It's you guys that design and build your own amplifiers that blow me away!

the Lenard Opals … Can't build anything that big

In the diy build do both tweeters play at the same time?

dave

Last edited:

Yes, and they do have independent level controls. Can adjust the horizontal dispersion angle too, which is something I just began test out.In the diy build do both tweeters play at the same time?

BTW, they are Hi-Vi Research RT2C-A planars crossed at 2.5 kHz.

Last edited:

As Turbowatch notes: a wholemlot of HF combing,

You should turn the level of the bottom one to Zero, or lose th etop one and put the MTMs on a stand.

dave

You should turn the level of the bottom one to Zero, or lose th etop one and put the MTMs on a stand.

dave

@perrymarshall

Usually you have to build ready developed loudspeakers from DIY loudspeaker magazines if you have no measurement equipment.

If you try without assistance (no magazines, no measurement system, no listening experience, no knowledge how to do it) the way is stoney to make a good loudspeaker and usually most commercial designs will sound better.

But with experience and time you learn to do things which you cannot buy anywhere.

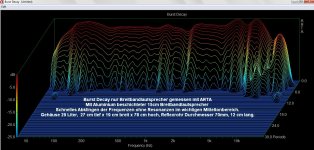

For example a simple 15cm fullrange driver which in a 29 liter reflex box made perfect sound, no crossover at all it goes up to 12khz with one sided diy aluminized paper cone (household aluminium foil and usual glue and a scissor to cut it thats all you need to do it).

Married it with an Audax like tweeter (mix of cone and dome) which works just with a simple 6db crossover to get more in the highs up to 20khz.

It sounded really really good with the box close to a back wall. Very vivid and transparent sound. Just the right amount of distortion that made listening fun.

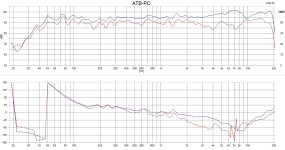

frequency response (blue line) is with the tweeter on axis measured

red line is 45 degrees off axis (also with tweeter) - (measurements were put optically apart - measured with different voltage)

This is only an example what diy can do what commercial systems cannot compete with:

The box / enclosure I got from the bulky waste

The 15cm fullrange driver is from a bargain selling - I got the drivers for 2.5 euro each

The tweeter was also from a bargain selling 0,5 euro each

So this is a kind of "high end" speaker which I could build "for nothing".

Pretty linear, fine burst decay for such a design and it has voila a linear phase(!)

Usually you have to build ready developed loudspeakers from DIY loudspeaker magazines if you have no measurement equipment.

If you try without assistance (no magazines, no measurement system, no listening experience, no knowledge how to do it) the way is stoney to make a good loudspeaker and usually most commercial designs will sound better.

But with experience and time you learn to do things which you cannot buy anywhere.

For example a simple 15cm fullrange driver which in a 29 liter reflex box made perfect sound, no crossover at all it goes up to 12khz with one sided diy aluminized paper cone (household aluminium foil and usual glue and a scissor to cut it thats all you need to do it).

Married it with an Audax like tweeter (mix of cone and dome) which works just with a simple 6db crossover to get more in the highs up to 20khz.

It sounded really really good with the box close to a back wall. Very vivid and transparent sound. Just the right amount of distortion that made listening fun.

frequency response (blue line) is with the tweeter on axis measured

red line is 45 degrees off axis (also with tweeter) - (measurements were put optically apart - measured with different voltage)

This is only an example what diy can do what commercial systems cannot compete with:

The box / enclosure I got from the bulky waste

The 15cm fullrange driver is from a bargain selling - I got the drivers for 2.5 euro each

The tweeter was also from a bargain selling 0,5 euro each

So this is a kind of "high end" speaker which I could build "for nothing".

Pretty linear, fine burst decay for such a design and it has voila a linear phase(!)

