How high?

All my outputs are 4P1L these days, so the HT stays under 300v. That's still dangerous, of course, but it's not like 600v or 1,000v....

over 1.5kv....

Aha the contest who has the highest voltage. I have seen quite some amps with B+ over 1 kV in homes with pets and children without cover and unsafe wiring. Not something I would brag about.

Working with high voltage installations one learns a lesson or two ;-)

Working with high voltage installations one learns a lesson or two ;-)

My problem is that I am a lurker.....I can and do lurk for ages on DIYA.BTW I hate that word.I'm not concealing or hiding my where abouts!

It's so addictive going from one topic to another and then there's the pictures of various posters builds.

Aargh! diyaudio.com is addictive!!! it takes me away from diy audio.

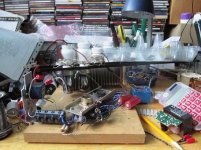

Here is what I've been building since March last year.Yes that's right,over a year ago!! Somebody please shoot me.

It's so addictive going from one topic to another and then there's the pictures of various posters builds.

Aargh! diyaudio.com is addictive!!! it takes me away from diy audio.

Here is what I've been building since March last year.Yes that's right,over a year ago!! Somebody please shoot me.

Attachments

Wow I too am the polar opposite, I hate the chassis metal work but I like the soldering and wiring. I sit there and procrastinate on drilling for days until I build the courage. I am a mechanic by trade and I hate drilling and tapping, I actually do a good job at it but I hate doing it. I just had to fix a Dodge Durango w/ a 4.7L, the exhaust manifold bolts rot out and break off, I love spending the afternoon drilling in a confined area with a drill that can break my wrists.

Lately I want to look into learning some sort of CAD program so I can just send out a file to a company to make me a chassis.

I got a copy of AutoCad 2016 and I'm learning to use it. I love the copy function where I draw a component such as a tube socket with nice ventilation holes and copy it where I need it. I'm using recessed RCA jacks which require a precision, odd sized hole with two countersunk screws. I could never be as consistent with something like this using hand tools. I've been using Landfall Systems for chassis. Great guys with an excellent product. They built their own CNC router.

Speaking of high voltages, it's not at all fun to get jolted by a modern ignition coil.

I feel the same way, it's hard for me to get accuracy and consistency with hand tools. I feel like the chassis is the part everybody sees so I want it to look perfect.

I got a copy of AutoCad 2016 and I'm learning to use it. I love the copy function where I draw a component such as a tube socket with nice ventilation holes and copy it where I need it. I'm using recessed RCA jacks which require a precision, odd sized hole with two countersunk screws. I could never be as consistent with something like this using hand tools. I've been using Landfall Systems for chassis. Great guys with an excellent product. They built their own CNC router.

I feel the same way, it's hard for me to get accuracy and consistency with hand tools. I feel like the chassis is the part everybody sees so I want it to look perfect.

the high voltages scares the hell out of me.......

Hmm , tube guys are worried about low I + 400V.

Us Class AB guys are worried about High I (melted screwdrivers) @ 60V.

Either can cause a "heart attack" with a ill positioned probe or finger. 😀

OS

Speaking of high voltages, it's not at all fun to get jolted by a modern ignition coil.

I've helped a few people upgrade classic Rover V8s (that buick cast off) from dizzy to wasted spark. When checking for a misfire the traditional test was to pull plugs and see if the misfire changed. After the upgrade owners only did it once!

Also good for jacobs ladders.

Hmm , tube guys are worried about low I + 400V.

Us Class AB guys are worried about High I (melted screwdrivers) @ 60V.

Either can cause a "heart attack" with a ill positioned probe or finger. 😀

OS

a youngster doing electronics, i once touched the anode cap of our 21 inch Admiral bnw tv set, i am glad i still live......that is how i got the scare of high voltages.....

i still bear scars at the back of my hand as reminders....

I did (CRT) TV's for 15 years. The 3 tube projection units used 50kV+ across

the R/G/B tubes. Lots more barium , bigger emitter (gun). More current on those

anodes.

I got shocked by one of those (with it on). WOW ! this changed my HV safety

checks considerably.

