Yes, my IPA is 91%.If people wash boards with water, then wouldn’t 91% alcohol be an acceptable substitute for IPA ?

”Corrosion is a natural process that occurs when metals react with oxygen and form metal oxides. All water contains some dissolved oxygen and is therefore somewhat corrosive. The rate of corrosion depends on many factors including the water's pH, electrical conductivity, oxygen concentration, and temperature.”

I use isopropanol.

I use isopropanol.

Just remember to use the dishwasher, not the washing machine(!!!)Yes, but with mild temperature, 40° or so and short program.

I blew out the remaining water with a compressor and let it dry for a few days.

Startup with reostat and all was fine.

The combination of water and oxygen allows more mechanisms of oxidation reaction, which is why iron/steel rust much faster when exposed to liquid water. So minimize the time for which things are wet, they warm and dry thoroughly. Some components should not be subjected to water, like boxed relays and transformers, however, as water will become trapped inside.

I wonder if a water pikmwould be an easier way than using a “toothbrush”

I am sure there are some solutions that would be safe for the water pik and still be effective in loosening dirt

I wonder if that would void the water pik warranty 🙂

I have got to try this on something not too valuable. I need to get a cheap dirty receiver somewhere to experiment on. And maybe a cheap old waterpik so my wife doesn’t freak out

I am sure there are some solutions that would be safe for the water pik and still be effective in loosening dirt

I wonder if that would void the water pik warranty 🙂

I have got to try this on something not too valuable. I need to get a cheap dirty receiver somewhere to experiment on. And maybe a cheap old waterpik so my wife doesn’t freak out

Here is the link if you want to learn more about the tongue scrapper !

https://www.amazon.com/SmilEglade-R...ravel+7+levels+portable+-black,aps,285&sr=8-1

https://www.amazon.com/SmilEglade-R...ravel+7+levels+portable+-black,aps,285&sr=8-1

In post 1 I see no particular reference to old or new boards, bare or stuffed with parts,

but we obviously discuss used gear here. Resin residual from new production boards is

removed with some solvent.

For dirty amplifiers and instruments see this thread :

https://www.diyaudio.com/community/threads/cleaning-an-extremely-dirty-amp.370742/

with nice pictures of cigarette dirt removal in my post 24.

but we obviously discuss used gear here. Resin residual from new production boards is

removed with some solvent.

For dirty amplifiers and instruments see this thread :

https://www.diyaudio.com/community/threads/cleaning-an-extremely-dirty-amp.370742/

with nice pictures of cigarette dirt removal in my post 24.

Hi,

you needed to go to the link to get the reference and info you are looking for

my question and the link are critical parts of the post I made

you needed to go to the link to get the reference and info you are looking for

my question and the link are critical parts of the post I made

If I use no-clean flux, then I do not clean the board. If I use rosin flux, I'll use IPA to clean it up. If I use water soluble flux, then the board gets cleaned with water & a detergent. Water or other solvent will be kept away from any component that could be damaged by it. I use D.I water for the final rinse to remove any ionic residue that could cause leakage in a humid environment. I blow-dry the board with a heat-gun, and might bake it at low temperature (120F or so) in my kitchen oven, or else I'll use sunlight on a hot day here in Southern CA. I make sure the board is bone-dry before I use it.

If you use detergent be aware that household detergent is usually heavily loaded with salt to make it thicken (and stop children drinking it?), that's not what you want to put on a PCB (you might as well dip it in the sea). Being a composite FR4 is able to allow infiltration of contaminants into the material along the boundaries between glass fibres and epoxy, so its best to be careful only to use non-ionic, non-acidic solvents on it.

FR4 can absorb water directly, note: https://www.google.com/url?sa=t&rct...usg=AOvVaw30IzFau6pu1PV3MWZp6XiB&opi=89978449

So baking after cleaning is a smart idea.

FR4 can absorb water directly, note: https://www.google.com/url?sa=t&rct...usg=AOvVaw30IzFau6pu1PV3MWZp6XiB&opi=89978449

So baking after cleaning is a smart idea.

91% Isopropyl alcohol, scrub with tooth brush (plenty of juice), blot with paper towel or tissue. To get the board extra clean, you can submerge in IPA using pie tin or other suitable container. IPA is also recommended for use with electrolytic caps, unlike chlorinated solvents, which are slow, unpredictable death for electrolytic caps. You want to clean the board, even if you are using no-clean flux. No-clean flux is hygroscopic, and doesn't play well with high voltage. Manual soldering with no-clean flux is problematic, as the fumes are very irritating.

I'm new to all this so someone (IAIMH) advised me to use 99% Isopropyl and scrub (acid brush), rinse (99% Isop), & wipe (kimwipe). I started with Kimwipes and an acid brush with cut bristles and that works just fine. Takes some effort to get everything off, but spick and span in the end. However...

