Hi and found something that i think definitely helps me to understand better ... not an easy task, something that i deem valuable to share here

This is the web page ...

Taking the B&W 801Fs active - AudioSmile Forum

and of course some kind of damping must be applied to the internal side of the panels, that is clear now.

Thanks to anyone. Regards, gino

This is the web page ...

Taking the B&W 801Fs active - AudioSmile Forum

.... A view of the internal bracing of the bass box. B&W obviously thought the bracing was inadequate! As they then went on to Matrix construction, although they also abandoned the sealed box....

... the bass unit. It is mounted with a rubber gasket and bolted through rubber shock mounts. So it’s more-or-less decoupled from the box whilst maintaining a “perfect” air seal. Any air leaks will affect the bass as it relies on the internal air spring as part of the suspension....

and of course some kind of damping must be applied to the internal side of the panels, that is clear now.

Thanks to anyone. Regards, gino

Where's the panel damping in the photo of the earlier B&W 801Fs ? It's non-existent. 1980's technology?

There's a lot to comment on the new B&W "matrix" construction.

System7, I'm not ignoring your thin damped wall construction comments, as they are valid. I just would like to address several others first.

There's a lot to comment on the new B&W "matrix" construction.

System7, I'm not ignoring your thin damped wall construction comments, as they are valid. I just would like to address several others first.

But afaiu decoupeling the mid or bass driver works against the whole concept of how most drivers work. To move the membran the motor of the driver has to "push against something" or "hold on to smt". When decoupled part of the energy / force the motor "generates" is lost (whole driver "swinging back+forth") and i would guess the driver is also less "exact".

Yes, this is true, except of the last phrase "less exact". It is just a linear effect, and reducing bass output; you have to handle that in your crossover.

But: how big is the loss? I have a subwoofer driver, 130g Mms, total weight 6.5 kg (OK, this example is quite extreme, but easy to calculate). If the cone moves forward, then the basket and magnet backwards. How much? Basket and magnet are 50x heavier than cone and voice coil, so they will move just 1/50 of the cone excursion (Newton's 3rd law). The cone itself will move 49/50 compared to mounted in an infinite mass, so the reduction in output is 0.18 dB.

This small value is only valid under the assumption that the decoupling is "perfect", but in reality the cabinet is still, but less, coupled to the driver. So the reduction will not be that much.

Where's the panel damping in the photo of the earlier B&W 801Fs ? It's non-existent. 1980's technology ?

There's a lot to comment on the new B&W "matrix" construction

Hi and yes you are right no panel damping just wool filling ...

The new Matrix series instead use damping foam inserts.

But as the woofer must be decoupled from the cabinet i guess that the bracing is just there to block vibes generated by the woofer back emission. Good ! Understood !

Thanks again, gino

Last edited:

But as the woofer must be decoupled from the cabinet i guess that the bracing is just there to block vibes generated by the woofer back emission. Good ! Understood !

Thanks again, gino

Mhhh maybe to break and spread (dissipate)the waves rather than block...'cos when you block the rear wave you'll also block the front one ( it's like a see-saw 🙄)

Mhhh maybe to break and spread (dissipate)the waves rather than block...

'cos when you block the rear wave you'll also block the front one ( it's like a see-saw 🙄)

Hi but this way they do not block the rear wave ... maybe i do not understand well what you mean.

As someone has put quite clearly the back emission of a woofer is so strong that can make the cabinet walls shaking. The bracing is there to block this shaking. I think a very similar effect could be obtained with damping panels as some others were suggesting.

I was wrongly overestimating the reduction in woofer output due to woofer decoupling ... even a 100% decoupled woofer has a very little output loss.

Thanks again, gino

Morning

i don't know if that was the consensus:

But afaiu decoupeling the mid or bass driver works against the whole concept of how most drivers work. To move the membran the motor of the driver has to "push against something" or "hold on to smt". When decoupled part of the energy / force the motor "generates" is lost (whole driver "swinging back+forth") and i would guess the driver is also less "exact".

Please excuse my english.

Regards

In a properly tuned decoupled driver system, very little transient response is lost. The compliance of the decoupling material and the preload (compressive tightening by the screws) are important. It's a designed tuned system. For good reliable results, you can't just go install some rubbery gasket compound. You could get lucky, probably not. See the performance curves of a decoupled 5" speaker in a article that I posted yesterday:

A link to a paper concerning driver decoupling from Andrew Jones, Director of Engineering, TAD and designer of the TAD Reference 1. I believe he posts on this site as AndrewJ. They used EAR type E-610-1 isolation grommets in the study.

http://www.linkwitzlab.com/Driver Decoupling.doc

i don't know if that was the consensus:

But afaiu decoupeling the mid or bass driver works against the whole concept of how most drivers work. To move the membran the motor of the driver has to "push against something" or "hold on to smt". When decoupled part of the energy / force the motor "generates" is lost (whole driver "swinging back+forth") and i would guess the driver is also less "exact".

Yes

Hi and just to say that i agree completely.

If some of the energy from the driver is dissipated in the decoupling/cabinet that will not be transmitted to the room. It will be just wasted.

The cabinte and the mounting must be as stiff as possible.

Possible resonances must be addressed and dealt with in some other ways.

Yes

In a properly tuned decoupled driver system, very little transient response is lost...

What's transient response got to do with it ?

Just to be clear, B&W decouple their mid and tweeter drivers, as well as the mid and tweeter enclosures in the 800 series, but they do not decouple the bass drivers.

From one of their technical papers (sorry, the pdf is too large to attach and I no longer have the link):

"It is vital to ensure that the fundamental spring /mass resonance of any reliable decoupling scheme is below the operating frequency range of the speaker drive unit. If this is achieved then any damping control is unnecessary and even undesirable. To achieve the lowest resonance the spring must be soft and the mass must be high.

So decoupling is effective if it is correctly applied, the big danger being that the resonance of the magnet on the decoupling spring may fall within the pass band. If that is the case, there will be a peak and a dip in the response the size of which depends on the decoupling spring losses.

Additional mass is coupled to the midrange magnet to further lower the resonance frequency and reduce chassis displacement, this being of additional importance because the cone impedance matching relies on the chassis as a virtual ground. The high loss of the gel at these elevated frequencies is thus invaluable, because it provides damping control of any structural modes in the chassis itself.

It will of course be noted that the bass drivers are not decoupled from the cabinet. This design decision follows from the Nautilus ™ 801 and was made fairly early in that speaker’s development stage, because the complications necessary to do the job correctly would have been impractical and perhaps unwarranted. Unlike the midrange and treble drivers, a bass driver reacts against a large air stiffness, so any orthodox compliance scheme would involve losses or in-band resonances unless the mass of the magnet was unreasonably high. "

Not that I understand all of the technical jargon, but from what I can gather, the Magico Q7 employs the same strategy - the woofers are firmly attached to massive and stiff cabinets with the mid and tweeter drivers decoupled from the baffles and the mid enclosure decoupled from the main cabinet as well as the front baffle section that the tweeter is attached to also decoupled from the first section of the front baffle (attached to the cabinet) that holds the mid and the woofers.

