or cause earthquakes and tsunamis....Be careful very careful...

mE

....or the New York Mets may win the 2011 World Series.....

Be verrryyyy careful..... "Run away..... Run away home..... Run away home" (Monte Python)

Shuld I post or shuld I not

If I post I be in truble...

Oh well please telme to shut the Fet up I can take it...

Could you Please let me know if I am welcome to post here?

If I post I be in truble...

Oh well please telme to shut the Fet up I can take it...

Could you Please let me know if I am welcome to post here?

Bksabath - You are building an F5, right? That's what this thread is about!

I'm still curious if you are going to use the biscuit tin as a transformer cover... 🙂

I'm still curious if you are going to use the biscuit tin as a transformer cover... 🙂

Okey dokey

Fell so much beter tanks

Woody

Ken is right about the limits and 40W is the going figure.

But is also trou that Papa said 1 They sound better at 2 amps and also They sound beter at higher voltagge

So the only way to get both is to improve the heat exchange process

Big heat sinks but slow in setling or Goop and mica versus Kerafol

Also Kerafol work beter with higher pressure so how much torque could you put on a screw before you strip the tread?

Bit like F5 racing port flow by hand wok best

One more question did you Ken / 6L6 mannage to get a temperature on the CL60

Fell so much beter tanks

Woody

Ken is right about the limits and 40W is the going figure.

But is also trou that Papa said 1 They sound better at 2 amps and also They sound beter at higher voltagge

So the only way to get both is to improve the heat exchange process

Big heat sinks but slow in setling or Goop and mica versus Kerafol

Also Kerafol work beter with higher pressure so how much torque could you put on a screw before you strip the tread?

Bit like F5 racing port flow by hand wok best

One more question did you Ken / 6L6 mannage to get a temperature on the CL60

6L6

Biscuit tin is a definite possibility it does work.

I am not shure if I will have to as on my case the PSU is practicaly in a separate enclosure so I am more on the no need for it and cooler trafo at the moment.

In your case IMO is worth a try

Biscuit tin is a definite possibility it does work.

I am not shure if I will have to as on my case the PSU is practicaly in a separate enclosure so I am more on the no need for it and cooler trafo at the moment.

In your case IMO is worth a try

One more question did you Ken / 6L6 mannage to get a temperature on the CL60

Using the extremely accurate pseudo-pscientific method of touching them and guessing, I would say that mine are in the neighborhood of 120-130F. (49-55C)

Very warm/hot to the touch, but not going to burn you, and able to touch for 5-10sec.

6L6

Tanks for temperature.

eventualy I will have to pull 2 maye 3 times the current as I got 4 homs speakers so mine will be much worst.

Question

your therminal block is rated at 80 C ?

May get britle 6 months down the line.

Tanks for temperature.

eventualy I will have to pull 2 maye 3 times the current as I got 4 homs speakers so mine will be much worst.

Question

your therminal block is rated at 80 C ?

May get britle 6 months down the line.

Using the extremely accurate pseudo-pscientific method of touching them and guessing, I would say that mine are in the neighborhood of 120-130F. (49-55C)

Very warm/hot to the touch, but not going to burn you, and able to touch for 5-10sec.

What size was your case again?

I get a little over 16vac with a bulb which does dim over time. Then I only get 0.6vdc at the caps

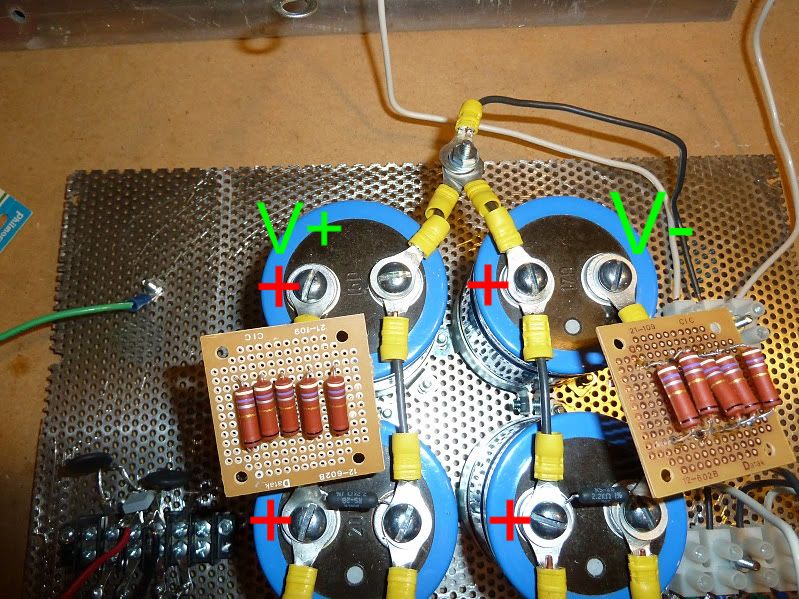

Please verify if the caps are orientated as I labeled them.

Also, are the V+ and V- labeled correctly?

Are the green wires from the rectifier blocks to the screw terminals DC positive?

That is correct. Green in positive. The caps are correct also and I have had a second set of ee eyes verify.

Using the extremely accurate pseudo-pscientific method of touching them and guessing, I would say that mine are in the neighborhood of 120-130F. (49-55C)

Very warm/hot to the touch, but not going to burn you, and able to touch for 5-10sec.

Mine are running about the same--warm to the touch, for the two CL-60's on the line side. The CL-60 common to the PSU is running a little cooler. All this, with about 0.63v across R11 and R12, for each channel.

I'd recommend you disconnect your leads from the bridge rectifier outputs, and measure both the VAC into each bridge, and then the VDC (unfiltered) comming out of each bridge.

While you have those leads "open" I'd also measure the resistance across the caps for each rail (do that using the leads you disconnected from the rectifiers. (You may have some residual DC in the caps, to touch both leads together to ground the caps, before you take this resistance reading).

Is your power supply currently (no pun intended....) connected to either/both of the amp boards?

While you have those leads "open" I'd also measure the resistance across the caps for each rail (do that using the leads you disconnected from the rectifiers. (You may have some residual DC in the caps, to touch both leads together to ground the caps, before you take this resistance reading).

Is your power supply currently (no pun intended....) connected to either/both of the amp boards?

It's not connected to the amp boards. I will check out what you said.

Thanks....that may be the best way to proceed--peeling back the layers of the onion, etc.

From a scan of your pics, your wiring on the primary side of the transformer looked ok.

On other simple measurement--the resistance reading across the two AC line leads (coming into the amp chassis) should be about 6-7 ohms (for a 400 VA transformer).

Are you sure each of the two secondary windings has one blue AND one green wire? (and how do you know which is which?) Have you tried with only one secondary at a time?

Last edited:

- Home

- Amplifiers

- Pass Labs

- How to build the F5