(Sorry if this is on the wrong subforum)

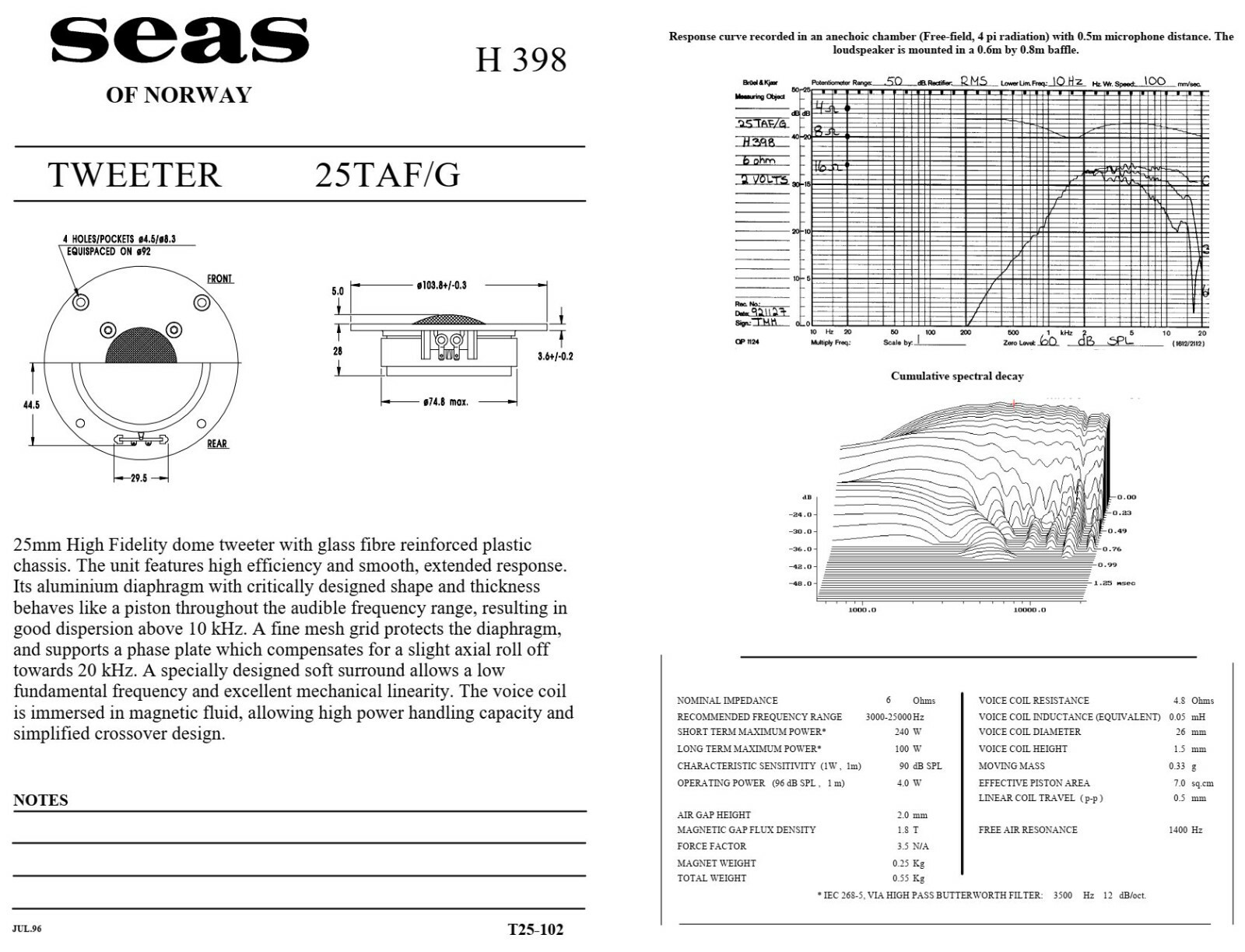

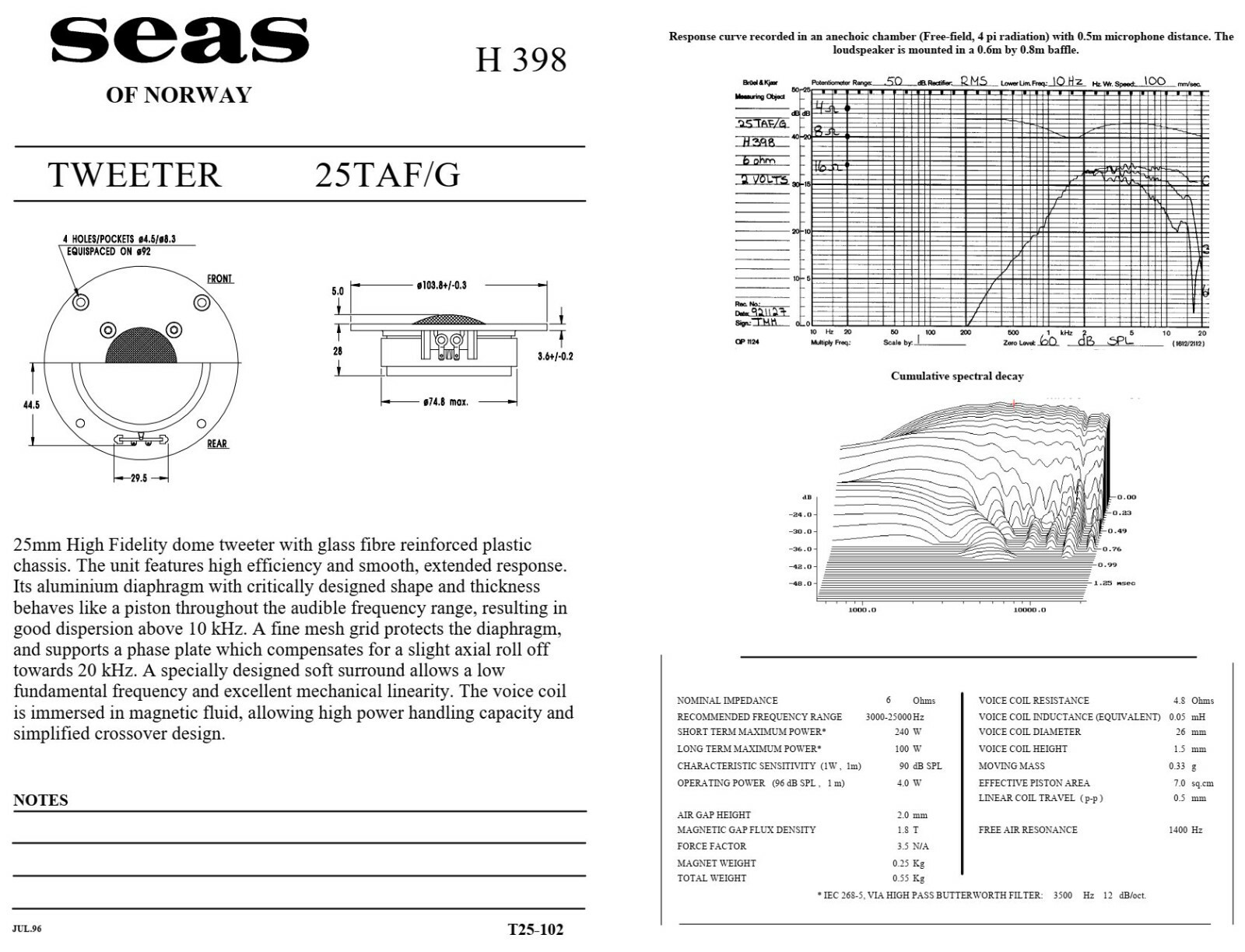

Hi, all! I'm looking for some advice on the safest method to remove the thin metal grill from a SEAS tweeter (specifically, 25TAF/G on a Totem Rainmaker).

I need to remove it because I bought it used and someone has poked the grill inwards, thus making the plastic dot/acoustic lens (which supposedly aids dispersion and frequency response) fall off from the grill.

