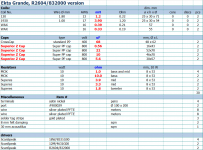

I am making Ekta Grandes with the following dampening in place from Troels Gravesen's design:

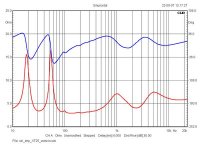

With this dampening, I have the attached impedance curve. So I still have some resonances at 100 and 200khz and a bit of a ripple at 400khz. I am hoping for suggestions on where to add dampening to lower the resonances even more. I can't add anything at the bottom anymore because of the crossovers. Maybe a clue is that with the port stuffed, those resonance bumps are significantly decreased.

Thanks!

Damping of cabinet: Use 8 mm felt material and 30 mm polyester foam (Acoustilux). Add felt to all internal panels incl. mid cab except front panel and bracings. Add four layers of 30 mm Acoustilux to the bottom of cabinet and two layers to top.

Place two layers of Acoustilux behind 18W drivers and behind 12M middriver.

Place two layers of Acoustilux behind 18W drivers and behind 12M middriver.

With this dampening, I have the attached impedance curve. So I still have some resonances at 100 and 200khz and a bit of a ripple at 400khz. I am hoping for suggestions on where to add dampening to lower the resonances even more. I can't add anything at the bottom anymore because of the crossovers. Maybe a clue is that with the port stuffed, those resonance bumps are significantly decreased.

Thanks!

Attachments

Something is wrong with the drivers loading. Measure one raw woofer in the air for t/s parameters first.

I am making Ekta Grandes with the following dampening in place from Troels Gravesen's design:

Damping of cabinet: Use 8 mm felt material and 30 mm polyester foam (Acoustilux). Add felt to all internal panels incl. mid cab except front panel and bracings. Add four layers of 30 mm Acoustilux to the bottom of cabinet and two layers to top.

Place two layers of Acoustilux behind 18W drivers and behind 12M middriver.

With this dampening, I have the attached impedance curve. So I still have some resonances at 100 and 200khz and a bit of a ripple at 400khz. I am hoping for suggestions on where to add dampening to lower the resonances even more. I can't add anything at the bottom anymore because of the crossovers. Maybe a clue is that with the port stuffed, those resonance bumps are significantly decreased.

Thanks!

If it isn't a cabinet leakage, it is resonance.

To deal with 180Hz resonance (standing wave in floorstanding loudspeaker) i had to use 10cm of felt on the bottom of the cabinet.

All of the problems you have are visible in Troels measurements but are hidden behind graph scaling.

Try adding some on the top baffle or layers of felt on the bottom instead. Acoustilux is too porous to absorb 100Hz-200Hz.

Last edited:

Something is wrong with the drivers loading. Measure one raw woofer in the air for t/s parameters first.

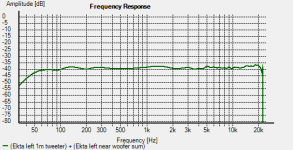

I'm not sure why you say that. Fb is intentionally lower than Fs. In any case, attached is the curve for the original built by Troels which I am aiming at. There still are some resonances, but very tiny.

Attachments

If it isn't a cabinet leakage, it is resonance.

To deal with 180Hz resonance (standing wave in floorstanding loudspeaker) i had to use 10cm of felt on the bottom of the cabinet.

All of the problems you have are visible in Troels measurements but are hidden behind graph scaling.

Yes, you are right about the scaling! Should have looked at that. Anyway, does it make sense to replace all or some of the acoustilux at bottom with felt? Does it make sense to add felt on the wall opposite the port?

Yes, you are right about the scaling! Should have looked at that. Anyway, does it make sense to replace all or some of the acoustilux at bottom with felt? Does it make sense to add felt on the wall opposite the port?

Of course. I've edited my post from above suggesting just that.

Try to add brace (presfit just for testing) about 5cm away from port inside the cabinet. Attach 2-3 layers of felt on that brace and measure between steps to see if it works. Similar thing is done by Technics in their two way coaxial speaker. It had problem probably higher in frequency but it doesn't hurt to try.

Last edited:

Try adding some on the top baffle or layers of felt on the bottom instead. Acoustilux is too porous to absorb 100Hz-200Hz.

Ahh... more felt. I'm going to do that before trying the brace because that would require more manipulation. Part of my problem is that I am reluctant to remove the crossovers because of the way I fastened them inside.

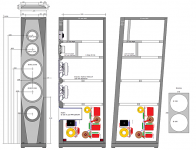

About adding felt on the top baffle. I am doing the angled version and from the attached you can see that the tweeter has its own compartment behind the baffle. So where would the felt on the top baffle go?

Appreciate your help, Zvu!

Attachments

Two choices

After a fretful descent into a rabbit hole of trying various dampening alternatives and measuring impedances, I am down to two choices. The lowest standing wave bumps I am able to achieve with the vented enclosure is with stuffing the two holes in the brace between the two woofers with rolled-up acoustilux. That's the first impedance graph. The drawback is that the impedance of the port resonance is lowered compared to leaving the two holes open, which on the other hand has more pronounced standing waves, as you can see in the second graph. Which should I choose, assuming I am limited to these two choices? Guidance welcome!!!

After a fretful descent into a rabbit hole of trying various dampening alternatives and measuring impedances, I am down to two choices. The lowest standing wave bumps I am able to achieve with the vented enclosure is with stuffing the two holes in the brace between the two woofers with rolled-up acoustilux. That's the first impedance graph. The drawback is that the impedance of the port resonance is lowered compared to leaving the two holes open, which on the other hand has more pronounced standing waves, as you can see in the second graph. Which should I choose, assuming I am limited to these two choices? Guidance welcome!!!

Attachments

Air resonances are the least of your problems. They can be taken care of in a matter of minutes. Your drivers behave nothing like Troels' do. Check both of the impedance graphs again.

Please help me understand. Fs, Fb, and the tweeter and mid drivers are very similar, but the ohms of the port resonance frequency, the first hump, is much lower than his, but Troels thinks that's acceptable. Also, my standing waves are not that different than his if you consider the differences in the graph scales.

- Home

- Loudspeakers

- Multi-Way

- Impedance Curve and Dampening question