Actually, I'm not sure if the 1st front baffle section is also decoupled from the cabinet but I don't think so given the 100 or so bolts that are used to attach it.

What I'm interested in is whether anybody might know of an inexpensive material that is easily available to the diy'er that might work in a similar manner while under compression. So far I've been looking at simple bathtub silicone and have found an easy way to make them into gaskets of whatever shape and thickness I may want, but I'm not 100% convinced that they are the best at vibration isolation.

From one of their technical papers (sorry, the pdf is too large to attach and I no longer have the link):

"It is vital to ensure that the fundamental spring /mass resonance of any reliable decoupling scheme is below the operating frequency range of the speaker drive unit. If this is achieved then any damping control is unnecessary and even undesirable. To achieve the lowest resonance the spring must be soft and the mass must be high.

So decoupling is effective if it is correctly applied, the big danger being that the resonance of the magnet on the decoupling spring may fall within the pass band. If that is the case, there will be a peak and a dip in the response the size of which depends on the decoupling spring losses.

Additional mass is coupled to the midrange magnet to further lower the resonance frequency and reduce chassis displacement, this being of additional importance because the cone impedance matching relies on the chassis as a virtual ground. The high loss of the gel at these elevated frequencies is thus invaluable, because it provides damping control of any structural modes in the chassis itself.

It will of course be noted that the bass drivers are not decoupled from the cabinet. This design decision follows from the Nautilus ™ 801 and was made fairly early in that speaker’s development stage, because the complications necessary to do the job correctly would have been impractical and perhaps unwarranted. Unlike the midrange and treble drivers, a bass driver reacts against a large air stiffness, so any orthodox compliance scheme would involve losses or in-band resonances unless the mass of the magnet was unreasonably high. "

Not that I understand all of the technical jargon, but from what I can gather, the Magico Q7 employs the same strategy - the woofers are firmly attached to massive and stiff cabinets with the mid and tweeter drivers decoupled from the baffles and the mid enclosure decoupled from the main cabinet as well as the front baffle section that the tweeter is attached to also decoupled from the first section of the front baffle (attached to the cabinet) that holds the mid and the woofers.

Actually, I'm not sure if the 1st front baffle section is also decoupled from the cabinet but I don't think so given the 100 or so bolts that are used to attach it.

What I'm interested in is whether anybody might know of an inexpensive material that is easily available to the diy'er that might work in a similar manner while under compression. So far I've been looking at simple bathtub silicone and have found an easy way to make them into gaskets of whatever shape and thickness I may want, but I'm not 100% convinced that they are the best at vibration isolation.

twinter, that was an interesting link you provided to the maker of Green Glue. I found this part particularly noteworthy:

What's interesting is that he seems to have arrived at just about the same cabinet strategy as Von Schweikert: a layer of MDF on the outside + a layer of high damping material in the middle + a layer of very high mass and stiffness the same thickness as the MDF on the inside (concrete or similar). Bracing is on the outside MDF panels. I'm going to assume that an appropriate absorption strategy would be used inside the cabinet.

Currently, I'm wondering about rubber sheets/mats for the middle layer and wondering if it would make any difference if it was attached to the other layers with a viscoelastic glue or just a normal adhesive.

I'd build an MDF shell of XXX thickness with bracing if i felt ambitious. Then i'd coat the inside with the prescribed amount of this sort of behind-the-scenes Audio Alloy product we don't talk about so much. It's a CLD system that you paint on, i know bobmd of this forum had a thread about it once.

Then i'd mix boring old drywall compound or plaster of paris with sand, and simply cast the inside of the box, rotate the box and repeat on each additional side. Or trowel/smear in the plaster to the desired thickness. The thickness of the plaster/sand layer should be approximately the same as the thickness of the MDF layer.

That'd be extremely high in damping, extremely heavy, and extremely stiff (the plaster/sand layer would have a modulus in the vicinity of 1.5 million PSI). You could substitute concrete for the plaster or drywall compound if you so desire.

Wouldn't cost much. MDF is pretty much necessary anyway, and you aren't building a 3-layer MDF box. Concrete is like 4 bucks for an 80 pound bag, drywall mud is like 4 bucks for a 25 pound bag, and sand is like 2-3 bucks for a 50 pound bag.

What's interesting is that he seems to have arrived at just about the same cabinet strategy as Von Schweikert: a layer of MDF on the outside + a layer of high damping material in the middle + a layer of very high mass and stiffness the same thickness as the MDF on the inside (concrete or similar). Bracing is on the outside MDF panels. I'm going to assume that an appropriate absorption strategy would be used inside the cabinet.

Currently, I'm wondering about rubber sheets/mats for the middle layer and wondering if it would make any difference if it was attached to the other layers with a viscoelastic glue or just a normal adhesive.

If you want more stiffness in a flat (not curved) panel you have basically three possibilities:

1) other material (with higher modulus)

2) thicker panel (doubled thickness => 8x stiffness)

3) bracing

Sorry, it's taken me a while to respond, but I'll just add one more aspect that is usually overlooked.

For a panel supported at its edges (like speaker cabinets), the ratio of panel length to width will also affect stiffness (or in other words, panel shape). So if you have 2 panels of the same material, same thickness and the same mass but one of them is square and the other is a long, thin rectangle, the rectangle will have more stiffness (and therefore also a higher resonant frequency too).

Thus the shape of the sub-panels that are created through the use of bracing will also affect the sub-panels' stiffness and resonance frequencies as well.

And let's not forget that the stiffness of the bracing matters too, stiffer bracing = stiffer panels.

Just to be clear, B&W decouple their mid and tweeter drivers, as well as the mid and tweeter enclosures in the 800 series, but they do not decouple the bass drivers. .... Not that I understand all of the technical jargon, but from what I can gather, the Magico Q7 employs the same strategy - the woofers are firmly attached to massive and stiff cabinets with the mid and tweeter drivers decoupled from the baffles and the mid enclosure decoupled from the main cabinet as well as the front baffle section that the tweeter is attached to also decoupled from the first section of the front baffle (attached to the cabinet) that holds the mid and the woofers ...

Hi and thanks a lot and this is what i really wanted to know.

Because i could always put the tweeter like in the B&W speakers out of the cabinet.

What for me is very important is to know that the cabinet for the woofer must be stiff and the woofer rigidly coupled to it. Very fundamental point.

I do not want to sound like a troll ... but i intend to improve a speaker with a Tannoy DC in which the tweeter looks to me rigidly mounted on the back of the woofer.

Should i try some form of decoupling for the tweeter ?

But what interested me most was the bass speaker solution.

Thanks a lot again. I think i have got it right now.

