Hi, I've just stumbled over this nice article + video from Cap supplier Murata.

Examples of Noise Countermeasures (Video) | Capacitors | Murata Manufacturing Co., Ltd.

It explains why we sometimes hear noise out of our notebooks during work. 😱

Effects happen when a monolytic ceramic smd cap is driven by a AC signal. This smd cap used nearly everywhere meanwhile can sing quiete nice. 😀

The ceramic cap is exited by the alternating fields inside and expands and compresses. The PCB acts as resonater. This finally makes the noise loud & detectable by our ears. It can be disturbing for the end user and therefore Murata advertises their own special cap design which really seems to compress the noise down to a minimum as you can see in the video.

For me the keypoint is another one: In any digital circuit wheter in Computer or pure CD drives it's expirienced that it's a benefit to mechanically couple them in a "right" way to the outer enviroment. By spikes or sand filled plates. Another point is to apply damping material on top of components etc...

This was sometimes seen as paradox as this is just a "digital" circuit" and not analog. 🙄

But ! I was told by computer audiophiles that micro vibration seems to alter capacity of for e.g. electrolytic components as the plates start to move. This introduces a small "swinging" signature to these capacities making the "C" smaller and bigger based on the vibration. I can confirm these tweaking potentials in digital areas through lots of tests I did.

Now I've learnt the following:

A) not only the typical "external" vibration exists and should be taken into consideration! If AC is passing a standard ceramic SMD cap the board may start creating its own noise. Hifi products are not known to "sing" loud as notebooks but higher numbers of ceramic caps could create a relevant influence to take notice from the design point of view. Maybe such noise can also be in a freq above our ears. Or the overall noise is lower than the ambient noise floor - not recognised by us but still an effect for the circuit an so finally detectable as sound detoriation after D/A conversion. Who knows...

B) And generally: The often under estimated correlation between electronic components to have mechanical side products as vibration (mechanical movement caused by fields) is definetly existing in "pratical world" and can grow to large scale like in the examples of notebooks.

Thougt that is interesting to report to you

Examples of Noise Countermeasures (Video) | Capacitors | Murata Manufacturing Co., Ltd.

It explains why we sometimes hear noise out of our notebooks during work. 😱

Effects happen when a monolytic ceramic smd cap is driven by a AC signal. This smd cap used nearly everywhere meanwhile can sing quiete nice. 😀

The ceramic cap is exited by the alternating fields inside and expands and compresses. The PCB acts as resonater. This finally makes the noise loud & detectable by our ears. It can be disturbing for the end user and therefore Murata advertises their own special cap design which really seems to compress the noise down to a minimum as you can see in the video.

For me the keypoint is another one: In any digital circuit wheter in Computer or pure CD drives it's expirienced that it's a benefit to mechanically couple them in a "right" way to the outer enviroment. By spikes or sand filled plates. Another point is to apply damping material on top of components etc...

This was sometimes seen as paradox as this is just a "digital" circuit" and not analog. 🙄

But ! I was told by computer audiophiles that micro vibration seems to alter capacity of for e.g. electrolytic components as the plates start to move. This introduces a small "swinging" signature to these capacities making the "C" smaller and bigger based on the vibration. I can confirm these tweaking potentials in digital areas through lots of tests I did.

Now I've learnt the following:

A) not only the typical "external" vibration exists and should be taken into consideration! If AC is passing a standard ceramic SMD cap the board may start creating its own noise. Hifi products are not known to "sing" loud as notebooks but higher numbers of ceramic caps could create a relevant influence to take notice from the design point of view. Maybe such noise can also be in a freq above our ears. Or the overall noise is lower than the ambient noise floor - not recognised by us but still an effect for the circuit an so finally detectable as sound detoriation after D/A conversion. Who knows...

B) And generally: The often under estimated correlation between electronic components to have mechanical side products as vibration (mechanical movement caused by fields) is definetly existing in "pratical world" and can grow to large scale like in the examples of notebooks.

Thougt that is interesting to report to you

Mind you, the sound you would hear out of a notebook computer would more likely be due to vibrations in magnetic coils as well as the existence of fans and mechanical drives in many models, all of which result in vibration levels which are magnitudes higher.

Laptops will be using high-k dielectrics, they want high capacitance in small sizes and minimum price. Nobody suggests that Z5U & Y5U capacitors are a good choice for audio

This happens occasionally with SMPS's, just have to design them so that the resonant frequency of the caps is not created, better to solve the problem rather than treat the symptoms.

