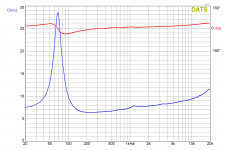

This is a new driver. SB17MFC35-8. The driver is mounted in a box that currently has no rear baffle. There is polyester stuffing in the box, but it simply radiates to the rear for now. I am using DATS v3.

There is a lot of non-smooth behavior 70 Hz and 150 Hz, and then a bump at 220 Hz. The blip at 1.2 kHz is not surprising, I would expect a polymer cone to have some breakup starting around 1k or so... but what is with the hash down low?

The SB17CAC35-4 drivers I worked with back in February did not exhibit this behavior.

There is a lot of non-smooth behavior 70 Hz and 150 Hz, and then a bump at 220 Hz. The blip at 1.2 kHz is not surprising, I would expect a polymer cone to have some breakup starting around 1k or so... but what is with the hash down low?

The SB17CAC35-4 drivers I worked with back in February did not exhibit this behavior.

Attachments

If you have a pair of drivers, do they both have this?

Is it possible to check in a different mounting (free air, different box, etc.)?

Are the fasteners tight?

Is it possible to close the rear of the box?

What happens if the stuffing is removed?

Is it possible to check in a different mounting (free air, different box, etc.)?

Are the fasteners tight?

Is it possible to close the rear of the box?

What happens if the stuffing is removed?

Dave mentioned some good ideas to check. I've found that proper stability is essential in measuring impedance, so if the driver isn't really fastened all strange artifacts appear. So for a quick reality check do the following, even if it isn't the proper way to measure impedance: press the driver (firing upwards) firmly down with the hand while measuring, if you have a hard floor maybe put a piece of tissue or something else in order not to damage the magnet/rear of the driver.

Ralf

Ralf

I think the easiest way to check the setup, is to measure the impedance of the driver alone in the free air without any kind of enclosure.

For a smooth curve, the driver should be away from large objects like the floor or a table.

George

For a smooth curve, the driver should be away from large objects like the floor or a table.

George

I installed the rear baffle, and "Voila !" ... problem gone. Of course now the impedance peak corresponds to Fc of the system rather than Fs of the driver.

It must have been room reflections. I would never have guessed that room reflections from 4 ft to 10 ft away would affect an impedance curve.

Thanks to everyone for your thoughts. It really helped me narrow down the problem.

It must have been room reflections. I would never have guessed that room reflections from 4 ft to 10 ft away would affect an impedance curve.

Thanks to everyone for your thoughts. It really helped me narrow down the problem.

Attachments

When the rear panel was installed, it may have added stiffness to the enclosure structure. It may have been acoustic energy translated into panel vibrations.

Is it possible to measure outdoors, or in another room? That could help determine if the impedance fluctuations are more acoustic-related than structure-related.

Is it possible to measure outdoors, or in another room? That could help determine if the impedance fluctuations are more acoustic-related than structure-related.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Is this impedance curve strange?