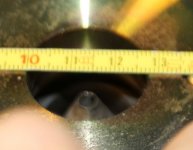

So, i went and measured quickly a bit earlier...

...umm forgot to measure the depth. Great.

anyhow these are the two measurements I took:

25.54mm

34.70mm

The second is very close to what I measured the last time... it's hard

to hit the very lip of the exit, so it is likely a bit bigger around.

You can measure the depth, it's the distance from the mounting face (without the gasket) to the

front most edge of the pole piece (the silver part between the two black parts on the side of the driver).

Sunday the depth can be had.

_-_-

Hello Bear,

On one of my JA6681, opened for verification, I could measure 35mm for the main throat and for the smaller which appears after removal of the front part (throat part) I could measure 27,5mm (so not exactly 1 inch)

See attached pictures.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Attachments

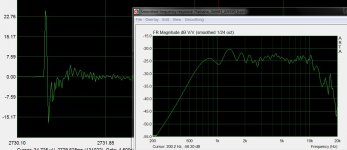

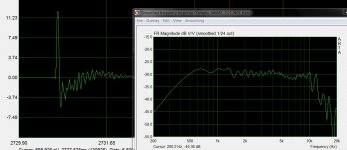

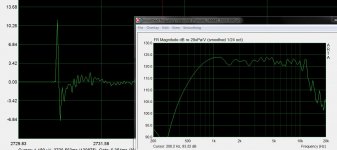

Hello,

Here are 3 screen copies (from Arta audio analysis software) showing the beautiful shape of an unequaized JA6681 on 3 different horns :

- AH550 horn (an axisymetrical Le Cléac'h horn with Fc = 550HZ, built by Martin Seddon in Australia and sold under the brand AzuraHorn),

- J321 horn (an axisymetrical Le Cléac'h horn with Fc = 320HZ, built by Marco Henry and used to be sold under the brand Musique Concrète )

- E-JMLC 600 horn (a non axisymetrical Le Cléac'h horn with Fc = 600Hz, built by Autotech in Poland).

If a better adaptation was provided between the JA6681 (27,5mm throat) and those horns (25,4mm throat) may be the treble will extend at 20kHz, but still the extension in treble is excellent.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Here are 3 screen copies (from Arta audio analysis software) showing the beautiful shape of an unequaized JA6681 on 3 different horns :

- AH550 horn (an axisymetrical Le Cléac'h horn with Fc = 550HZ, built by Martin Seddon in Australia and sold under the brand AzuraHorn),

- J321 horn (an axisymetrical Le Cléac'h horn with Fc = 320HZ, built by Marco Henry and used to be sold under the brand Musique Concrète )

- E-JMLC 600 horn (a non axisymetrical Le Cléac'h horn with Fc = 600Hz, built by Autotech in Poland).

If a better adaptation was provided between the JA6681 (27,5mm throat) and those horns (25,4mm throat) may be the treble will extend at 20kHz, but still the extension in treble is excellent.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Attachments

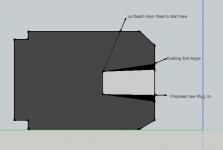

Jean-Michel,do you think a metal plug which fits tightly into the drivers throat and exits at what a LeCleach horn would be at 35mm along (a LeCleach horn profile) the y axis be a worthwhile improvement?

I imagine the 27.5mm to 35mm expansion to have some negative impact.

I imagine the 27.5mm to 35mm expansion to have some negative impact.

Last edited:

Hello 3GGG,

I would recomand to remove the throat cast metallic front part of the JA6681 and to start from the plane at the apex of the phase plug inserting some annular part in the 27,5mm throat and prolongating then in a Le Cléac'h horn. (an angle of 0° or lesser than 5° can be considered).

Myself I intend to use one of my pairs of JA6681 with an E_Jmlc horns and will just introduce an annular part at the exit of the driver after to obtain a 25,4mm throat.

Best regards from Paris, France

Jean-Michel Le Cléac'h

I would recomand to remove the throat cast metallic front part of the JA6681 and to start from the plane at the apex of the phase plug inserting some annular part in the 27,5mm throat and prolongating then in a Le Cléac'h horn. (an angle of 0° or lesser than 5° can be considered).

Myself I intend to use one of my pairs of JA6681 with an E_Jmlc horns and will just introduce an annular part at the exit of the driver after to obtain a 25,4mm throat.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Hello 3GGG,

I would recomand to remove the throat cast metallic front part of the JA6681 and to start from the plane at the apex of the phase plug inserting some annular part in the 27,5mm throat and prolongating then in a Le Cléac'h horn. (an angle of 0° or lesser than 5° can be considered).

Myself I intend to use one of my pairs of JA6681 with an E_Jmlc horns and will just introduce an annular part at the exit of the driver after to obtain a 25,4mm throat.

Best regards from Paris, France

Jean-Michel Le Cléac'h

How would you attach the horn without the cast? The surface underneath is shiny metal without holes, and I don't want to drill so close to the magnet.

I used a digital dial caliper.

The smaller measurement was to the bottom of the pole piece, not the exit of the pole piece. I can do this since I have one driver that is truly completely disassembled. Pole piece removed from the magnet. Do not fear, I did not destroy a useful driver - it was submerged in salt water and was corroded and covered with salt deposits.

3GGG, if you have a lathe, there is enough "meat" in the casting to move the angle a few degrees. Otherwise you have to machine a new piece for the job.

Rewind, how is the present front held on? You could work off those holes with a new piece/adapter to mount the horn?

