Hi all , I have MasterSound duetrenta parallel se amp with auto bias that's need new tubes . I can get nos valves with these readings 190ma, 196ma,198ma and 210ma would this be good for my amp ? If so how to pair these in my amp . Many thanks

Daniel

Daniel

Is the auto bias circuit separate for each individual tube?

An auto bias that only adjusts the total current of the parallel tubes might be a problem if the tubes are not well matched.

What is the output tube type?

If you post a schematic with current and voltage values, it might help to determine the answer.

Some thread readers will not spend the time to look up the MasterSound duetrenta, and find information on it.

Did you do that?

An auto bias that only adjusts the total current of the parallel tubes might be a problem if the tubes are not well matched.

What is the output tube type?

If you post a schematic with current and voltage values, it might help to determine the answer.

Some thread readers will not spend the time to look up the MasterSound duetrenta, and find information on it.

Did you do that?

Unfortunately I don't have any schematics as mastersound don't provide any ! Output tubes are kt88/6550.

"Unfortunately I don't have any schematics as mastersound don't provide any ! Output tubes are kt88/6550."

Then make a schematic and post it here !!

It cannot be very difficult to follow the wires/board traces and make your own schematics, handy for

future work and a snap on the nose for mastersound.

Then make a schematic and post it here !!

It cannot be very difficult to follow the wires/board traces and make your own schematics, handy for

future work and a snap on the nose for mastersound.

KT88 specification lists a higher maximum resistance for grid, g1. Thermal Run-away is less likely.

6550 specification lists a lower maximum resistance for grid, g1. Thermal Run-away is more likely in the same circuit.

Check those g1 return resistor values before using a 6550.

The maximums are based on whether the circuit is self biased or fixed adjustable bias.

In either case, individual bias for each tube is better unless the tubes are very well matched.

6550 specification lists a lower maximum resistance for grid, g1. Thermal Run-away is more likely in the same circuit.

Check those g1 return resistor values before using a 6550.

The maximums are based on whether the circuit is self biased or fixed adjustable bias.

In either case, individual bias for each tube is better unless the tubes are very well matched.

Hi all , I have MasterSound duetrenta parallel se amp with auto bias that's need new tubes . I can get nos valves with these readings 190ma, 196ma,198ma and 210ma would this be good for my amp ? If so how to pair these in my amp . Many thanks

Daniel

I don’ think that the value are correct

190 mA or similar doesn’t mean anything without the specs for test

The values are too high apparently

The selection must be done not only with a static point ( as a bias point) but also dynamic and this is not so simply

Normally the standard tube tester check the tube in one single point

With other stuff like Amplitrex the selection is fine

Normally the standard tube tester check the tube in one single point

With other stuff like Amplitrex the selection is fine

The best place to test valves for matching is in the amp using ohms law or a small sense resistor, say 10r on the cathode. Failing that knock up a power supply and test jig. If you have the cash ring Billington, they'll match valves to your spec.Forget buying matched valves, the ones I've bought from the UK big valve sellers like Langrex are not matched, how can they be, they have no spec attached but Langrex sent me several matched Quads for me to match myself, excellent service. I was trying to find two matched sextets, tricky.

When I've matched valves in the past I've done so using a simple emission test, you need about 20 valves to select a quad if your lucky. Add another parameter like gm and you'll be there testing for the next 100 years. Match to 5% emission and your good for most amps. If your amp needs valves matched to less than 1% emission at several operating conditions and needs them matched gm wise then the amp is badly designed or blowing smoke up your pipe. A well designed amp will have a way to balance DC & AC conditions, to a point. Unmatched valves don't add that much THD, but matched valves might be more important if the amp OP stage uses a shared cathode resistor, which, is a bad design but still, there you go.

To find anode current in an amp check out Uncle Dougs channel on Youtube.

Andy.

When I've matched valves in the past I've done so using a simple emission test, you need about 20 valves to select a quad if your lucky. Add another parameter like gm and you'll be there testing for the next 100 years. Match to 5% emission and your good for most amps. If your amp needs valves matched to less than 1% emission at several operating conditions and needs them matched gm wise then the amp is badly designed or blowing smoke up your pipe. A well designed amp will have a way to balance DC & AC conditions, to a point. Unmatched valves don't add that much THD, but matched valves might be more important if the amp OP stage uses a shared cathode resistor, which, is a bad design but still, there you go.

To find anode current in an amp check out Uncle Dougs channel on Youtube.

Andy.

Last edited:

