Yeah, I can't argue with the joys of one's craft, however it is manifested. We do this stuff to improve our quality of life, right?

Justifies a 5.5 or 6.5 digit meter, so got to be good 🙂

I am going a bit extreme at the moment and matching 0.1% parts cos, well I can...

I am going a bit extreme at the moment and matching 0.1% parts cos, well I can...

Considering the mix of R's and C's and that a couple of the caps were 3% tolerance I figured this means the manufacturing processes are better than the specs these days.

Film caps anyway... electrolytics are still usually off a good bit. Comically though is they tend to be off by similar amounts which makes you wonder why they don't just give them a new value.

According to the same statistics, the more resistors you have series/parallel, the lower is MTBF. If one of resistors fail, you are out of tolerance.

Interesting. Our own Conrad Hoffman discusses it here: How to Build a Hamon Resistor Divider Network

Here's another good reference. http://www.introni.it/pdf/Fluke - Calibration Philosophy in practice.pdf

That's unsurprising 0.1dB being 1%, no?

Jan

Ah no. 10exp(.1/10) =1.02329 and +/- .1 dB = 4.7%

Having fun watching this.

Voltage coefficient would expected to be linear or second order distortion. It should not vary with applied signal voltage.

Thermal would be non-linear and expected to generate third order products. It would grow faster than the increase in signal voltage.

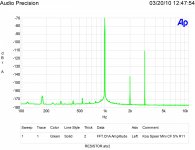

Attached is a shot of a poor quality resistor tested at 1/4 power. The third order distortion should increase by 12 dB if used at full power. Used with some modern op-amps (Oh the horror of that!) the feedback resistor would be the limit on lowering distortion.

As to electrolytic capacitors, their value decreases in storage or non-use. So at manufacture time they tend to be high in value to allow for transit.

Attachments

Last time I bought 1-3% caps with 1% resistors for an RIAA the result was +-.1dB out of the box no sorting.

Yes - the spreads nowadays are fantastically tight IMV.

Mark, I agree with your point worst case is worst case - but you have to be pretty unlucky to end up skewed like that I have to say.

Separately, when I was involved in semi's for the auto industry, If I had shipped Bosch a batch of components that were all off any key parameter by 1% (or towards whatever the spec limit was for the parameter), it would have been rejected. Most professional customers now - and especially so in high volume critical applications like auto - expect very good centering on all parameters. If anything is skewed . . . there must be a reason and its probably process related and that is not acceptable.

"Self also discusses parallel/series of passive storytelling improve accuracy" (Bonsai)

I have absolutely no idea where the 'storytelling' came from. The joys of an iPad and no reading glasses.

I have absolutely no idea where the 'storytelling' came from. The joys of an iPad and no reading glasses.

"Self also discusses parallel/series of passive storytelling improve accuracy" (Bonsai)

I have absolutely no idea where the 'storytelling' came from. The joys of an iPad and no reading glasses.

I was wondering about that, and figured it was an autocomplete error.

I checked the R code; the Tangentsoft people assume a Gaussian pdf which is definitely not the worst case; and, perhaps, not necessarily a good match to actual production statistics of actual resistors.

I would expect something more like a truncated Gaussian or, the average of a triangle PDF and a uniform PDF. Remember that a resistor which measures 608.00 ohms, can be sold as either a 604 ohm, 1% resistor OR a 612 ohm, 1% resistor. (Both are E96 standard values)

I would expect something more like a truncated Gaussian or, the average of a triangle PDF and a uniform PDF. Remember that a resistor which measures 608.00 ohms, can be sold as either a 604 ohm, 1% resistor OR a 612 ohm, 1% resistor. (Both are E96 standard values)

My experience is that to get good matches you have to handle the parts with plastic tweezers. Actually touching them introduces too much temperature variation. Also 1 dB is not a 1% variation! I get 10exp.1 (dB/10) is more like 25%.

handling will obviously affect the results...... I am not sure I would try to match to 0.1% or better if the R's environment is not temp stable itself and if the R's are not located in tight close to one another.

And, you surely don't want temp gradients across the R's..... so orientation matters as well.

-RM

And, you surely don't want temp gradients across the R's..... so orientation matters as well.

-RM

Last edited:

I checked the R code; the Tangentsoft people assume a Gaussian pdf which is definitely not the worst case; and, perhaps, not necessarily a good match to actual production statistics of actual resistors.

I would expect something more like a truncated Gaussian or, the average of a triangle PDF and a uniform PDF. Remember that a resistor which measures 608.00 ohms, can be sold as either a 604 ohm, 1% resistor OR a 612 ohm, 1% resistor. (Both are E96 standard values)

It depends on technology. If machinery is precision and outcome is good and keeps tolerances, it can be Gaussian, but when automatically selected, there can be almost zero within 1% when 5% specified. When select pairs I never aim for certain value, I just select better match.

EEVblog #1017 - Enter The World Of Atto Amps - YouTube

Interesting and entertaining instrument teardown video. Imagine what would happen to that fA range if you sprayed wd40 on the board.

(As an experiment I have sprayed some of my P2P wired electronics. The rubbers and plastics are ok, but overall it is not a good idea. Good thing I will be moving soon. I am in a coastal area and the environment is quite harsh, this prompted the experiment.)

Do you ultrasonic bathe your boards? With distilled water or chemicals?

Interesting and entertaining instrument teardown video. Imagine what would happen to that fA range if you sprayed wd40 on the board.

(As an experiment I have sprayed some of my P2P wired electronics. The rubbers and plastics are ok, but overall it is not a good idea. Good thing I will be moving soon. I am in a coastal area and the environment is quite harsh, this prompted the experiment.)

Do you ultrasonic bathe your boards? With distilled water or chemicals?

Anatoly, interesting question you raise. When will bugs acquire the ability to digest commonly used plastics? It took 'm the whole Carboniferous Period to learn how to chew down wood, and ever since we have to paint our houses.

Anatoly, interesting question you raise. When will bugs acquire the ability to digest commonly used plastics? It took 'm the whole Carboniferous Period to learn how to chew down wood, and ever since we have to paint our houses.

There are folks working on breeding microbes to do that. Too bad they haven't seen enough of the end of the world movies to know they will get out of control!

Probably OK at first when they start on spandex....

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II