various fillers to blend your own.

If you need to center something glass bead filler is recommended.

Glass microbeads are sold in controlled size ranges known as bondline fillers. If you need a precise gap dimension then you mix the beads with the epoxy. LCD displays are made with a small amount of glass microbeads to achieve the optimal thickness of fluid cavity.

Honestly, I was just thinking about sealing the gap so dust couldn't get to the vc gap. Even a simple caulking gun would suffice.

I do use west system and love it. Type 105 resin and both 205 (fast) and 206 (slow) hardeners. My friend the boatbuilder used the micro balloons for floatations, graphite filler for lubricated cast bearings, and microfibers for...who knows??

I make hardwood 3 and 5 ply 8 inch square blanks for my wooden gear clocks, west hasn't failed me yet.

Jn

I do use west system and love it. Type 105 resin and both 205 (fast) and 206 (slow) hardeners. My friend the boatbuilder used the micro balloons for floatations, graphite filler for lubricated cast bearings, and microfibers for...who knows??

I make hardwood 3 and 5 ply 8 inch square blanks for my wooden gear clocks, west hasn't failed me yet.

Jn

Honestly, I was just thinking

If a problem is worth thinking about it's worth overthinking about.

If a problem is worth thinking about it's worth overthinking about.

I'll have to think about that...

A lot.😉

What I was thinking about, is do I start a thread on Ls/Rs measurement, shorted ring, slit faceplate, measuring Le(x), BLI(x), Jn drive.... Or just leave it on this thread where it dies as a forgotten thought buried in the trash heap of digression and animosity?

Jn

Edit: been researching silicon steel in 2 to 5 mil thicknesses for building laminated front plates. 3 to 6 inch diameter plates aren't a problem for my 12 ton shop press, I was looking to make plates with 98% fill factor to go out to 50 kHz give or take.

Last edited:

If it gets a lot of attention you may find your workload multiplies or you spend more time responding to comments and less time actually working on it. It can take the fun out of it.

This would be my first stop for magnetic laminations: Welcome to Metglas - Home of the Metglas Brazing Foil "Back in the day" it was the best for tape heads. Used photomachining to make them.

It will be interesting to see what happens when the ring has permeability orders of magnitude higher than free air.

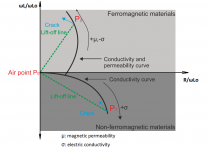

For coil impedance change, see attachment

Origin is coil on air.

Axis values are normalized for coil impedance on air.

This is for fixed test frequency.

What you will measure with a certain steel bar or ring will be totally different when the metal is magnetically saturated (as is the case on the loudspeaker assy) because with the magnetically saturated metal, the huge effect of mag. permeability is being suppressed or vanishes.

George

Attachments

JN, I did a bit of looking to get up to speed of what you are researching and came up with these - Push-pull versus shorting rings and JBL Magnet structures.

A bit more searching and sleuthing came up with these papers which may be of help - View attachment 780530 and View attachment 780531

It seems the first thing to implement is T section centre pole piece and then flux disc on top of polepiece and aluminium ring at the base of the centre pole piece.

Cheers, Dan.

Thanks for sharing those links.

I have the 703's discussed in the white paper and love them. I've got a pair of KEF LS50's that sit alongside them and I can quickly swap cables over to compare them.

The 703's sound is big, sonorous, meaty and very exciting on pop, rock and some jazz like George Benson, but the top end is a little too bright for my liking. The LS50's are far more accurate and produce amazing bass for their size - I do use a sub bass for the stuff below c. 80Hz where they drop off quickly though - expected of course because the cabinet size is only a fraction of the LS50's. The KEF's are my go to speakers for classical and acoustic music. That said, I've driven them so hard on rock music that the clipping indicator on my big amp was regularly going off - its set to 56V peak, or 200W into 8 Ohms. I would add, the LS50's don't sing in a big room. Put them in an average size UK living room (say 4m x 4m) and they really come into their own where perhaps the 703's are a bit overpowering.

