Hello from the Garden State. I'm Mike and I know very little about troubleshooting/repair of audio equipment, But while my profession is in Radiation Health Physics, I've worked on all aspects of cars, trucks, machinist/tool and die, welding, HVAC install and service, plumbing, and owned/operated a tree service-Night shift leaves spare time for all manner of side gigs. I also replaced a bad cap on a dell laptop once. So I understand the basic logic and concept of proper troubleshooting, but lack the in depth technical knowledge to test audio components without some advice. I have several Fluke meters, including a model 16, but it only has the capability to test capacitors up to 10,000μF. So that excludes the big ones in the Adcoms.

I'm browsed/lurked here for a few months since inheriting this collection of vintage gear, and I thought I might need to ask for help someday, so here's my introduction.

What I inherited: (In no particular order), NAD gear, 1} 4155 tuner. 1} 1155 preamp. 1} Monitor series 1600 preamp tuner. 1} Monitor series 1700 preamp tuner. 1} 2200 PE Amp.

1} Adcom GTP-500 preamp tuner. 2} GFA-555 Amps. 2} Adcom GFA-555mk2 Amps. 1} Fisher "Studio Standard" integrated amp tuner. All 4 Adcoms were in service until about a year ago, and are one owner(+me now) I don't know the ownership history of the rest of the gear.

I currently have the NAD1700 and one Adcom GFA-555ii in service, as well as the Fisher(Shop tunes upgrade), as those were in service when I inherited them. I plan to pull the covers on all the gear and look for obvious things like bulged caps/leakage, but beyond that I'm not well versed. I'd hate to power up an amp and see smoke. I did ReCap 2 Samsung TV power supplies, but that's pretty trivial compared to audio gear.

I hope that when/if the time comes to ask for advice I can do so in a respectful and humble manner.

P.S. I downloaded all the schematics and service manuals I could find for all the gear mentioned above.

Thank You, Regards, Mike

I'm browsed/lurked here for a few months since inheriting this collection of vintage gear, and I thought I might need to ask for help someday, so here's my introduction.

What I inherited: (In no particular order), NAD gear, 1} 4155 tuner. 1} 1155 preamp. 1} Monitor series 1600 preamp tuner. 1} Monitor series 1700 preamp tuner. 1} 2200 PE Amp.

1} Adcom GTP-500 preamp tuner. 2} GFA-555 Amps. 2} Adcom GFA-555mk2 Amps. 1} Fisher "Studio Standard" integrated amp tuner. All 4 Adcoms were in service until about a year ago, and are one owner(+me now) I don't know the ownership history of the rest of the gear.

I currently have the NAD1700 and one Adcom GFA-555ii in service, as well as the Fisher(Shop tunes upgrade), as those were in service when I inherited them. I plan to pull the covers on all the gear and look for obvious things like bulged caps/leakage, but beyond that I'm not well versed. I'd hate to power up an amp and see smoke. I did ReCap 2 Samsung TV power supplies, but that's pretty trivial compared to audio gear.

I hope that when/if the time comes to ask for advice I can do so in a respectful and humble manner.

P.S. I downloaded all the schematics and service manuals I could find for all the gear mentioned above.

Thank You, Regards, Mike

You certainly have plenty of work in the queue.

Some like to use a light bulb tester to turn on an old amp. That's a series light bulb in the amp transformer

primary, with a wattage rating that is greater than the normal equipment draw. Say 200W for a 100W amp.

https://www.diyaudio.com/community/threads/light-bulb-tester.167579/

I prefer using a fused Variac (variable autotransformer) to slowly bring up the amp over an hour or so.

Stop if there's any problem.

Neither is isolated from the AC line, so exercise caution.

Some like to use a light bulb tester to turn on an old amp. That's a series light bulb in the amp transformer

primary, with a wattage rating that is greater than the normal equipment draw. Say 200W for a 100W amp.

https://www.diyaudio.com/community/threads/light-bulb-tester.167579/

I prefer using a fused Variac (variable autotransformer) to slowly bring up the amp over an hour or so.

Stop if there's any problem.

Neither is isolated from the AC line, so exercise caution.

I'd say a more clearly stated goal with this equipment would be helpful. Perhaps something like;

- I'd like to get another 15 years of service out of these; I'm fine with their sound, just want the reliability solid.

- I'd like to simply check them for base functionality, fix what I can, then sell off most of it as "working" with a clear conscious.

- I'd like all of the above, while distinctly improving the sound of the couple / few units I decide to keep via DIYAudio "circuit mods".

Thanks so much for the replies!

To rayma, I'd read the testing protocol before, but you explained it much more clearly, Thanks!

To jjasniew, I have 2 rooms I would like to have independent systems in (not counting the shop-which is already covered) It's my understanding that some or all of this gear is as good or better than much of the current gear in the same or slightly higher price range.

