DIY can mean a lot of things to many people. It ranges from experimenting (a few very notable DIY'ers here started that way here with tube amps without prior knowledge or training) to someone collecting tested parts and following colour coded diagrams and step by step instructions.

End of the day, a part of the DIY'ers drive is that he choses his components and customizes the end product without being hemmed in and reigned in with buying a single completed box that you just need to power up. I have done it all from putting complete kits together (Bob Latino's ST70 and my friend who got in over his head being without a good soldering iron and multiple DMMs or VTVMs, but credit to Bob Latino as the kit was so well laid out and the instructions so straightforward, it was paint by numbers for me and 2 days later my friend happily collected a tank of an amp) to attempting to Manhattan style dead bugging a headphone amp (instead I ended up with something so ugly, it was a "you know it when you see it" dead bugging... I need through the hole PCBs...)

Someone will argue, but the Bob latino I put together isn't my friend's DIY project. I disagree. He had every intention on doing it after being inspired by my projects; he researched it, he attempted, it was just too big of a bite of scariness for him. A B+ of 350 VDC is not for everyone. I am happier he handed over the project and was honest about not being able to do it versus going zappity zap zap. For me, I told him, it is as good as he did it because it was a step in the right direction. Just smaller steps and maybe solid state or headphones first.

The other part of it all is that the DIY'er chooses to do it themselves versus having a corporation pump it out for them and it ships to them in stayofoam and cardboard. Add to that, it also doesn't matter which project he bought into -- from tiny low parts count opamp based headphone amp to a window shaking "why are the lights flickering on the low notes?" multi tube amplifier.

I will be first to admit that I will NEVER design my own amplifier. Period. I need someone else's design and knowledge that I just absolutely do not posses and probably will never understand the math and genius behind a design. How many Hiraga's are there out there? How many Nelson Pass's are there out there? How many Williamson's are there out there? I don't know about you, but that is way above my level of genius. Well, geez I am sure glad they shared their designs with everyone otherwise this DIY adio community is going to be way smaller and you might as well buy your amp from a big box store.

Finally, on kits... I won one of Nelson Pass's SONY VFET amplifiers and paid for the prize. It is a Nelson Pass designed amplifier. The kit came with partially populated PCBs, measured, and initialed by Nelson Pass himself with a designed and custom sized stunning chassis plus heatsinks, all the internal components. Add in some very difficult to find SONY VFET SITs with production having ended decades ago as donated by Nelson Pass himself. There is wire cut to length inside the bag. All from the diyaudio.com store.

Is this kit to be considered as, "not DIY"? Or is it no better than flat pack furniture from IKEA with those non-standard connectors unique to IKEA? Whatever... not looking for your answers as I do not believe that I am mistaken in my own beliefs and convictions that it is DIY... just more of something to think about for those looking for a soap box to stand on.

DIY. Your choice of project, your choice of parts, your choice of design, and your choice of putting it together.

End of the day, a part of the DIY'ers drive is that he choses his components and customizes the end product without being hemmed in and reigned in with buying a single completed box that you just need to power up. I have done it all from putting complete kits together (Bob Latino's ST70 and my friend who got in over his head being without a good soldering iron and multiple DMMs or VTVMs, but credit to Bob Latino as the kit was so well laid out and the instructions so straightforward, it was paint by numbers for me and 2 days later my friend happily collected a tank of an amp) to attempting to Manhattan style dead bugging a headphone amp (instead I ended up with something so ugly, it was a "you know it when you see it" dead bugging... I need through the hole PCBs...)

Someone will argue, but the Bob latino I put together isn't my friend's DIY project. I disagree. He had every intention on doing it after being inspired by my projects; he researched it, he attempted, it was just too big of a bite of scariness for him. A B+ of 350 VDC is not for everyone. I am happier he handed over the project and was honest about not being able to do it versus going zappity zap zap. For me, I told him, it is as good as he did it because it was a step in the right direction. Just smaller steps and maybe solid state or headphones first.