I wanted to remove it, fix the dent, clean and glue back the plastic dot and then reassembly it.

Any help is appreciated.

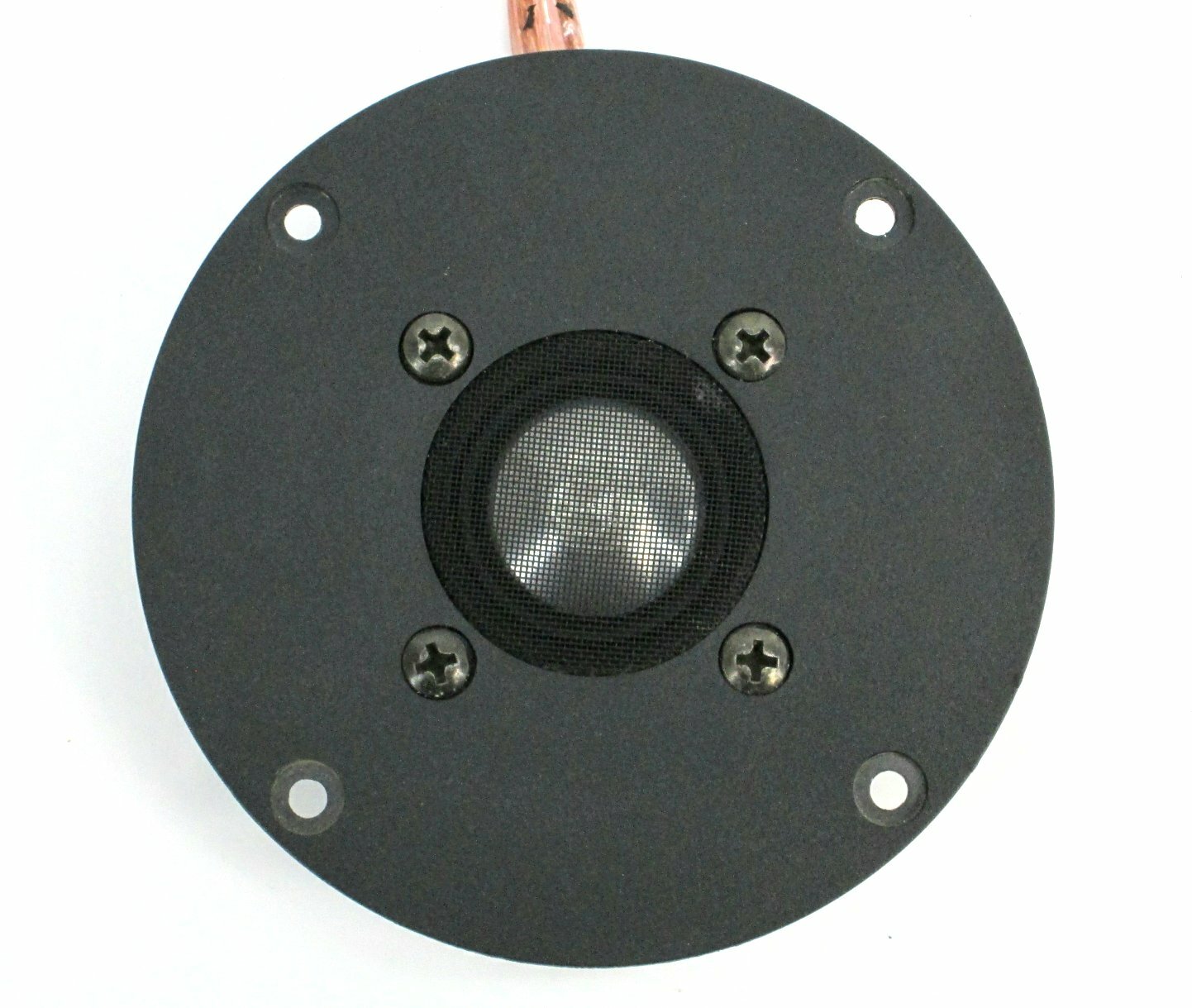

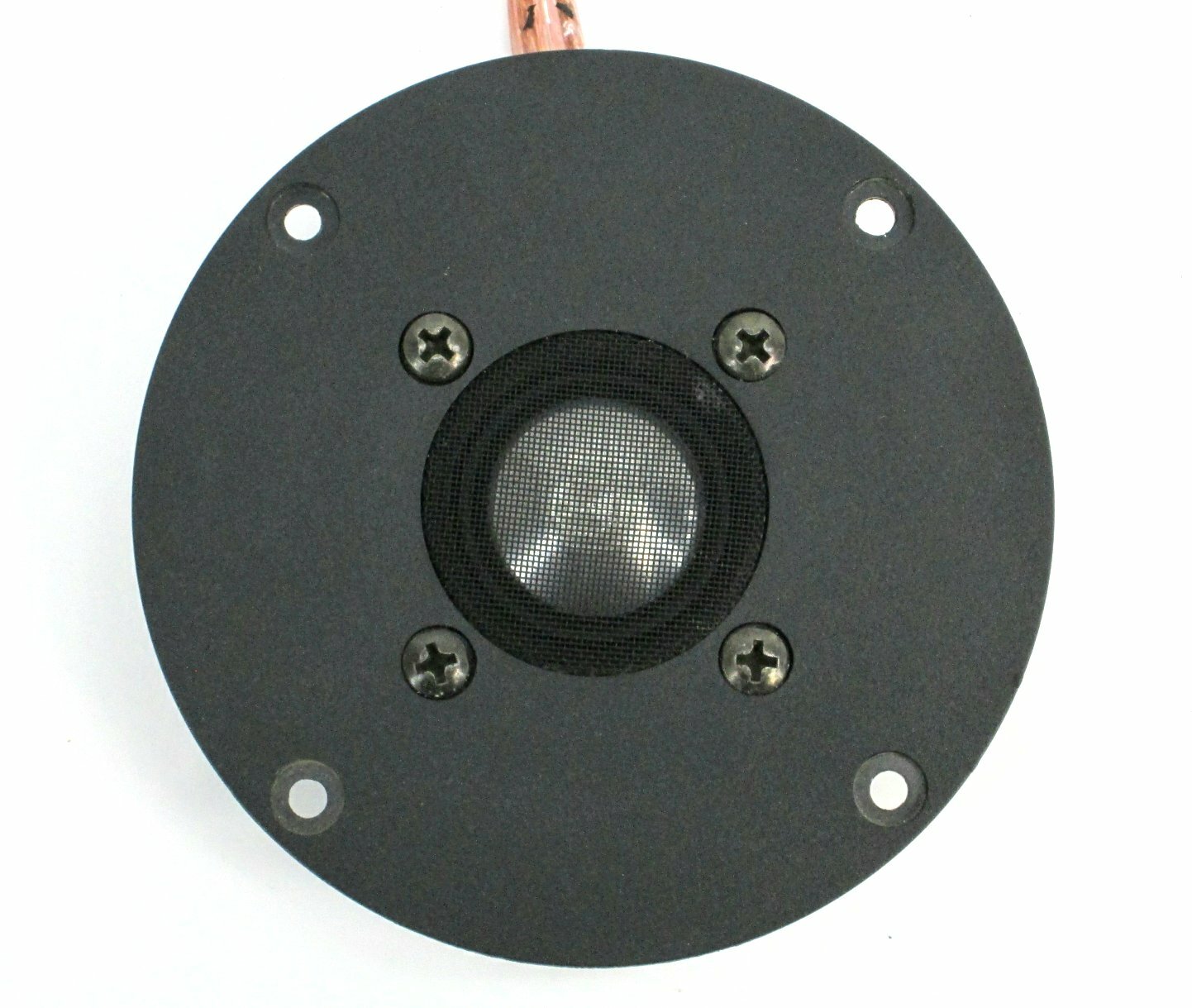

Pic of the tweeter in question:

Hi, all! I'm looking for some advice on the safest method to remove the thin metal grill from a SEAS tweeter (specifically, 25TAF/G on a Totem Rainmaker).