If I can do the preventative work (I was told everything worked when last used) I'd like to keep and use/possibly improve via 'circuit mods" if that's something I'm capable of, for any of the equipment considered most desirable.

Anything I don't feel compelled to keep as a spare, I'd like to render as reliable as reasonably possible, and give to younger relatives. From what I can tell, the most valuable of these bits of gear sell for no more than about 400 bucks max., and that's in perfect condition. So resale on eBay or elsewhere would be a net waste of my time.

Also, I have a friend who now lives in California and has a pair of 555ii's driving what he says are highly modified Altec VoT's and says not only do they sound great, but some of his "audiophile" friends turned green when they listened to his setup that cost about a tenth of what they'd spent on "boutique" setups. I'd love to go visit him for a listen, but it's just not in the cards right now.

I've also heard people swear the NAD 2200 makes the Adcoms sound like a Walmart boom box. So, as time allows, I'd like to dig in to what I've got and see where testing leads me.

As the Adcoms are most likely the Amps that were most recently in use, I plan to start there. I hope they check out OK--I have some speakers I can sacrifice for testing purposes without shedding a tear should they get "DC'ed". In any event, any unit worth keeping should be re-capped at a minimum I would think.

I appreciate the replies and any advice, including where else I should post if I get into things and have questions that don't sound too idiotic.

Kind regards, Mike

To rayma, I'd read the testing protocol before, but you explained it much more clearly, Thanks!

To jjasniew, I have 2 rooms I would like to have independent systems in (not counting the shop-which is already covered) It's my understanding that some or all of this gear is as good or better than much of the current gear in the same or slightly higher price range.

If I can do the preventative work (I was told everything worked when last used) I'd like to keep and use/possibly improve via 'circuit mods" if that's something I'm capable of, for any of the equipment considered most desirable.

Anything I don't feel compelled to keep as a spare, I'd like to render as reliable as reasonably possible, and give to younger relatives. From what I can tell, the most valuable of these bits of gear sell for no more than about 400 bucks max., and that's in perfect condition. So resale on eBay or elsewhere would be a net waste of my time.

Also, I have a friend who now lives in California and has a pair of 555ii's driving what he says are highly modified Altec VoT's and says not only do they sound great, but some of his "audiophile" friends turned green when they listened to his setup that cost about a tenth of what they'd spent on "boutique" setups. I'd love to go visit him for a listen, but it's just not in the cards right now.

I've also heard people swear the NAD 2200 makes the Adcoms sound like a Walmart boom box. So, as time allows, I'd like to dig in to what I've got and see where testing leads me.

As the Adcoms are most likely the Amps that were most recently in use, I plan to start there. I hope they check out OK--I have some speakers I can sacrifice for testing purposes without shedding a tear should they get "DC'ed". In any event, any unit worth keeping should be re-capped at a minimum I would think.

I appreciate the replies and any advice, including where else I should post if I get into things and have questions that don't sound too idiotic.

Kind regards, Mike

I think a good place to start is to get together a decent dummy load. This is basically a 4 or 8 ohm resistor, capable of dissipating 100W or more. No speaker (you'd have just lying around) can take the output of these amplifiers as a single tone, continuously, at rated power. So with this piece, you can test the amplifiers for rated power.

If you have a PC, laptop, phone you can use that as a signal source for driving the amplifiers. They should be able to drive them up to full power output via their headphone outs. There's many programs that will generate a continuous tone...

You can use your Fluke meter to measure the voltage the amplifiers impress across the dummy load. This will tell you if the amp is making its claimed output and if there's a significant difference between channels when driven simultaneously using the same signal.

To see clipping, you'll need an oscilloscope. Fortunately the PC / Laptop can come to the rescue there, however you'll need to scale the voltage across the dummy load down so it fits within the range of a line input. That's going to involve some resistors - albeit smaller than the ones comprising the dummy load!

You should be able to bring the amplifiers up to clipping, as displayed via the "PC-Oscilloscope". Note you're only looking for the relative waveshape differeing from a sinewave, while measuring with the Fluke meter. Or other wonkiness on the waveform that shouldnt be there.

If you have a PC, laptop, phone you can use that as a signal source for driving the amplifiers. They should be able to drive them up to full power output via their headphone outs. There's many programs that will generate a continuous tone...

You can use your Fluke meter to measure the voltage the amplifiers impress across the dummy load. This will tell you if the amp is making its claimed output and if there's a significant difference between channels when driven simultaneously using the same signal.

To see clipping, you'll need an oscilloscope. Fortunately the PC / Laptop can come to the rescue there, however you'll need to scale the voltage across the dummy load down so it fits within the range of a line input. That's going to involve some resistors - albeit smaller than the ones comprising the dummy load!