Kindest regards, gino

Last edited:

Thanks to all, particularly Twinter for all your useful information and particularly the info on extensional damping. As a result of all this I have just lined my internal mid chambers, which are fairly soft 2mm plastic sealed tubes of approx 2.5 litre volume, with over 8mm of silent coat.

I hoped this would lower the mid chamber's resonance and increase damping enough to move problems out of the midrange driver passband.....It has.

Having a fully active system I can listen to each driver separately and using the stethoscope to listen to one mid driver with the additional damping and the other without, over all areas of each panel. I could go directly back and forth with various tones/music and compare. There is an enormous reduction in panel noise on all panels. I am over-joyed.

The mid range driver is now the quietest driver when using the stethoscope, whereas previously it was the loudest. I guess I now have a fairly flexible, highly damped, sealed mid-chamber which has low, well damped resonances which aren't being excited by the mid driver any more.

Comparing the modification to the unlined cabinet was dramatic. The tweeter and woofer are now the main sources of panel noise, so I will try the sorbothane with the tweeters next. I have 40 Duro 3mm sorbothane sheet, so once I have calculated the gasket area, I will work out how much to torque up the screws to get the appropriate pressure for maximum damping.

I will report back.

I hoped this would lower the mid chamber's resonance and increase damping enough to move problems out of the midrange driver passband.....It has.

Having a fully active system I can listen to each driver separately and using the stethoscope to listen to one mid driver with the additional damping and the other without, over all areas of each panel. I could go directly back and forth with various tones/music and compare. There is an enormous reduction in panel noise on all panels. I am over-joyed.

The mid range driver is now the quietest driver when using the stethoscope, whereas previously it was the loudest. I guess I now have a fairly flexible, highly damped, sealed mid-chamber which has low, well damped resonances which aren't being excited by the mid driver any more.

Comparing the modification to the unlined cabinet was dramatic. The tweeter and woofer are now the main sources of panel noise, so I will try the sorbothane with the tweeters next. I have 40 Duro 3mm sorbothane sheet, so once I have calculated the gasket area, I will work out how much to torque up the screws to get the appropriate pressure for maximum damping.

I will report back.

Last edited:

Thanks to all, particularly Twinter for all your useful information and particularly the info on extensional damping.

As a result of all this I have just lined my internal mid chambers, which are fairly soft 2mm plastic sealed tubes of approx 2.5 litre volume, with over 8mm of silent coat.

I hoped this would lower the mid chamber's resonance and increase damping enough to move problems out of the midrange driver passband.....It has.

Having a fully active system I can listen to each driver separately and using the stethoscope to listen to one mid driver with the additional damping and the other without, over all areas of each panel. I could go directly back and forth with various tones/music and compare. There is an enormous reduction in panel noise on all panels. I am over-joyed.... Comparing the modification to the unlined cabinet was dramatic ....

I will report back...

Hi and very interesting. Thank you. I have some question 🙄

1) what is the mid-range working range in Hz ?

2) how would you characterize the sound after the mod ? what has improved ?

3) do you have any picture of your speakers ? i am curious ? 😱

Thanks a lot and kind regards, gino 😀

Last edited:

See my thread for more details:

http://www.diyaudio.com/forums/mult...r-anyone-spot-any-probs-before-i-start-6.html

Here is a photo.

[URL=http://s845.photobucket.com/user/Plinkerking/media/Almostfinished.jpg.html] [/URL]

[/URL]

