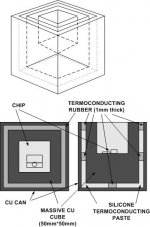

I also see a devolopment in this thread. While in the beginning I was considering to place the whole chip in some sort of fluid, I already know that I won't pursue it and I will use a copper plate attached to it for improved efficiency. I want to place that plate inside another copper pipe and use some sort of medium to transfer the heat. I would prefer not to use liquid as it's very problematic and not practical. One option was to use silicone, bu tit seems that is not that good for that purpose. Please also remember that GC chip doesn't generate that much heat.

I was thinking about filling the cylinder with sand. The plate would probably be around 3/4" x 5" . The cylinder 1 1/4" in dia and 6" long.. So how good is sand with heat? I believe that if I keep the plate at 40 deg C it is still fine.

I was thinking about filling the cylinder with sand. The plate would probably be around 3/4" x 5" . The cylinder 1 1/4" in dia and 6" long.. So how good is sand with heat? I believe that if I keep the plate at 40 deg C it is still fine.

millwood said:

a fair comparison is to

1) hit the bucket filled with water while your head is in it.

2) hit the bucket filled with air while your head is in it.

which one would you rather it be?

Water?😉

pardon, did someone say something ?

you probably wouldn't have to worry to much about hi-fi for a while - if ever !!!

Peter Daniel said:

Water?😉

you probably wouldn't have to worry to much about hi-fi for a while - if ever !!!

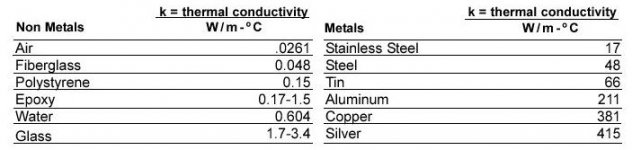

sand is not a very good heat conductor since there is a lot of air in the void.

void = density of bulk/density of a single grain

assuming the sand has a density of roughly granite, 2500 kg/m3

and a bulk density of 1250 gives a void of 0,5 , half the volume is air.

Unfortunately, the sand is not a good heat conductor because the air trapped is a very bad heat conductor, and you cant expect the sand grains to have much contact wich each other , which would be bypassing the less conducting air. In such small spaces as between the grains only heat conduction comes in play, there is virtually no convection in the air.

It all depends on the shape and size of the sand grains of course. Generally, the finer the better, preferably 10 um or less.

(which is very fine powder)

/rickard

void = density of bulk/density of a single grain

assuming the sand has a density of roughly granite, 2500 kg/m3

and a bulk density of 1250 gives a void of 0,5 , half the volume is air.

Unfortunately, the sand is not a good heat conductor because the air trapped is a very bad heat conductor, and you cant expect the sand grains to have much contact wich each other , which would be bypassing the less conducting air. In such small spaces as between the grains only heat conduction comes in play, there is virtually no convection in the air.

It all depends on the shape and size of the sand grains of course. Generally, the finer the better, preferably 10 um or less.

(which is very fine powder)

/rickard

Originally posted by Peter Daniel

I guess I want both. The external vibrations (mostly from sound waves) are picked up by the chassis, both from the air and from supporting platform.

Then what you want is isolation. Not damping.

Damping doesn't isolate. Damping simply describes resonant behavior. And if your isolation is successful, resonance, and therefore damping becomes a non-issue. At least with respect to the device you're isolating. In terms of isolation, if you're using a resonant system for isolation, then you actually want very little damping.

se

SY will correct me since my freshmen chem is rusty

Nah, I won't. The critical thing is not the number of molecules but the density.

I had some thoughts on this, but I think Steve got there first- the problem needs to be defined better. Airborne versus structure-borne vibrations are very different issues that have to be dealt with (assuming, arguendo, any real importance, which I still doubt in theis case...) in very different ways. It's not just propagation through the medium, it's also coupling between the vibration source and the medium- isolation.

Thermal effects seem to be a richer potential payoff here, but it's Peter's project, not mine.

SY said:

Nah, I won't. The critical thing is not the number of molecules but the density.

Thanks

I had some thoughts on this, but I think Steve got there first- the problem needs to be defined better. Airborne versus structure-borne vibrations are very different issues that have to be dealt with (assuming, arguendo, any real importance, which I still doubt in theis case...) in very different ways. It's not just propagation through the medium, it's also coupling between the vibration source and the medium- isolation.

Actually it's pretty simple when the terms are defined.

In my 11 setting on my anal scale I would put the amp on an air table to get rid of the subsonic/low end audio freq. vibrations.

I believe that high frequencies are already taken care by the heavy construction of Peter's enclusure.

What works for sensitive measurements in optical laser spectroscopy better be good for Peter's gainclone.

Thermal effects seem to be a richer potential payoff here, but it's Peter's project, not mine.

I know that it's Peter's project but you definitely went overboard in making this statement cryptic. 😉

grataku said:Actually it's pretty simple when the terms are defined.

In my 11 setting on my anal scale I would put the amp on an air table to get rid of the subsonic/low end audio freq. vibrations.

Or just put the chip on a heatsink and mount the heatsink to the chassis with some simple coil springs with enough compliance to get the natural frequency as low as possible.

I believe that high frequencies are already taken care by the heavy construction of Peter's enclusure.

