Wrong, plain bs, as you would say. However, I am not responsible

for the design of ADAM amp modules, Hypex is.

Hello, As from the Adam website:

"So ADAM spared no efforts and decided to design its own high frequency power amp to allow the new high frequency unit to live up to its unique talents."

Do not see how Hypex can be blamed. And the problem seems to be a linear power supply - just how is the Hypex's fault???? Talk about BS.

You seem to have some practical knowledge of these products.

See ADAM Active Studio Monitor schematic diagrams help

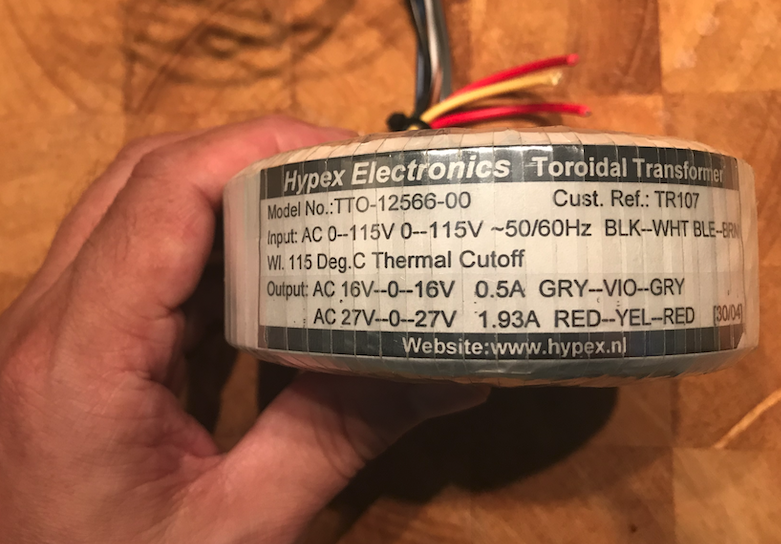

ADAM Hypex transformer picture :

https://www.diyaudio.com/forums/chi...or-schematic-diagrams-help-3.html#post6330768

See ADAM Active Studio Monitor schematic diagrams help

ADAM Hypex transformer picture :

https://www.diyaudio.com/forums/chi...or-schematic-diagrams-help-3.html#post6330768

Last edited:

Thanks.

Funny,

it looks very very different from the one shown in the OP picture:

which piqued my curiosity because it looks way taller and narrower (less diameter) than usual in Toroids.

You sure you are talking about the same transformers?

The pictures are there for anybody to see and compare.

Yours looks more like a "normal" toroid.

As a side note, it looks somewhat tightly specified (lack of space for a larger one?) : 100VA (54VAC * 1.93A) for a nominal 50+50W amplifier WILL work, no doubt, but with not much spare room.

I seem to having estimated diameter right, about 4"/10 cm 🙂 but visible height does not match.

Funny,

it looks very very different from the one shown in the OP picture:

which piqued my curiosity because it looks way taller and narrower (less diameter) than usual in Toroids.

You sure you are talking about the same transformers?

The pictures are there for anybody to see and compare.

Yours looks more like a "normal" toroid.

As a side note, it looks somewhat tightly specified (lack of space for a larger one?) : 100VA (54VAC * 1.93A) for a nominal 50+50W amplifier WILL work, no doubt, but with not much spare room.

I seem to having estimated diameter right, about 4"/10 cm 🙂 but visible height does not match.

The company is in existence for a long time and produced a variety of different models. Point is, Hypex was denied in post 42.

I got this Pioneer receiver to fix, it came from a pawn shop and most of the cover screws were missing. I really don't like to touch such stuff, but well, trying to help a mate. There were two problems with the AC supply. The fuse inside the transformer were broken and the other fault that I have never seen were the voltage selector that was faulty. That really buggered me around, that thing gets switched one time in its life, how can it break ? Well the transformer were welded as well, I grind-ed it open and found a loose connection on the thermal fuse. Re-welded the lamination's with one less that couldn't fit and it works great.

This is the first time I've tried it, I was worried about a shorted turn fault but it worked out good.😀

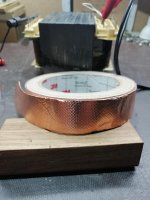

I use the copper tape for a belly band.

This is the first time I've tried it, I was worried about a shorted turn fault but it worked out good.😀

I use the copper tape for a belly band.