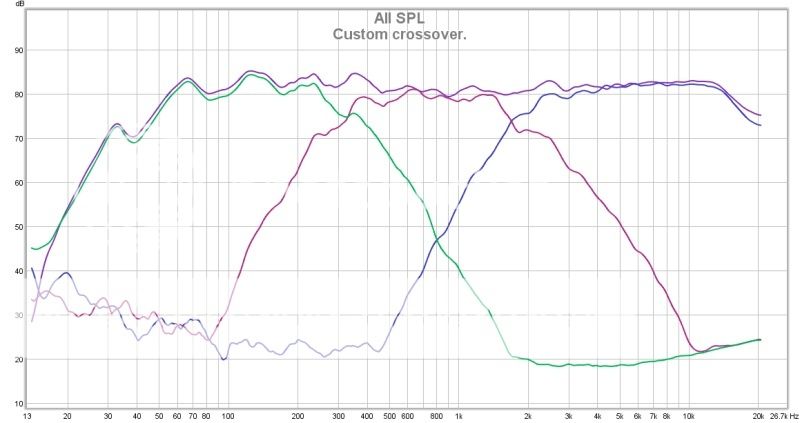

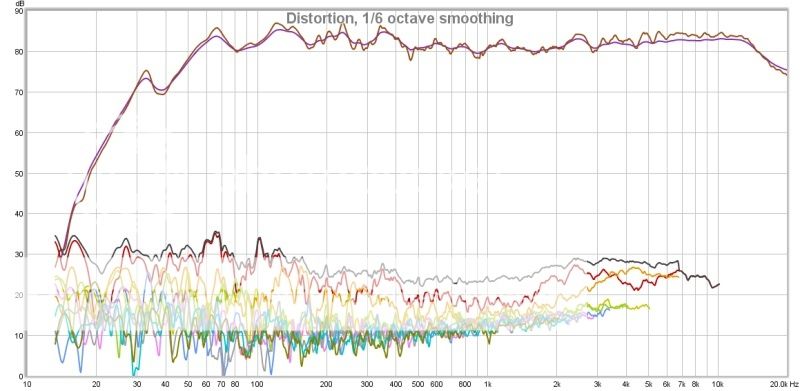

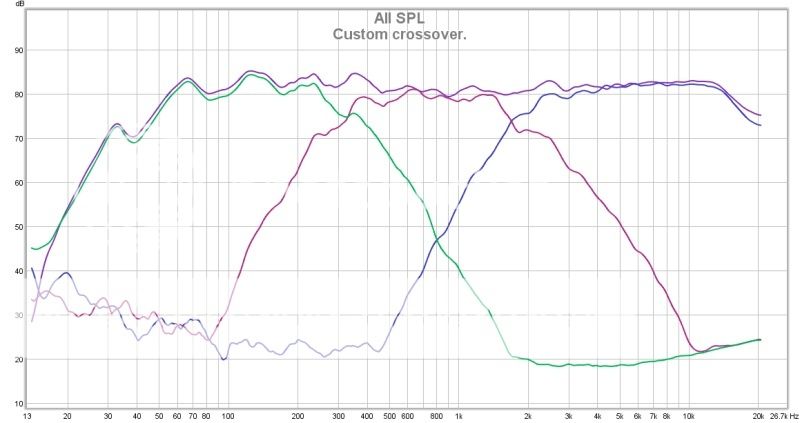

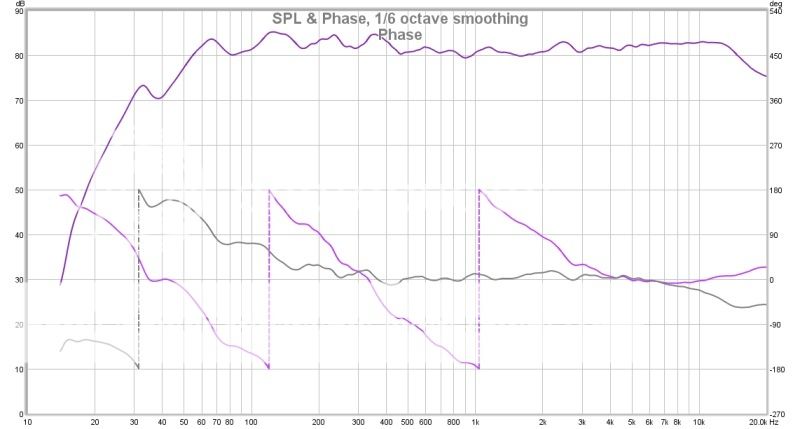

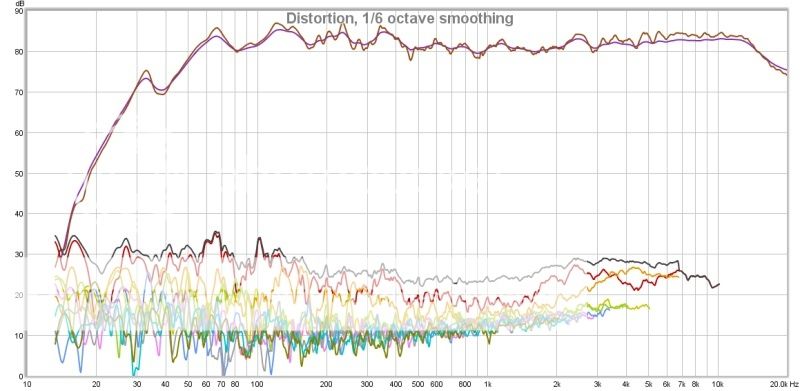

Since this photo was taken I have had numerous crossover prototypes, and after months of measurements and listening sessions, built my own active crossovers with fixed crossover points of 340hz and 1.8khz LR4. This seems to provide the best subjective sound quality with the best measured polar/power response and distortion:

http://i845.photobucket.com/albums/ab20/Plinkerking/custom crossover.jpg

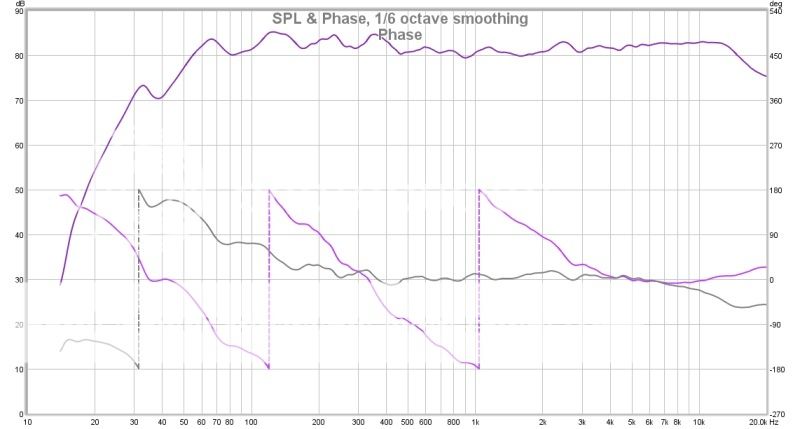

http://i845.photobucket.com/albums/ab20/Plinkerking/phase.jpg

Originally the mid chamber tubes were lined just with a 2 mm bitumen damping sheet and a layer of felt. Listening to the outer cabinet walls with a stethoscope, I was dismayed to hear the mid driver clearly through them.....so began my modifications to the cabinet to reduce all noise and resonance.....

After reading this thread and realising I would need a lot more damping on the mid chambers I added two layers of 4mm silent coat to one chamber. Comparing that with the other speaker demonstrated a massive difference. I can barely hear the mid driver through the outer cabinet now, and that is using a stethoscope.

How this all equates to how the speakers sound when run full range with music is a difficult question to answer. It is very subjective. The most notable thing is that on a few of my 'test tracks' - a female voice would occasionally 'smear' towards the speaker cabinets when singing certain notes, rather than the usually 'locked in' central image. I wondered whether this was caused by excessive midrange sounds/cabinet resonances escaping via the cabinet side-walls - this led me to the current journey I am on, trying to minimise cabinet noise and resonance....

When I now listen to the same tracks I can't detect any of that 'smear' that was there before - so I think this may tie in with the reduction in audible noise from the mid enclosure after the extra damping.

To be honest the de-coupling of the mid/tweeter and woofer, is probably just my obsession now with minimising cabinet noise - I have no idea whether it will make a discernible difference to the sound quality...

However, given I have used expensive drivers, custom active crossovers, and expensive MC2 amps, I want to try to maximise all aspects of the design - including the cabinet.

I hope this helps.

http://www.diyaudio.com/forums/mult...r-anyone-spot-any-probs-before-i-start-6.html

Here is a photo.

[URL=http://s845.photobucket.com/user/Plinkerking/media/Almostfinished.jpg.html]

[/URL]

[/URL]Since this photo was taken I have had numerous crossover prototypes, and after months of measurements and listening sessions, built my own active crossovers with fixed crossover points of 340hz and 1.8khz LR4. This seems to provide the best subjective sound quality with the best measured polar/power response and distortion:

http://i845.photobucket.com/albums/ab20/Plinkerking/custom crossover.jpg

http://i845.photobucket.com/albums/ab20/Plinkerking/phase.jpg

Originally the mid chamber tubes were lined just with a 2 mm bitumen damping sheet and a layer of felt. Listening to the outer cabinet walls with a stethoscope, I was dismayed to hear the mid driver clearly through them.....so began my modifications to the cabinet to reduce all noise and resonance.....

After reading this thread and realising I would need a lot more damping on the mid chambers I added two layers of 4mm silent coat to one chamber. Comparing that with the other speaker demonstrated a massive difference. I can barely hear the mid driver through the outer cabinet now, and that is using a stethoscope.

How this all equates to how the speakers sound when run full range with music is a difficult question to answer. It is very subjective. The most notable thing is that on a few of my 'test tracks' - a female voice would occasionally 'smear' towards the speaker cabinets when singing certain notes, rather than the usually 'locked in' central image. I wondered whether this was caused by excessive midrange sounds/cabinet resonances escaping via the cabinet side-walls - this led me to the current journey I am on, trying to minimise cabinet noise and resonance....

When I now listen to the same tracks I can't detect any of that 'smear' that was there before - so I think this may tie in with the reduction in audible noise from the mid enclosure after the extra damping.

