If MDF is OK for you might cut several layers of wood and glue them together (one over the other) like I did in this video on yt

YouTube

I did it for a torqued cabinet but it can be used for many shapes....

Video also shows some (very basic) veneering...

YouTube

I did it for a torqued cabinet but it can be used for many shapes....

Video also shows some (very basic) veneering...

Attachments

Thanks, I looked at the video and it might be the way to go.

Fortunately my local wood store will cut the MDF strips 🙂 this will save me a lot of work (+ I don't have a table-saw)

I hope I'll be able to plane the wood, seems quite simple in your video...

Same for the veneering...

Thanks again

Fortunately my local wood store will cut the MDF strips 🙂 this will save me a lot of work (+ I don't have a table-saw)

I hope I'll be able to plane the wood, seems quite simple in your video...

Same for the veneering...

Thanks again

The mitre cuts at the pointy ends are the problem because very few saws can cut at more than 45 degrees.You could cut by hand I suppose but I do not like your chance of getting a perfect joint that way.You could use solid blocks there but that would mean having to route a cavity for the tweeter.

If MDF is OK for you might cut several layers of wood and glue them together (one over the other) like I did in this video on yt

YouTube

I did it for a torqued cabinet but it can be used for many shapes....

Video also shows some (very basic) veneering...

But, for god's sake when working with MDF wear a mask! Man, belt sanding and routing MDF will do a number on your lungs. Also, FYI, butt joints with any wood, particularly MDF, without some fastener (biscuit, dowel, tenon, half-lap) will never hold. Now, that's mitigated to a degree because you're glueing frames on top of each other ... but still not a good method.

What can I say? You are completely right. Specially when routing (to my excuse I can say that the aspiration of the belt sander works very well)But, for god's sake when working with MDF wear a mask!

That's the reason why I put the rod. It works both as a reference jig and as a fasterer. Also: glueing and pressing MDF together properly on the cut side (the cross-section) is quite stable (I once tried to unmount 2 glued panels and ended up breaking the wood 😱 ).Also, FYI, butt joints with any wood, particularly MDF, without some fastener (biscuit, dowel, tenon, half-lap) will never hold. Now, that's mitigated to a degree because you're glueing frames on top of each other ... but still not a good method

Based on your suggestion you may put other rods at the other sides BUT since it is very difficult to predict the exact positions of the holes (twisted cabinet) I suggest a step by step approach: mount (without glueing) 3 frames (height of drill bit) using the first (reference) rod, drill a hole through the 3 frames, unmout, mount again with glue, proceed with the next 3 frames...

- Home

- Loudspeakers

- Multi-Way

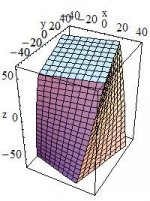

- How to build odd-shaped speaker cabinet (without CNC)