You should be able to bring the amplifiers up to clipping, as displayed via the "PC-Oscilloscope". Note you're only looking for the relative waveshape differeing from a sinewave, while measuring with the Fluke meter. Or other wonkiness on the waveform that shouldnt be there.

What electronic test equipment do you have available to use?

Do you just want to get these units functional, or to completely restore them for long term use?

Do you just want to get these units functional, or to completely restore them for long term use?

To rayma;

Several DVM's, Flukes mostly, one Beckman and 10 or more laptops from a single core Win XP machine to newer Dell, HP, and Toshiba machines running 7, 8.1, and 10.

I just D/Led "Soundcard Oscilloscope" <https://www.zeitnitz.eu/scope_en> and it seems to have plenty of functions (I've got some learning to do!)

I also dug out a Cutler Hammer "Motor Controller" last night that looks like it's from the 40's or 50's, but it's basically a big rheostat that ranges from 117ohms to effectively zero. the nameplate says "WATTS 360, VOLTS 115, AMPS 3.15, RHEO. OHMS 110". Perhaps I should post a picture of this thing--It looks like it belongs in museum, but it checks out with my meter, and it progressively dims (or brightens) a 150w incandescent bulb.

I've got a Variac (I think It's a Variac) somewhere-it's a heavy piece and has a big knob and a grey case about 12" square as I recall. Anyway, it has heavy windings and a graphite brush-like contact that moves along the flattened part of the windings like a motor commutator. It could likely be used as a power resistor as well.

Beyond that, BOXES of all manner of electronic parts and other mysterious hardware that my Dad took home from work, Anyone need a Heat Treat Furnace? Anyway, he took many bits destined for the dumpster as he managed the Harrisburg R&D shop for AMP inc. from around 1980 until 2000 or so. He retired a few years after Tyco "rescued" AMP and gutted much of it in "Venture Capital" style.

I could possibly borrow a real oscilloscope from a rather "odd" friend who has WAY too much gear, but he's about 2 hours away and detests anything that isn't analog--he won't even touch a modern TV and only uses a computer at work because he has to-- so if I can get by with the computer based version that would be ideal. Thanks for helping me get started on this new adventure.

To jjasniew; I greatly appreciate all your help! I know what clipping looks like on a scope (flat tops on the sine), but one part I'm not clear on is:

"however you'll need to scale the voltage across the dummy load down so it fits within the range of a line input. That's going to involve some resistors - albeit smaller than the ones comprising the dummy load!"

When you say "Smaller", are you referring to ohms, or am I totally missing the what "range of a line input" means in this context? Or where the resistors and measurements are to be located/taken? I'm guessing that means connecting to the outputs under load, and feeding that signal at reduced voltage to the virtual scope on my laptop? Apologies for being such a neophyte on this subject. Perhaps you could recommend a book or 2 for a beginner like me. I'll be looking for something online as soon as I post this, and I'll dig out that Variac (or whatever it is) once I get home.

Again, Sincere thanks to all who are kind enough to help me out on this learning adventure, Regards, Mike

Several DVM's, Flukes mostly, one Beckman and 10 or more laptops from a single core Win XP machine to newer Dell, HP, and Toshiba machines running 7, 8.1, and 10.

I just D/Led "Soundcard Oscilloscope" <https://www.zeitnitz.eu/scope_en> and it seems to have plenty of functions (I've got some learning to do!)

I also dug out a Cutler Hammer "Motor Controller" last night that looks like it's from the 40's or 50's, but it's basically a big rheostat that ranges from 117ohms to effectively zero. the nameplate says "WATTS 360, VOLTS 115, AMPS 3.15, RHEO. OHMS 110". Perhaps I should post a picture of this thing--It looks like it belongs in museum, but it checks out with my meter, and it progressively dims (or brightens) a 150w incandescent bulb.

I've got a Variac (I think It's a Variac) somewhere-it's a heavy piece and has a big knob and a grey case about 12" square as I recall. Anyway, it has heavy windings and a graphite brush-like contact that moves along the flattened part of the windings like a motor commutator. It could likely be used as a power resistor as well.

Beyond that, BOXES of all manner of electronic parts and other mysterious hardware that my Dad took home from work, Anyone need a Heat Treat Furnace? Anyway, he took many bits destined for the dumpster as he managed the Harrisburg R&D shop for AMP inc. from around 1980 until 2000 or so. He retired a few years after Tyco "rescued" AMP and gutted much of it in "Venture Capital" style.

I could possibly borrow a real oscilloscope from a rather "odd" friend who has WAY too much gear, but he's about 2 hours away and detests anything that isn't analog--he won't even touch a modern TV and only uses a computer at work because he has to-- so if I can get by with the computer based version that would be ideal. Thanks for helping me get started on this new adventure.

