I am building a preamp and I'm wondering about the benefit of including internal aluminum panels to separate the audio circuits from the power supply and digital circuits.

The preamp will have two toroidal transformers with steel covers, regulated power supplies, and also an OLED display board.

There is only an inch or so (~30mm) of space between the power supply boards and the audio circuitry. Maybe 6 inches (150mm) between the OLED board and audio boards.

Is there any benefit adding aluminum panels in between these circuits. I'd obviously have to fish some wires/cables through/under the panels, but otherwise the spaces could be completely separated.

Thanks.

The preamp will have two toroidal transformers with steel covers, regulated power supplies, and also an OLED display board.

There is only an inch or so (~30mm) of space between the power supply boards and the audio circuitry. Maybe 6 inches (150mm) between the OLED board and audio boards.

Is there any benefit adding aluminum panels in between these circuits. I'd obviously have to fish some wires/cables through/under the panels, but otherwise the spaces could be completely separated.

Thanks.

Steel will be better, mu-metal the best. Magnetic field is usually the problem at audio frequencies and magnetic alloys shield more effectively (which is why the toroidals use steel). If that shielding is insufficient, adding aluminium is unlikely to have a great effect, but more steel would.

If you have high impedance circuitry electrostatic shielding could be useful though, but most modern solid-state audio circuits are low impedance. The high frequency switching in the digital (OLED) circuitry should be shielded from the audio (aluminium is fine here as its capacitive coupling you want to reduce)

If you have high impedance circuitry electrostatic shielding could be useful though, but most modern solid-state audio circuits are low impedance. The high frequency switching in the digital (OLED) circuitry should be shielded from the audio (aluminium is fine here as its capacitive coupling you want to reduce)

A guerrilla method to isolate parts of the circuit is, if you are using a home made PCB, solder blank copper clad boards vertically to the circuits.

Copper foil is routinely used in transformers and guitars to shield them, such as this:

You can get sheets of Mu-metal such as this:

The price for a 30X90 cm sheet is $85 USD 😱

You can get sheets of Mu-metal such as this:

The price for a 30X90 cm sheet is $85 USD 😱

something i've never done yet always thought of was to fold my own copper or brass cover into a shape like a box over the components that i want shielded and actually soldering these covers to the ground plane on the PCB. You could glue the panel, but the copper/brass must be grounded. You have to watch for 'shorted turns' while performing any work around transformers though. Steel does not need to be grounded and sometimes can cause trouble if you do with shorted turns common. Steel will also perform best in close proximity to the transformer. The magnetic flux follows the steel towards the opposite pole, limiting it's expansion into the chassis. The copper will be good as long as it's between the devices that you intend to shield. I've actually incorporated some facility to do this in my projects, yet I haven't had any issues without it, so, it's like not really an issue and you may want to try without anything at all first.

The typical transformer shielding using copper is the well known "belly band" like the one used on the transformers of these preamps.

An externally hosted image should be here but it was not working when we last tested it.

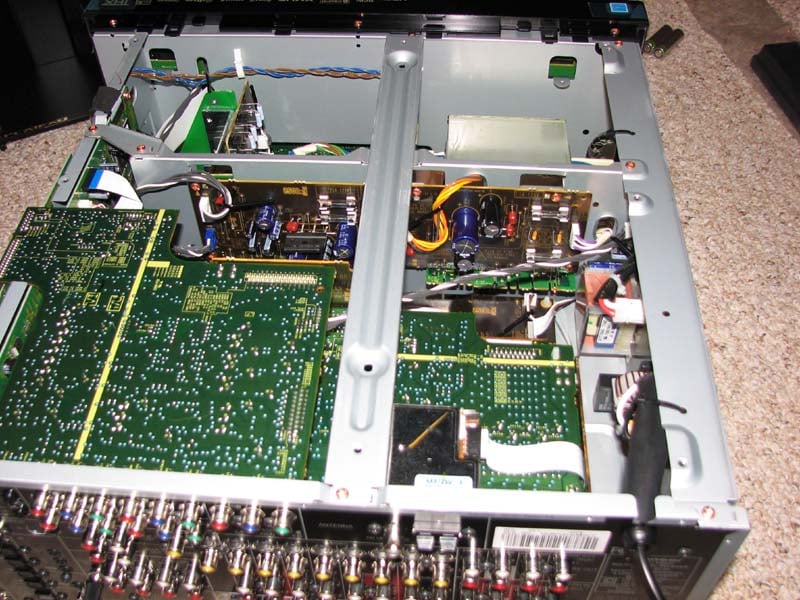

FWIW old time commercial Audio equipment used lots of metallic flaps, boxes and screens to isolate one block from another, as can readily be seen in any gut picture or if you own some and look under the hood.I am building a preamp and I'm wondering about the benefit of including internal aluminum panels to separate the audio circuits from the power supply and digital circuits.

The preamp will have two toroidal transformers with steel covers, regulated power supplies, and also an OLED display board.

There is only an inch or so (~30mm) of space between the power supply boards and the audio circuitry. Maybe 6 inches (150mm) between the OLED board and audio boards.

Is there any benefit adding aluminum panels in between these circuits. I'd obviously have to fish some wires/cables through/under the panels, but otherwise the spaces could be completely separated.

Thanks.

They had the metalworking muscle and production scale to do it efficiently.

We modern DIYers do not and tend to throw everything together inside a single chassis.

Which does not mean it´ s not needed or useless, AT ALL.

People obsess on capacitor colour or brand and similar minor stuff and forget that important contribution to noise and performance. 🙄

Only difference compared to what you suggest is that in an Industrial environment galvanized steel reigns supreme, since resistance soldering allows easy and quick assembly of complex shapes and having the proper dies means per piece cost is nil.

and so on and on and on.

No DIYer can match the best examples but tasteful shielding, at least protecting preamp, can go a long way.

FWIW I make high gain Guitar amps and sensible shielding helps me to avoid oscillatio0n, instability, buzz, RF interference ... what´s not to like?

Quite simple shielding, huh?

Thanks for the feedback and suggestions. The transformers already have a static shield with ground wire, a magnetic shield, and steel covers, so I'm not particularly concerned about them. I was more wondering about the power supply PCBs and the digital logic.

Aluminum panels (grounded to the chassis) would be the cheapest and easiest to implement, so if this would be reasonably effective, I'd prefer to go that route.

Thanks.

Aluminum panels (grounded to the chassis) would be the cheapest and easiest to implement, so if this would be reasonably effective, I'd prefer to go that route.

Thanks.

- Home

- Source & Line

- Analog Line Level

- Internal panels to separate circuits