Are ther e some calculation s that can show the effect on a signal in a wire running next to these different materials - for example a Phono signal ?

What about encasing transformers in mumetal, as is often done with MC step-up transformers. Good or bad?

Bonsai said:Are ther e some calculation s that can show the effect on a signal in a wire running next to these different materials - for example a Phono signal ?

Cauhtemoc said:What about encasing transformers in mumetal, as is often done with MC step-up transformers. Good or bad?

The transient current draw through the devices is affected, with regards to it's 'peak' linearity. And the way the ear hears, and the way the amplifier operates, means that the non-linear characteristics of the Mu-metal end up being heard, even though the non-linearity are minor components compared to the larger 'mass' of the signal.

As in loudspeaker design, we are confronted with differing issues that contradict one another when it comes to known avenues of resolution for their given 'problems'. As an example, in a loudspeaker driver/cabinet system, we need the driver cone to operate in perfect pistonic motion, translating no motion or activity anywhere else but out the front face of the cone. However, the truth is far from that, and the issues give even the most astute engineers migraines-when they spend the time to come to an understanding the magnitude of the conflicting sum total of considerations. A basic flaw there, is that the ear is designed to be a single sided device, ie, the ear/brain is literally designed to hear the human voice, which has no negative waveform aspects, it only possesses a single sided positive waveform..with lumps/peaks. The ear only works with those peaks, the level differences between them..and the timing between them. With regards to 'normal' measurement practices, this equates to maybe 10% or less of the total 'sine' averaged/whatever signal. Yet, to the ear/brain, this minor component represents 100% of the 'listened to' signal. The loudspeaker, as a system that is not thoughtfully designed, can greatly distort the positioning and level of those minor components that the ear MUST have delivered correctly, in order to determine the 'intelligence' in the signal. The closest we have ever seen to creating a signal that is 'correct' to the ear, is the plasma tweeter. All else is a joke.

For example, the very aspect of how a transistor works on the fundamental molecular level, is also part of what gives designers the fits as being the major source of noise in the signal.

It is interesting to note that the minor components we speak of have their greatest level of contributing distortion to the single component/aspect that the ear hears.

It IS possible to create an amplification device that is more complimentary to the ear's design, via the use of a 'positive only' type amplification circuit, that has positive flow only. DC coupled, positive flow only. Not AC, but modulated level single direction flow. It is in the conceptualization with regards to the issues- that it becomes more clear.

I am not a phycsist, or whatever the hell those guys are that do differential eqautions all day are called, but, KBK, this does not sound sensible to me:-

"The transient current draw through the devices is affected, with regards to it's 'peak' linearity. And the way the ear hears, and the way the amplifier operates, means that the non-linear characteristics of the Mu-metal end up being heard, even though the non-linearity are minor components compared to the larger 'mass' of the signal. "

Just answer the Q: what is the effect (distortion, harmonics etc) of running a 1mV 1KHz signal via a shielded wire next to a piece of aluminium, a piece of mild steel and a piece of any other material (your choice)?

Please share some numbers with us so we can 'scale' the issue in real world terms.

"The transient current draw through the devices is affected, with regards to it's 'peak' linearity. And the way the ear hears, and the way the amplifier operates, means that the non-linear characteristics of the Mu-metal end up being heard, even though the non-linearity are minor components compared to the larger 'mass' of the signal. "

Just answer the Q: what is the effect (distortion, harmonics etc) of running a 1mV 1KHz signal via a shielded wire next to a piece of aluminium, a piece of mild steel and a piece of any other material (your choice)?

Please share some numbers with us so we can 'scale' the issue in real world terms.

KBK said:The transient current draw through the devices is affected, with regards to it's 'peak' linearity. And the way the ear hears, and the way the amplifier operates, means that the non-linear characteristics of the Mu-metal end up being heard, even though the non-linearity are minor components compared to the larger 'mass' of the signal.

So it would be better to encase a transformer in copper or aluminium?

KBK said:Of course, the perfect (far closer than the currently used standard) heatsink already exists. We've even used them extensively. And we have noted that those particular audio devices that use them..have a certain undefinable sonic charm, all out of proportion to what we normally expect. I am of course, remembering as I write this..that I determined that it was the heatsink to use about 10 years ago..but I forgot..and had to discover it again. How many times you done that, John? It happens a lot over here....

[/B]

immersion in freon works pretty good 🙂

Bonsai said:Are ther e some calculation s that can show the effect on a signal in a wire running next to these different materials - for example a Phono signal ?

Good question, but I would like to see some actual measurements. Then we all could all know if the effects (they obviously exist) are of sufficient magnitude to be of concern. Otherwise our projects will become more and more disconnected from reality.

Nobody expects typical amateurs to go to great lengths in order to shield or worry about induced distortion. However, in hi end, we compete with the best, and we have to worry about potentially small distortion additions, such as steel vs aluminum as an outside shield. Measurements have been made by the Japanese, I believe, and there is an AES paper on it, somewhere.

john curl said:Nobody expects typical amateurs to go to great lengths in order to shield or worry about induced distortion.

John,

Perhaps some typical amateurs are taking care of shielding and magnetic induced distortions? When it makes sense, of course, like in ultra low distortions power amplifiers.

But if you keep insulting anybody that debates your axiomes, then expect no mercy in return. For the moment, here's my small contribution Re: your post http://www.diyaudio.com/forums/showthread.php?postid=1668475#post1668475

The CTC enclosures denotes a lack of understanding of elementary notions of EM field theory and practice and it's a waste of metal, manpower, energy and ultimately a rip off for the naive, but stinking rich, customers. The same shielding results could be obtained by using good industry practices and some common sense.

Thank you for your attention.