To jjasniew; I greatly appreciate all your help! I know what clipping looks like on a scope (flat tops on the sine), but one part I'm not clear on is:

"however you'll need to scale the voltage across the dummy load down so it fits within the range of a line input. That's going to involve some resistors - albeit smaller than the ones comprising the dummy load!"

When you say "Smaller", are you referring to ohms, or am I totally missing the what "range of a line input" means in this context? Or where the resistors and measurements are to be located/taken? I'm guessing that means connecting to the outputs under load, and feeding that signal at reduced voltage to the virtual scope on my laptop? Apologies for being such a neophyte on this subject. Perhaps you could recommend a book or 2 for a beginner like me. I'll be looking for something online as soon as I post this, and I'll dig out that Variac (or whatever it is) once I get home.

Again, Sincere thanks to all who are kind enough to help me out on this learning adventure, Regards, Mike

Go ahead and check out the Variac(s) to verify they are ok. Measure the output and make a mark at 120VAC,

so you don't overvoltage the equipment. Some Variacs are wired to go to 115% of the nominal AC line.

Make sure that the outputs are fused with a similar fuse as is in the equipment being tested, or else the rated

current of the Variac, whichever is lower.

so you don't overvoltage the equipment. Some Variacs are wired to go to 115% of the nominal AC line.

Make sure that the outputs are fused with a similar fuse as is in the equipment being tested, or else the rated

current of the Variac, whichever is lower.

To jjasniew:

I have a question regarding dummy load-- since these Amps are rated at 200w/ch continuous, wouldn't I need a 250-300w load per channel to reliably induce clipping? Or can a 100w resistor withstand the length of overload time needed to perform any/all necessary tests? I only ask because I'll need to purchase those from Mouser or Newark, and the price difference is significant. Also, as I understand it, I need to also bring the output under load voltage (separately) to .07v or less to use as an oscilloscope signal--or risk frying my laptop.

To rayma;

Sorry I didn't fully answer your question, Yes, I'd like to restore these to full functionality for long term use, unless something is beyond reasonable repair, in which case I'd attempt to find someone who'd take it for parts or their own resto project. It's my understanding that everything worked as of a few years ago.

I have a question regarding dummy load-- since these Amps are rated at 200w/ch continuous, wouldn't I need a 250-300w load per channel to reliably induce clipping? Or can a 100w resistor withstand the length of overload time needed to perform any/all necessary tests? I only ask because I'll need to purchase those from Mouser or Newark, and the price difference is significant. Also, as I understand it, I need to also bring the output under load voltage (separately) to .07v or less to use as an oscilloscope signal--or risk frying my laptop.

To rayma;

Sorry I didn't fully answer your question, Yes, I'd like to restore these to full functionality for long term use, unless something is beyond reasonable repair, in which case I'd attempt to find someone who'd take it for parts or their own resto project. It's my understanding that everything worked as of a few years ago.

Clean all the switches and controls with D5 first, and vacuum out any loose dust.

Unless the units have been damaged, the electrolytic capacitors should be the main thing to check.

If those are not bulging or leaking, and there are no other visual issues, use a Variac to slowly raise

the line voltage to 120VAC and burn the DUT in for an hour or so. If there are no bad noises out of

the test speakers during this time, and there is no DC on the speaker outputs, then disconnect

the Variac and try it out. They will likely need a few weeks to burn in, to sound like normal.

Unless the units have been damaged, the electrolytic capacitors should be the main thing to check.

If those are not bulging or leaking, and there are no other visual issues, use a Variac to slowly raise

the line voltage to 120VAC and burn the DUT in for an hour or so. If there are no bad noises out of

the test speakers during this time, and there is no DC on the speaker outputs, then disconnect

the Variac and try it out. They will likely need a few weeks to burn in, to sound like normal.

Last edited:

Hi Mike, I looked on line and found "https://www.virtins.com/P601PC-P601PPC.shtml" which shows an oscilloscope probe meant specifically for use with sound cards. At ~$30, shipping included, not too bad for observing the clipping point of an amplifier's output.

The scope probe is only good for +/- 25V however. At 200W, your amp will be putting out +/- 40V, so at least a 2:1 reduction is needed to fit the capability of the probe. Perhaps a couple 1000 Ohm resistors in series would do the trick. This would be connected in parallel with the 8 Ohm "dummy" load. Even so, those 1k resistors would need to be two watts each.

I think you can make a decent assessment of the amplifier's output capability using a transient signal, i.e. one that's not "on" continuously. Given the cost difference in the dummy load resistors, I'm sure you could put 200W into the 100W continuously rated parts for a short time. Short, being just long enough to get the trace captured on the oscilloscope software. A bit inconvenient perhaps.