To be honest the de-coupling of the mid/tweeter and woofer, is probably just my obsession now with minimising cabinet noise - I have no idea whether it will make a discernible difference to the sound quality...

However, given I have used expensive drivers, custom active crossovers, and expensive MC2 amps, I want to try to maximise all aspects of the design - including the cabinet.

I hope this helps.

Last edited:

Hi and thank you very much indeed and this helps a lot indeed

I am sick for soundstage and every action that provides an improvement in this regard is a godsend for me. Actually for me 3D sound is what stereo is about (especially depth of soundstage of course, when the front wall disappear is magic)

Following your experience i will buy a stethoscope and try some damping of speaker panels

I will read your thread with the greatest interest.

Thanks again and kind regards, gino

I am sick for soundstage and every action that provides an improvement in this regard is a godsend for me. Actually for me 3D sound is what stereo is about (especially depth of soundstage of course, when the front wall disappear is magic)

Following your experience i will buy a stethoscope and try some damping of speaker panels

I will read your thread with the greatest interest.

Thanks again and kind regards, gino

Thanks to all, particularly Twinter for all your useful information and particularly the info on extensional damping. As a result of all this I have just lined my internal mid chambers, which are fairly soft 2mm plastic sealed tubes of approx 2.5 litre volume, with over 8mm of silent coat.

I hoped this would lower the mid chamber's resonance and increase damping enough to move problems out of the midrange driver passband.....It has.

Having a fully active system I can listen to each driver separately and using the stethoscope to listen to one mid driver with the additional damping and the other without, over all areas of each panel. I could go directly back and forth with various tones/music and compare. There is an enormous reduction in panel noise on all panels. I am over-joyed.

The mid range driver is now the quietest driver when using the stethoscope, whereas previously it was the loudest. I guess I now have a fairly flexible, highly damped, sealed mid-chamber which has low, well damped resonances which aren't being excited by the mid driver any more.

Comparing the modification to the unlined cabinet was dramatic. The tweeter and woofer are now the main sources of panel noise, so I will try the sorbothane with the tweeters next. I have 40 Duro 3mm sorbothane sheet, so once I have calculated the gasket area, I will work out how much to torque up the screws to get the appropriate pressure for maximum damping.

I will report back.

Bushmeister, glad to hear you made significant progress. There's more related information to come.

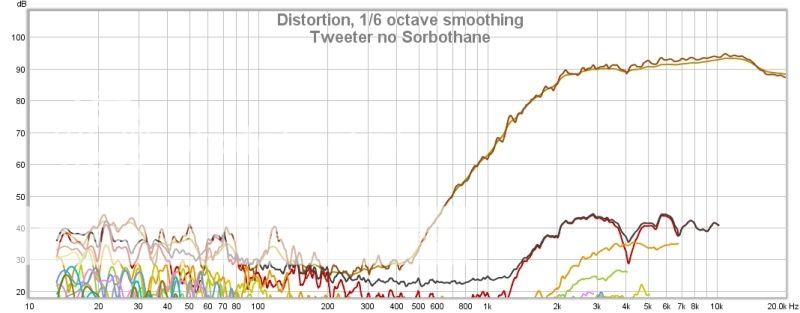

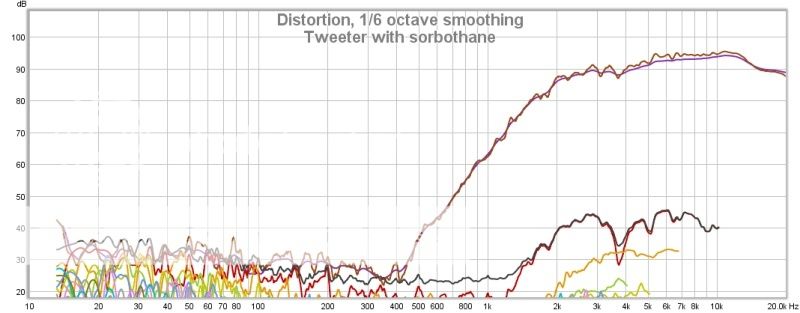

So I am quite frankly shocked at the difference the sorbothane gasket has made with the tweeter. I had intellectually decided that most of the energy transferred to a cabinet must be mechanical (after reading this thread), but I don't think I really believed it!

The stethoscope test is completely dead with the sorbothane. I mean totally no transfer of noise from the tweeter to the upper cabinet panel at all....nothing.