I did get shocked by charged anodes (set off - residual) ... occasionally.

The 50K experiance , I ALWAYS discharged everything afterwards.

Most 19-25" (color) sets had smaller 25-30kV supplies , nowhere near the robustness

of the 50K projection units.

PS - B and W .... Ha , never more than 15K , very low current flyback. I touch them for fun. 😀😀😀

OS

the R/G/B tubes. Lots more barium , bigger emitter (gun). More current on those

anodes.

I got shocked by one of those (with it on). WOW ! this changed my HV safety

checks considerably.

I did get shocked by charged anodes (set off - residual) ... occasionally.

The 50K experiance , I ALWAYS discharged everything afterwards.

Most 19-25" (color) sets had smaller 25-30kV supplies , nowhere near the robustness

of the 50K projection units.

PS - B and W .... Ha , never more than 15K , very low current flyback. I touch them for fun. 😀😀😀

OS

Last edited:

Hi All, I have a pre-amp on my bench that is 98% complete with only 32% left to go. The designing and making the chassis is the fun part for me. I like them to look like little sculptures, but dang, I just have a hard time getting the wiring done. I don't know why, but I hold off on jumping into that part of the project. I can read schematics easily and correctly and have been soldering for years. I have all the necessary test gear and know how to use it, but hold off, compulsively, on the wiring.

Why is that?

Any guesses?

My problem along the same lines as you is I have a s*it load

of Backed-Up audio projects to do. Half of a recap on a Realistic sta-2100. Why I tackled that to start beats me.

About that time I quit on it, I realized I have a sh*t-load of

speakers & I thought it through & decided to do cross-overs

After 5 pair of Infinity's (where they hang on the input). That was enough. I did 25 pair of assorted speakers, looked at the

2100 & it looked a hell of a lot smaller than I remembered.

I always came back to the backups when I felt I could do it.

Too true! Our society (parents, teachers, employers, etc) encourage perfectionism. But once you have it, it actually holds you back a great deal of the time.It comes down to wanting to be 100% "right" or having a perfect outcome...<snip>

...If you want this compulsively, the disappointment of a build that ...doesn't...perform as ....expected.....reach a point of paralysis when even starting.

An acquaintance who is an artist had found herself creatively blocked for a long period of time, and eventually went to a therapist to look for some answers. The therapist said a large part of the problem was her desire to always create a perfect piece of art, which was preventing her from even getting started. In fact, it turns out that mental health professionals now classify perfectionism as a depressive disorder!

When she told me about it, that last part came as quite a shock. 😱

Like so many of us, I have struggled with the same issue (let's call it ingrowing perfectionism) for some years. As a child and young boy, even well into my teens, I was extremely creative, and prodigiously productive with my creations.

That ability got completely knocked out of me in college; there was intense competition, and intense pressure to be absolutely, perfectly, correct, all the time.

Since then, the (often subconscious) desire for a perfect outcome often keeps me from even getting started on a creative project.

Now I am trying to unlearn perfectionism - which is not, as it turns out, an easy thing to do!

-Gnobuddy

Like so many of us, I have struggled with the same issue

Your story sounds so familiar. I was the neighborhood whiz kid who built his own guitar amps, ham radios, and had the only color TV set in the entire neighborhood when the Apollo mission broadcast live color TV from the moon in 1969. There must have been 40 people crammed into my bedroom in the middle of the night to watch it. I had rebuilt a junked 1957 vintage color TV and adapted it to a modern (1966) picture tube.

Yes, my first pass at college (1970 -1972) ended with me leaving due to near zero GPA. 20 years later the second pass had me on the deans list while also working a full time job.....

found herself creatively blocked for a long period of time

Myself and friends used to jam with the tape recorder, two of them actually. It was "poor mans multitracking." We kinda thought we were good at playing the surf music stuff of the 60's......The "end" came when two of us went to see this new guy open for the Monkees, Jimi Hendrix in 1967. After that we realized that we sucked, and within a few weeks we pretty much quit jamming. Most of our tapes got tossed in the lake a few months later.