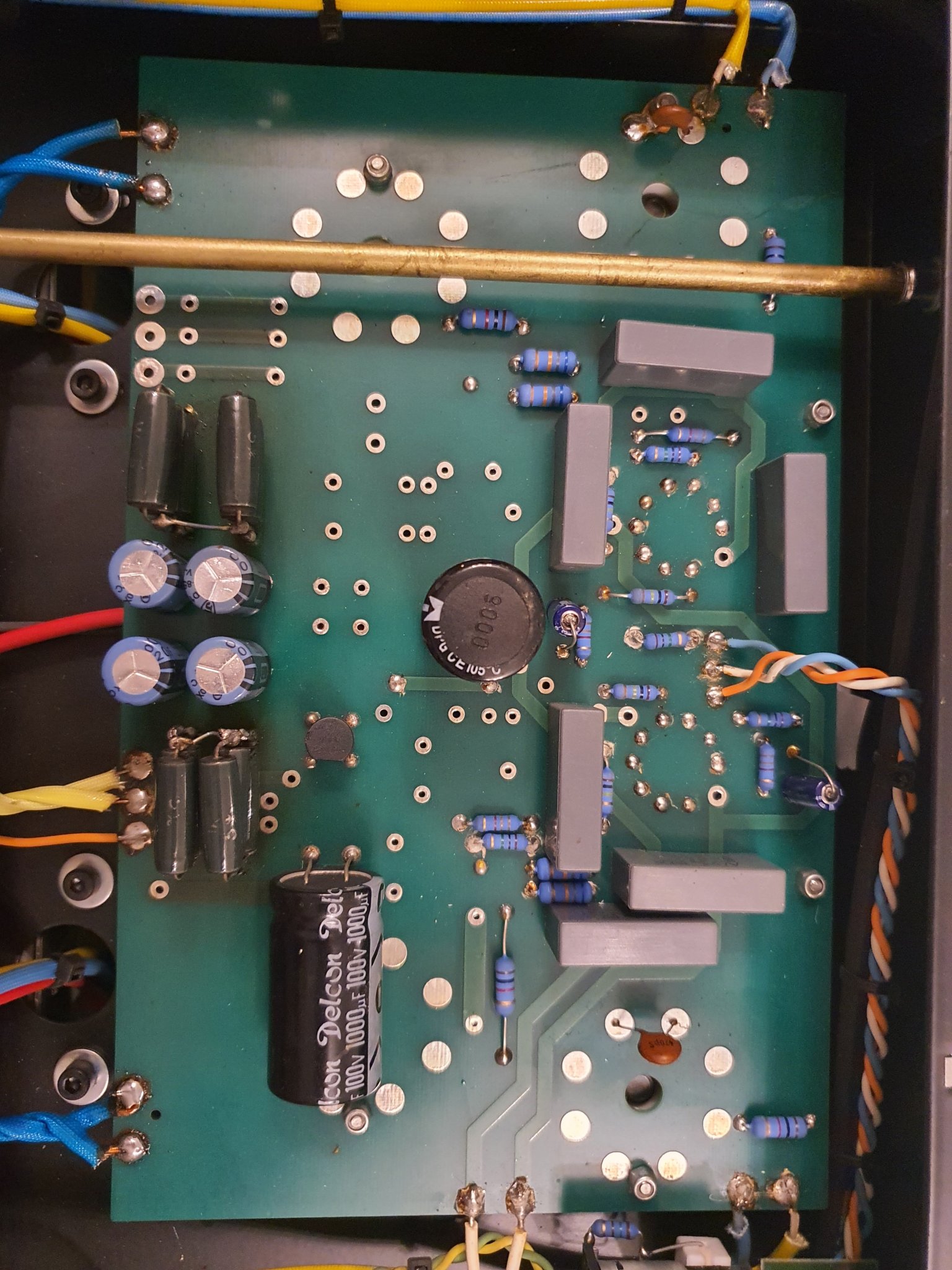

Hi ,thanks for all replies. As I'm newbie to valve apms and not really feel confident enough to do any DIY with it I think I'll pass these 6550 tubes and will buy kt88 instead. I opened bottom of the amp so maybe someone with more knowledge can tell from the photo if the bias is separate for every tube or just per chanel. Many thanks

A lot of the connections are copper traces on the backside of the PCBs.

It is hard to tell whether there is individual bias for each tube.

I bet the tubes are not individually biased; and perhaps each channel has both parallel tubes with only one bias.

There appear to be 16 wires to the main PCB. Not easy to determine much about the circuit that has 3 PCBs.

This proves my preference for point to point wiring.

1. Easier to see and draw a schematic with point to point wiring, instead of having to completely disassemble the amplifier, to see the backsides of the PCBs.

2. Easier to make a modification to the circuit with point to point wiring, instead of cutting traces on a PCB.

It is hard to tell whether there is individual bias for each tube.

I bet the tubes are not individually biased; and perhaps each channel has both parallel tubes with only one bias.

There appear to be 16 wires to the main PCB. Not easy to determine much about the circuit that has 3 PCBs.

This proves my preference for point to point wiring.

1. Easier to see and draw a schematic with point to point wiring, instead of having to completely disassemble the amplifier, to see the backsides of the PCBs.

2. Easier to make a modification to the circuit with point to point wiring, instead of cutting traces on a PCB.

It also shows the very need to demand proper schematics/repair when purchasing an amp.

No schematics - no buy !

No schematics - no buy !

The soldering looks pretty dire but that aside those big green Welwyn WW resistors look like the OP valve cathode bias resistors, which probably means each OP valve is individually cathode biased so no auto bias or servo wotnots. To find the operating conditions you'll need to poke about with a voltmeter - you'll need two values , IE HT and the cathode voltage, with those you can work out what the valves operating conditions are. The OP stage is triode strapped from what I've read, so a simple design probably.

Any quad of reasonably matched valves should do the job, no need for anything mad I think.

Andy.

Any quad of reasonably matched valves should do the job, no need for anything mad I think.

Andy.

What I see also a jumper between the green resistors( cathode I suppose) that seems to be not original. There are also four cap probably one for each resistor ( two in parallel for each tube)

I will try to ask the diagram here in Italy. Time ago. I sent them some components

Walter

I will try to ask the diagram here in Italy. Time ago. I sent them some components

Walter

Once again many many thanks for all your value input. Yes I noticed soldering is really bad ,definitely someone did some work on this amp and previous owner probably forgot 🙂 to mention it . However I'm very happy with the sound so far.

I've paid £1000How much was this thing for ?

Will do ,thanksAny quad of reasonably matched valves should do the job, no need for anything mad I think.

Andy.

- Home

- Amplifiers

- Tubes / Valves

- How to match tubes for parallel SE amp