I just bought this "7AN2M" ultrasonic toothbrush last week and use it with copious amounts of 99% Isop. The brush even has 4 different modes to suit your cleaning enjoyment.

https://www.amazon.com/gp/aw/d/B09XB65FLN?psc=1&ref=ppx_pop_mob_b_asin_title

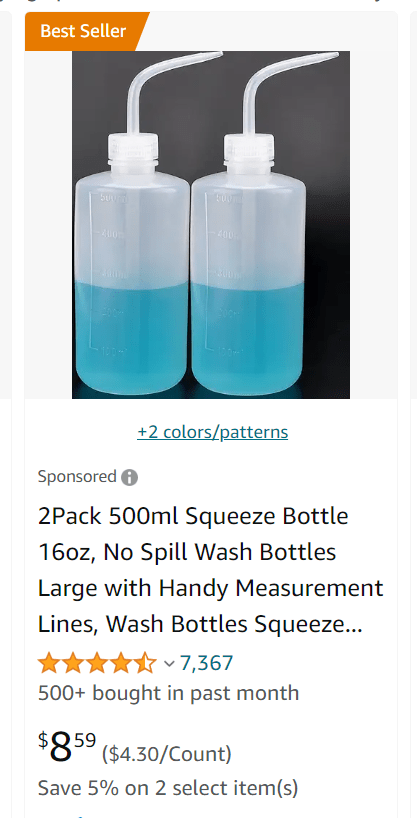

I put the Isop in one of these safety wash bottles and totally rinse the board surface after a 60 second ultrasonic brush over. I'll use a lot of Isop to rinse the flux away and the nozzle affords some spray away force. I do it over a bowl to catch all the fluid.

https://www.amazon.com/gp/aw/d/B07D6KZZQL?psc=1&ref=ppx_pop_mob_b_asin_title

After 3 cycles, that board is amazingly clean and I'm a little dizzy from the fumes. Win win all around 😉 I'm not very experienced with other methods but this seems to work wonders and I don't need kimwipes. Just be sure to do it in a well ventalated area.

I just bought this "7AN2M" ultrasonic toothbrush last week and use it with copious amounts of 99% Isop. The brush even has 4 different modes to suit your cleaning enjoyment.

https://www.amazon.com/gp/aw/d/B09XB65FLN?psc=1&ref=ppx_pop_mob_b_asin_title

I put the Isop in one of these safety wash bottles and totally rinse the board surface after a 60 second ultrasonic brush over. I'll use a lot of Isop to rinse the flux away and the nozzle affords some spray away force. I do it over a bowl to catch all the fluid.

https://www.amazon.com/gp/aw/d/B07D6KZZQL?psc=1&ref=ppx_pop_mob_b_asin_title

After 3 cycles, that board is amazingly clean and I'm a little dizzy from the fumes. Win win all around 😉 I'm not very experienced with other methods but this seems to work wonders and I don't need kimwipes. Just be sure to do it in a well ventalated area.

Last edited:

IPA with a small acid brush cut down to 5mm bristles for scrubbing. A second acid brush with full length bristles for rinsing. Lint free tissue for drying up.

Some of this I would do, some I think is very bad on a level that we may not be aware of. Straight to using a household kitchen dishwasher for chemical cleaning of a circuit board? "Yah, but everything rinses out",right? Yah sure, absolutely not a chance that I would take with my family, especially if the affects weren't seen in years. Do you also use your oven for powder coating? Before or after the cake, or will they both fit at the same time and save energy?

On to toothbrushes. Probably great for cleaning (as long as it is not your personal one). Acid brush? Seems reasonable for the job. Some cleaning alcohols are what I have used in the past, but with a Q-tip. Not real efficient, but when I am done there are no residues left. Might try the toothbrush idea after all.

On to toothbrushes. Probably great for cleaning (as long as it is not your personal one). Acid brush? Seems reasonable for the job. Some cleaning alcohols are what I have used in the past, but with a Q-tip. Not real efficient, but when I am done there are no residues left. Might try the toothbrush idea after all.

Some of the advice above is poor. The advice I gave came straight out of my training manuals from a career working in the aerospace industry.

That's why I use de-ionized water as a final soak-rinse--to remove any ionic residue. I have not had any leakage problems with PCBs that I cleaned in this way. Your advice is well taken, though. I was not aware of salt in liquid dish detergents.If you use detergent be aware that household detergent is usually heavily loaded with salt to make it thicken (and stop children drinking it?), that's not what you want to put on a PCB (you might as well dip it in the sea). Being a composite FR4 is able to allow infiltration of contaminants into the material along the boundaries between glass fibres and epoxy, so its best to be careful only to use non-ionic, non-acidic solvents on it.

FR4 can absorb water directly, note: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwijnI7wpYaEAxWV-gIHHSezAukQFnoECBIQAQ&url=https://jmep.scholasticahq.com/api/v1/articles/40197-a-technique-for-detecting-moisture-absorption-in-printed-circuit-boards.pdf&usg=AOvVaw30IzFau6pu1PV3MWZp6XiB&opi=89978449

So baking after cleaning is a smart idea.

If you build pH sensor amps on a PCB, you have to be extremely scrupulous about these things, source-impedances of ~1G are common 🙂

99% IPA and a dollar store vibrating toothbrush, two cleanings, the first cleaning still leaves a little bit of sticky flux, then the second cleaning its perfect. I lay out a dishcloth and dispense the IPA all over the board via one of these bottles, let the IPA sit for a while and it dissolves the flux: I've tried denatured alcohol but found 99% IPA works better and is more pleasant to smell.

- Home

- Design & Build

- Construction Tips

- How do you clean circuit boards?