The smaller measurement was to the bottom of the pole piece, not the exit of the pole piece. I can do this since I have one driver that is truly completely disassembled. Pole piece removed from the magnet. Do not fear, I did not destroy a useful driver - it was submerged in salt water and was corroded and covered with salt deposits.

3GGG, if you have a lathe, there is enough "meat" in the casting to move the angle a few degrees. Otherwise you have to machine a new piece for the job.

Rewind, how is the present front held on? You could work off those holes with a new piece/adapter to mount the horn?

How would you attach the horn without the cast? The surface underneath is shiny metal without holes, and I don't want to drill so close to the magnet.

Hello Rewind,

There is 2 screws that you can remove and use to fix the horn.

See picture :

http://www.diyaudio.com/forums/atta...compression-driver-ja6681_smaller_throat_.jpg

Best regards from Paris, France

Jean-Michel Le Cléac'h

That is a simple solution!

Hello Rewind,

There is 2 screws that you can remove and use to fix the horn.

See picture :

http://www.diyaudio.com/forums/atta...compression-driver-ja6681_smaller_throat_.jpg

Best regards from Paris, France

Jean-Michel Le Cléac'h

Those screws are too tight. And the driver is so beautiful with that fake alnico extension.

I managed with a method I have come to call the pen-trick!

If the pen is pushing away your new horn throat, when it is aligned with the drivers throat, then you still have some more grinding left to do.

I managed with a method I have come to call the pen-trick!

If the pen is pushing away your new horn throat, when it is aligned with the drivers throat, then you still have some more grinding left to do.

Attachments

Last edited:

Those screws are too tight. And the driver is so beautiful with that fake alnico extension.

If the pen is pushing away your new horn throat, when it is aligned with the drivers throat, then you still have some more grinding left to do.

Hello Rewind,

I don't care of anything fake and never take in consideration cosmetics, so I used to modify many drivers I have...

You have to use some solvent before they seem glued But i succeed to remove them on one of the pairs of JA6681A I possess and I could mount them on my E-Jmlc 600 horn (see the obtained frequency response in a recent message).

Bestregards from Paris, France

Jean-Michel Le Cléac'h

Hello Rewind,

I don't care of anything fake and never take in consideration cosmetics, so I used to modify many drivers I have...

You have to use some solvent before they seem glued But i succeed to remove them on one of the pairs of JA6681A I possess and I could mount them on my E-Jmlc 600 horn (see the obtained frequency response in a recent message).

Bestregards from Paris, France

Jean-Michel Le Cléac'h

Cosmetics mean everything to me, so I built the horn around the drivers extension throat. Seems to be good for a horn that can play down to 500-600Hz. The bigger half should be identical to a Avantgarde Trio when I am done with it.

Below it another pair of yammies will be playing to around 340Hz. I was looking at the JMLC 200 horn foe this. Is this the best option to reach 340Hz?

Last edited:

Use one driver - it is a shame to waste two of these drivers, or to use the 6681 for just one octave.

If one was to make a break it ought to be above say 4500Hz or higher... imo

If one was to make a break it ought to be above say 4500Hz or higher... imo

Trying that now since I accidently smashed my tubes with a Fane S 8M that came flying through the air. And it is not working for me. I can't wait to get the kugelwellen trio mids channel in working condition to properly load 600-2500Hz.

Trying that now since I accidently smashed my tubes with a Fane S 8M that came flying through the air. And it is not working for me. I can't wait to get the kugelwellen trio mids channel in working condition to properly load 600-2500Hz.

Let us know on listening impressions

Someone can do the trig now...

... the height of the throat section, NOT including the pole piece is ~50mm

or 2"...

... the height of the throat section, NOT including the pole piece is ~50mm

or 2"...

I measured one of my drivers with a plastic ruler tonight. The diameter of the exit of the throat section is 35 mm, that of the entry is 27 mm. The length of the throat including the two thin gaskets (cork at the entry and rubber at the exit) is 52 mm. Doing the math gives an angle of 4.4 degrees per side.

Jean-Michel measured 27.5 mm at the entry of the throat. On such a short distance, half a mm makes a difference. Using his figure yields 4.1 degrees instead of 4.4.

I discovered that the phase plug in both of my units has corroded. I purchased them from eBay and don't know in what conditions they were used or stored. Wondering if this is a common problem and if it will affect the sound... I have not tested them yet.

Pierre

Jean-Michel measured 27.5 mm at the entry of the throat. On such a short distance, half a mm makes a difference. Using his figure yields 4.1 degrees instead of 4.4.

I discovered that the phase plug in both of my units has corroded. I purchased them from eBay and don't know in what conditions they were used or stored. Wondering if this is a common problem and if it will affect the sound... I have not tested them yet.

Pierre

greetings just an inquiry i got 4 of these driver units and my problem is the diaphragm and coils which are already busted when i got them i thought we could rewind them but the diaphragms are already torn is there any way possibly for me to acquire replacements? did radian already produced replacements?

thanks for your help guys

thanks for your help guys

greetings just an inquiry i got 4 of these driver units and my problem is the diaphragm and coils which are already busted when i got them i thought we could rewind them but the diaphragms are already torn is there any way possibly for me to acquire replacements? did radian already produced replacements?

thanks for your help guys

The diaphragms are irreplaceable sorry. I m sure someone has some but I had not seen any in the market for years.

Radian did not reply to my query to manufacture a batch of replacement diaphragms.

- Home

- Loudspeakers

- Multi-Way

- Info on the Yamaha JA-6681 compression driver