Attachments

-

4 onewayspeaker 15 cm Breitbandlautsprecher.jpg395.6 KB · Views: 151

4 onewayspeaker 15 cm Breitbandlautsprecher.jpg395.6 KB · Views: 151 -

5 onewayspeaker 15 cm Breitbandlautsprecher.jpg440.7 KB · Views: 121

5 onewayspeaker 15 cm Breitbandlautsprecher.jpg440.7 KB · Views: 121 -

3 onewayspeaker 15 cm Breitbandlautsprecher.jpg277.6 KB · Views: 136

3 onewayspeaker 15 cm Breitbandlautsprecher.jpg277.6 KB · Views: 136 -

burst decay 15 cm Breitbandlautsprecher onewayspeaker_.jpg213.3 KB · Views: 147

burst decay 15 cm Breitbandlautsprecher onewayspeaker_.jpg213.3 KB · Views: 147 -

15cm Breitbandlautsprecher - Rundstrahlverhalten.jpg99.2 KB · Views: 138

15cm Breitbandlautsprecher - Rundstrahlverhalten.jpg99.2 KB · Views: 138

Last edited:

Thanks for the suggestions. I am well aware of the combing effect but I don't hear it as a problem in my room.

I know the diagram is real physics but only in a non-reflective environment. Who knows what its like with the reflections added?

The reason for the addition of the top tweeter was to increase vertical dispersion and make it more uniform for a standing listener vs sitting. Just expanding the sweet spot.

I did try stands as you suggeted but wasn't impressed. This works well for me. Thanks.

I know the diagram is real physics but only in a non-reflective environment. Who knows what its like with the reflections added?

The reason for the addition of the top tweeter was to increase vertical dispersion and make it more uniform for a standing listener vs sitting. Just expanding the sweet spot.

I did try stands as you suggeted but wasn't impressed. This works well for me. Thanks.

No, I said I just borrowed some of the design principles of the Opals.Are we talking the same speakers Lenard Opals?

Overall horizontal dispersion is adjusted by rotating the top tweeter vs the lower one - it's a separate unit.

Let me add a long pennyworth.Mo Bronze is hardly a common "mainstream" design. First-order LPF (acording to the following thread which I haven't read) requiring highly proprietary drivers descended from the Mo Studio series (1990s high-end SOTA) which has served as my reference in the States and now in Beijing.

https://www.diyaudio.com/community/...ronze-bx2-speakers-2010-2015-yr-model.388989/

Mo Studio being first-order ceramic-coated Al/AlMg throughout has many high-fidelity qualities including: seemless integration, high resolution treble to bass, coherent pinpoint imaging, while easy to drive. Serving as my "reference" inevitably influenced my diy choices: so I do a lot of widerange drivers minimally filtered -- to get the same benefits. Of course the Mo Studios aren't perfect. The biggest 60's main fault is being stored States-side. The smallest 2's is BR resonance and limited extension. Before diy (Covid-era) I used the Mo Studio 2 port-plugged with a pair of decent 8" Jamo active subs. Nowadays I make-do a poor man's 60 with 8" Mo RST C-CAM (Ceramic-Coated Al Mg) drivers up-firing over a steel tube, lowpassed 1st-order with aircore inductor and natural off-axis attenuation. But the legacy of Mo (Iqbal) surely includes "modern" AlMg speakers such as Mark Audio's Alpair 5 (holographic beyond Mo, which while phase-coherent was not acoustic-centers-aligned), Alpair 10 (7-14khz plateau), MAOP 5 and 7 (more refined but less dynamic) -- just the ones I've tried. Their "material" and "coherence" sound signatures are similar to the Moes, each with its own shortcomings. Ditto a test-run 4" AlMg Michael's Audio (China), superb once coated per planet10's recipe and upgraded in a small TL for better bass than Mo 2 (but much less HF extension and dispersion than the anodized-gold dome of course; also more open and dynamic than my MAOP).

I wrote about all these in the fullrange forum.

If I had $150k to spend on speakers I wouldn't be building them myself......How about we flip this question on it's head? When you are doing a DIY build is that your main concern to equal or beat a commercial design?

Rob 🙂

I have been racing cars for 20 years and I DEFINITELY wouldn't keep building them if I could afford a factory Porsche Cup Car

If I had $150k to spend on speakers I wouldn't be building them myself......

You know I don't know for sure? It was cost that started me but after doing it I like it. It's a hobby not sure I would give it up?

I have been racing cars for 20 years and I DEFINITELY wouldn't keep building them if I could afford a factory Porsche Cup Car

Even if you could would keep your hands off drive only and leave it to the mechanics? You must be having fun! After being hands on that's tuff to just walk away from!

