In what way? (assuming here sane cable and not audiophool cable)

The are some small parameters of subjective cable sound that are hard to relate to what I would expect from static LRC effects alone.

Source is grounded in OEO.

Yes, usually best in practice.

BTW Wayne, if you are lurking, my friend very much likes the XP-25 and XP-30 stack he has just had delivered. I'm not sure I have seen a more overkill looking preamp stack before!

That's E101 stuff. Did you not take such cour... Never mind. 😴About high frequency in cables and skin effects, can someone indicates the differences between a single strand cable and a multi-strand?

T, I personally would say that there is not much difference between single strand and multi-strand cable of the same gauge, except for the larger surface area of the multi-strand to the outside world and subsequent oxidation, etc. BUT, if you insulate each strand to make up the same gauge, then you have some form of 'Litz' wire that has known high frequency characteristics that changes the cable performance. Yes, these effects have been heard.

Thanks, John. Of course, I was not referring to the Litz cable.BUT, if you insulate each strand to make up the same gauge, then you have some form of 'Litz' wire that has known high frequency characteristics that changes the cable performance.

Just I have the feeling (just a feeling, never done measurements on this question) that single wire 'sound' slightly less "grainy" and i would like to understand why. Reason why I use CAT6 cables for low signals since a long time now.

May-be I fool myself and it is purely psychological ;-)

I had never seen any study on this question.

Last edited:

Still, multi-strand wire has increase oxidation, etc. This could be the cause of your 'grainy' sound.

Its known that oxides make good contact diodes. Copper oxide diode are easy to demonstrate and i suggest it is a source of trouble in multi-strand copper wires in contact with each other.

[usually i would just make the statement. but, seems many here cannot accept info without a T&M associated with the statement. A PITA because a lot of info was done long ago and would require a duplication of effort to show/demo the T&M today. Fortunately, others have done similar tests]

THx-RNMarsh

[usually i would just make the statement. but, seems many here cannot accept info without a T&M associated with the statement. A PITA because a lot of info was done long ago and would require a duplication of effort to show/demo the T&M today. Fortunately, others have done similar tests]

THx-RNMarsh

Last edited:

There's a way to get around that, though mentioning it tends to generate a flamefest.Thanks, John. Of course, I was not referring to the Litz cable.

Just I have the feeling (just a feeling, never done measurements on this question) that single wire 'sound' slightly less "grainy" and i would like to understand why. Reason why I use CAT6 cables for low signals since a long time now.

May-be I fool myself and it is purely psychological ;-)

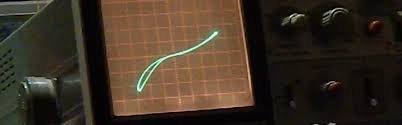

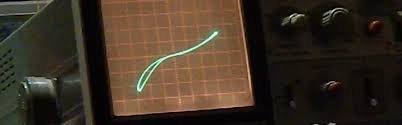

The trace seems to have hysteresis (that loop on the left), as from an iron-core coil. But it's definitely curved and non-linear. I'd like to see values for the horizontal and vertical scales of that scope trace.Its known that oxides make good contact diodes. Copper oxide diode are easy to demonstrate and i suggest it is a source of trouble in multi-strand copper wires in contact with each other.

View attachment 814889 View attachment 814890

THx-RNMarsh

I suppose I could look up the V-I characteristics of a copper oxide rectifier. As I recall they were specified in the original standard for a VU meter.

I have to call some things good or bad based on a belief you would most likely agree if you heard it. In other words, it is a statement about estimated probability.

Did it ever occur to you there is a high probability that those ******** hunting you around may not hear **** of what you are preaching, at your place or while on orbit around Jupiter?

Funny thing, I’m travelling on business in the SF Bay area for a few days almost every month and didn’t even thought about picking your invitation. There’s simply no reason I could think of why something would be easier to hear in a foreign place then in the comfort of my home, and God knows, I have enough audio SOTA stuff around, I could even borrow a Blowhard if it comes to that 😀

BTW, I tried once to take JC to a Chez Panisse lunch in Berkeley on Shattuck Ave. but he did not pick my invitation (was made through a common acquaintance, since I was not on the forum at the time). I guess I’m the guy your mothers warned you about

.

.I did indeed do my Google Research, found one of my favorite sites has an article on making copper oxide rectifiers, and it's got a scope trace that looks Remarkably Familiar!

Home Made Diodes From Copper Oxide | Hackaday

Home Made Diodes From Copper Oxide | Hackaday

I did indeed do my Google Research, found one of my favorite sites has an article on making copper oxide rectifiers, and it's got a scope trace that looks Remarkably Familiar!

Home Made Diodes From Copper Oxide | Hackaday

I built a working copper oxide rectifier using borax when I was 10 years old and a big fan of chemistry (had a lab and made a few spectacular messes with silver nitrate on my hands and hydrogen peroxide on the clothes).

I did indeed do my Google Research, found one of my favorite sites has an article on making copper oxide rectifiers, and it's got a scope trace that looks Remarkably Familiar!

Home Made Diodes From Copper Oxide | Hackaday

Lots of people have done it ... " oxidising copper to make a surface of cupric oxide onto which he can make a contact for a simple diode."