I need to remove it because I bought it used and someone has poked the grill inwards, thus making the plastic dot/acoustic lens (which supposedly aids dispersion and frequency response) fall off from the grill.

I wanted to remove it, fix the dent, clean and glue back the plastic dot and then reassembly it.

Any help is appreciated.

Pic of the tweeter in question:

Normally they are not attached, the magnet in the driver holds them in place, so try gently prying out with the end of a paperclip?

The tweeter driver will fall off the back. Just get a paperclip or a pin maybe and see it its just held on by the magnetism (standard practice as I said). If that fails venture to the screws.

I removed the grill successfully. All there is to it is grabbing the grill's outer edges with your fingernails in a claw position and firmly pulling it outwards. It's glued, but the glue is very gentle.

Here are some pics (look how nasty the plastic dot was! Gonna clean it up later today and glue it back.

Tweeter taken apart (front plate at the right - grill was totally unacessible from there, so taking it apart is not needed/wont help):

Grill being removed

https://i.imgur.com/avVysyh.jpg

Nasty plastic dot which was triggering my hereditary OCD:

https://i.imgur.com/VcN7nP2.jpg

Here are some pics (look how nasty the plastic dot was! Gonna clean it up later today and glue it back.

Tweeter taken apart (front plate at the right - grill was totally unacessible from there, so taking it apart is not needed/wont help):

Grill being removed

https://i.imgur.com/avVysyh.jpg

Nasty plastic dot which was triggering my hereditary OCD:

https://i.imgur.com/VcN7nP2.jpg

The previous owner did not do a good soldering job of the wire connections to the terminal.

The braided voice coil connecting wire should be attached to a separate point on the bracket not sticking up through the blob - applied apparently by heating the solder more more along the lines of hot melt glue than heating the area of the joint first and bringing the solder to this to allow this to flow on.

You should be able to fix this by replacing the terminal bracket ( I bought a couple of these recently from a local over the counter source so they should not be hard to find)

The braided voice coil connecting wire should be attached to a separate point on the bracket not sticking up through the blob - applied apparently by heating the solder more more along the lines of hot melt glue than heating the area of the joint first and bringing the solder to this to allow this to flow on.

You should be able to fix this by replacing the terminal bracket ( I bought a couple of these recently from a local over the counter source so they should not be hard to find)

The previous owner did not do a good soldering job of the wire connections to the terminal.

The braided voice coil connecting wire should be attached to a separate point on the bracket not sticking up through the blob - applied apparently by heating the solder more more along the lines of hot melt glue than heating the area of the joint first and bringing the solder to this to allow this to flow on.

You should be able to fix this by replacing the terminal bracket ( I bought a couple of these recently from a local over the counter source so they should not be hard to find)

Thanks for your input.

I don't think the previous owner has ever touched the tweeter's guts. It was probably done by Totem itself.

Also, should I be worried about that rusty surface on the magnet?

Thanks for your input.

I don't think the previous owner has ever touched the tweeter's guts. It was probably done by Totem itself.

Also, should I be worried about that rusty surface on the magnet?

That would not affect performance. You can buy fish oil products at a hardware store to penetrate rust to seal it off from air. I have a pair of Rogers speakers that have some slight rust on the rear of SEAS tweeters.

These had been put in storage by an owner who moved overseas and sold them years later when he returned to New Zealand. They were in the original boxes inside custom plastic bags.

In my experience with storage units here these are often cold and damp.

In contrast with this I have had some work experience the field of archives where regulated temperature and humidity of the environment is paramount for preservation of records.

With regard to the Rogers speakers the connections to the speakers are by spade connectors crimped to the speaker leads. The same method is used in a set of Paradigm speakers. Have a look at the solder joints on the crossover network in your speakers which would have to pass some quality control check at Totem. That should say something better about the manufacturers standards than the blobs you have seen.

- Home

- Design & Build

- Construction Tips

- How to properly remove/reassembly SEAS tweeter grills?