You may find it less expensive to use a parallel combination of higher value resistors, than to purchase a single 100 or 200W capable part. For example, let's say you stumbled upon a pile of

I've used the "https://digilent.com/shop/software/digilent-waveforms/" for an oscilloscope on PC. When you set it to "soundcard" as input, it asks for your name / email. I just provide it and havent been harassed by them to buy something. It can do a triggered capture (transient) and also will generate tones - though I've never used that function simultaneously with the oscilloscope part.

The latest REW (http://www.roomeqwizard.com/help/help_en-GB/html/scope.html) has an oscilloscope, good enough for showing what you want to see. It will also generate tones. Since REW can do so much more regarding audio analysis, if you're getting into this hobby, probably one of the better choices to begin learning on, getting familiar with.

The scope probe is only good for +/- 25V however. At 200W, your amp will be putting out +/- 40V, so at least a 2:1 reduction is needed to fit the capability of the probe. Perhaps a couple 1000 Ohm resistors in series would do the trick. This would be connected in parallel with the 8 Ohm "dummy" load. Even so, those 1k resistors would need to be two watts each.

I think you can make a decent assessment of the amplifier's output capability using a transient signal, i.e. one that's not "on" continuously. Given the cost difference in the dummy load resistors, I'm sure you could put 200W into the 100W continuously rated parts for a short time. Short, being just long enough to get the trace captured on the oscilloscope software. A bit inconvenient perhaps.

You may find it less expensive to use a parallel combination of higher value resistors, than to purchase a single 100 or 200W capable part. For example, let's say you stumbled upon a pile of

120 ohm 17W Philips Power Sandbox Wire Resistor 120ohm 120R, 12pcs

on ebay for $7, plus $6 shipping. Perhaps haggling with the seller, you could get a couple sets of 15 units for $10 each. That would give 8 Ohms, 225W continuous load with 15 of them all connected in parallel. There is a matter of inductance in wire wound resistors, but to assess that these amps are putting out their proper power, you could avoid the effect of that by testing using a low frequency.I've used the "https://digilent.com/shop/software/digilent-waveforms/" for an oscilloscope on PC. When you set it to "soundcard" as input, it asks for your name / email. I just provide it and havent been harassed by them to buy something. It can do a triggered capture (transient) and also will generate tones - though I've never used that function simultaneously with the oscilloscope part.

The latest REW (http://www.roomeqwizard.com/help/help_en-GB/html/scope.html) has an oscilloscope, good enough for showing what you want to see. It will also generate tones. Since REW can do so much more regarding audio analysis, if you're getting into this hobby, probably one of the better choices to begin learning on, getting familiar with.

Hi jjasniew, Wow! Thanks For all the info. Certainly plenty for me to work with over the weekend.

Newark has "Resistor, 6.8 ohm, TJT Series, 250 W, ± 5%, Wire Leaded" TE connectivity brand Panel/chassis mount units for $9.93/ea.

I'm guessing 1.2 ohms less would just draw a bit more amperage and still be capable for testing. They also have 10 ohm 250 W parts, same Mfg., design and price.

Any opinion on which would be the better choice? I'd think the 6.8's but maybe I'm missing some important detail here.

Many Thanks, Regards, Mike

Newark has "Resistor, 6.8 ohm, TJT Series, 250 W, ± 5%, Wire Leaded" TE connectivity brand Panel/chassis mount units for $9.93/ea.

I'm guessing 1.2 ohms less would just draw a bit more amperage and still be capable for testing. They also have 10 ohm 250 W parts, same Mfg., design and price.

Any opinion on which would be the better choice? I'd think the 6.8's but maybe I'm missing some important detail here.

Many Thanks, Regards, Mike

Nice - those resistors are a steal at <$10! The 6.8 Ohm would be fine, methinks. You'll just have to remember the odd value when doing calculations. I'm pretty sure any one of the amplifiers you have would have no problem driving 6.8 Ohms to their rated power for 8.

Just remember they're going to get HOT running continuously; you may want to mount them in a little metal cage with feet that lifts them up off your bench surface.

Just remember they're going to get HOT running continuously; you may want to mount them in a little metal cage with feet that lifts them up off your bench surface.

Yeah--they caught my eye, seems like they were just trying to clear out product that wasn't selling--the lined out price is $51.35ea. Now I just have to wait a few days for them to arrive.

If my math is correct and the resistors ohm out at 6.8, I would need 29.41v to achieve a 200w load. I assume I should have a pair of pigtails wired to the RCA connectors that these connect to for voltage measurement as well as deriving a signal for the Laptop 'scope. The spec sheet also says you need a heat sink for full rated power, It drops to 125w in free air. That shouldn't be a problem though, I've got plenty of aluminum and thermal paste.

If I remember correctly a tone signal of 4000-5000Hz is a good number for testing. Again, I really appreciate your help with this, Regards, Mike

P.S. I hope the attached image doesn't look too "Hacky" I assume a thumbnail image is the correct etiquette, rather than "Full Size"--but I guess I'll have to post it to find out!