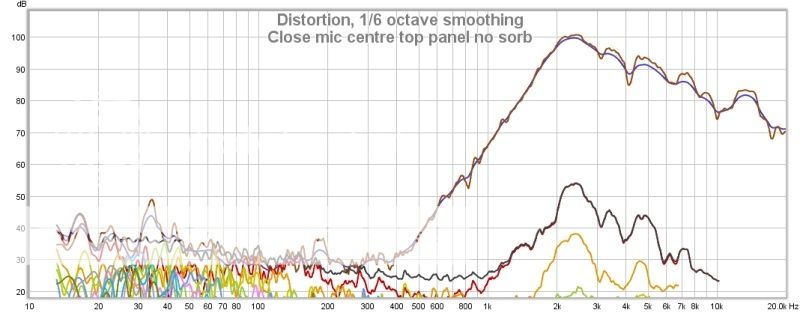

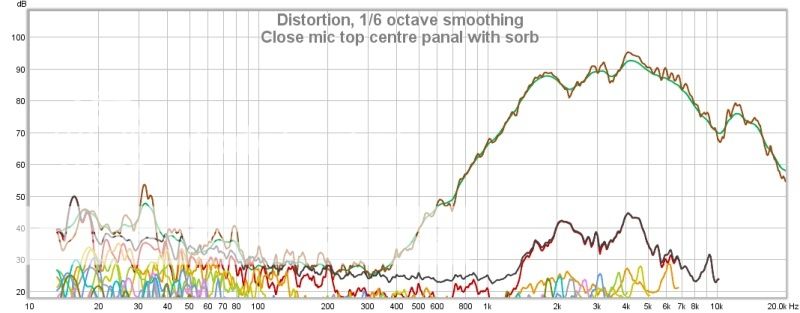

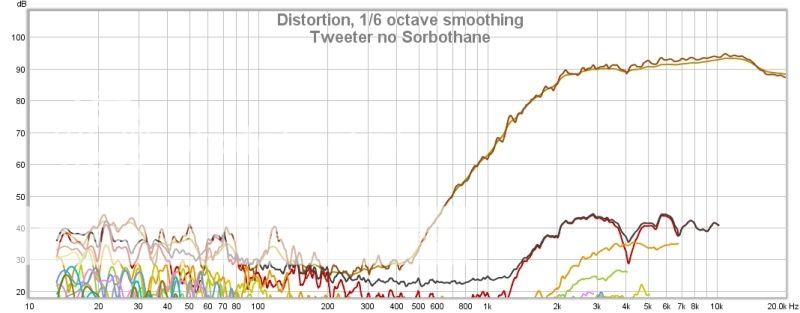

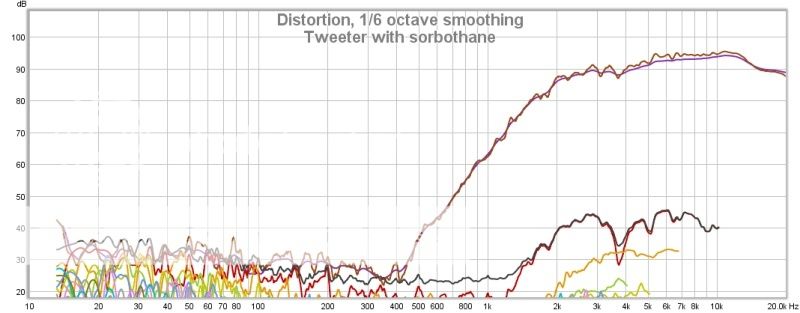

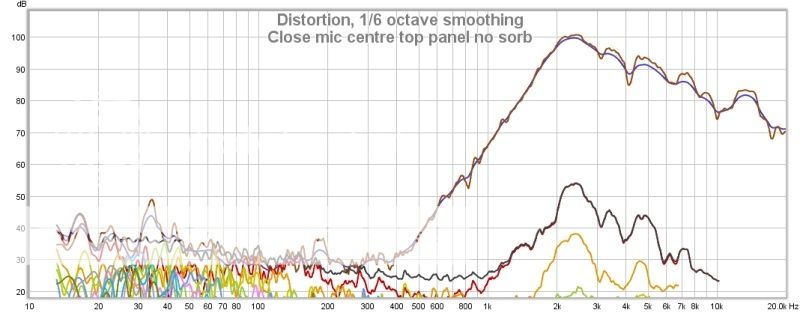

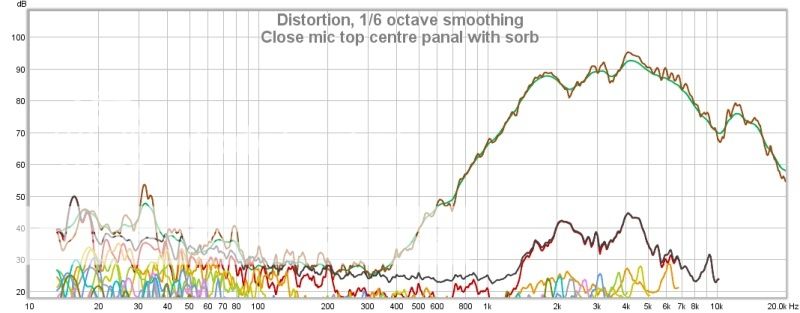

I was so shocked by the complete night and day difference that I tried some close mic (5mm) measurements of the centre of the top panel with REW. I thought it had to be measurable.

So I guess they speak for themselves - the on-axis difference in the tweeter response is likely due to the diffraction of the the tweeter frame, as the gasket has lifted it off the baffle by 2.5mm - I need to re-route the baffle to accommodate the larger gaskets.

These measurements are obviously the sum of the driver output and the output from the panel at 5mm. The difference I think is pretty obvious.

There appears to be a large panel resonance at 2.5Khz which is completely gone with the sorbothane gasket - it raises the reponse 10dB. However, the actual difference when listening with a stethoscope as I have said is much more dramatic - more so than the extra damping of the mid.

Talking about the mid - time to mount that with a new gasket......I will report back.

The stethoscope test is completely dead with the sorbothane. I mean totally no transfer of noise from the tweeter to the upper cabinet panel at all....nothing.

I was so shocked by the complete night and day difference that I tried some close mic (5mm) measurements of the centre of the top panel with REW. I thought it had to be measurable.

So I guess they speak for themselves - the on-axis difference in the tweeter response is likely due to the diffraction of the the tweeter frame, as the gasket has lifted it off the baffle by 2.5mm - I need to re-route the baffle to accommodate the larger gaskets.

These measurements are obviously the sum of the driver output and the output from the panel at 5mm. The difference I think is pretty obvious.

There appears to be a large panel resonance at 2.5Khz which is completely gone with the sorbothane gasket - it raises the reponse 10dB. However, the actual difference when listening with a stethoscope as I have said is much more dramatic - more so than the extra damping of the mid.

Talking about the mid - time to mount that with a new gasket......I will report back.

Last edited:

The BBC paper "Factors in the Design of Loudspeaker Cabinet" by H.D. Harwood and R. Mathews is frequently referenced. See the link:

http://www.diy-audio.narod.ru/litr/1977-03.pdf

Harwood and Mathews performed extensive testing and wrote an excellent paper with good insightful analysis. They achieved their goal. They developed a cost effective enclosure, with wall damping, that reduced panel sound emissions to meet their criteria for non-perceptibility. They tested numerous enclosure wall materials and damping configurations. The testing and paper were not intended to develop an enclosure configuration with the lowest possible panel sound emissions.

This paper is frequently referenced by others, sometimes extrapolating its results and crediting it with more extensive implications. I have therefore included some detailed comments, encase one does not desire to spend the time deciphering the paper. Reading this will still take some dedication, sorry. Having a printed copy of the article in hand when reading the comments below would be helpful, almost required. Maybe this material can be condensed again.

Comments:

1) The enclosure panel emission level relative criteria is shown on article page 19, Figure 12, without reference. It is also superimposed on the frequency response plots of the loudspeakers panel sound emission tests.

Relative Level of Enclosure Panels Emission to Loudspeaker Driver Output To Avoid Perceptibility - As given in the Article

100 Hz -13 dB

200 Hz -21 dB

300 Hz - 26 dB

420 Hz -30 Hz

1000 Hz -30 Hz

10,000 Hz -30 Hz

2) Page 7, Table 2 lists the properties of different material for enclosure construction. Harwood & Mathews developed a "figure of merit" (their words) index in the next to last column:

SQRT((modulus of elasticity)(density)/Q x 10EE-5.

Another perspective is: damping x SQRT(Stiffness x Mass)

The greatest values 0.086, 0.085, 0.068, & 0.097 are for lines 15 through 18, and are glass reinforced plastic products. The next highest set of 0.044, 0.43, & 0.042, are for lines 6, 9, & 10 and are for 9mm and 17mm resin bonded birch plywood.

Harwood & Mathews state on page 10:

"...However the figures of merit obtained for the glass reinforced plastic material clearly exceeds that of woodbased types and although the cost is high at present they have the virtue that their cost is not rising as quickly as that of the woodbased products. When therefore an irregular shaped cabinet is being designed the advantages of the type of material should be remembered.

However it should be noted that all of the materials tested are seen to have an excessive Q, the lowest values being about 30. It is therefore evident that additional mechanical damping is required for the panels and under these conditions the natural Q of the material is of much less importance and the values of the characteristic impedance alone are therefore given in the Table (last column)..........it should be noted that the glass reinforced plastic materials retain their first place."

