Question for the engineers. But first a little history. I have a pair of KEF 105 series 2 with the isolastically mounted drivers. The drivers are in front of the cabs on rubber mounts with a soft closed cell foam gasket uncompressed but in contact with both driver and cab. This system made it more economical in cab production due to drastically reduced vibration transfer as well as yielding a better FR. However the series 1 is known to be the better performer but they also came with better drivers so it's hard to say if the isolastic system is a general sq engineering improvement. Because of the nature of dynamic driver function, it seems to me that if the rubber mounts are tuned, which I'm sure the KEFs are, any driver would see an increase in transient performance since the motor is now moving opposite the cone, thereby responding more quickly, no? I'm about to start a JBL build and curious. TIA

Last edited:

KEF used the compliant mounts on the series 1 as well. They also used them on the rest of the Reference series. Linkwitz measured reduced cabinet resonance using compliant mounts as far back as the early '70s. It can't hurt.

You are mistaken. The series 1 has rigidly mounted drivers. The main cabs also weigh almost twice as much. Three isolastic mounts on the Series 2 bass driver but multiple fasteners all around the series 1.

The tuning would consist of making the isolating spring as soft as possible so that the resonant frequency was well below the passband of the driver. The lower the better the isolation. The upside is that the vibration of the driver is only weakly transmitted to cabinet driver via the soft spring. The downside is that the driver can now move about on its own in reaction to the cone motion. As the cone moves forward the driver will move backwards and the air will be slightly under compressed. The heavier the driver relative to the mass of the cone plus air the less the effect. There needs to be enough travel in the soft spring to avoid the driver knocking on the cabinet. The system becomes less robust and the drivers may need screwing down before moving to avoid damage.Because of the nature of dynamic driver function, it seems to me that if the rubber mounts are tuned, which I'm sure the KEFs are, any driver would see an increase in transient performance since the motor is now moving opposite the cone, thereby responding more quickly, no?

Isolating the drivers is an obvious, cheap and easy thing to do but is rarely done in commercial speakers. One or two on the forum have expressed strong enthusiasm for it but it is clearly not an unqualified win.

The tuning would consist of making the isolating spring as soft as possible so that the resonant frequency was well below the passband of the driver. The lower the better the isolation. The upside is that the vibration of the driver is only weakly transmitted to cabinet driver via the soft spring. The downside is that the driver can now move about on its own in reaction to the cone motion. As the cone moves forward the driver will move backwards and the air will be slightly under compressed. The heavier the driver relative to the mass of the cone plus air the less the effect. There needs to be enough travel in the soft spring to avoid the driver knocking on the cabinet. The system becomes less robust and the drivers may need screwing down before moving to avoid damage.

Isolating the drivers is an obvious, cheap and easy thing to do but is rarely done in commercial speakers. One or two on the forum have expressed strong enthusiasm for it but it is clearly not an unqualified win.

Hi Andy. What I understand then is that the driver is not only less efficient but less dynamic? In regards to tuning, do you mean well below fs? In the Kef, it's the soft foam gasket that keeps the driver from hitting the cab as well as sealing the gap which is about 1/16". There are large rubber mounts at the bass driver's 3 fastening points, hence the odd triangular shape of the frame. I went through all the paraphernalia I've collected over the years and found the Kef brochure showcasing the Series 2. Kef does in fact claim transient performance is improved with this system.

The effect is a small distortion in the sense that the output does not follow the signal. It will be a few tens of dB below the input signal. It is nowhere near large enough to influence the efficiency of the driver.Hi Andy. What I understand then is that the driver is not only less efficient but less dynamic?

I mean the passband of the driver. A mass on a soft spring is going to resonate strongly and the frequency of this needs to be a long way below the lowest frequency the driver produces or else it will make matters worse not better. For example, to effectively passively isolate a woofer the resonant frequency needs be down at a few Hz or so. If you prod the metalwork of your woofers what frequency do they bounce at? The midrange and tweeter tend to be better candidates for passive isolation.In regards to tuning, do you mean well below fs?