If my math is correct and the resistors ohm out at 6.8, I would need 29.41v to achieve a 200w load. I assume I should have a pair of pigtails wired to the RCA connectors that these connect to for voltage measurement as well as deriving a signal for the Laptop 'scope. The spec sheet also says you need a heat sink for full rated power, It drops to 125w in free air. That shouldn't be a problem though, I've got plenty of aluminum and thermal paste.

If I remember correctly a tone signal of 4000-5000Hz is a good number for testing. Again, I really appreciate your help with this, Regards, Mike

P.S. I hope the attached image doesn't look too "Hacky" I assume a thumbnail image is the correct etiquette, rather than "Full Size"--but I guess I'll have to post it to find out!

A couple pics of vintage gear; The Variac has internal taps that are currently set so that the max voltage is "line in", not 130 volts as the dial might suggest if the High tap were selected. From what I can find on the history, this unit was built prior to the mid-50's based on the Cambridge address.

The Cutler Hammer "Frankenstein Rheostat" looks like a 1910-1920ish contraption based on the lack of any insulated enclosure for the line terminals.

The Cutler Hammer "Frankenstein Rheostat" looks like a 1910-1920ish contraption based on the lack of any insulated enclosure for the line terminals.

Time to get to work--after work, that is.

I ordered 2 of those 6.8ohm resistors, and they sent me 3. I called and said "maybe I screwed up the checkout", and when I asked them about returning 1 of them, they said "Just keep it or throw it out". I guess being that was the last 3, and they were trying to sell them for $9.93, returning one didn't interest them.

Anyway, I checked them and they measured 6.9Ω, 7.0Ω, and 7.1Ω. respectively. I'm thinking that I should use the 7 and 7.1Ω units for my test setup. I also read that a 1000Hz signal is "ideal" for load testing, although the article didn't specify why. If anybody has any thoughts on the subject, I'd love to hear them.

Regards, Mike

I ordered 2 of those 6.8ohm resistors, and they sent me 3. I called and said "maybe I screwed up the checkout", and when I asked them about returning 1 of them, they said "Just keep it or throw it out". I guess being that was the last 3, and they were trying to sell them for $9.93, returning one didn't interest them.

Anyway, I checked them and they measured 6.9Ω, 7.0Ω, and 7.1Ω. respectively. I'm thinking that I should use the 7 and 7.1Ω units for my test setup. I also read that a 1000Hz signal is "ideal" for load testing, although the article didn't specify why. If anybody has any thoughts on the subject, I'd love to hear them.

Regards, Mike

What a steal on those resistors! You have a spare.

1000Hz is typically where they quote power and distortion for an audio amplifier. You could use 60Hz just as well to get a good estimate of an amplifiers power output. What Hi-Fi amplifier cant do 60 Hz, as well as any other value between 20 - 20k?

1000Hz is typically where they quote power and distortion for an audio amplifier. You could use 60Hz just as well to get a good estimate of an amplifiers power output. What Hi-Fi amplifier cant do 60 Hz, as well as any other value between 20 - 20k?

Hi jjasniew,

Thanks for the reply, I did get lucky with those plate resistors!--I posted that screen shot because I figured anyone reading my post would think I was just some bragging poser lying about a good deal! (I am somewhat clueless--but I'm working on fixing that!). Regarding frequency, I guess I'm just showing my ignorance here, I was thinking there might be an ideal frequency where clipping would occur at rated "plus" load, or where some other anomaly would be more readily apparent on an oscilloscope. I still have to source some resistors (as you mentioned earlier) to create a safe "line" signal from the outputs to my "Mic In".

While I bought a lot of stuff when the local Radio Shack liquidated, the drawers of resistors, potentiometers and the like were pretty well picked clean, and I don't think they had much if anything in the 2+ watt range anyway.

So this presents a challenge if I'm thinking about this clearly--If I load the Amp(s) to rated power or thereabouts, and I check the voltage out, I have one element of the equation, but if my laptop 'Scope app needs ~0.7v, what number do I use for amperage in order to source the correct resistors? Do I just start high and work down, trial and error style, or is there a better way to get it right from the start?

My original plan was to use one laptop as a signal (tone) generator, and another for the Oscilloscope. But from what I can gather from the REW user guide, while this would eliminate any possibility of "Loopback", they are referring to Mic's and speakers, and pretty much every other function is performed using one laptop or "soundcard" to perform testing, so I'm really kinda in the dark here.

I've read the REW guide several times, and nowhere is there any statement of what a safe voltage would be for "Mic in" on a laptop.

Reading about Microphones, it seems the output typically ranges from 0.001v to about 0.1v. So if 0.7v is acceptable and desirable, what might be the max voltage before my laptop becomes a Smoke Generator? I'm getting the impression that this will be a cautious trial and error exercise, but any info beyond what I've been able to find would be greatly appreciated.

