Hi All

As per the title above, I was wondering if anyone had a picture of an un-folded AMT diaphragm. I'm in the middle of bodging together a small clone or three to fill my evenings and want to keep the whole project under 60GBP so replacement diaphragms are out.

So far I've spent:

25GBP on mild steel.

30GBP on magnets.

10GBP on various thicknesses of Mylar/PET

0GBP on alu foil from the kitchen.

Ideally i'd also like to know the overall dimensions and the number and depth of the pleats so I know how much density to achieve in MY folded element. I'm also nosey for just what they look like! 😀

I've had a rough attempt working but think that I need more pleats so need to narrow pleat width and increase the number, parallelling some of them, as Re was already high.

I've searched all over the net and there are no pics that I can find, surely someone took a pic or two when they pulled out a duff element for replacement.

Pics of everything WILL follow but not till I'm finished and they work. 🙄

Cheers

Nick.

As per the title above, I was wondering if anyone had a picture of an un-folded AMT diaphragm. I'm in the middle of bodging together a small clone or three to fill my evenings and want to keep the whole project under 60GBP so replacement diaphragms are out.

So far I've spent:

25GBP on mild steel.

30GBP on magnets.

10GBP on various thicknesses of Mylar/PET

0GBP on alu foil from the kitchen.

Ideally i'd also like to know the overall dimensions and the number and depth of the pleats so I know how much density to achieve in MY folded element. I'm also nosey for just what they look like! 😀

I've had a rough attempt working but think that I need more pleats so need to narrow pleat width and increase the number, parallelling some of them, as Re was already high.

I've searched all over the net and there are no pics that I can find, surely someone took a pic or two when they pulled out a duff element for replacement.

Pics of everything WILL follow but not till I'm finished and they work. 🙄

Cheers

Nick.

Last edited:

I was wondering if anyone had a picture of an un-folded AMT diaphragm.

You might check out the DIY AMT article posted here:

http://www.diyaudio.com/forums/planars-exotics/171441-hornloading-heil-amt1-6.html#post2399614

There is a picture of an unfolded diaphragm on page 22.

There is a picture of an unfolded diaphragm on page 22.

Thanks for the heads up but I had already seen that and I have the original Neil Davis/AA article (I have been searching), I was hoping for one of the OEM diaphragms, I shall keep looking.

Nick.

I'll mail some files for you, if you provide an address which will accept a 2 Mbyte file 😉

Last edited:

Baldin

Thank you for the offer, you could try:

Nick at kowal1 dot fsnet dot uk

replacing the at for @ and dot for . as required.

Nick.

Thank you for the offer, you could try:

Nick at kowal1 dot fsnet dot uk

replacing the at for @ and dot for . as required.

Nick.

Baldin

I've just re-checked this thread and realised the email address I put up was wrong, my apologies, 800mile road trips tend to make me overly tired.

would you mind re-sending the email but to:

nick at kowal1 dot fsnet dot co dot uk

Sorry for wasting your time and thanks again.

Nick.

I've just re-checked this thread and realised the email address I put up was wrong, my apologies, 800mile road trips tend to make me overly tired.

would you mind re-sending the email but to:

nick at kowal1 dot fsnet dot co dot uk

Sorry for wasting your time and thanks again.

Nick.

Two items in this post.

First: Thanks to Baldon for his email.

Secondly: I've completed the first of the tweeters and it seems to be working nicely when i just run it instead of the tweeter in my main system so progress continues on the other two (I want them all across the fronts of my main system) I will try and get some freq responses done next week.

Now the reason for my post. I had to sell all my spare drivers some time ago and I would like to build a nice low/mid section to match these tweeters.

I was thinking cheap transmission lines, and the cheapest drivers I've seen recently that appeal are the Eminence Alpha 8A. does anyone have an opinion on these before I buy them or download the MJK worksheets. Basically I want a low cost TL and I dont really want full range, so fostex are out, some suggestions of completed projects would be nice as time and cash are limited right now.

Thanks

Nick.

PS: cant seem to upload photos or create albums etc.. anyone know how to do this?

PPS: found it

First: Thanks to Baldon for his email.

Secondly: I've completed the first of the tweeters and it seems to be working nicely when i just run it instead of the tweeter in my main system so progress continues on the other two (I want them all across the fronts of my main system) I will try and get some freq responses done next week.

Now the reason for my post. I had to sell all my spare drivers some time ago and I would like to build a nice low/mid section to match these tweeters.

