What I am trying to point out in my previous input is that while metal might be potentially a problem, it is also a great shield. In the CTC case, we separate the case from almost all the wiring and we space the circuit board on plastic spacers to keep it away from the case itself. The case is just a 'cavern' to isolate the wiring, switches, and boards, from the outside environment, from RFI, dust, and most air pollutants. If you open a CTC case after several years you will find it dust free, for example. Now the way that Charles Hansen does it, 'might' be a potential problem according to KBK, but I don't think so.

This is what is called a 'microscopic' view, looking at only one aspect of a design, rather than the whole.

This is what is called a 'microscopic' view, looking at only one aspect of a design, rather than the whole.

john curl said:Distance between shields and conductors helps as well. Then eddy currents cannot be as easily generated or transferred to the audio signals. It can be a 3 dimensional approach.

john curl said:What I am trying to point out in my previous input is that while metal might be potentially a problem, it is also a great shield. In the CTC case, we separate the case from almost all the wiring and we space the circuit board on plastic spacers to keep it away from the case itself. The case is just a 'cavern' to isolate the wiring, switches, and boards, from the outside environment, from RFI, dust, and most air pollutants. If you open a CTC case after several years you will find it dust free, for example. Now the way that Charles Hansen does it, 'might' be a potential problem according to KBK, but I don't think so.

This is what is called a 'microscopic' view, looking at only one aspect of a design, rather than the whole.

A different perspective: Electric and magnetic fields are not a mystery. For a given voltage and current a predictable field is created and its strength diminishes exponentially as the distance from the source increases.

Conversely, a circuit’s susceptibility to these fields is determined by its geometry and the physical relationships controllable through the circuit layout.

The discussion here is centering on the circuit interaction with the chassis metal; an inspection of the field strengths internally generated related to the AC voltages and currents in a preamp such as the Blowtorch would be interesting input in determining the effect of chassis metal located an inch away from the circuitry.

The effect of a shield and the currents circulating on it, due to its proximity to the signal conductor, is of more concern; although by separating the signal and it’s shield (return) you create other issues.

Mike.

As for Charles' gear, I realized both before during and after that it might be viewed ans either a cogent or unrealized punting of Charles gear. I thought about that and posted anyway. Iffin' I was looking at Charles' gear directly..the simple change I might make is one where the wells of signal or PS wire passages were slightly enlarged and the wires encircled with foamed dielectric of some sort (Antistatic foam to be exact) to keep them away from the metal surfaces-and to damp from mechanically induced reflective self induction... To each their own, 'Vive La Difference', otherwise we'd be all marching up and down the square in green uniforms. Yes, it is one small point from a guy who has not produced a single piece of gear in the market, whereas Charles is on the other end of the spectrum.

An exact science it is...MikeBettinger said:A different perspective: Electric and magnetic fields are not a mystery. For a given voltage and current a predictable field is created and its strength diminishes exponentially as the distance from the source increases.

One point: external to a round conductor, the field expresses as 1/r. If the conductor is not round, that relationship changes. For distances sufficiently far from the largest conductor aspect, it will be 1/r, but closer it will not fall as fast.

I'd not worry about flat pc traces if they are not too wide..say 1/4 inch down, but for a chassis current, that spreads out quite a bit, and the 1/r rule is no longer consistent with the actual behaviour.

agreed.MikeBettinger said:Conversely, a circuit’s susceptibility to these fields is determined by its geometry and the physical relationships controllable through the circuit layout.

Absolutely. One would do well to use a 3-D coil pickup to determine the field relationships within a chassis. Very specifically, the control of any and all ground loop currents that are caused by the connection to external sources or sinks that have NEC power.MikeBettinger said:The discussion here is centering on the circuit interaction with the chassis metal; an inspection of the field strengths internally generated related to the AC voltages and currents in a preamp such as the Blowtorch would be interesting input in determining the effect of chassis metal located an inch away from the circuitry.

MikeBettinger said:The effect of a shield and the currents circulating on it, due to its proximity to the signal conductor, is of more concern; although by separating the signal and it’s shield (return) you create other issues.Mike.

Eddies within a nearby conductive material as a result of current in the primary wire will do two things...first, lower the system inductance by the attempt of exclusion of field, and second, cause some dissipation. For low level circuits, I'd neglect the second, but the first has implications.

Cheers, John

john curl said:What I am trying to point out in my previous input is that while metal might be potentially a problem, it is also a great shield. In the CTC case, we separate the case from almost all the wiring and we space the circuit board on plastic spacers to keep it away from the case itself. The case is just a 'cavern' to isolate the wiring, switches, and boards, from the outside environment, from RFI, dust, and most air pollutants. If you open a CTC case after several years you will find it dust free, for example. Now the way that Charles Hansen does it, 'might' be a potential problem according to KBK, but I don't think so.

This is what is called a 'microscopic' view, looking at only one aspect of a design, rather than the whole.

isn't there a point of diminishing returns though?

Curious...

If i replace the gainstage only of the blowtorch with an AD797,

how would it compare to the JC-2 considering all the other blowtorch benefits?

If i replace the gainstage only of the blowtorch with an AD797,

how would it compare to the JC-2 considering all the other blowtorch benefits?

Most definitely. But historically, there has been very little true analysis of the effects, just a broad brushstroke in an attempt to minimize the effects.myhrrhleine said:isn't there a point of diminishing returns though?