Kind Regards, Mike

Thanks for the reply, I did get lucky with those plate resistors!--I posted that screen shot because I figured anyone reading my post would think I was just some bragging poser lying about a good deal! (I am somewhat clueless--but I'm working on fixing that!). Regarding frequency, I guess I'm just showing my ignorance here, I was thinking there might be an ideal frequency where clipping would occur at rated "plus" load, or where some other anomaly would be more readily apparent on an oscilloscope. I still have to source some resistors (as you mentioned earlier) to create a safe "line" signal from the outputs to my "Mic In".

While I bought a lot of stuff when the local Radio Shack liquidated, the drawers of resistors, potentiometers and the like were pretty well picked clean, and I don't think they had much if anything in the 2+ watt range anyway.

So this presents a challenge if I'm thinking about this clearly--If I load the Amp(s) to rated power or thereabouts, and I check the voltage out, I have one element of the equation, but if my laptop 'Scope app needs ~0.7v, what number do I use for amperage in order to source the correct resistors? Do I just start high and work down, trial and error style, or is there a better way to get it right from the start?

My original plan was to use one laptop as a signal (tone) generator, and another for the Oscilloscope. But from what I can gather from the REW user guide, while this would eliminate any possibility of "Loopback", they are referring to Mic's and speakers, and pretty much every other function is performed using one laptop or "soundcard" to perform testing, so I'm really kinda in the dark here.

I've read the REW guide several times, and nowhere is there any statement of what a safe voltage would be for "Mic in" on a laptop.

Reading about Microphones, it seems the output typically ranges from 0.001v to about 0.1v. So if 0.7v is acceptable and desirable, what might be the max voltage before my laptop becomes a Smoke Generator? I'm getting the impression that this will be a cautious trial and error exercise, but any info beyond what I've been able to find would be greatly appreciated.

Kind Regards, Mike

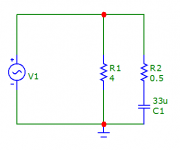

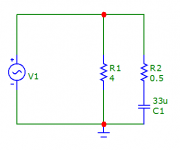

So you want to "pad" down the 50V (or so) across the load resistor you just bought to a 0.7V level. This can be done with a resistor divider. Since there's little current going into the laptop mic/line input, these resistors can be relatively small wattage values. You'll need two resistors, connected in series across the power load resistor; one a big value going to (+), the other a small value going to (-). Hopefully the negative (-) terminal of your amplifiers is earth ground. You'll connect the junction of these resistor into your laptop audio input.

So 50V / 100 = 0.5V. It doesnt matter if you come right up to the 0.7V max input level (assuming that value is valid) 0.5 would be fine. We'll also assume the mic/line input to laptop load is relatively high, so we could choose a 100 or 1K value for the lower resistor - the voltage across which you'll be measuring. Then it's just a matter of calculating the value of the "upper" resistor in the voltage divider.

Since they have everything on-line for such calculations, you could visit https://ohmslawcalculator.com/voltage-divider-calculator and solve for the upper resistor. For 100 Ohm on the bottom, I got 9.9k - a weird value - so 10K is probably close enough. Nearly all the 50V will be across the 10K, so it'll dissipate 1/4 Watt. Use a 1/2 W resistor, so that part doesnt get so hot as to burn if you run your test for a while.

You can refine the idea, using 40V, which is 200W into 8 Ohms. Perhaps the max input into your laptop sound card isnt 0.7, it's more like 0.1? So you can run through the calculation for these numbers - even for resistor values you happen to have on hand to make up the voltage divider. Just keep the bottom one - the one going to ground - low, the top one - the one going to the amp's output - high in relative value; like around 100X. It's usually pick a reasonable value for the lower one you happen to have; 100, 200, 240, 330, 640 - and solve for the upper; hopefully you'll have a close one on hand too; pick the "best looking" pair meeting all the criteria.

Dont make it so 40V is exactly = 0.1 out - right up to the limit - leave a little margin lower, like 40V in = 0.09 out. Why? because you could clip the input to your laptop sound card and instead think you're clipping your amplifiers! Using 50V to start the calculation (for a 300W amp) is just a way to put a little margin in, if you know the biggest amp you're ever going to test is 200W.

This is just for observing the sine wave quality change as clipping is approched. For measurement, you'd want to design the voltage divider so that you can calibrate (adjust) what the PC scope application displays into real voltage / division values. That would take some more investigation into how the PC scope app handles the sound input on the PC - or USB ADC; if it gets the digital data directly, or only after the signal goes through some Windows sound system volume control / processing.

Er, hope this helps!