Good Luck

Hope you hit Loto so you can find out.

Rob 🙂

If I had $150k to spend on speakers I wouldn't be building them myself

But i would at least be designing them.

dave

Yeah, I am 38 now. It hurts my back to work on the car. If I could leave it to a crew of mechanics I 100% would.You know I don't know for sure? It was cost that started me but after doing it I like it. It's a hobby not sure I would give it up?

Even if you could would keep your hands off drive only and leave it to the mechanics? You must be having fun! After being hands on that's tuff to just walk away from!

Good Luck

Hope you hit Loto so you can find out.

Rob 🙂

A very interesting thread, as it tries to answer a question that I keep asking myself with every audio related DIY project I start.

During the pandemic phase I read myself into cloning a Schröder tonearm. I've spent endless hours of reading, evaluating material combinations, building parts, listen, start over and over again, making tools for the lathe and the mill so I can produce the parts that are required, I've bought sensors I could measure even the smallest resonances and so forth. I then started to build a turntable. Same approach. Read, understand, theory, different materials, experiment, etc, etc.

What I'm trying to get over: DIY for me is both Design and Build it yourself - with a semi professional approach.

And here's the speaker discussion. I would really want to give it a try. But only if the result would outperform my current speakers. And that's the problem I guess: My own attitude.

During the pandemic phase I read myself into cloning a Schröder tonearm. I've spent endless hours of reading, evaluating material combinations, building parts, listen, start over and over again, making tools for the lathe and the mill so I can produce the parts that are required, I've bought sensors I could measure even the smallest resonances and so forth. I then started to build a turntable. Same approach. Read, understand, theory, different materials, experiment, etc, etc.

What I'm trying to get over: DIY for me is both Design and Build it yourself - with a semi professional approach.

And here's the speaker discussion. I would really want to give it a try. But only if the result would outperform my current speakers. And that's the problem I guess: My own attitude.

I wouldn’t have thought so. I recall it was fully active

I agree. But who does that?The first step to loudspeaker design is to measure or at least simulate your room. No manufacturer is going to set off there, so DIY has an advantage from the off

Brian

I did it when l bought my last home. Fully treated as a critical listening room. I love the improvements

You and me apparently 😉

Would be interesting to know how many others have at least an audio understanding of their listening rooms

Would be interesting to know how many others have at least an audio understanding of their listening rooms

Personally, the workflow should begin with analyzing your requirement like your room, the position to place speakers, the SPL, directivity of speaker.Since I am newbie I would like you to comment whether or not my workflow is correct. Here is what I plan to be doing.

1. I find drivers and try crossing them over in vituixcad until I can find a set that should work well together based on traced data

2. I take their impedence measurements using REW and build the box around those.

3. I build the box, drop the drivers in, wire them all up to individual posts

4. Take all of their measurement including impedence again, then on and off axis for each driver

5. I then use those measurements to design the final crossover.

6. I wire up said Xover into the box and wire everything up.

7. I take a final measurement of the entire system to see if I screwed anything up

Is this the correct workflow?

1. Determine which type of speaker you should build: box speaker, horn, open baffle. Then decide whether it should be one way, two-way, three-way or four-way speaker.

2. Then decide the combo of drver you should use. For example with two ways you can have 5+1 (with waveguide or not), 6+1, 8+1. For three ways you can have 8+5+1, 10+5+1, 10+6+1,...

3. After that, choosing drivers to fit your concept. Pay attention to directivity of driver at potential crossover frequency.

4. Buy drivers, measure it raw and design the baffle and box to fit those values.

5. Build the box, pay attention to this part because box is the most frustrated thing in speaker build. Building a good speaker enclosure takes good amount of time and money, so you don't want to do it over again.

6. Fit the driver to the box, measure the response then use it in virtuixcad to design crossover.

7. Measure the total response, can be done in outside without side reflection like park, or use ground plane to measure bass response.

8. Put in your house and listening

8. Repeat step 6-7-8 until satisfy with the result.

- Home

- Loudspeakers

- Multi-Way

- How good are our DIY units compared to off the shelf stuff?