I bought a real 4 track Teac in the late 70's and had several synthesizers, but never finished a single complete piece of music....it just wasn't good enough. The Teac and all the synths were sold several years later.

I have had a DAW station for about 15 years, but again never finished anything of my own. The stuff I did in Florida still exists on a hard drive somewhere, I haven't seen it yet, but there are still several old drives I haven't gone through, but the old stuff with all my daughter's band mates is likely gone forever. It was done on a DOS / Win 3.1 machine that used RLL drives. Serious percussion by people who knew how to play. State of the art 16 bit 44 KHz stuff too....for the late 90's.

Now I am trying to unlearn perfectionism - which is not, as it turns out, an easy thing to do!

I had a hard time with that at work too....It's hard to argue with a room full of "idiots" when you are on a "design by committee" team. After losing my cool too many times, and becoming rather stressed out, I had to leave the cell phone design group. I told my boss in a large meeting that if I didn't leave, either I was going to have a heart attack, or he was going to have a phone up his a$$, either way, I would be leaving in the back of a city owned vehicle.

I took the only other job available, the research department.....how do you cure perfectionism? You surround yourself with people who are "more perfect" than you. Hey, there really are some better engineers, I just hadn't met many until then. Instead of "inventing the state of the art" I was happy to just build it for the guys that couldn't be bothered with things like PC board layouts and soldering irons......It turned out to be the most fun years of my career. I learned the most too.

Now, If I can only bring myself to hook my newly built synthesizer up to the DAW and record something...........Naw, it would probably just suck.

Familiar in some respects, indeed. In April 1981 I was still a teenager living with my mother and two sisters; my mother had just left my father, and we'd just moved to a new apartment in a new city, leaving behind the radio; we'd never had a TV.

So when I found out from the newspaper that the first Space Shuttle launch was going to be broadcast on local radio in a couple of hours, I grabbed my soldering iron, dived into my box of parts, and quickly soldered together a crude AM radio - basically a crystal radio hooked up to a little audio amplifier I'd made previously.

I remember winding the tuning coil on a piece of cardboard rolled into a tube, soldering it up to a small fixed capacitor (I didn't have a variable one in the junk box), and sliding a little piece of ferrite rod in and out of the tuning coil until the contraption picked up the nearest AM radio station.

With a few feet of lamp cord running up to the ceiling as the antenna, it worked well enough for all of us to listen to the launch broadcast - Columbia making its first flight ever.

Nowhere near as impressive as your bodged-together colour TV, for sure. But it did work, and gave us a little window onto a historic event. And I whipped it up on very short notice, and never stopped to worry whether I could get it done or not.

What would happen now, several decades later, if I found out that NASA was about to launch it's first manned mission to Mars? One thing for sure, I wouldn't be whipping up any quick-n-dirty electronics to let me follow the launch. I don't even remember how to wind an AM radio tuning coil from scratch and get the inductance in the right ballpark for it to work the first time - without even a proper variable tuning capacitor.

I have a possible cure for the worry about making sucky music...just go listen to Sonny and Cher singing "I Got You, Babe". Those two not only created and sang that absurd monstrosity of a song, but actually had the gall (or stupidity, or naiveté ) to present it to the public. And the public liked it...or at least, enough of them did, to make it a hit. 😱

Now, there is no way on earth that anything you create with your new synth could possibly be worse than "I Got You, Babe". Right? So just go do it! 😀

-Gnobuddy

So when I found out from the newspaper that the first Space Shuttle launch was going to be broadcast on local radio in a couple of hours, I grabbed my soldering iron, dived into my box of parts, and quickly soldered together a crude AM radio - basically a crystal radio hooked up to a little audio amplifier I'd made previously.

I remember winding the tuning coil on a piece of cardboard rolled into a tube, soldering it up to a small fixed capacitor (I didn't have a variable one in the junk box), and sliding a little piece of ferrite rod in and out of the tuning coil until the contraption picked up the nearest AM radio station.

With a few feet of lamp cord running up to the ceiling as the antenna, it worked well enough for all of us to listen to the launch broadcast - Columbia making its first flight ever.