The 703's are about 89dB efficient while the LS50's are rated at 85dB and its quite noticeable when you swap the cables over - you have to crank the volume up on the LS50's to get back to the same level and vice-a-versa.

I mentioned the bright top end on the 703's to Troels Gravenstein [sp?] and his response was they were deliberately engineered like that because a bright top end 'sells speakers' - he unfortunately had not done any tuning on the 703 (as he has done on some other commercial speakers for private clients) but suggested I try a c. 1 Ohm power resistor in series with the tweeter.

Last edited:

Or just leave it on this thread

Start it’s own thread.

been researching silicon steel in 2 to 5 mil thicknesses for building laminated front plates.

There is one possible scenario that favors a magnetic structure in proximity to the VC (center pole and front plate) that affect the impedance of the VC as much as uniformly across the freq range of operation.

Geometric variations (radial slits) introduced into the magnetic structure will cause complex VC impedance variation with frequency because the ECs in the slitted construction and the secondary magnetic field they produce varies a lot in amplitude (more so at LFs) as well as in phase (more so at HF) with excitation frequency. It is more complex than what happens in the core of an audio transformer, due to the VC movement (variance of EC edge effect)

It is hard to “visualize” the whole outcome with multiple slits, so better start with a single slit and compare electrically and acoustically against the non slitted construction.

George

I mentioned the bright top end on the 703's to Troels Gravenstein [sp?]

Troels Gravesen. A lot of excellent speaker work.

DIY-Loudspeakers

You're welcome.....B&W 703 Parts ManualThanks for sharing those links.

Yeah, all the B&W's that I've heard are overly lively/ovely bright for my ears.......coax speaker cable with terminating resistors could be worth a try. I've not heard such subjective descriptions from you before !.I have the 703's discussed in the white paper and love them. I've got a pair of KEF LS50's that sit alongside them and I can quickly swap cables over to compare them.

The 703's sound is big, sonorous, meaty and very exciting on pop, rock and some jazz like George Benson, but the top end is a little too bright for my liking.

That 4dB sensitivity difference changes things....a lot. I have always found LS3/5A for example to sound 'chocked' or overly damped or something.The LS50's are far more accurate and produce amazing bass for their size - I do use a sub bass for the stuff below c. 80Hz where they drop off quickly though - expected of course because the cabinet size is only a fraction of the LS50's. The KEF's are my go to speakers for classical and acoustic music. That said, I've driven them so hard on rock music that the clipping indicator on my big amp was regularly going off - its set to 56V peak, or 200W into 8 Ohms. I would add, the LS50's don't sing in a big room. Put them in an average size UK living room (say 4m x 4m) and they really come into their own where perhaps the 703's are a bit overpowering.

I mentioned the bright top end on the 703's to Troels Gravenstein [sp?] and his response was they were deliberately engineered like that because a bright top end 'sells speakers' - he unfortunately had not done any tuning on the 703 (as he has done on some other commercial speakers for private clients) but suggested I try a c. 1 Ohm power resistor in series with the tweeter.

Polypropylene caps for Mid, Polyester caps for tweeter ????

Dan.

You have to drive the LS50's Dan. I am currently using my 28 W class A kx-Amp but the listening space is small. Even so, a decent 100-200W amp is what's required IMV - and then I think they are outstanding - absolutely no glare and they image much better than the 703's. The B&W's will sing with 28W in a small space as well.

I am quite happy to describe stuff as 'warm' 'bright' 'harsh' 'airy' 'holographic' etc but I don't link subjective impressions to any specific topology, part or cables unless etc I can link them with measurements.

(I heard some 12 grand Magico's in December last year - very disappointing. The dealer apologized and said they weren't 'run in yet'. Ditto the new B&W 802's at the NWA show here in the UK in June - sounded very, very forward for me and not at all 'open' and relaxed which is what I like in a speaker. YMMV)

yes - fantastic site with lots of designs if you are good practically.