Yes but it depends what is being improved upon. The B110 driver has a stamped frame which is not particularly stiff and so bolting it to something rigid will support the magnet with a medium stiffness undamped spring which could give a poor transient response. If the basket of the midrange was stiff and it was rigidly bolted to the middle of a thin front baffle that could then provide a medium stiffness spring with little damping on which to vibrate the driver and give a poor transient response. If...Kef does in fact claim transient performance is improved with this system.

In the past someone has provided a link to a study by someone in KEF (I think) showing positive results for isolating a B110 (I think) but I cannot find the link. Anyone?

The effect is a small distortion in the sense that the output does not follow the signal. It will be a few tens of dB below the input signal. It is nowhere near large enough to influence the efficiency of the driver.

I mean the passband of the driver. A mass on a soft spring is going to resonate strongly and the frequency of this needs to be a long way below the lowest frequency the driver produces or else it will make matters worse not better. For example, to effectively passively isolate a woofer the resonant frequency needs be down at a few Hz or so. If you prod the metalwork of your woofers what frequency do they bounce at? The midrange and tweeter tend to be better candidates for passive isolation.

Yes but it depends what is being improved upon. The B110 driver has a stamped frame which is not particularly stiff and so bolting it to something rigid will support the magnet with a medium stiffness undamped spring which could give a poor transient response. If the basket of the midrange was stiff and it was rigidly bolted to the middle of a thin front baffle that could then provide a medium stiffness spring with little damping on which to vibrate the driver and give a poor transient response. If...

In the past someone has provided a link to a study by someone in KEF (I think) showing positive results for isolating a B110 (I think) but I cannot find the link. Anyone?

The mid-range driver of the Series2 is also isolated but with rubber grommets on the 4 corner holes of the basket. The soft foam gasket is also incorporated. The tweeter/plate is simply held against a foam mat at the 4 corners and therefore is also floating.

Last edited:

To answer my own question, Twinter in another thread has provided this link to work by Andrew Jones (ex KEF) at Pioneer with a stamped steel 5" midwoofer that is not a B110. So much for my recollection.In the past someone has provided a link to a study by someone in KEF (I think) showing positive results for isolating a B110 (I think) but I cannot find the link. Anyone?

Figure 4 is probably the key figure which shows that bolting the driver to the cabinet works better than a grommet in holding the magnet still below the large undamped resonance at 300 Hz. Above this resonance there isn't much difference because that medium stiffness spring is now starting to passively isolate the magnet in the same way as the grommet.

The medium stiffness spring is very likely the stamped steel frame or the front baffle. If this was a woofer the solution would be to stiffen the frame of the driver and/or the front baffle to push that resonance above the passband. Which aligns with what is usually done in the industry. There really doesn't seem to be a case for rubber grommets on woofers and I would still like to know the frequency of the bounce of your woofers if you prod the frame.

What to do for a midrange is less clear. Can the lowest resonance be pushed above the passband? If not, a soft grommet can push the resonance well below the passband but the magnet will be held less still than a stiff structure that is not resonating. I doubt it would be practical to introduce enough damping to pull that resonance down to only a dB or two above the grommet level.

The horrible transient response shown is for the magnet bouncing on that medium stiffness spring and not the output of the driver. The frequency responses of the driver are shown in Figure 1 and can be seen to be essentially the same. The transient response is not improved by the grommets.

If the driver is rigidly bolted to the cabinet then the cabinet will need to deal with stronger forces at and below that resonance. This is a win for the grommets which may or may not be of importance depending on how the cabinet performs.

Isolating the drivers is an obvious, easy and cheap thing to do but is only going to be an improvement in particular circumstances.

Isolating the drivers is an obvious, easy and cheap thing to do but is only going to be an improvement in particular circumstances.

I wouldn't really look at it that way. The resonances shown are always cabinet resonances. Resonant motion of the magnet is evidence that energy is fed from the chassis to the cabinet and the cabinet resonances make it the uneven function.

In no case are we seeing an impact in woofer output, as cone acceleration is always a smooth function. We also don't care about the magnet motion, as it is not effectively radiating sound (sealed inside a stuffed box). The real issue is that the cabinet walls are at resonance and they are very effective radiators. The 300 and 500 Hz resonances are purely cabinet effects (slightly shifted by driver mass).