I was thinking cheap transmission lines, and the cheapest drivers I've seen recently that appeal are the Eminence Alpha 8A. does anyone have an opinion on these before I buy them or download the MJK worksheets. Basically I want a low cost TL and I dont really want full range, so fostex are out, some suggestions of completed projects would be nice as time and cash are limited right now.

Thanks

Nick.

PS: cant seem to upload photos or create albums etc.. anyone know how to do this?

PPS: found it

Last edited:

the magnets are badly placed , only half of the stacked sheets have contact to the pole surface , a lot of flux is wasted , change the geometry for more efficiency ..

Actually the magnets contact all the laminations as the openings/shorter laminations have 45 degree cuts reversed from the longer pieces so there are no gaps.

Nick.

Nick.

ah okay hard to see on the pic .. but the flux can be unevenly distributed across the conductors , a FEMM simulation would show you where there is room for improvement , even it is only a 2D FEA program (freeware) .....

<vent>

I can't currently get ARTA to work, stoooooopid thing, I want graphs damnit!

</vent>

Pictures WILL follow at some point.

Nick.

I can't currently get ARTA to work, stoooooopid thing, I want graphs damnit!

</vent>

Pictures WILL follow at some point.

Nick.

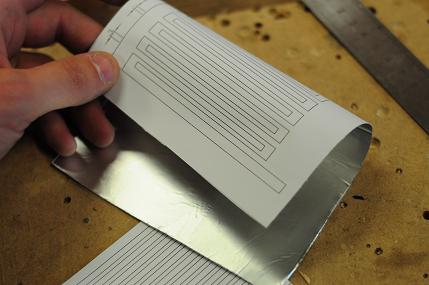

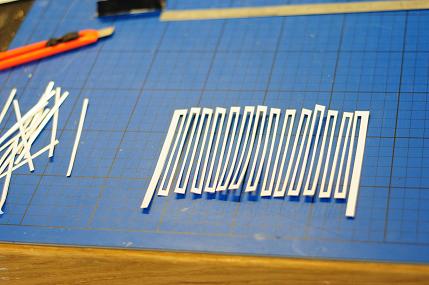

My Diaphragms

So I've made diaphrams, I have achieved an Re of around 3.2Ohms which shouldn't kill my amps and is close to the AMT-1 of 2.9Ohms.

I was having issues with torn foil so I started to tack it to the paper overlay with the required pattern on.

Used:

Sainsburys basics range kitchen foil.

5 micron Mylar (model airplane lightweight covering material)

2 micron Mylar (model airplane lightweight covering material)

3M Spray adhesive (for Photo mounting)

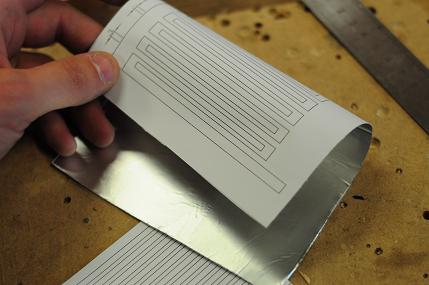

First I print a 1:1 scale drawing of my pattern on paper then I spray the back of this with a very light coat of glue.

I spray for as long as it takes me to make the sound "Tsch", just like the spray can!

This is then bonded to the foil, I do this as I was losing 90% of my attempts due to ripped foil, I'm now getting around an 80% success rate.

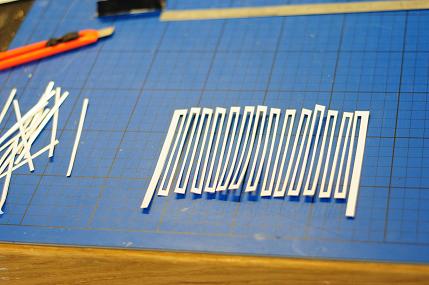

I then cut the pattern out of the paper/foil.

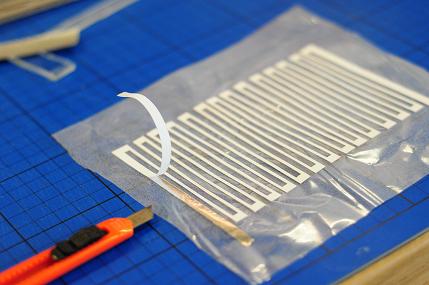

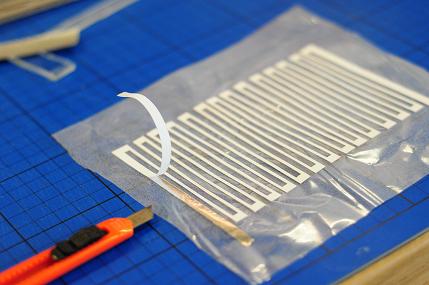

Next I turn the pattern over so the foil layer is uppermost and I spray the 5 micron mylar liberally with the spray adhesive.