I am quite happy to describe stuff as 'warm' 'bright' 'harsh' 'airy' 'holographic' etc but I don't link subjective impressions to any specific topology, part or cables unless etc I can link them with measurements.

(I heard some 12 grand Magico's in December last year - very disappointing. The dealer apologized and said they weren't 'run in yet'. Ditto the new B&W 802's at the NWA show here in the UK in June - sounded very, very forward for me and not at all 'open' and relaxed which is what I like in a speaker. YMMV)

yes - fantastic site with lots of designs if you are good practically.

Where would be the best place? Parts, fullrange, lounge?Start it’s own thread.

George

Best in terms of what?

Parts will be the least frequented place. Lounge the most. Fullrange lies in the middle.

Parts and fullrange are relevant to the subject. Lounge not.

George

Parts will be the least frequented place. Lounge the most. Fullrange lies in the middle.

Parts and fullrange are relevant to the subject. Lounge not.

George

I have ordered two more visaton BG20-8 drivers.

One will be for reference.

The second one, I am going to very gently remove the cone from the driver, and I am going to place it face down on a bandsaw and cut through the basket, magnet, faceplate, backplate all the way to the OD of the gap. I was thinking about going to the center of the pole piece, but do not know if the back and pole piece are integral or press fit. Press fit would be compromised if I cut to center of pole piece.

I will do a facedown Ls/Rs scan prior to taking it apart, and again once put together and hopefully working. I will also compare Ls/Rs of the cut through basket, and then short across that cut to see if it makes a difference.

George,

That graph looks suspiciously like a flaw detection setup. I had to do some research on how to measure a deposited titanium thin film through a .25 inch thick alumina wall. None of the established methods would work, so I had to invent a different way.

jn

One will be for reference.

The second one, I am going to very gently remove the cone from the driver, and I am going to place it face down on a bandsaw and cut through the basket, magnet, faceplate, backplate all the way to the OD of the gap. I was thinking about going to the center of the pole piece, but do not know if the back and pole piece are integral or press fit. Press fit would be compromised if I cut to center of pole piece.

I will do a facedown Ls/Rs scan prior to taking it apart, and again once put together and hopefully working. I will also compare Ls/Rs of the cut through basket, and then short across that cut to see if it makes a difference.

George,

That graph looks suspiciously like a flaw detection setup. I had to do some research on how to measure a deposited titanium thin film through a .25 inch thick alumina wall. None of the established methods would work, so I had to invent a different way.

jn

Last edited:

George,

That graph looks suspiciously like a flaw detection setup

It is.

Impedance plane EC instruments display the real and imaginary parts of the connected search coil impedance. This is essentially the same with what we are doing when we extract the real and imaginary parts from an impedance frequency scan on the loudspeaker coil .

DR. Foerster had developed the EC test theory and did extensive experimentation with encircling coils after the end of WW2. He published in German 1959, then translated in English in "Nondestructive Testing Handbook", Vol.II (ed. R.C. McMaster) Ronald,

New York, 1959

Your test plan sounds good. 🙂

George

Attachments

I've seen a couple of make-a-driver threads, and Pnalars And Exotics is partly about making them, but what we're discussing here are are "traditional" electrodynamic drivers. I'm thinking (okay, hoping) it would be fruitful to have a "Designing and Making Traditional Drivers" forum.I suggest multi-way, fullrange is too niche

ETA: "Designing, Making, and Modifying Traditional Drivers"

Tape (such as gaffer's tape) may be enough to keep metal filings out of the gap going only that far, but I wonder what it would take if you cut into the gap.I have ordered two more visaton BG20-8 drivers.

One will be for reference.

The second one, I am going to very gently remove the cone from the driver, and I am going to place it face down on a bandsaw and cut through the basket, magnet, faceplate, backplate all the way to the OD of the gap.

I'm thinking loops of wire (so you can pull them out along with ...) and then something like cotton stuffed into the gap, so you can pull out the cotton by pulling the loops out. This still wouldn't work 100 percent.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III