3) Page 12, Table 4, Effects of Damping Treatment on 9mm Birch 7 Ply Along Surface Grain

Q and n damping factor values are listed. n = 1/Q.

Mode Fundamental Q's (second column) of 10 or below represents good damping.

The n fund (thirteenth column), damping factor of the fundamental mode, of 0.100 or greater represents good damping also (remember n = 1/Q).

Only damping treatments for lines 12, 16, and 19 have n fund of 0.100 or greater, denoting good damping.

Line 12 is part of a group, lines 10, 11, & 12 with increasing numbers of layers of Bostik. The damping increases as the damping material thickness increases (1.82 then 3.64 then 5.45 mm), extensional damping principals applied.

Line 16 has me a little puzzled. The 2.9 mm layer of damping material Aquaplas and Thixofix contact cement treatment is well damped with damping factor = 0.100. That's some very effective damping material.

Line 19 is part of a group, lines 17, 18, & 19 of intended constrained layer damping (CLD). Damping material Mutacell is used with Thixofix contact cement and a steel layer. However, Mutacell does not have the desirable shear damping properties for CLD. The damping increases to 0.1428 as the damping layers (4) increases to 7.15 mm. Harwood and Mathews comment on this on page 13.

4) Page 13, Table 6 Effect of Breaks In Damping Layer

Results show the importance of maintaining the integrity of the damping layer for effective damping.

5) Pages 15 & 16, Figures 5, 6, & 7 For Loudspeaker LS 3/6

Figure 5, loudspeaker with erroneously applied one layer of damping material shows slightly increased panel sound output at 200 Hz with "noticeable" & "objectionable" coloration. Figure 6, same loudspeaker with designed two layers of damping, reduced and "permissible" panel sound output at 200 Hz. Figure 7, same loudspeaker with loose stiffening fillets on back panel resulted in broader frequency spectrum with lower output around 200 Hz.

6) Figures 8 & 9 For Loudspeaker LS 3/5

Figures 8 and 9 show the difference in panel sound output when Parana pine fillets were erroneously used instead of the specified beech fillets, with a "audible" and "honky" 9 dB peak at 350 Hz.

7) Figures 10 & 11 Loudspeaker LS 3/4

Figure 10, loudspeaker with inadequate damping resulted in elevated panel sound output at 150 Hz and 490 Hz, with only the smaller 490 Hz peak audible.

Figure 11, loudspeaker with proper damping.

8) Figures 13(a) & 13(b) and 14(a) & 14 (b) Loudspeakers size of LS 3/6, 25" x 12" x 12" (63 x 30 x 30 cm)

Figure 13 (a), loudspeaker 9 mm birch plywood panels, no panel damping, fiberglass fill

Figure 13 (b), loudspeaker 18 mm birch plywood panels, no panel damping, fiberglass fill

Figure 14 (a), loudspeaker 9 mm birch plywood panels, 2 layers Mutcell damping with Aquaseal adhesive, fiberglass fill

Figure 14 (b), loudspeaker 18 mm birch plywood panels, 2 layer Mutcell damping with Aquaseal adhesive, fiberglass fill

Harwood & Mathews comments on page 19:

".....It will be observed that in the case of the thinner wall cabinet, Fig 14(a), the criterion is met whereas it is not met in the case of the thicker walled cabinet, Fig. 14(b). Listening tests confirm these results. Presumably the thicker walled cabinet could be brought within the criterion by the extensive use of much thicker, and therefore more expensive, damping material. Thus, the thicker walled cabinet is more expensive in plywood and in damping material, and is of course unnecessarily heavy, an important point from the outside broadcast aspect. It has no advantages and is clearly an inferior design to that normally used."

I agree with Harwood and Mathews comments, with qualifications concerning the last sentence. If you accept their criteria for panel sound reduction goals, I fully agree.

Looking at Fig. 14(a) and Fig. 14(b), the 160 and 250 Hz peaks of the thinner 9 mm panel have shifted to 230 and 400 Hz for the thicker 18 mm panel, with no change in magnitude. The 18 mm panel has reduced sound emission from 1000 Hz and above. Standard guidelines for application of extensional damping call for a thicker damping layer for a 18 mm panel than for a 9 mm panel.

Comparing Fig. 13(b) to Fig 14(b) reveals the impact of adding the 2 layers of Mutacell damping material (3.85 mm thickness if the same as referenced in Table 4) to the bare panels of the 18 mm speaker. The peaks at 230 and 490 Hz decreased approximately 5 dB, the peak at 900 Hz decreased about 2 dB, the peak at 350 Hz remained unchanged, and the peak at 650 Hz increased 3 dB.

As a general comment, today's high loudspeaker drivers are lowering even order harmonic distortion with improved cones, and lowering odd order harmonic distortion with improve motor designs (shortening rings and contoured pole pieces). Midrange harmonic distortion in the -60 and sometime -70 dB territory has been achieved. Reference SB Acoustics Satori, Scanspeak, Wavecor, Accuton.

http://www.diy-audio.narod.ru/litr/1977-03.pdf

Harwood and Mathews performed extensive testing and wrote an excellent paper with good insightful analysis. They achieved their goal. They developed a cost effective enclosure, with wall damping, that reduced panel sound emissions to meet their criteria for non-perceptibility. They tested numerous enclosure wall materials and damping configurations. The testing and paper were not intended to develop an enclosure configuration with the lowest possible panel sound emissions.

This paper is frequently referenced by others, sometimes extrapolating its results and crediting it with more extensive implications. I have therefore included some detailed comments, encase one does not desire to spend the time deciphering the paper. Reading this will still take some dedication, sorry. Having a printed copy of the article in hand when reading the comments below would be helpful, almost required. Maybe this material can be condensed again.

Comments:

1) The enclosure panel emission level relative criteria is shown on article page 19, Figure 12, without reference. It is also superimposed on the frequency response plots of the loudspeakers panel sound emission tests.

Relative Level of Enclosure Panels Emission to Loudspeaker Driver Output To Avoid Perceptibility - As given in the Article

100 Hz -13 dB

200 Hz -21 dB

300 Hz - 26 dB

420 Hz -30 Hz

1000 Hz -30 Hz

10,000 Hz -30 Hz

2) Page 7, Table 2 lists the properties of different material for enclosure construction. Harwood & Mathews developed a "figure of merit" (their words) index in the next to last column:

SQRT((modulus of elasticity)(density)/Q x 10EE-5.

Another perspective is: damping x SQRT(Stiffness x Mass)

The greatest values 0.086, 0.085, 0.068, & 0.097 are for lines 15 through 18, and are glass reinforced plastic products. The next highest set of 0.044, 0.43, & 0.042, are for lines 6, 9, & 10 and are for 9mm and 17mm resin bonded birch plywood.

