Good afternoon my friends

So I may have bungled a bit on my custom top-cover by sheer over enthusiasm.

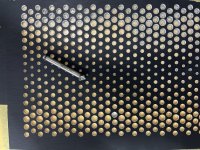

I drilled all these and was confident the holes would be shard and clean on the upper side, but the all have that tiny little sharp burrmaking it looking and feeling a bit rough.

I want to have them clean and, well, somewhat shiny, but don’t want to make the countersunk by ≈ 1 mm…

The tool I use tends to not bite unless I press so hard that it instantly cuts off too much material.

What should I use? Something to go with a very simple table-drill, or just a hand-tool?

(I was thinking of something that would rather grind than cut, but it’s 2 - 5 mm diameter…)

As you can see, this particular plate already is, erm, failed, but nevermind I fine if I can improve it (better than starting over, right?)

Thank you!

So I may have bungled a bit on my custom top-cover by sheer over enthusiasm.

I drilled all these and was confident the holes would be shard and clean on the upper side, but the all have that tiny little sharp burrmaking it looking and feeling a bit rough.

I want to have them clean and, well, somewhat shiny, but don’t want to make the countersunk by ≈ 1 mm…

The tool I use tends to not bite unless I press so hard that it instantly cuts off too much material.

What should I use? Something to go with a very simple table-drill, or just a hand-tool?

(I was thinking of something that would rather grind than cut, but it’s 2 - 5 mm diameter…)

As you can see, this particular plate already is, erm, failed, but nevermind I fine if I can improve it (better than starting over, right?)

Thank you!

Attachments

Ah very nice! I‘ll have a look at both.

I hadn’t heard of the Janka scale before, thank you!

(The repaint job was already decided, ≈ 450 tiny circles to do … 🥹 )

I hadn’t heard of the Janka scale before, thank you!

(The repaint job was already decided, ≈ 450 tiny circles to do … 🥹 )

Try a countersink bit with more flutes or cutting edges. Some have 8-10 and produce a cleaner cut.

Ja, and mount it in a hand chuck, since it's just soft aluminum...

Attachments

If you haven't got a hand chuck, or a counter sink with a handle (which is what I use at work) you could always use a spare drill chuck, just a 1/4 turn should be enough.

I disagree.this particular plate already is, erm, failed

The job you did isn't bad at all IMO, and if that cover were mine I wouldn't touch it anymore.

Since you have (rightly) decided to paint it, I would give it a couple of coats of emery cloth of at least a couple of different shades to eliminate those (small) burrs and then I would repaint it.

In my opinion it would be great! 😉

Sand the whole panel flat/smooth with 320grit to remove the standing burrs, submerse the panel in sodium hydroxide solution to chemically remove the feather burrs remaining, then sand again and repaint.

Any kind of mechanical deburring will always leave tiny burrs remaining, and given the terrible machineability of most soft sheet aluminium, often quite big ones!

Any kind of mechanical deburring will always leave tiny burrs remaining, and given the terrible machineability of most soft sheet aluminium, often quite big ones!

You'll always leave a tiny bevel with a countersink. If you make them all identical you could just market it as a design feature. The insides of the holes won't be anodized anyway, so what's the harm in having a little bevel showing?

I use a countersink intended for woodworking and use a drill press. It leaves a clean bevel that can actually be pretty small. Certainly less than 1 mm.

Alternatively, there are pens intended for touching up scratches on black anodized aluminum. You could use one ... or a black permanent marker.

Tom

I use a countersink intended for woodworking and use a drill press. It leaves a clean bevel that can actually be pretty small. Certainly less than 1 mm.

Alternatively, there are pens intended for touching up scratches on black anodized aluminum. You could use one ... or a black permanent marker.

Tom

I second that!The job you did isn't bad at all IMO

It looks perfect to me - was that done by hand? If so it's an amazing result!

Yes, sometimes perfectionism leads us to underestimate what we do ourselves. 🙄

The different diameter of holes are also nice.

All it takes is a little sanding, which you can perhaps insist on on some holes in particular, a splash of primer, a splash of matt black and it will be beautiful. 🙂

The different diameter of holes are also nice.

All it takes is a little sanding, which you can perhaps insist on on some holes in particular, a splash of primer, a splash of matt black and it will be beautiful. 🙂

The angle of countersink bits is too steep to remove burs without cutting into the hole, as you indeed mentioned. For large holes you can cut through the bur with a special debur tool/knife. Best option with these smaller holes is follow the advice above and sand them with fine emery. Start with light pressure so as not to push the burs back into the holes.

No problem, although I still think that I would no longer touch those holes with a tool since in my opinion they are already too close and there is a risk of ruining everything.

Anyway, it does not matter maybe, since I have a strange feeling that the OP won't do either thing. 😉

By the way, if you push and rotate with the tip of the fingertip of your index finger with the emery cloth, in my opinion you achieve the goal, or you can make a sort of cone with the emery cloth wrapped around itself two or three times and sand the initial part of the holes without unnecessarily going too deep into the hole, but as already said before I believe that it doesn't have too much importance.

Anyway, it does not matter maybe, since I have a strange feeling that the OP won't do either thing. 😉

By the way, if you push and rotate with the tip of the fingertip of your index finger with the emery cloth, in my opinion you achieve the goal, or you can make a sort of cone with the emery cloth wrapped around itself two or three times and sand the initial part of the holes without unnecessarily going too deep into the hole, but as already said before I believe that it doesn't have too much importance.

- Home

- Design & Build

- Construction Tips

- How to deburr holes in Aluminium without creating a countersunk drilling?