Syn08 Please show use how to get the same shielding without any further compromise. If you can, we will do it your way in our next project.

JohnCurl.john curl said:Nobody expects typical amateurs to go to great lengths in order to shield or worry about induced distortion. However, in hi end, we compete with the best, and we have to worry about potentially small distortion additions, such as steel vs aluminum as an outside shield. Measurements have been made by the Japanese, I believe, and there is an AES paper on it, somewhere.

Thinking aloud, I suppose that if you had made the Blowtorch's case larger, the internal circuitry could have been spaced further from the case, reducing the induced distortions, and thus had an even better sounding preamp for the high end.

I think that we should understand what the box is, and why it is the size that it is. As many of us know, there are many tradeoffs in analog audio. As far as the box is concerned, we wanted a sturdy frame in order to mount out big silver switches, enough height to make sure that the knobs that we made to use with the big, hard to turn switches would not scrape on the top or bottom. We made the width of the box about what most hi fi products, but the depth was chosen to make sure that we had enough internal to put in anything that a potential customer wanted, (these were to be custom designs for each customer) and different customers might want: Phono, balanced in and out, buffered line drivers to drive very long lines, as some customers put their amps below the floor, or behind the loudspeakers, and this might necessitate long cables, more than 20 ft, for example.

In fact, only a few phono stages were put in, only one customer wanted a balanced input, and nobody needed the active buffer, so in hindsight, we might have been able to shave a few inches off the depth of the box, IF we knew what our customers had wanted in advance.

Once we made the box, we kept them all the same superficially, and it was fairly empty inside for the most part. This did make it easier to route our cables away from each other inside the box, to reduce any potential crosstalk.

Now for the thickness of the box material: The box started out as a solid piece of aluminum, so the machinist had to 'hog out' the interior of the box. Therefore, the LESS material that we removed from the box, saved time and money, BUT we also had to mount the switches, volume controls, phono and XLR connectors, etc so that they could be approached from the outside of the box, and this made the thickness of the front and back slightly thinner than we would want, but it was necessary. In the end, the boxes were fairly heavy, but not as heavy as a good power amp, and fairly expensive, $3000 our cost for the main and power supply case.

In the end we got an almost airtight box, with shielding even down to 60 Hz to some degree, and very high interference reduction at higher frequencies. It is also stable, doesn't rattle or ring when struck to any extent, and our customers appreciate that sort of thing.

Would I do it again? Maybe not, but MY CTC Blowtorch will stay with me for the rest of my life, and I would not think of replacing it. I do have a JC-80 and a Levinson JC-2 for sale, if you would want one.

In fact, only a few phono stages were put in, only one customer wanted a balanced input, and nobody needed the active buffer, so in hindsight, we might have been able to shave a few inches off the depth of the box, IF we knew what our customers had wanted in advance.

Once we made the box, we kept them all the same superficially, and it was fairly empty inside for the most part. This did make it easier to route our cables away from each other inside the box, to reduce any potential crosstalk.

Now for the thickness of the box material: The box started out as a solid piece of aluminum, so the machinist had to 'hog out' the interior of the box. Therefore, the LESS material that we removed from the box, saved time and money, BUT we also had to mount the switches, volume controls, phono and XLR connectors, etc so that they could be approached from the outside of the box, and this made the thickness of the front and back slightly thinner than we would want, but it was necessary. In the end, the boxes were fairly heavy, but not as heavy as a good power amp, and fairly expensive, $3000 our cost for the main and power supply case.

In the end we got an almost airtight box, with shielding even down to 60 Hz to some degree, and very high interference reduction at higher frequencies. It is also stable, doesn't rattle or ring when struck to any extent, and our customers appreciate that sort of thing.

Would I do it again? Maybe not, but MY CTC Blowtorch will stay with me for the rest of my life, and I would not think of replacing it. I do have a JC-80 and a Levinson JC-2 for sale, if you would want one.

yeah, stop them buying local made products!syn08 said:

it's a waste of metal, manpower, energy and ultimately a rip off for the naive, but stinking rich, customers.

CNC-workers don't need jobs! Save rich peoples money!

More parties and Wall Street gambling!

me too!Thank you for your attention.

regards

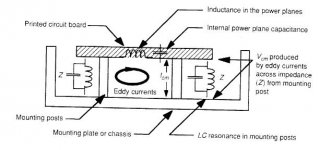

You right, at least for low frequencies, but I guess the problem with steel is not only linearity. Sometimes you can get a transformer, where you do not expect it to have. I know about a problem with 60Hz and harmonics that were conducted on the inputs ground loop (amp main ground -> right channel connector->source ground->left channel connector->amp main ground), because of steel case and not very good power supply transformer. It was easily measured at about -80dB. However a gap between inputs holes should help a lot. I think this technique could help with linearity too.john curl said:Makola, thanks for putting up the graph. This should more easily show how difficult it is to get enough shield thickness from anything except steel, and unfortunately steel is nonlinear.

Attachments

John Curl, although you didn't mention induced distortions in relation to the Blowtorch's size, I thank you for your detailed reply.

Maybe we don't have to be as concerned with induced distortions as previous posts on this subject would suggest.

But now you are in the mood, if today you wanted to make the untimate sounding preamp, not necessarily commercial, would you go with FETs, Opamps or Tubes ?

Maybe we don't have to be as concerned with induced distortions as previous posts on this subject would suggest.

But now you are in the mood, if today you wanted to make the untimate sounding preamp, not necessarily commercial, would you go with FETs, Opamps or Tubes ?

I think I know JC's answer, but he resents us second guessing.fredex said:John Curl, ..........., if today you wanted to make the ultimate sounding preamp, not necessarily commercial, would you go with FETs, Opamps or Tubes ?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- John Curl's Blowtorch preamplifier