When I'm selecting parts, is there any benefit for seeking out tight tolerance versions? Is getting 1% resistors functionally better than 5%?

Depends what type/area of circuit they're being applied to

Should I infer from that that the power supply would be less vital than the driver board in a power amplifier, say?

They will be more stable than the 5% parts, to have the 1% rating.

That makes sense. On that basis it would seem that getting tighter tolerance parts would be a good idea as long as it wasn't silly expensive.

I've used only 1% metal film resistors (if the power level allows) for many years.

And you can hear a difference, so try it for yourself, no DBT is needed.

And you can hear a difference, so try it for yourself, no DBT is needed.

Last edited:

A typical example of a place where it would be beneficial to use tight tolerance parts is in filters that mess up the stereo image to some extent when left and right don't match, like the RIAA correction networks in phono amplifiers. Another example would be the gain setting resistors of a balanced-to-unbalanced converter, assuming its common-mode rejection gets poor when those resistors don't match.

As they are not expensive anyway, I also use 1 % resistors for the feedback network of any audio amplifier I make. That's not that useful, as you can always use the balance control to trim away any differences between left and right gain.

By the way, metal film and thin film resistors have less 1/f noise than carbon film and thick film resistors. Whether that matters again depends on the application.

As they are not expensive anyway, I also use 1 % resistors for the feedback network of any audio amplifier I make. That's not that useful, as you can always use the balance control to trim away any differences between left and right gain.

By the way, metal film and thin film resistors have less 1/f noise than carbon film and thick film resistors. Whether that matters again depends on the application.

Last edited:

Yes, using 5% resistors in both channels to set the gains can have a worst case imbalance error

of about 20% (1.6dB) between the channels.

of about 20% (1.6dB) between the channels.

Should I infer from that that the power supply would be less vital than the driver board in a power amplifier, say?.

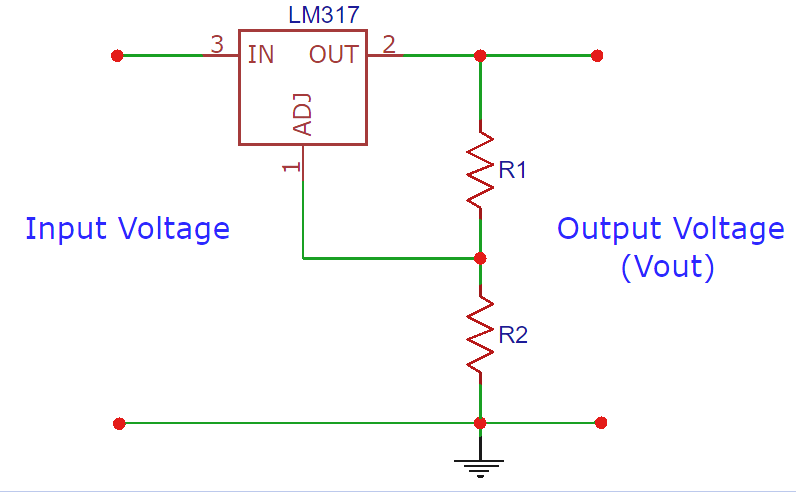

As I said it depends, if you're choosing resistors for the voltage devider in a LM317/LM337 power supply for example.

If the resistors were for example R1=1k and R2 2.7K

0% tolerence resistors (i.e. perfect value resistors) you'd get 4.625V output

With 10% tolerence you could have a worse case spread of 4.011V to 5.375V

With 5% tolerence you could have a worse case spread of 4.3V to 4.98V

With 1% tolerence you could have a worse case spread of 4.55V to 4.69V

Apologies if any of the above are slightly off, it's late and I've had a beer. 😉

None of the above values take into account any errors by the regulator itself.

If you were selecting bleed resistors in a power supply across reservoir caps then it wouldn't really matter if they were 20%+ out

Just choose based on cost difference, if you can get 1% for decent price compared to 5% why not use them and save the calculations 😀

Last edited:

As I said it depends, if you're choosing resistors for the voltage devider in a LM317/LM337 power supply...

What is the tolerance of the '317? It's not zero. (It may be +/-4%.)