John

One pre-supposes that $25,000 pre-amps or $30,000 power amps are well down that curve. A Ford Pinto is no Ferrari, but the Pinto will still get you there.myhrrhleine said:

isn't there a point of diminishing returns though?

hermanv said:One pre-supposes that $25,000 pre-amps or $30,000 power amps are well down that curve. A Ford Pinto is no Ferrari, but the Pinto will still get you there.

i was referring to distance.

start with 2in spacing and try to get another 40db

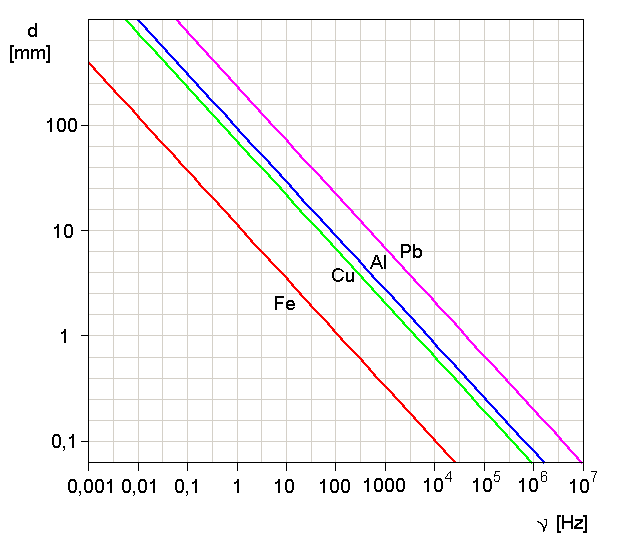

I would think that the first 1/4 inch would be the most important, but more spacing is better. When it comes to aluminum thickness, 1/4 inch is almost too little, IF you want any significant shielding at 60Hz from low impedance sources.

john curl said:I would think that the first 1/4 inch would be the most important, but more spacing is better. When it comes to aluminum thickness, 1/4 inch is almost too little, IF you want any significant shielding at 60Hz from low impedance sources.

I'm not an expert on shielding, but I suspect skin depth has something to do with different shielding properties of metals. Does anyone know how the skin depth of aluminum compares to that of copper? I've often wondered. I believe the skin depth of copper is about 1/3 inch at 60 Hz.

Cheers,

Bob

А shield with thickness of skin depth reduces magnetic field in e times.

Hope this helps, Nick.

jneutron said:An exact science it is...

Absolutely. One would do well to use a 3-D coil pickup to determine the field relationships within a chassis. Very specifically, the control of any and all ground loop currents that are caused by the connection to external sources or sinks that have NEC power.

Cheers, John

Hi John,

I use a simpler magnetic field probe that has been quite educational. I might suggest a slight variation. Take the NEC connections out of the picture and study the currents circulating on the grounds between components (say between an amp and a preamp), note what happens to them once they enter a chassis. The interconnects shields are the normal path inside (the NEC ground can confuse this) but, as I'm sure you know, once inside the chassis the currents tend to choose their own path.

Many years ago I took a class on grounding and shielding in which I witnessed a demonstration with a magnetic field probe that showed the return path of a signal completely ignoring a solid metal bar shunting the shield on a loop of coax and following the coax shield instead; definitely not the intuitive result. Another demonstration traced the return path of a signal trace over a ground plane which showed the return current concentrating under the signal trace.

Interesting food for thought.

Regards, Mike

National Electrical Code

I suspect not Nippon Electric Corporation, nor Necrophiliac Engorgement Considerations, or any other funny business.

I suspect not Nippon Electric Corporation, nor Necrophiliac Engorgement Considerations, or any other funny business.

Makola, thanks for putting up the graph. This should more easily show how difficult it is to get enough shield thickness from anything except steel, and unfortunately steel is nonlinear.

john curl said:Makola, thanks for putting up the graph. This should more easily show how difficult it is to get enough shield thickness from anything except steel, and unfortunately steel is nonlinear.

I wonder...

steel shielding, then aluminum to stop steel's effects?

I am literally in the middle of designing my own chassis materials from scratch. I have all the expertise required immediately at hand. As for disclosure, sadly, no. It's the same question as asking if someone would please take their most cutting edge innovation and post it for all to use, when 'food on the table' is the reason for it's creation. It's sad that if you want it done right--when you gots ta do it yerself! If I can get it right, ie, exactly the way I want it, I may make it available to others. But only as a finished material, and similar to blocks or sheeting.

Of course, the perfect (far closer than the currently used standard) heatsink already exists. We've even used them extensively. And we have noted that those particular audio devices that use them..have a certain undefinable sonic charm, all out of proportion to what we normally expect. I am of course, remembering as I write this..that I determined that it was the heatsink to use about 10 years ago..but I forgot..and had to discover it again. How many times you done that, John? It happens a lot over here....

Those dang audiophile (and videophile) designer guys. Secrets, secrets, always with the secrets. Then again, when the knowledge IS the propulsive force within the business model, what do you expect? 🙂

Of course, the perfect (far closer than the currently used standard) heatsink already exists. We've even used them extensively. And we have noted that those particular audio devices that use them..have a certain undefinable sonic charm, all out of proportion to what we normally expect. I am of course, remembering as I write this..that I determined that it was the heatsink to use about 10 years ago..but I forgot..and had to discover it again. How many times you done that, John? It happens a lot over here....

Those dang audiophile (and videophile) designer guys. Secrets, secrets, always with the secrets. Then again, when the knowledge IS the propulsive force within the business model, what do you expect? 🙂

I, once, had to evaluate a heatsink shaped as a 'chamber pot' or 'Greek vase' (you choose) as an amp heat sink. I WOULD look OK in a living room, I guess. It came out fairly OK.

What about multilayer GRAPHENE for an enclosure?

In my opinion, most high end audio amps appear designed for looking impressive rather than working efficiently.

What about multilayer GRAPHENE for an enclosure?

In my opinion, most high end audio amps appear designed for looking impressive rather than working efficiently.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- John Curl's Blowtorch preamplifier