The compliant mounts create a second order LC filter (magnet structure mass and grommet compliance) which rolls off the magnet acceleration transference to the cabinet.

This is still an issue of cabinet resonance. If we can't shift it out of band or damp it effectively, then can we reduce the excitation drive level by decoupling?

David

Disocpete, there had been several relatively recent threads on this forum related to driver de-coupling and panel vibrations that have many informative posts, references, and links. Dave and Andy provided many of these posts. While the whole thread of the first link is a worthwhile read, Post #271 in particular has several references directed at de-coupling.

http://www.diyaudio.com/forums/multi-way/235908-how-brace-speaker-cabinet-28.html

http://www.diyaudio.com/forums/multi-way/265240-woofer-choice-maple-mdf.html

http://www.diyaudio.com/forums/multi-way/230419-cabinet-structure-mdf-vs-hdf.html

http://www.diyaudio.com/forums/multi-way/235908-how-brace-speaker-cabinet-28.html

http://www.diyaudio.com/forums/multi-way/265240-woofer-choice-maple-mdf.html

http://www.diyaudio.com/forums/multi-way/230419-cabinet-structure-mdf-vs-hdf.html

To answer my own question, Twinter in another thread has provided this link to work by Andrew Jones (ex KEF) at Pioneer with a stamped steel 5" midwoofer that is not a B110. So much for my recollection.

Figure 4 is probably the key figure which shows that bolting the driver to the cabinet works better than a grommet in holding the magnet still below the large undamped resonance at 300 Hz. Above this resonance there isn't much difference because that medium stiffness spring is now starting to passively isolate the magnet in the same way as the grommet.

The medium stiffness spring is very likely the stamped steel frame or the front baffle. If this was a woofer the solution would be to stiffen the frame of the driver and/or the front baffle to push that resonance above the passband. Which aligns with what is usually done in the industry. There really doesn't seem to be a case for rubber grommets on woofers and I would still like to know the frequency of the bounce of your woofers if you prod the frame.

What to do for a midrange is less clear. Can the lowest resonance be pushed above the passband? If not, a soft grommet can push the resonance well below the passband but the magnet will be held less still than a stiff structure that is not resonating. I doubt it would be practical to introduce enough damping to pull that resonance down to only a dB or two above the grommet level.

The horrible transient response shown is for the magnet bouncing on that medium stiffness spring and not the output of the driver. The frequency responses of the driver are shown in Figure 1 and can be seen to be essentially the same. The transient response is not improved by the grommets.

If the driver is rigidly bolted to the cabinet then the cabinet will need to deal with stronger forces at and below that resonance. This is a win for the grommets which may or may not be of importance depending on how the cabinet performs.

Isolating the drivers is an obvious, easy and cheap thing to do but is only going to be an improvement in particular circumstances.

Resonance of the woofer frame appears to be virtually zero, cancelled by the sealing foam gasket. Remember, the frame is suspended approx. 1/16" in front of the baffle. The gasket is only slightly compressed whose purpose is to maintain a sealed cab; and now I presume to also damp the resonance of the entire assembly.

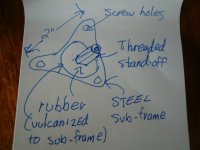

This apparatus is installed on the back-side of the woofer opening via three screws, corresponding to the fastening points of the frame. The stand-ff then protrudes through a 1/2" hole, extending past the surface about 1/16", to which the driver is then mounted. The gasket runs the circumference of the frame glued in a groove and sits against the baffle, in front of the three suspensions.

Attachments

Disocpete, there had been several relatively recent threads on this forum related to driver de-coupling and panel vibrations that have many informative posts, references, and links. Dave and Andy provided many of these posts. While the whole thread of the first link is a worthwhile read, Post #271 in particular has several references directed at de-coupling.

http://www.diyaudio.com/forums/multi-way/235908-how-brace-speaker-cabinet-28.html

http://www.diyaudio.com/forums/multi-way/265240-woofer-choice-maple-mdf.html

http://www.diyaudio.com/forums/multi-way/230419-cabinet-structure-mdf-vs-hdf.html

Excellent. Lots of good info. Thanks.