(I mistakenly bought metallised 5 micron mylar so remove the metal with Mr Muscle foaming oven cleaner, it takes alu off a treat due to the NaOH!)

Once the glue is evenly on the mylar I stick it to the foil.

The next step is to remove the paper from the foil, this should be easy if you used little enough glue, if not I can recomment RS label remover and a cotton bud (Q-tip).

If you get the paper damp this should be enough to release the glue and prevent ripping, do not apply to the mylar!

Once removed there should be sufficient tack on the 5 micron mylar left to stick down a layer of 2 micron mylar, this completes the diaphragm.

All that is left to do is fold the diaphragm. I use the edge of a plastic rule to get a nice rounded edge.

Nick.

So I've made diaphrams, I have achieved an Re of around 3.2Ohms which shouldn't kill my amps and is close to the AMT-1 of 2.9Ohms.

I was having issues with torn foil so I started to tack it to the paper overlay with the required pattern on.

Used:

Sainsburys basics range kitchen foil.

5 micron Mylar (model airplane lightweight covering material)

2 micron Mylar (model airplane lightweight covering material)

3M Spray adhesive (for Photo mounting)

First I print a 1:1 scale drawing of my pattern on paper then I spray the back of this with a very light coat of glue.

I spray for as long as it takes me to make the sound "Tsch", just like the spray can!

This is then bonded to the foil, I do this as I was losing 90% of my attempts due to ripped foil, I'm now getting around an 80% success rate.

I then cut the pattern out of the paper/foil.

Next I turn the pattern over so the foil layer is uppermost and I spray the 5 micron mylar liberally with the spray adhesive.

(I mistakenly bought metallised 5 micron mylar so remove the metal with Mr Muscle foaming oven cleaner, it takes alu off a treat due to the NaOH!)

Once the glue is evenly on the mylar I stick it to the foil.

The next step is to remove the paper from the foil, this should be easy if you used little enough glue, if not I can recomment RS label remover and a cotton bud (Q-tip).

If you get the paper damp this should be enough to release the glue and prevent ripping, do not apply to the mylar!

Once removed there should be sufficient tack on the 5 micron mylar left to stick down a layer of 2 micron mylar, this completes the diaphragm.

All that is left to do is fold the diaphragm. I use the edge of a plastic rule to get a nice rounded edge.

Nick.

Last edited:

Cool. Thanks for sharing 😎

What do you use for the frame, where to you you mount the diaphragm?

And what glue do you use for this?

Baldin 🙂

What do you use for the frame, where to you you mount the diaphragm?

And what glue do you use for this?

Baldin 🙂

Hello Nick - I think that the work you are sharing with us here is absolutely fantastic!!!

I'm interested in how you went about mounting the folded diaphragm and also wondering about using a different (i.e. fewer parts - less complicated) magnet arrangement similar to Beyma TPL-150 or the AMT-3's.

I'm interested in how you went about mounting the folded diaphragm and also wondering about using a different (i.e. fewer parts - less complicated) magnet arrangement similar to Beyma TPL-150 or the AMT-3's.

Baldon and c2cThomas, thanks for the kind words, none of this work is finished yet and I'm just experimenting with things.

Here is the element mounted in a perspex frame

This isnt finished yet as there is some unwanted movement in the diaphragm, I intend to try using cotton thread to ensure everything stays in place.

The diaphragm is held to the frame with generic double sided tape and will be mounted in the magnetic circuit with wedges and foam.

The glue used to hold the mylar and alu foil is this:

3M Spray adhesive

Hope that is some more useful info.

Nick

PS: Thomas I was considering a simpler magnet sturcture but I wanted something ott to look at, I may look at different structures in the future but I'm happy for the moment.

I will have a look for some of my notes and reasoning on other structures.

Here is the element mounted in a perspex frame

This isnt finished yet as there is some unwanted movement in the diaphragm, I intend to try using cotton thread to ensure everything stays in place.

The diaphragm is held to the frame with generic double sided tape and will be mounted in the magnetic circuit with wedges and foam.

The glue used to hold the mylar and alu foil is this:

3M Spray adhesive

Hope that is some more useful info.