So 50V / 100 = 0.5V. It doesnt matter if you come right up to the 0.7V max input level (assuming that value is valid) 0.5 would be fine. We'll also assume the mic/line input to laptop load is relatively high, so we could choose a 100 or 1K value for the lower resistor - the voltage across which you'll be measuring. Then it's just a matter of calculating the value of the "upper" resistor in the voltage divider.

Since they have everything on-line for such calculations, you could visit https://ohmslawcalculator.com/voltage-divider-calculator and solve for the upper resistor. For 100 Ohm on the bottom, I got 9.9k - a weird value - so 10K is probably close enough. Nearly all the 50V will be across the 10K, so it'll dissipate 1/4 Watt. Use a 1/2 W resistor, so that part doesnt get so hot as to burn if you run your test for a while.

You can refine the idea, using 40V, which is 200W into 8 Ohms. Perhaps the max input into your laptop sound card isnt 0.7, it's more like 0.1? So you can run through the calculation for these numbers - even for resistor values you happen to have on hand to make up the voltage divider. Just keep the bottom one - the one going to ground - low, the top one - the one going to the amp's output - high in relative value; like around 100X. It's usually pick a reasonable value for the lower one you happen to have; 100, 200, 240, 330, 640 - and solve for the upper; hopefully you'll have a close one on hand too; pick the "best looking" pair meeting all the criteria.

Dont make it so 40V is exactly = 0.1 out - right up to the limit - leave a little margin lower, like 40V in = 0.09 out. Why? because you could clip the input to your laptop sound card and instead think you're clipping your amplifiers! Using 50V to start the calculation (for a 300W amp) is just a way to put a little margin in, if you know the biggest amp you're ever going to test is 200W.

This is just for observing the sine wave quality change as clipping is approched. For measurement, you'd want to design the voltage divider so that you can calibrate (adjust) what the PC scope application displays into real voltage / division values. That would take some more investigation into how the PC scope app handles the sound input on the PC - or USB ADC; if it gets the digital data directly, or only after the signal goes through some Windows sound system volume control / processing.

Er, hope this helps!

Last edited:

Thanks again, jjasniew,

I think I have a bit clearer picture now. For whatever reason I was thinking the 2 signal phases per channel would be isolated and I didn't consider the implications--or rather the need, to keep everything sharing a common ground--I would have had that DOH! moment when I tried to wire both outputs to a 3.5mm Mic input though!. I should have known better anyway, because I've seen some high neutral voltage on home wiring that wasn't very well balanced or had a neutral or ground continuity issue.

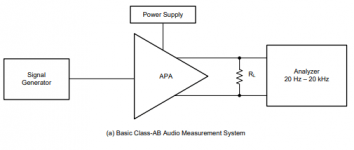

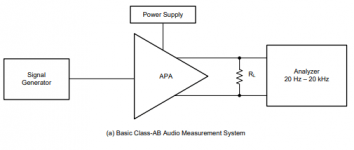

I clicked on the voltage divider link, and I'm a bit puzzled by that schematic. I was picturing a simple parallel circuit where the Amp outputs feed the power resistors as well as "power beyond" to be fed through an adequate resistor on the "hot" side of each channel to drop the voltage to 0.7v or less at max output of the amp. I feel like I'm missing some fundamental concept here, but I've looked at Images/Posts (here and elsewhere) that range from water heater elements as resistors to complex schematics for "reactive load testing" and they all look something like the block diagram or the schematic with the added R2 and C1 for "complex stability" testing at different frequencies. Am I really out of my league here, or am I just missing something basic? I hope I'm not being too much of a PIA for asking questions that might sound really dumb to anyone with some experience in the field. Thanks as always, Mike

I think I have a bit clearer picture now. For whatever reason I was thinking the 2 signal phases per channel would be isolated and I didn't consider the implications--or rather the need, to keep everything sharing a common ground--I would have had that DOH! moment when I tried to wire both outputs to a 3.5mm Mic input though!. I should have known better anyway, because I've seen some high neutral voltage on home wiring that wasn't very well balanced or had a neutral or ground continuity issue.

I clicked on the voltage divider link, and I'm a bit puzzled by that schematic. I was picturing a simple parallel circuit where the Amp outputs feed the power resistors as well as "power beyond" to be fed through an adequate resistor on the "hot" side of each channel to drop the voltage to 0.7v or less at max output of the amp. I feel like I'm missing some fundamental concept here, but I've looked at Images/Posts (here and elsewhere) that range from water heater elements as resistors to complex schematics for "reactive load testing" and they all look something like the block diagram or the schematic with the added R2 and C1 for "complex stability" testing at different frequencies. Am I really out of my league here, or am I just missing something basic? I hope I'm not being too much of a PIA for asking questions that might sound really dumb to anyone with some experience in the field. Thanks as always, Mike

- Home

- Member Areas

- Introductions

- Intimidated, but just trying to learn some basics