Harwood & Mathews state on page 10:

"...However the figures of merit obtained for the glass reinforced plastic material clearly exceeds that of woodbased types and although the cost is high at present they have the virtue that their cost is not rising as quickly as that of the woodbased products. When therefore an irregular shaped cabinet is being designed the advantages of the type of material should be remembered.

However it should be noted that all of the materials tested are seen to have an excessive Q, the lowest values being about 30. It is therefore evident that additional mechanical damping is required for the panels and under these conditions the natural Q of the material is of much less importance and the values of the characteristic impedance alone are therefore given in the Table (last column)..........it should be noted that the glass reinforced plastic materials retain their first place."

3) Page 12, Table 4, Effects of Damping Treatment on 9mm Birch 7 Ply Along Surface Grain

Q and n damping factor values are listed. n = 1/Q.

Mode Fundamental Q's (second column) of 10 or below represents good damping.

The n fund (thirteenth column), damping factor of the fundamental mode, of 0.100 or greater represents good damping also (remember n = 1/Q).

Only damping treatments for lines 12, 16, and 19 have n fund of 0.100 or greater, denoting good damping.

Line 12 is part of a group, lines 10, 11, & 12 with increasing numbers of layers of Bostik. The damping increases as the damping material thickness increases (1.82 then 3.64 then 5.45 mm), extensional damping principals applied.

Line 16 has me a little puzzled. The 2.9 mm layer of damping material Aquaplas and Thixofix contact cement treatment is well damped with damping factor = 0.100. That's some very effective damping material.

Line 19 is part of a group, lines 17, 18, & 19 of intended constrained layer damping (CLD). Damping material Mutacell is used with Thixofix contact cement and a steel layer. However, Mutacell does not have the desirable shear damping properties for CLD. The damping increases to 0.1428 as the damping layers (4) increases to 7.15 mm. Harwood and Mathews comment on this on page 13.

4) Page 13, Table 6 Effect of Breaks In Damping Layer

Results show the importance of maintaining the integrity of the damping layer for effective damping.

5) Pages 15 & 16, Figures 5, 6, & 7 For Loudspeaker LS 3/6

Figure 5, loudspeaker with erroneously applied one layer of damping material shows slightly increased panel sound output at 200 Hz with "noticeable" & "objectionable" coloration. Figure 6, same loudspeaker with designed two layers of damping, reduced and "permissible" panel sound output at 200 Hz. Figure 7, same loudspeaker with loose stiffening fillets on back panel resulted in broader frequency spectrum with lower output around 200 Hz.

6) Figures 8 & 9 For Loudspeaker LS 3/5

Figures 8 and 9 show the difference in panel sound output when Parana pine fillets were erroneously used instead of the specified beech fillets, with a "audible" and "honky" 9 dB peak at 350 Hz.

7) Figures 10 & 11 Loudspeaker LS 3/4

Figure 10, loudspeaker with inadequate damping resulted in elevated panel sound output at 150 Hz and 490 Hz, with only the smaller 490 Hz peak audible.

Figure 11, loudspeaker with proper damping.

8) Figures 13(a) & 13(b) and 14(a) & 14 (b) Loudspeakers size of LS 3/6, 25" x 12" x 12" (63 x 30 x 30 cm)

Figure 13 (a), loudspeaker 9 mm birch plywood panels, no panel damping, fiberglass fill

Figure 13 (b), loudspeaker 18 mm birch plywood panels, no panel damping, fiberglass fill

Figure 14 (a), loudspeaker 9 mm birch plywood panels, 2 layers Mutcell damping with Aquaseal adhesive, fiberglass fill

Figure 14 (b), loudspeaker 18 mm birch plywood panels, 2 layer Mutcell damping with Aquaseal adhesive, fiberglass fill

Harwood & Mathews comments on page 19:

".....It will be observed that in the case of the thinner wall cabinet, Fig 14(a), the criterion is met whereas it is not met in the case of the thicker walled cabinet, Fig. 14(b). Listening tests confirm these results. Presumably the thicker walled cabinet could be brought within the criterion by the extensive use of much thicker, and therefore more expensive, damping material. Thus, the thicker walled cabinet is more expensive in plywood and in damping material, and is of course unnecessarily heavy, an important point from the outside broadcast aspect. It has no advantages and is clearly an inferior design to that normally used."

I agree with Harwood and Mathews comments, with qualifications concerning the last sentence. If you accept their criteria for panel sound reduction goals, I fully agree.

Looking at Fig. 14(a) and Fig. 14(b), the 160 and 250 Hz peaks of the thinner 9 mm panel have shifted to 230 and 400 Hz for the thicker 18 mm panel, with no change in magnitude. The 18 mm panel has reduced sound emission from 1000 Hz and above. Standard guidelines for application of extensional damping call for a thicker damping layer for a 18 mm panel than for a 9 mm panel.

Comparing Fig. 13(b) to Fig 14(b) reveals the impact of adding the 2 layers of Mutacell damping material (3.85 mm thickness if the same as referenced in Table 4) to the bare panels of the 18 mm speaker. The peaks at 230 and 490 Hz decreased approximately 5 dB, the peak at 900 Hz decreased about 2 dB, the peak at 350 Hz remained unchanged, and the peak at 650 Hz increased 3 dB.

As a general comment, today's high loudspeaker drivers are lowering even order harmonic distortion with improved cones, and lowering odd order harmonic distortion with improve motor designs (shortening rings and contoured pole pieces). Midrange harmonic distortion in the -60 and sometime -70 dB territory has been achieved. Reference SB Acoustics Satori, Scanspeak, Wavecor, Accuton.

Last edited:

I do not want to sound like a troll ... but i intend to improve a speaker with a Tannoy DC in which the tweeter looks to me rigidly mounted on the back of the woofer.

Should i try some form of decoupling for the tweeter ?

The tweeter in a Tannoy DC is a CD - it has to be bolted onto the back of the magnet to keep its VC in alignment, given that both 'drive units' use the same magnet / gap 😱

AND Afaik all the 'newer' DC's have ferro-fluid in there as well, so un-bolting and removing the tweeter will turn the unit into 'bin fodder'.

I have speakers from a kit designed and documented by David Beryman (might be incorrect sp of surname) in a mid 90's HFN&RR design - DBS-7.

They have a form of 'cld' incorporated between the braced panels, formed with 3 off 3.5 mm 'press board' rectangles, 'bonded' with quite a thick layer of Evostik to the 18mm mdf carcass.

The front baffle is cld as well as cld internally..... and the driver is braced solidly a-la Planet10 styleeeee.

Both mid/woof and tweet are paper gasketed (REAL gasket paper).

The designer said in the build notes:

'Leave the cld out of the finished cabinet and listen for a few days, then add them 1 at a time and listen between each layer.

You'll be surprised at what you hear as you add layers."

One of the best non-sounding boxes I've ever heard..... or not as the case may... IS 😉

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- how to brace a speaker cabinet?