Look for parts getting too hot, anything that's shorted or partially shorted pulls more current,more current = more ripple,more ripple = hum.

Triple check your work,it's soooo easy to fit an electrolytic cap round the wrong way, or sub the wrong resistor. Also check for solder shorts.I go over my work with a magnifying glass. When working on amps it's possible that wires and joints get strained, check this isn't the case, especially grounds.

Also try giving the board etc a poke with a stick, or other non conductive thing to see if prodding things changes anything.

Another trick to find hum is to pull valves, one at a time,but you need to study the schematic first to check doing so won't make things go bang.

Andy.

Triple check your work,it's soooo easy to fit an electrolytic cap round the wrong way, or sub the wrong resistor. Also check for solder shorts.I go over my work with a magnifying glass. When working on amps it's possible that wires and joints get strained, check this isn't the case, especially grounds.

Also try giving the board etc a poke with a stick, or other non conductive thing to see if prodding things changes anything.

Another trick to find hum is to pull valves, one at a time,but you need to study the schematic first to check doing so won't make things go bang.

Andy.

Last edited:

Thanks - I will do just that.

My input valve on the line stage a 12AX7 hums when I touch it but I can't find a good reason for that.....

My input valve on the line stage a 12AX7 hums when I touch it but I can't find a good reason for that.....

There are a couple of 1500uF 50V caps in the heater supply - they should be candidates for replacement. Another thread was investigating a hum in an Elektor amp, and it was the heater supply in tha case.

ahh ok - I am also swapping those out - so fingers crossed.

They are 2 x 1000 uF in the Rev E I have, strangely less than the earlier revisions. I chose to get 1000 uF for this and stick to circuit design in this revision.

They are 2 x 1000 uF in the Rev E I have, strangely less than the earlier revisions. I chose to get 1000 uF for this and stick to circuit design in this revision.

So I have got my hum down to a sort of acceptable level BUT it is still there. I have a friends similar preamp here and it is totally silent....but it is also a two box keeping AC away from the active signal stages.

My 'noise' seems to be intervals for 50 Hz, is there any way of determining if this is induced or coming from PS directly by looking at the frequencies?

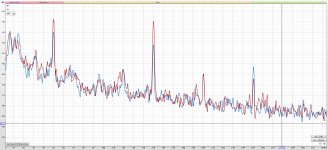

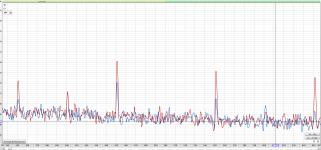

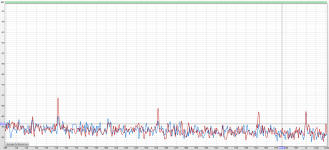

The two traces are with no signal playing but unmuted and the red trace is at full volume, which is quite hummy/noisy.

Thoughts?

My 'noise' seems to be intervals for 50 Hz, is there any way of determining if this is induced or coming from PS directly by looking at the frequencies?

The two traces are with no signal playing but unmuted and the red trace is at full volume, which is quite hummy/noisy.

Thoughts?

Attachments

No obvious mains 2nd harmonic so its mainly direct pickup from the mains, not PS ripple which is strongly even harmonics.

I note the steel plate arrangement could be transporting mains hum field into the circuitry, the only sensible shield for a transformer is a mu-metal jacket around the transformer with no protruding parts that could leak flux. Pointy parts are where flux comes out strongest.

Distance is a good defence against magnetic hum fields as magnetic dipole fields fall off with the cube of distance.

The signal paths probably need screened cable (screen grounded at one end only). Ground layout and ground loops may be a factor. Deteriorating ground connections are worth checking for (tighten any ground points that are bolted).

I note a lot of large sized film caps - are these all the right way round (outer film to low impedance part of circuit)? Valve circuitry is high enough impedance that this can make a big difference to stray pick-up. For a coupling cap both ends are sensitive to pickup and these need to be kept away from any 50Hz source.

I note the steel plate arrangement could be transporting mains hum field into the circuitry, the only sensible shield for a transformer is a mu-metal jacket around the transformer with no protruding parts that could leak flux. Pointy parts are where flux comes out strongest.

Distance is a good defence against magnetic hum fields as magnetic dipole fields fall off with the cube of distance.

The signal paths probably need screened cable (screen grounded at one end only). Ground layout and ground loops may be a factor. Deteriorating ground connections are worth checking for (tighten any ground points that are bolted).

I note a lot of large sized film caps - are these all the right way round (outer film to low impedance part of circuit)? Valve circuitry is high enough impedance that this can make a big difference to stray pick-up. For a coupling cap both ends are sensitive to pickup and these need to be kept away from any 50Hz source.

Last edited:

According to schematics V3 and V6 ( ECC88 ) are AC heated. Try to replace those.

Do you mean try to move from AC to DC heaters on V3 and V6?

No i mean to replace v3 & v6 with new tubes.Do you mean try to move from AC to DC heaters on V3 and V6?

It's a bad move to start redesigning whiteout first fixing the fault. Besides that i do not think DC filament is needed on those. If the tubes as cathode<>heater problems it affects sound too.

No i mean to replace v3 & v6 with new tubes.

It's a bad move to start redesigning whiteout first fixing the fault. Besides that i do not think DC filament is needed on those. If the tubes as cathode<>heater problems it affects sound too.

The V3 is a relatively new valve, but it's true I should try another swap. The V6 is a dirty old one as I don't use the phono stage atm....so wanted to keep the nice NOS for listening but maybe it creeps some noise/hum in. Good call i'll try it

no joy on V3 and v6 swap BUT, I saw this and wondered if an extra cap on the B+ might do anything as a possible easy try.

https://mapoulin.wixsite.com/audiobymartin/audio-upgrade?lightbox=dataItem-j15g4b0f

It is just a 3.3 uF to ground from the B+ prior to feeding the line stage anode supplies?

Worth a shot or a bit of a waste of time!! ?

https://mapoulin.wixsite.com/audiobymartin/audio-upgrade?lightbox=dataItem-j15g4b0f

It is just a 3.3 uF to ground from the B+ prior to feeding the line stage anode supplies?

Worth a shot or a bit of a waste of time!! ?

- Home

- Amplifiers

- Tubes / Valves

- Humm on old amplifier