things sometimes. IMO, it's good to have a shunt coil next to a tweeter to damp the Fs.

Following these restore projects with interest. Knowing your history is always useful with a mature subject like loudspeakers. Very little new under the sun. 🙂

Attachments

Last edited:

Wow thanks for sharing the KEF Cara pictures. I remember listening to them a long time ago. The HF was a Morel MDT29? Speaker technology is still very much the same today. Just need to take the pragmatic approach on parts quality and proper integration.

I wrote to Falcon Acoustics regarding the B200 and Jerry replied very promptly that there will be new drivers from them in the near future. As to how soon is near future that could well be another one year.

The KEF 104aB for restoration I intend to drive it via active cross over (3rd order BW or 4th order LR) and bi amp. Every driver has to be performing within spec. My old B200 SP1039 have deteriorated curtains and spiders. Cannot complain after 40 years especially for the past 4 years they were in storage.

Despite the recommendations by Wilmslow audio and Willy's HiFi to use the Monacor SPM 205/8 to replace the B200, I have yet seen any published article, reports, images, test results or reviews about this driver. ( I have however a pair of Monacor SPH 135 and they are of very good quality and works well in a clone LS3/5a, replacing the crippled B110).

I will drive the SPM 205/8 directly and would add a Zoble of (9ohm+8uf) to match the driver electrical characteristics. I would also test it thru the KEF 104 passive cross over and compare the sound (listen and some measurement).

For the T27, I would drive it via a series 3R//10uf notch for 1.2khz as found in the original crossover. The amplifier will not be able to tame the properties of the T27. Theoretically, the notch can be made more narrow and sharp by increasing to a 3R//47uF. Not sure how that will sound but I will try that out. Definitely, I will compare the active crossover vs the passive. I may end up driving the bass unit directly, and drive the HF section via passive filters.

Active provides further adjustments of Fc and amplitude. The passive cross over will not provide such flexibility.

I wrote to Falcon Acoustics regarding the B200 and Jerry replied very promptly that there will be new drivers from them in the near future. As to how soon is near future that could well be another one year.

The KEF 104aB for restoration I intend to drive it via active cross over (3rd order BW or 4th order LR) and bi amp. Every driver has to be performing within spec. My old B200 SP1039 have deteriorated curtains and spiders. Cannot complain after 40 years especially for the past 4 years they were in storage.

Despite the recommendations by Wilmslow audio and Willy's HiFi to use the Monacor SPM 205/8 to replace the B200, I have yet seen any published article, reports, images, test results or reviews about this driver. ( I have however a pair of Monacor SPH 135 and they are of very good quality and works well in a clone LS3/5a, replacing the crippled B110).

I will drive the SPM 205/8 directly and would add a Zoble of (9ohm+8uf) to match the driver electrical characteristics. I would also test it thru the KEF 104 passive cross over and compare the sound (listen and some measurement).

For the T27, I would drive it via a series 3R//10uf notch for 1.2khz as found in the original crossover. The amplifier will not be able to tame the properties of the T27. Theoretically, the notch can be made more narrow and sharp by increasing to a 3R//47uF. Not sure how that will sound but I will try that out. Definitely, I will compare the active crossover vs the passive. I may end up driving the bass unit directly, and drive the HF section via passive filters.

Active provides further adjustments of Fc and amplitude. The passive cross over will not provide such flexibility.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- KEF Carlton III resurrection with Seas 22T/AF