It's radius 330mm, not diameter, so there is no 165mm.

You need a circle cutting jig. You can buy it, but that big is expensive. You can make one easily from thin piece of plywood. Drill pivot point at one end, I use 1/8" pivot. The center to center from pivot to router bit is 330mm.

The work piece must be long enough to make this cut before cutting it down to the correct length. Maybe you can figure a way to cut both baffle from one longpiece to save wood. If you don't understand rsvp and I'll draw a picture.

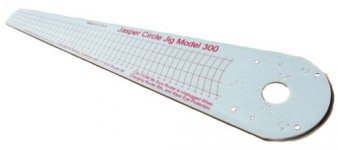

Photo of adjustable commercial tool. Pivot at one end, router that the other end. Yours can be non adjustable. Just drill a new pivot hole for different jobs.

You need a circle cutting jig. You can buy it, but that big is expensive. You can make one easily from thin piece of plywood. Drill pivot point at one end, I use 1/8" pivot. The center to center from pivot to router bit is 330mm.

The work piece must be long enough to make this cut before cutting it down to the correct length. Maybe you can figure a way to cut both baffle from one longpiece to save wood. If you don't understand rsvp and I'll draw a picture.

Photo of adjustable commercial tool. Pivot at one end, router that the other end. Yours can be non adjustable. Just drill a new pivot hole for different jobs.

Attachments

Last edited:

It's radius 330mm, not diameter, so there is no 165mm.

You need a circle cutting jig. You can buy it, but that big is expensive. You can make one easily from thin piece of plywood. Drill pivot point at one end, I use 1/8" pivot. The center to center from pivot to router bit is 330mm.

The work piece must be long enough to make this cut before cutting it down to the correct length. Maybe you can figure a way to cut both baffle from one longpiece to save wood. If you don't understand rsvp and I'll draw a picture.

Photo of adjustable commercial tool. Pivot at one end, router that the other end. Yours can be non adjustable. Just drill a new pivot hole for different jobs.

Hi if you could draw a picture that would be great... 🙂

Thanks for the help

hmm, maybe a lot of sanding?

5 axis CNC would be my first choice 😀, but for a hand-bomb, I'd be more inclined to use the router circle jig set up. As you'd need two of these, work piece could start out much longer, and be cut to length after bevel is detailed on the round end. Router table and big-a$$ 45dg bit for chamfer on the radiused end, and table saw for the others.

5 axis CNC would be my first choice 😀, but for a hand-bomb, I'd be more inclined to use the router circle jig set up. As you'd need two of these, work piece could start out much longer, and be cut to length after bevel is detailed on the round end. Router table and big-a$$ 45dg bit for chamfer on the radiused end, and table saw for the others.

Jig saw or router. A table mounted drum sander would make life easier after doing the rough cuts.

after more thought on this. just cut it on the band saw or with a jig saw with a piece of scrap on the bottom then use a 45 degree router bit with a bearing on the bottom running along the scrap piece to chamfer it. I don't know why that didn't occur to me immediately...

A 45dg bit with sufficient cutting length to chamfer a full 3/4" thick isn't a tiny thing, and would require at a router with a base plate that might make for a fun job of securing the work piece to bench. If available, I think a router table would make that operation a bit easier/safer.

A 45dg bit with sufficient cutting length to chamfer a full 3/4" thick isn't a tiny thing, and would require at a router with a base plate that might make for a fun job of securing the work piece to bench. If available, I think a router table would make that operation a bit easier/safer.

That is true, you would need about a 2.5" diameter 45 degree router bit, a router table would be ideal taking small passes and making sure to use a fulcrum pin when making the final pass.

That certainly looks like a feature of a Troels Gravesen design - among the many assembly photos on his site, does he not chronicle fabrication of that piece?

Jig saw or router. A table mounted drum sander would make life easier after doing the rough cuts.

Retracting my previous post for being incorrect, I missed something in the blueprint.

Last edited:

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- How to get this cut