Hi, im not that good at cutting strange shapes thru a chassis, Whats an alternative to an IEC socket something round i could use instead ?

2 Pcs Black 3 Pin IEC320 C14 Plug Power Socket Connector AC 250V 15A | eBay

2 Pcs Black 3 Pin IEC320 C14 Plug Power Socket Connector AC 250V 15A | eBay

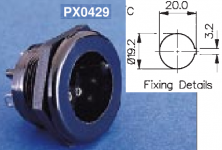

IEC-style with mounting specs of the orig. Bulgin

Seems to be made to fit a 20mm round hole, & I think this is the bulgin they mean

Rgds

James

Seems to be made to fit a 20mm round hole, & I think this is the bulgin they mean

Rgds

James

Attachments

A PX0249 is only rated at 50Volts! There is a proprietary tank cutter, (Q Max type) from RS Components, Maplin, CPC and Farnell to list a few. Makes life easy and looks professional.

Search for IEC tank cutter.

Search for IEC tank cutter.

If you have a graphics program, you can make a template for the cutout, and then use that to trace the pattern on your box.

I start with a large drill, and then use a combination of a metal nibbler and a files to make the IEC cutout.

I think most IEC's cover up the hole itself, so they are forgiving of non perfect cutouts, you really can't see how bad it is 😉.

The other thing you can do is forget the IEC, and just wire directly from the plug to whatever you are powering. If you go this route, you just need to drill a hole, and put a grommet in it so the metal does cut the cable. I would also tie it down inside the chassis some where to provide strain relief.

Randy

I start with a large drill, and then use a combination of a metal nibbler and a files to make the IEC cutout.

I think most IEC's cover up the hole itself, so they are forgiving of non perfect cutouts, you really can't see how bad it is 😉.

The other thing you can do is forget the IEC, and just wire directly from the plug to whatever you are powering. If you go this route, you just need to drill a hole, and put a grommet in it so the metal does cut the cable. I would also tie it down inside the chassis some where to provide strain relief.

Randy

enlarge the round hole to the final shape and size with a file.

Thanks yes this is what i did last time took a while but did the trick nicely

If your panel is aluminum, I have had good luck drilling small holes in the corners, and a large hole in the middle and use a saber saw with a wood blade to cut away the remainder material then finish with a file. Most wood blades and hole saws will cut aluminum. Though I did invest in a freud triple chip blade for my table saw when I cut sheet aluminum to size.

Bill

Bill

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- IEC alternative