This site has been so helpful. I've had a couple other threads on this build (most recent here), but I wanted to get something with a more appropriate subject line.

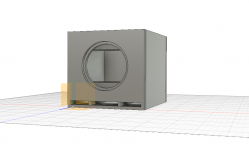

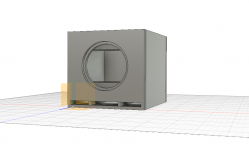

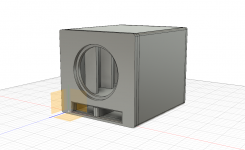

My speaker is modeled - A Dayton 12" 305-4, sticking with manufacturer specs which is 3.4 cubic feet internal, with a tuning of about 26/27hz.

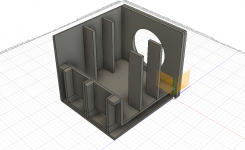

In terms of the physical build, how does this look to you all? This'll be my biggest woodworking project yet, and just wanted to get any suggestions from the pros who have done this already. Also, any tips on how much polyfill to put in? Thanks!

My speaker is modeled - A Dayton 12" 305-4, sticking with manufacturer specs which is 3.4 cubic feet internal, with a tuning of about 26/27hz.

In terms of the physical build, how does this look to you all? This'll be my biggest woodworking project yet, and just wanted to get any suggestions from the pros who have done this already. Also, any tips on how much polyfill to put in? Thanks!

A few notes:

- The top and bottom panels have stiff bracing. Consider bracing the other panels as well.

- Keep the aspect ratio (width : height) of the port below 5:1 for high performance. Ports with a larger aspect ratio have higher losses.

- Having the port exit near a boundary is not necessarily a problem, though the air between port exit and boundary becomes part of the port. Now the port length is increased and there is a 90 deg bend in the port, which must be rounded.

- Add a generous round over to both ends of the port to minimize chuffing noises. This is especially important at the port end that is at the inside of the enclosure, as the air is forced to make a 90 degree turn.

- Keep the air velocity inside the port at full power below 10 m/s if possible. Chuffing might occur at higher velocities.

- Polyfill is not necessary for subwoofer duty. If you are going to use it, keep the area around the port exit free.

- The top and bottom panels have stiff bracing. Consider bracing the other panels as well.

- Keep the aspect ratio (width : height) of the port below 5:1 for high performance. Ports with a larger aspect ratio have higher losses.

- Having the port exit near a boundary is not necessarily a problem, though the air between port exit and boundary becomes part of the port. Now the port length is increased and there is a 90 deg bend in the port, which must be rounded.

- Add a generous round over to both ends of the port to minimize chuffing noises. This is especially important at the port end that is at the inside of the enclosure, as the air is forced to make a 90 degree turn.

- Keep the air velocity inside the port at full power below 10 m/s if possible. Chuffing might occur at higher velocities.

- Polyfill is not necessary for subwoofer duty. If you are going to use it, keep the area around the port exit free.

Last edited:

In terms of the physical build, how does this look to you all?

- The port looks kinda small (low surface area)

Increasing the port surface area will increase the port length, to increase length you can give the port a 90 degree bend and let it go up the rear panel.

- The bracing on top of the port panel looks redundant

In my experience that's one of the stiffest panels in there. I'd look at increasing bracing on the other panels.

- Polyfill can lower the tuning a bit (by increasing virtual volume) at the cost of overall output

At the time I've measured this as an 10 - 15% increase in virtual volume, when using at least 10 - 15 ounces per cubic ft. Output suffered 1 - 1.5 dB.