What is the tolerance of the '317? It's not zero. (It may be +/-4%.)

Which is why I said

Maybe I should have said tolerence instead of error🙂None of the above values take into account any errors by the regulator itself.

That's a little different, as "tolerance" generally involves a single component.

As an integrated circuit, the 317 is spec'd by how well it does the job - line and load regulation. Briefly put, 0.02%/V for the former and 0.1%Vo for the latter. The actual resistor values are a much bigger factor, as MikePP noted.

As an integrated circuit, the 317 is spec'd by how well it does the job - line and load regulation. Briefly put, 0.02%/V for the former and 0.1%Vo for the latter. The actual resistor values are a much bigger factor, as MikePP noted.

That's a little different, as "tolerance" generally involves a single component.

As an integrated circuit, the 317 is spec'd by how well it does the job - line and load regulation. Briefly put, 0.02%/V for the former and 0.1%Vo for the latter. The actual resistor values are a much bigger factor, as MikePP noted.

I don't understand what you mean, as the LM317 also has a 4 % initial tolerance on its reference voltage.

Edit: it's 4 % for the combination of initial tolerance, line, load and thermal regulation. It looks like line, load and thermal regulation cause about half of it. Apologies to the LM317.

Last edited:

What is the tolerance of the '317? It's not zero. (It may be +/-4%.)

Correct. And it's not ±4% either... The actual answer is complicated:

The reference voltage has a tolerance of ±4 %.

The line regulation is 0.07 %/V.

The load regulation is 70 mV (Vout < 5.0 V) or 1.5 %/Vout (Vout ≥ 5.0 V).

The temperature stability is 0.7 %/Vout.

The current that flows out of the adjust pin is 100 µA but can vary by 5 µA depending on operating conditions. This current will affect the voltage on the adjust pin, thereby the output voltage of the regulator.

Then there's the long-term stability or drift of 1 % per 1k hours.

All these numbers are worst case across process, voltage, temperature and from page 6 of the TI LM317 data sheet.

Basically the conclusion here is that if you use ±1 % tolerance resistors and choose the resistors such that the adjust current has minimal impact, the precision in the output voltage will be dominated by other tolerances.

The good news is that most power supply voltages are not that critical. That's why 1976 technology like the LM317 is still selling. They're great regulators. I use them quite a bit. But one can do better with modern parts. The modern parts tend to be nearly impossible to solder by hand, unfortunately.

I generally use ±1 % for leaded resistors and ±0.5 % for SMD ones. I always use metal film resistors. It used to be that ±1 % tolerance types were more expensive than ±5 % types, but that's no longer the case. So there's no real reason not to use ±1 % tolerance resistors. Even ±0.1 % tolerance is not that expensive. 20 years ago those resistors would be $10-20/each. Now they're <$1 and a few cent (or maybe 10 cents/each) in quantity.

That said, only use the tight tolerance resistors where a small change in resistance would impact the circuit performance. So in filters, differential inputs, and such.

Tom

Last edited:

Edit: it's 4 % for the combination of initial tolerance, line, load and thermal regulation. It looks like line, load and thermal regulation cause about half of it. Apologies to the LM317.

You are correct, sir. My apologies to the LM317 as well. 🙂

That simplifies the math as you now only have to account for the adjust current and the long-term stability.

Tom

And of course 1% resistors have many more standard values than the 5%.

True. But you'll often find that the distributors only carry a subset of the values available. At least I rarely find all values within the E192 series available at Mouser/Digikey. I usually design for E24 (24 values per decade) unless I really need a specific value.

Tom

5% types are often cheaper technologies. 2%, 1% and better going to be metal film or oxide and the better accuracy are just selected

You can get 5% types in metal film if you wish. But that seems pointless when 1% metal film is the same cost.

Tom

Tom

Irrelevant anecdote: a then colleague once gave me a collection of 5 % tolerance metal film resistors that he didn't need anymore (he had decided to stop building electronics as a hobby; one year later he took up building electrostatic loudspeakers). I measured some of the resistors with an hp34401A multimeter and those all turned out to be within 0.01 % from their nominal value.

- Home

- Design & Build

- Parts

- How much do tolerance levels matter?