Actually the heavy construction increases its resonant frequency. But then as you get higher in frequency, there's much less energy to deal with in the first place.

se

Sometimes , change just for change sake is not always the best.

My current case project is either going to made out of lexan or MDF as both have an excellent damping factor.The case will be 8" wide X 5" depth X 3 " height.(a cigar for those who can see why those dimensions!!)The inside of the case will be groved with a router so there will be tiny pyramids of material , then the inside will be covered in a coat of truck bed liner for internal wave damping.

As i have always used batt power and isolated the chip/heatsink using a silicone bed for the H/S i will keep the same design principal for isolation and P/S.

ron

My current case project is either going to made out of lexan or MDF as both have an excellent damping factor.The case will be 8" wide X 5" depth X 3 " height.(a cigar for those who can see why those dimensions!!)The inside of the case will be groved with a router so there will be tiny pyramids of material , then the inside will be covered in a coat of truck bed liner for internal wave damping.

As i have always used batt power and isolated the chip/heatsink using a silicone bed for the H/S i will keep the same design principal for isolation and P/S.

ron

Lexan is used in ultrasonic testing as a refraction layer and also as a medium to help adsorbe some of the fresnel zone, yes it has slightly less damping than acrylic but i have worked with both and as far as machining , tapping holes ect ect, i am going to go with lexan but will try the MDF first as its cheap and easy to work with.

ron

ron

I know that it's Peter's project but you definitely went overboard in making this statement cryptic.

Mrs. Y says that I do that a lot to make people think I'm smarter than I actually am.

The intention of the nylon monofiliment part of my previous post was to create an isolating spring. of course you would need a few inches in any given direction to insure adquate stretching. The idea is to create a trampoline type suspenstion inside the outer box. A few years ago, someone was claiming that this had a very positive effect on the sound, and I think there is good reason to think it would work well. All you need to do is thread the monofiliment through holes in each corner of the suspended module, and through small screw eyes inside each corner of the outer box. The idea is to use a continuous length so it can be easily tightened. The guitar tuning peg is my idea to make it easy to tighten AND to be able to adjust the resonant frequency. Different diameters of mono would affect this too.

You can have fun tweaking the tension to get the best sound- I can see the fights online: " No you idiot, you MUST tune the preamp to F sharp, and the amp to D flat"

You can have fun tweaking the tension to get the best sound- I can see the fights online: " No you idiot, you MUST tune the preamp to F sharp, and the amp to D flat"

peter

I don't want to pour cold water on your current favourite idea but having thought about a bit it, my best suggestion would be to put the amp in a heavy hermetically sealed box and suspend this with rubber bands inside another heavy hermetically sealed box.

having said that personally I think I would put the amps just behind the speaker in which case one box on the rubber bands would probably suffice.

I'm fascinated, does 1ft of good quality cable hardwired both ends make an audible difference ?

mike

I don't want to pour cold water on your current favourite idea but having thought about a bit it, my best suggestion would be to put the amp in a heavy hermetically sealed box and suspend this with rubber bands inside another heavy hermetically sealed box.

having said that personally I think I would put the amps just behind the speaker in which case one box on the rubber bands would probably suffice.

I'm fascinated, does 1ft of good quality cable hardwired both ends make an audible difference ?

mike

Water Cooling Systems

Take a look at some back issues of the magazine "Maximum PC". This caters to the overclocking gang, there are some articles about water coooling systems for CPUs. Maybe you can adapt something. There was even an example a couple of months ago of a system where the CPU is maintained below 0-deg ( F or c ?). If you can put plumbing in a PC case why not in an amp enclosure.

Take a look at some back issues of the magazine "Maximum PC". This caters to the overclocking gang, there are some articles about water coooling systems for CPUs. Maybe you can adapt something. There was even an example a couple of months ago of a system where the CPU is maintained below 0-deg ( F or c ?). If you can put plumbing in a PC case why not in an amp enclosure.

Steve Eddy said:Actually the heavy construction increases its resonant frequency.se

That's right, if you do some calcs you can put that resonant freq above the audio range where it would matter even less that the little it already does.

Hi,

In the real world that won't be feasable.

Besides I don't even feel it's advisable to go down that path, what you want is sufficient mass so that the whole doesn't resonate at the slightest wavefront.

I found add some layer of lead foil to add mass and damping of side and bottom panels is usually very beneficial.

Cheers,😉

That's right, if you do some calcs you can put that resonant freq above the audio range where it would matter even less that the little it already does.

In the real world that won't be feasable.

Besides I don't even feel it's advisable to go down that path, what you want is sufficient mass so that the whole doesn't resonate at the slightest wavefront.

I found add some layer of lead foil to add mass and damping of side and bottom panels is usually very beneficial.

Cheers,😉

Different thought: Did you consider to use a Peltier cooler element ? This element is cooling on one side by the use of electricity.

The chip could be fixed (glued, soldered) onto one element and the whole package can then be freely suspended by the supply wires prob. in an acoustically, not thermally insulated space. The chip heatsink temperature could be controlled by a NTC, etc.

This will use more electricity, but we are not talking of Class A here.

just an idea

Klaus

The chip could be fixed (glued, soldered) onto one element and the whole package can then be freely suspended by the supply wires prob. in an acoustically, not thermally insulated space. The chip heatsink temperature could be controlled by a NTC, etc.

This will use more electricity, but we are not talking of Class A here.

just an idea

Klaus

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- Is LM3875 chip waterproof?