Attachments

Have had the defective selector too and wondered the same. Is using plural for singular standard in south african english (like: the transformer were)? Just curious and getting Die Antwoord vibes 🙂

Last edited:

JP, sorry that was a finger fault.😀 (transformer were broken). English is my second language and sometimes the focus is not all ways there, specially on a weekend ! Where I live we very rarely speak English although I read it everyday." Die Antwoord " meaning the answer is not my cup of tea, weirdos, they are people with more problems that I will ever have !😀

Of course, if the transformer is defective, then it certainly needs replacement. A normally functioning one that has not been abused does not need replacement since there is nothing in transformers made with modern-day materials that wears out. Old transformers may have insulation that is drying out and cracking, and that could cause a catastrophic failure. That's more of a materials failure than a transformer one, and the unfortunate transformer takes the hit for that.

I had a few amps from friends I was asked to fix. In the most cases it were transformers which couldn't handle the grid voltage change from 220..230..240V on the long run (still overall just a few compared to other problems) and two which had the thermal fuse blown because of a defective final amp stage. Transformers are the most rare things to break in an amp if it's not grossly (electrical or mechanical) misused or in use with defective boards. I've got HiFi and PA amps which are 40-70 years old and the transformers show no sign of aging.

Mechanical defects are usually on laminated tranformers (E-I core) loose and/or bent metal layers, on toroidial broken core rings. Both can be repaired and even mechanical noise fixed with molding the core in epoxy or similar material. However, that affects the thermal dissipation and it has to be taken care of it for the unit to not exceed the lower average power capability.

SMPS's are a whole other thing though. While many work decently without fail for a very long time, others die within 2-5 yrs, the half of it after about 10-15 yrs. That's at least the experience I've made.

Mechanical defects are usually on laminated tranformers (E-I core) loose and/or bent metal layers, on toroidial broken core rings. Both can be repaired and even mechanical noise fixed with molding the core in epoxy or similar material. However, that affects the thermal dissipation and it has to be taken care of it for the unit to not exceed the lower average power capability.

SMPS's are a whole other thing though. While many work decently without fail for a very long time, others die within 2-5 yrs, the half of it after about 10-15 yrs. That's at least the experience I've made.

Thanks again for all the thoughts everyone. I've inspected inside so here are some answers some more questions.

The transformer is about 60mm (2.4in) high, 70mm (2.8in) diameter. It says Pri: 0V - 115V - 230V and Sec: 24.5V - 0V - 24.5V . I'm in the UK so on 240V. To confirm, the first repair that was done was only a transformer replacement, the second was the whole "amp board," so yes, may not have been a faulty transformer.

Based on all your thoughts, I'm currently thinking I will a) install some extra rubber under the transformers, b) make sure they're not screwed down too tightly, c) buy a new upgraded transformer only if/when needed and d) hope that any spare parts I may need in the future are working on the spare "amp board" I have.

If it makes any difference, I don't actually use these monitors very often (maybe 5 hours a month), don't listen loudly, and use a sub-woofer so filter out very low frequencies through these monitors.

The transformer is about 60mm (2.4in) high, 70mm (2.8in) diameter. It says Pri: 0V - 115V - 230V and Sec: 24.5V - 0V - 24.5V . I'm in the UK so on 240V. To confirm, the first repair that was done was only a transformer replacement, the second was the whole "amp board," so yes, may not have been a faulty transformer.

Based on all your thoughts, I'm currently thinking I will a) install some extra rubber under the transformers, b) make sure they're not screwed down too tightly, c) buy a new upgraded transformer only if/when needed and d) hope that any spare parts I may need in the future are working on the spare "amp board" I have.

If it makes any difference, I don't actually use these monitors very often (maybe 5 hours a month), don't listen loudly, and use a sub-woofer so filter out very low frequencies through these monitors.

No VA number?

If it are the windings getting shorted as indicated by a person that seems to know more then the extra rubber is to be done. It does not make any difference if you use them or not when it is a technical complaint causing electrical complaints. It does make a difference if you take measures as soon as possible as (if all the info is correct) you will prevent a failure and thus save frustration and money. That seems a better idea than waiting till it breaks down.

If it are the windings getting shorted as indicated by a person that seems to know more then the extra rubber is to be done. It does not make any difference if you use them or not when it is a technical complaint causing electrical complaints. It does make a difference if you take measures as soon as possible as (if all the info is correct) you will prevent a failure and thus save frustration and money. That seems a better idea than waiting till it breaks down.