I would not use Z5U and Y5U caps anywhere, but cost is king on some designs and so they do get used!!!! X7R are ok for decoupling, and in these positions you are unlikely to cause this problem.

I would not use Z5U and Y5U caps anywhere, but cost is king on some designs and so they do get used!!!! X7R are ok for decoupling, and in these positions you are unlikely to cause this problem.

X7R's offer the best solution for high speed digital decoupling, (very low value COG can be used for mega critical decoupling, say an oscillator) but for all other decoupling the case sizes become a problem, so you are better with small package size X7Rs.

This should really not be a problem but cost is king and it shows how cheap they are making lap top power supplies.

This should really not be a problem but cost is king and it shows how cheap they are making lap top power supplies.

182 page pdf:

http://www.murata.com/products/catalog/pdf/c02e.pdf

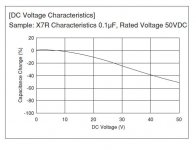

on page 142 (pdf page 161) a graph shows X7R capacitance vs applied voltage. (jpg)

Probably why X7R's are not recommended for frequency sensitive use.

As strict coupling caps...just use a larger value if DC biased.

IMHO.

🙂

http://www.murata.com/products/catalog/pdf/c02e.pdf

on page 142 (pdf page 161) a graph shows X7R capacitance vs applied voltage. (jpg)

Probably why X7R's are not recommended for frequency sensitive use.

As strict coupling caps...just use a larger value if DC biased.

IMHO.

🙂

Attachments

X7Rs provide the BEST decoupling capacitor for digital because of the small package sizes available, the rule for a decoupling capacitor is pick the smallest available package size for the value chosen, usually 1-100nf or a decade set 1-10-100 depending on the chip being decoupled.

There is not one layout I have done for years where small case size X7R MLCC SMD capacitors have been used for the decoupling, with the odd COG used as stated above. With decoupling it is the parasitic inductance that is the killer and so must be reduced to the absolute minimum value, and X7R caps give you the smallest case sizes and thus the lowest parasitic inductance for a given value.

There are areas where there use is not recommended, but like all designs you choose the right capacitor for the job, and for IC decoupling these are the BEST.

There is not one layout I have done for years where small case size X7R MLCC SMD capacitors have been used for the decoupling, with the odd COG used as stated above. With decoupling it is the parasitic inductance that is the killer and so must be reduced to the absolute minimum value, and X7R caps give you the smallest case sizes and thus the lowest parasitic inductance for a given value.

There are areas where there use is not recommended, but like all designs you choose the right capacitor for the job, and for IC decoupling these are the BEST.

So ...I've just learnt that in a SMPS design one should ideally avoid the resonant freq of the cap. Interesting!

When reading through your findings that the inductance is really important in decoupling I think the advertised "long legs" are worse than standards? (Haven't checked the datasheet yet)

PS: Interesting to read your expirience about decoupling.

When reading through your findings that the inductance is really important in decoupling I think the advertised "long legs" are worse than standards? (Haven't checked the datasheet yet)

PS: Interesting to read your expirience about decoupling.

wrt resonant frequency and other finer points of decoupling caps, there's an interesting little app note from TI: How (Not) to Decouple High-Speed Operational Amplifiers

When reading through your findings that the inductance is really important in decoupling I think the advertised "long legs" are worse than standards? (Haven't checked the datasheet yet)

This isn't my findings this is what is taught and has been taught for decoupling for many years, the ever increasing speed of digital circuitry just makes decoupling more critical. Most data speed for high speed FPGA's processors etc have whole sections of decoupling and capacitor placement.

We also use and provide a service for our customers where we use this software:

http://www.algozen.com/DS_CADSTAR_LT_PowerIntegrityAdvanced_ENG_2011_10_05.pdf

So we regularly attend courses on this stuff, like 4 days in Munich last year looking at power supply integrity and decoupling!!!!! Thank goodness for decent German beer, it was my saviour.

If you want any info on it let us know and I'll plow through my links and docs.

When a SMPS has a singing capacitor it is very obvious, what worrys me is that every project I have worked on where this happens the engineer will change the design or cap to get rid of the problem, as it will affect reliability, it worries me that some designs they just let them through!!!!!

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- INFO : The noise of SMD ceramic capacitors