Nowhere near as impressive as your bodged-together colour TV, for sure. But it did work, and gave us a little window onto a historic event. And I whipped it up on very short notice, and never stopped to worry whether I could get it done or not.

What would happen now, several decades later, if I found out that NASA was about to launch it's first manned mission to Mars? One thing for sure, I wouldn't be whipping up any quick-n-dirty electronics to let me follow the launch. I don't even remember how to wind an AM radio tuning coil from scratch and get the inductance in the right ballpark for it to work the first time - without even a proper variable tuning capacitor.

I have a possible cure for the worry about making sucky music...just go listen to Sonny and Cher singing "I Got You, Babe". Those two not only created and sang that absurd monstrosity of a song, but actually had the gall (or stupidity, or naiveté ) to present it to the public. And the public liked it...or at least, enough of them did, to make it a hit. 😱

Now, there is no way on earth that anything you create with your new synth could possibly be worse than "I Got You, Babe". Right? So just go do it! 😀

-Gnobuddy

Self doubt is one of the biggest hurdles people face in life and it seems to me that it's often intelligent people who suffer the most from it.

Any human activity not connected to survival is either a time filler or a distraction so enjoy it and don't take it (or yourself) too seriously.

btw i love building amps but i hate not having the budget to do what i want or the patience/capacity to properly learn the theory so i can design my own circuit layouts.

Any human activity not connected to survival is either a time filler or a distraction so enjoy it and don't take it (or yourself) too seriously.

btw i love building amps but i hate not having the budget to do what i want or the patience/capacity to properly learn the theory so i can design my own circuit layouts.

Last edited:

Now, what the ???

I dislike the debug 😕 part of a project. Gives me headaches. Electronic Mysteries are not your friend. Or mine.

I dislike the debug 😕 part of a project. Gives me headaches. Electronic Mysteries are not your friend. Or mine.

Any human activity not connected to survival is either a time filler or a distraction so enjoy it and don't take it (or yourself) too seriously.

btw i love building amps but i hate not having the budget to do what i want or the patience/capacity to properly learn the theory so i can design my own circuit layouts.

Best thought i've heard in a long long time.

I've spent upwards of ten years on a single project due to lack of funds to get it done quicker. But, the end result was very satisfying.

THx-RNMarsh

Thanks Richard, the important bit is achieving satisfaction, that usually takes time.

Who would enjoy a 6 month old single malt whiskey 🙂

Who would enjoy a 6 month old single malt whiskey 🙂

Over the last couple of years, I've re-kindled some of my long-lost enthusiasm for DIY electronics with a guitar amp build. The amp itself has been a bit of an ongoing research project, using oddball valves, and some oddball ideas too.

For testing, the only audio signal generator I have at the moment is a little DDS (digital synthesis) one I built from a kit. Sadly, it has a number of usability problems. I really need a better signal generator.

So of course I decided to design and build my own. I came up with a simple design using a couple of TL072 op-amps, and ran it through LTSpice to work out any major issues; after a few tweaks, it was time to build. Grab some proto-board, set out the soldering iron and wire cutters, off we go.

And that's what brings me back to this thread. When did 0.1 inches suddenly become so tiny? 😕 I can barely tell one pin of the (through-hole) IC from the next. 😡 Soldering is (almost literally) a stab in the dark. 😱 After 30 minutes of straining to see these suddenly too-tiny components, and squinting through a variety of cheap, low-quality magnifying lenses, my middle-aged eyes are watering from the strain. 😡

I'm not yet prepared to say "I hate building electronics". But clearly the days when I happily and effortlessly soldered 0.1" pitch through-hole electronics components using no optical aids are over for good.

Guess I better stick with valves from now on!

-Gnobuddy

For testing, the only audio signal generator I have at the moment is a little DDS (digital synthesis) one I built from a kit. Sadly, it has a number of usability problems. I really need a better signal generator.

So of course I decided to design and build my own. I came up with a simple design using a couple of TL072 op-amps, and ran it through LTSpice to work out any major issues; after a few tweaks, it was time to build. Grab some proto-board, set out the soldering iron and wire cutters, off we go.