I propose this is what JC and T and many other audiophiles hear in multi-strand copper [which has oxidised.]

Insulated individual strands would work better.

Yes, there are always good scientific and measurable reasons for people's explanations for what they hear. But, not all are as easy to discover as oxide formation affects.

Same goes for unmasked copper PCB traces creating surface diode. Which would affect the higher freq at surface (skin effect) the most . A reason to gold plate and/or mask/seal coat/insulate it from oxidation affects.

THx-RNMarsh

Last edited:

A reason to gold plate

Nope. Unless one can afford hard gold plating (very hard to justify outside the space/military realm), otherwise the usual ENIG plating increases the PCB losses at very high frequencies, where the skin effect would, otherwise, m-aybe affected by the surface oxidation. I’ll let you find out why ENIG is bad at very high frequencies, you seem to be handy with copy/pasting without indicating the source.

All skin effects being by far non issues at audio frequencies. Oxide/corrosion could obviously affect the wire/cable contacts, but definitely not the propagation of the signals along the cable, be it solid or stranded.

BTW Wayne, if you are lurking, my friend very much likes the XP-25 and XP-30 stack he has just had delivered. I'm not sure I have seen a more overkill looking preamp stack before!

Yes it is a pretty big stack. Should provide some great sound.

Nope. Unless one can afford hard gold plating (very hard to justify outside the space/military realm), otherwise the usual ENIG plating increases the PCB losses at very high frequencies, where the skin effect would, otherwise, m-aybe affected by the surface oxidation. I’ll let you find out why ENIG is bad at very high frequencies, you seem to be handy with copy/pasting without indicating the source.

All skin effects being by far non issues at audio frequencies. Oxide/corrosion could obviously affect the wire/cable contacts, but definitely not the propagation of the signals along the cable, be it solid or stranded.

We are not talking VERY high freqs. The skin affect can be seen to come into play about 50-100KHz and above.

This is well within the amplifier BW and the DIODE effects due to oxidation can cause distortion... perhaps IM into audio depending on PA. However, we are talking about oxidation of copper surface and diode affects caused by the boundary between copper and oxide layer. This can occure at any freq but would be worse for HF.

Of course hard gold. That goes without stating. And, we do not consider cost when we are talking of audible sources and tests. Cost is a marketing issue. Many places can be masked... but then masks have their own undesired / measured affects. Not all masking material is the same.... some better than others for audio.

THx-RNMarsh

Last edited:

Nope. Unless one can afford hard gold plating (very hard to justify outside the space/military realm), otherwise the usual ENIG plating increases the PCB losses at very high frequencies, where the skin effect would, otherwise, m-aybe affected by the surface oxidation. I’ll let you find out why ENIG is bad at very high frequencies, you seem to be handy with copy/pasting without indicating the source.

All skin effects being by far non issues at audio frequencies. Oxide/corrosion could obviously affect the wire/cable contacts, but definitely not the propagation of the signals along the cable, be it solid or stranded.

Most cell phone PCBs are finished with OSP that I have seen, I assume this is because they are produced in the millions and not because it offers any kind of performance improvement over ENIG?

PCB Surface Finishes Comparison: HASL, OSP, & ENIG

For lowest distortion caused by masks... see Victor's ultra-low distortion osc in Equip forum.

One needs to take care on how Hard Gold is made. Better to dope it with arsenic to harden it rather than a ferrous metal layer or alloy.

Mogami makes soft gold connectors direct deposited on ultra pure copper. Or, they used to. Been awhile. That is the best IMO.

THx-RNMarsh

For lowest distortion caused by masks... see Victor's ultra-low distortion osc in Equip forum.

One needs to take care on how Hard Gold is made. Better to dope it with arsenic to harden it rather than a ferrous metal layer or alloy.

Mogami makes soft gold connectors direct deposited on ultra pure copper. Or, they used to. Been awhile. That is the best IMO.

THx-RNMarsh

Last edited:

Of course, without those it's useless, Richard regularly posts graphs etc without scales.I'd like to see values for the horizontal and vertical scales of that scope trace.

PCB Surface Finishes Comparison: HASL, OSP, & ENIG

For lowest distortion caused by masks... see Victor's ultra-low distortion osc in Equip forum.

One needs to take care on how Hard Gold is made. Better to dope it with arsenic to harden it rather than a ferrous metal layer or alloy.

Mogami makes soft gold connectors direct deposited on ultra pure copper. Or, they used to. Been awhile.

THx-RNMarsh

Well, yes I know the general trade-offs between those finishes in the link you gave. My question was specifically about RF loss. One step of OSP is micro-erosion of the copper to assist in deposition. Anyway, I would guess any effect is dominated by the PCB material.

LDI soldermask is a relatively new process used where better tolerances and registration are needed, but I don't know if the liquid performs any differently than the usual LPI mask.

Of course, without those it's useless, Richard regularly posts graphs etc without scales.

yes, i do.

And, it is not needed to show/illustrate the diode effect of copper surface oxidation exists on bare wires or pcb.

I think it is informative and not useless knowledge to know that a diode effect exists and to how prevent it.

You wonder why cable and wires can sound different? Well here is one other reason. Oxidation. And a test to prove it exists too.

-RNM

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part IV