Nick

PS: Thomas I was considering a simpler magnet sturcture but I wanted something ott to look at, I may look at different structures in the future but I'm happy for the moment.

I will have a look for some of my notes and reasoning on other structures.

Last edited:

Hello Nick - thank you for posting the photo of your diaphragm. If you look at the Heil patent there are some square cutouts that align with the pleats (folds). These were used to anchor the top and bottom of the diaphragm to the frame and thus space the alignment between the folds. Hope this info helps.

Ooh I really should re-read the patents, however this batch of diaphragms is done.

I'll try the cotton with these and change the layout for the next batch as I want to try a slightly wider strip of foil so I can make a bigger diaphragm with more pleats.

I was using toilet paper before, nice and transparent when the plys are seperated!

Nick

I'll try the cotton with these and change the layout for the next batch as I want to try a slightly wider strip of foil so I can make a bigger diaphragm with more pleats.

I was using toilet paper before, nice and transparent when the plys are seperated!

Nick

Last edited:

Hi Nick

Do you really think the non-permanent spray will hold for long?

For the planar prototype I have made I used 3M permanent spray. Still looks to hold after 2 years (but they haven't been playing much), but I would actually consider something like diluted Araldite or something ...

But 3M also has something much stronger than the oe you are using:

90 HIGH STRENGTH AERO ADHESIVE - Nextag Stores

Do you have any means to make measurements of the units??

Would be super cool to see both freq response and distortion figures.

What is the sensivity of the drivers (just like same as a normal dome, more, or less)?

And again, you are really on to something here 😎 .... keep it up, and keep us posted 🙂

Best regards Baldin

Do you really think the non-permanent spray will hold for long?

For the planar prototype I have made I used 3M permanent spray. Still looks to hold after 2 years (but they haven't been playing much), but I would actually consider something like diluted Araldite or something ...

But 3M also has something much stronger than the oe you are using:

90 HIGH STRENGTH AERO ADHESIVE - Nextag Stores

Do you have any means to make measurements of the units??

Would be super cool to see both freq response and distortion figures.

What is the sensivity of the drivers (just like same as a normal dome, more, or less)?

And again, you are really on to something here 😎 .... keep it up, and keep us posted 🙂

Best regards Baldin

Baldin

I have had a square of sprayed mylar hanging in the lab open to the air for several weeks now and it is still sticky so I have reasonably high hopes for its holding ability.

If it fails in the future I will investigate other options, for now it was what I had available so I used it, the fact that the build up (thickness) is low I consider a desirable trait so I will stick with spray adhesives, I would think that Araldite would probably become too brittle once set to be considered a suitable alternative.

I have been trying to get my old measurement system working but have too many computers which dont appear suitable, also my original laptop with external soundcard has been formatted and the card disappeared so am having trouble getting a measurement system working, this will be a task for this weekend assuming my wife lets me.

I too would like frequency, sensitivity, phase, impedance, distortion and TS parameters but initially I will settle for the first two.

Sensitivity appears to be higher than a standard dome, I have two magnetic circuits completed, they are the same except one has a 9mm gap and the other a 6mm gap, the 6mm gap is much more efficient, with them both playing I cannot hear the tweeter with the larger gap!

I've no idea of freq response but it sounds better than a portable radio when I play full frequency music through it, though bass is obviously missing.

Nick.

I have had a square of sprayed mylar hanging in the lab open to the air for several weeks now and it is still sticky so I have reasonably high hopes for its holding ability.

If it fails in the future I will investigate other options, for now it was what I had available so I used it, the fact that the build up (thickness) is low I consider a desirable trait so I will stick with spray adhesives, I would think that Araldite would probably become too brittle once set to be considered a suitable alternative.

I have been trying to get my old measurement system working but have too many computers which dont appear suitable, also my original laptop with external soundcard has been formatted and the card disappeared so am having trouble getting a measurement system working, this will be a task for this weekend assuming my wife lets me.

I too would like frequency, sensitivity, phase, impedance, distortion and TS parameters but initially I will settle for the first two.

Sensitivity appears to be higher than a standard dome, I have two magnetic circuits completed, they are the same except one has a 9mm gap and the other a 6mm gap, the 6mm gap is much more efficient, with them both playing I cannot hear the tweeter with the larger gap!

I've no idea of freq response but it sounds better than a portable radio when I play full frequency music through it, though bass is obviously missing.

Nick.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Image Request: AMT / Heil diaphragm.