And that's what brings me back to this thread. When did 0.1 inches suddenly become so tiny? 😕 I can barely tell one pin of the (through-hole) IC from the next. 😡 Soldering is (almost literally) a stab in the dark. 😱 After 30 minutes of straining to see these suddenly too-tiny components, and squinting through a variety of cheap, low-quality magnifying lenses, my middle-aged eyes are watering from the strain. 😡

I'm not yet prepared to say "I hate building electronics". But clearly the days when I happily and effortlessly soldered 0.1" pitch through-hole electronics components using no optical aids are over for good.

Guess I better stick with valves from now on!

-Gnobuddy

For 41 years I worked at Motorola. At first I worked on the venerable HT220 walkie talkie. All leaded parts hand stuffed into two layer pc boards. Even though it was seriously crowded by anyone's standards, I was 20 years old so changing parts was easy.

In the 80's SMD came, and we actually did a radio, the STX that had both, leaded parts on one side of the PCB, and SMD on the other side of the 6 layer board. Set a couple of the early prototype boards on fire attempting to fix internal shorts with a 20 amp power supply equipped with a "NoBlo" fuse. It was a standard glass fuse filled with solder. I made it just for fixing those pesky shorted PC boards. Sometimes it actually worked.

The 90's and 00's brought smaller and smaller SMD parts. My eyes weren't getting any younger, but they kept getting me better microscopes. The problem was my shaky hands. OK, I left the cell phone rat race and got into a research group that was working on big mobile (car trunk mounted) radio equipment. That worked for a while, but when a big a$$ mobile radio that weighs in at over 20 pounds uses 0204 SMD (.020" by .040") parts, something is wrong. WHY? When you are making a million cell phones a month guess which parts you get the cheapest?

By 2014 the peak to peak vibration in my hands became larger than even the big SMD stuff, so I took the buyout and left.

Soldering tube amp parts is still easy. Blowing stuff up is still fun to me, and fixing what I blow up is still an educational experience. Fixing the messed up software I write, not so much fun, but still educational. Sometimes it's frustrating, but you have to keep learning, something, even if it's what not to do tomorrow. Just keep at it.

So when I was vacationing in Florida, after stopping at ESRC to pick up 270 tubes, I went to Planet Surplus and bought a microscope exactly like the one I had back in the cell phone days. The 30% off everything sale helped me make the decision.......now I hate building SMD things.....but the little critters aren't going away, but many of our favorite through hole chips ARE!

In the 80's SMD came, and we actually did a radio, the STX that had both, leaded parts on one side of the PCB, and SMD on the other side of the 6 layer board. Set a couple of the early prototype boards on fire attempting to fix internal shorts with a 20 amp power supply equipped with a "NoBlo" fuse. It was a standard glass fuse filled with solder. I made it just for fixing those pesky shorted PC boards. Sometimes it actually worked.

The 90's and 00's brought smaller and smaller SMD parts. My eyes weren't getting any younger, but they kept getting me better microscopes. The problem was my shaky hands. OK, I left the cell phone rat race and got into a research group that was working on big mobile (car trunk mounted) radio equipment. That worked for a while, but when a big a$$ mobile radio that weighs in at over 20 pounds uses 0204 SMD (.020" by .040") parts, something is wrong. WHY? When you are making a million cell phones a month guess which parts you get the cheapest?

By 2014 the peak to peak vibration in my hands became larger than even the big SMD stuff, so I took the buyout and left.

Soldering tube amp parts is still easy. Blowing stuff up is still fun to me, and fixing what I blow up is still an educational experience. Fixing the messed up software I write, not so much fun, but still educational. Sometimes it's frustrating, but you have to keep learning, something, even if it's what not to do tomorrow. Just keep at it.

So when I was vacationing in Florida, after stopping at ESRC to pick up 270 tubes, I went to Planet Surplus and bought a microscope exactly like the one I had back in the cell phone days. The 30% off everything sale helped me make the decision.......now I hate building SMD things.....but the little critters aren't going away, but many of our favorite through hole chips ARE!

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- I hate building amps