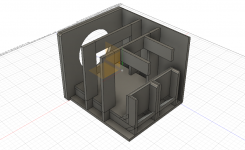

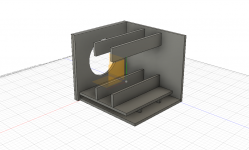

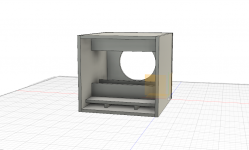

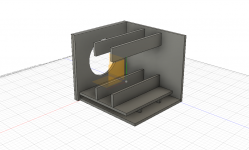

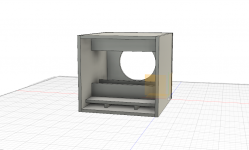

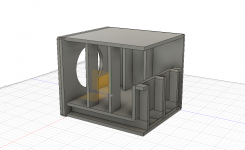

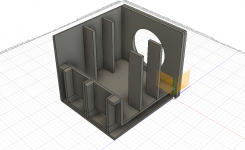

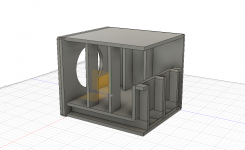

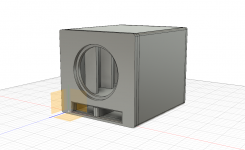

Thank you a ton. I've reworked the box. There are now two 2x6" ports, with a length of 29.3" each (measured from the center of the port). Air velocity is modeling at 10.5m/s. Port resonance is 231Hz. I added in the beveling to these CAD drawings. Just ignore where the bevels join at a corner; I couldn't get it right in Fusion 360. A couple questions still:

- I tried softening the 90 degree bend, but I'm guessing it needs more?

- I have two cavities in the box on either side of the port which have zero airflow and are completely separated from the main chamber. Are these alright to have? I tried resizing the ports to be wider, but they just messed up the port length too much. I thought that having MDF span the width would add strength to the box. I was also wondering if opening up that area would create weird airflow, but maybe I'm overthinking it.

- The box has up-down bracing. Do you think it needs to be in another direction as well?

- TBTL, you mentioned having a port exit near a 'boundary'... What do you mean by this? Like the edge of the front face?

Great tips on the polyfill. Sounds like I'll just leave it out. The only other tweak I know I'll need to make to the box is adding 1.5" in height to get my internal volume back to optimal size.

Thank you for all the feedback and I look forward to any other guidance you guys can offer!

- I tried softening the 90 degree bend, but I'm guessing it needs more?

- I have two cavities in the box on either side of the port which have zero airflow and are completely separated from the main chamber. Are these alright to have? I tried resizing the ports to be wider, but they just messed up the port length too much. I thought that having MDF span the width would add strength to the box. I was also wondering if opening up that area would create weird airflow, but maybe I'm overthinking it.

- The box has up-down bracing. Do you think it needs to be in another direction as well?

- TBTL, you mentioned having a port exit near a 'boundary'... What do you mean by this? Like the edge of the front face?

Great tips on the polyfill. Sounds like I'll just leave it out. The only other tweak I know I'll need to make to the box is adding 1.5" in height to get my internal volume back to optimal size.

Thank you for all the feedback and I look forward to any other guidance you guys can offer!

I meant the rear panel of the cabinet.🙂- TBTL, you mentioned having a port exit near a 'boundary'... What do you mean by this? Like the edge of the front face?

Yes. You can use a split pvc pipe to make the bend or use two 45 degree bends.- I tried softening the 90 degree bend, but I'm guessing it needs more?

There is no problem having these chambers, though you can safely connect them with the main volume. Having the top panel of the port span the full cabinet width is not necessary, because there already is sufficient bracing at the side panels.- I have two cavities in the box on either side of the port which have zero airflow and are completely separated from the main chamber. Are these alright to have? I tried resizing the ports to be wider, but they just messed up the port length too much. I thought that having MDF span the width would add strength to the box. I was also wondering if opening up that area would create weird airflow, but maybe I'm overthinking it.

Another note: the top panel and the upper part of the rear panel could use some bracing. Bracing is especially effective if it supports the center of a panel. At corners / edges it does not contribute because these locations already are stiff.

Last edited:

Hi Stonesif.

Very solid looking box now.

Unless you have calculated in the new cross sectional area of the ports to accommodate the 2) 45 degree reflectors , you could have a choke point that may cause issues.

I see you will be fixing that. Nevermind. Good work so far!

Very solid looking box now.

Unless you have calculated in the new cross sectional area of the ports to accommodate the 2) 45 degree reflectors , you could have a choke point that may cause issues.

I see you will be fixing that. Nevermind. Good work so far!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- How does this box look?