Last edited:

If it makes any difference, I don't actually use these monitors very often (maybe 5 hours a month), don't listen loudly

No VA number?

Get equivalent weight, or the next size UP - suitable for the same frequency. “60 Hz only” transformers are often smaller than 50/60 for a given VA rating. 24-0-24 with a primary configurable for 240V should be common enough. I can’t see it being more than a 200VA, given what its supplying (chip amps) - although people building gainckones often use 600 or more VA thinking it will improve the sound.

I have a large toroidal transformer which had very hard resin poured to completely fill the middle hole. This was from the factory. Seeing that damn resin, and knowing it is actually a thermal insulator blanketing a portion of the windings, I made it a point to somehow remove that resin from where it does not belong!

I used a hot air gun with a selected air temperature of 120C to soften the resin. After about three hours it was all removed and the transformer looks it never had resin poured to seal the middle hole.

Why did I do this? The enemies of transformers are heat and overloads. The latter is impossible, as the rating is about 3kW (Yes, yes some use VA!) and I do not want to deafen myself beyond hearing for the rest of my life!

When I succeed to purchase a properly manufactured transformer, there is a sense of satisfaction I do not get buying the most shiny of modern equipment. Transformers are everlasting components if properly used.

I used a hot air gun with a selected air temperature of 120C to soften the resin. After about three hours it was all removed and the transformer looks it never had resin poured to seal the middle hole.

Why did I do this? The enemies of transformers are heat and overloads. The latter is impossible, as the rating is about 3kW (Yes, yes some use VA!) and I do not want to deafen myself beyond hearing for the rest of my life!

When I succeed to purchase a properly manufactured transformer, there is a sense of satisfaction I do not get buying the most shiny of modern equipment. Transformers are everlasting components if properly used.

Last edited:

Mmm, toroids often hum with a slight DC component on the mains voltage. Resin filled toroids can't hum as easily and I never experienced a humming one. When resin filled they are derated but who cares? They are silent which is what counts. Just choose a larger type than one calculated. The enemy of audiophiles is (mechanical and electrical) hum and by removing the resin that did belong there you effectively now have created a less silent transformer. If that is a true 3 kVA transformer then one will not easily overheat that one as the factory took that fact in account when they resin filled it. You also state that you will never overload it so ... it would never have overheated for 2 valid reason so what is achieved exactly? The enemy of transformers are laymen that just do something. Anyway, just make sure you use slow start with that one.

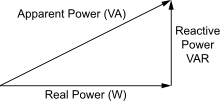

VA is the standard when describing transformer power so all do that. P = U x I is in VA. P = U x I x cos phi is in W. Please look up apparent power, reactive power and real power.

VA is the standard when describing transformer power so all do that. P = U x I is in VA. P = U x I x cos phi is in W. Please look up apparent power, reactive power and real power.

Attachments

Last edited:

There's no number for VA listed on the transformer. On the back panel of the monitor, it says 100w for maximum power consumption.

Last edited:

The circuit topology completely excludes the possibility of any DC present on the primary side. DC has to be deliberately introduced like using halve wave rectification.Mmm, toroids often hum with a slight DC component on the mains voltage.

Well, I never heard it humming.The enemy of audiophiles is hum and by removing the resin that did belong there you effectively now have created a less silent transformer.

The requirement of slow start very heavily depends on the value of smoothing capacitors. These are not very big. The total combined capacitance for all four rails for two channels is: 3300uF*8 = 26.4mF.If that is a true 3 kVA transformer then one will not easily overheat that one as the factory knew this when they resin filled it. Anyway, just make sure you use slow start with that one.

That is advanced level Physics. I have university level. The power factor also features in mechanical work using the dot product of two vectors, which are, the force vector and the displacement vector. The definition of the dot product is:VA is the standard when describing transformer power. P = U x I is in VA. P = U x I x cos phi is in W.

Code:

dot product = |force|*|displacement|*cosine(angle)

For vectors using the i, j, k component system, it is calculated using:

For vectors A = ai + bj + ck and B = di + ej + fk, the product is:

A.B = (ai + bj + ck).(di + ej + fk)

A.B = ad + be + cf, and is a SCALAR quantity.- Home

- Amplifiers

- Solid State

- How often should transformers blow