Hm. Why are we worried about the movement of the driver's magnet? I thought isolating the driver from the cabinet was to reduce the amount of cabinet motion, and that indeed it helped with that...

Damping is harmful not helpful for passive isolation. If the resonant frequency is well below the passband it will not get driven and so damping will not be needed. If significant damping is present then at the frequencies in the driver's passband the stiffness forces from the soft spring will be small as intended but the damping forces will be significant transmitting the motion of the driver to the cabinet and defeating the purpose of passive isolation.Resonance of the woofer frame appears to be virtually zero, cancelled by the sealing foam gasket. Remember, the frame is suspended approx. 1/16" in front of the baffle. The gasket is only slightly compressed whose purpose is to maintain a sealed cab; and now I presume to also damp the resonance of the entire assembly.

I was interested in the resonant frequency to see if the isolation of the woofer had been well implemented.

Last edited:

If the driver and perhaps some part of the baffle around it moves,

is that a passive radiator alignment? And since the gap is now

moving in tune with the cone, does that extend xmax as well?

is that a passive radiator alignment? And since the gap is now

moving in tune with the cone, does that extend xmax as well?

Some of use take it to account because it changes the sound radiated by around the same amount as the cabinet radiation, that is, a few tens of dB below the wanted signal. Driving the cabinet less is the upside but the driver's magnet is now potentially moving around more and adding its motion to the radiated sound. Which is better is going to depend on the driver and cabinet construction.Hm. Why are we worried about the movement of the driver's magnet? I thought isolating the driver from the cabinet was to reduce the amount of cabinet motion, and that indeed it helped with that...

Damping is harmful not helpful for passive isolation. If the resonant frequency is well below the passband it will not get driven and so damping will not be needed. If significant damping is present then at the frequencies in the driver's passband the stiffness forces from the soft spring will be small as intended but the damping forces will be significant transmitting the motion of the driver to the cabinet and defeating the purpose of passive isolation.

I was interested in the resonant frequency to see if the isolation of the woofer had been well implemented.

I would assume then that the resonant frequency is indeed lower. There is no detectable resonance when prodding the frame. It is dead.

If by dead you mean it is damped and doesn't bounce at a low frequency then that is not good in terms of isolation performance. If the resonant frequency is near the bottom of the driver's passband it would get driven to some extent and the driver would knock on the cabinet. Adding damping could do something to address this but at the cost of decreased isolation.I would assume then that the resonant frequency is indeed lower. There is no detectable resonance when prodding the frame. It is dead.

There is probably a story there. Perhaps it is a case of an engineer having to get something to work that he knows isn't sensible but the instructions have come from above or from sales.

If by dead you mean it is damped and doesn't bounce at a low frequency then that is not good in terms of isolation performance. If the resonant frequency is near the bottom of the driver's passband it would get driven to some extent and the driver would knock on the cabinet. Adding damping could do something to address this but at the cost of decreased isolation.

There is probably a story there. Perhaps it is a case of an engineer having to get something to work that he knows isn't sensible but the instructions have come from above or from sales.

How then is isolation even possible in a closed cabinet design? Some level of damping is inevitable since there has to be some sort of permanent contact at the driver/cab interface. This would be the case in a bass reflex design as well. Mind you that because I'm unable to detect resonance doesn't mean there isn't any. Those rubber mounts are fairly stiff so I don't think the driver would hit the cab if the gasket were removed. It just barely makes contact with the cab. However there appears to be a compromise, albeit a necessary one, no? Interestingly enough, B&W or others have not attempted isolation of the woofer but opted for shifting cab resonance in the LF. Implementing it higher up in the mid/high regions seems to be where it's feasible. But intuitively, bass reflex seems to be where this sort of compromise is more practical because the gasket barely making contact is merely a virtual seal, intermittent at best. A workable interface with a vent.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Isolastic speaker design