The other part of it all is that the DIY'er chooses to do it themselves versus having a corporation pump it out for them and it ships to them in stayofoam and cardboard. Add to that, it also doesn't matter which project he bought into -- from tiny low parts count opamp based headphone amp to a window shaking "why are the lights flickering on the low notes?" multi tube amplifier.

I will be first to admit that I will NEVER design my own amplifier. Period. I need someone else's design and knowledge that I just absolutely do not posses and probably will never understand the math and genius behind a design. How many Hiraga's are there out there? How many Nelson Pass's are there out there? How many Williamson's are there out there? I don't know about you, but that is way above my level of genius. Well, geez I am sure glad they shared their designs with everyone otherwise this DIY adio community is going to be way smaller and you might as well buy your amp from a big box store.

Finally, on kits... I won one of Nelson Pass's SONY VFET amplifiers and paid for the prize. It is a Nelson Pass designed amplifier. The kit came with partially populated PCBs, measured, and initialed by Nelson Pass himself with a designed and custom sized stunning chassis plus heatsinks, all the internal components. Add in some very difficult to find SONY VFET SITs with production having ended decades ago as donated by Nelson Pass himself. There is wire cut to length inside the bag. All from the diyaudio.com store.

Is this kit to be considered as, "not DIY"? Or is it no better than flat pack furniture from IKEA with those non-standard connectors unique to IKEA? Whatever... not looking for your answers as I do not believe that I am mistaken in my own beliefs and convictions that it is DIY... just more of something to think about for those looking for a soap box to stand on.

DIY. Your choice of project, your choice of parts, your choice of design, and your choice of putting it together.

If you are questioning about mimicking the look of nice commercial products, I find it's interesting that some people seem to try to make their DIY project look like a fancy commercial product as much as possible, while people build tube amps, FR and high efficient speakers seem to appreciate DIY look.What if at the end, i want to have it nice looking, so i buy nice box with nice face plate.

I like to think of myself as a DIY type. I do my own car repair, plumbing, electrical (inspected and approved), yard work, and construction. Built my 1st kit in 8th grade in 1969, built Haflers in the 80’s. Im knee deep in Pass gear these days thanks to being able to get #108 V-Fet. I have to rely on the expert advice and projects for this, but I can knock together a power supply for non critical use, relay selectors switches, wire disparate parts into a nice whole.

So for me this is my DIY and I’m perfectly fine with where I am.

Peace,

Billy

So for me this is my DIY and I’m perfectly fine with where I am.

Peace,

Billy

I consider DIY status to be in the eye of the constructor. Unless one is winding their own transformers, building their own tubes/resistors/capacitors/transistors etc. - then it really is a matter of degree isn't it? The more inclusive the better. It doesn't detract from whatever level one is currently residing.

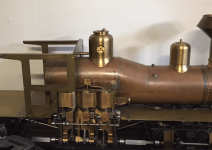

Machine every part of a car, that's ambitious, maching a crank from solid, even a " bent wire " Austin 7 three bearing crank would be a challenge. When younger I was interested in model engineering, old men in sheds making working live steam locomotives, some would make their own lathe ( no cheep Chinese tools back then ). I buy Chinese DAC and amp boards, but I make auxiliary boards from strip ( verio? ) boards. I also try and use as much " found " ( discarded ) materials as I can find. I'd say "diy audio " encompasses a broad church, from simple repair/assembling kits to starting with raw materials. We all share the same interest, and willing to pass on knowledge and, erm, " opinions".I always wanted to machine every part of a car and put it all together. Is that DIY or BIY?

My personal DIY adventure started out repairing an amplifier. Since then, I bought power amp PCB's, soldered all the components onto the PCB's and installed them into the amplifier. The original power amp boards were worn out after almost 50 years and me repairing them several times.

I'm almost shocked that all that isn't considered DIY...

I've had to DIY on many things over the decades.

As to Burnedfingers original post mentioning the chinese products, I've had to "de-chinese" many things in order to make them more reliable for my own use, safety, and pleasure.

And that's because of the cheapening and cutbacks of those products, of course.

For instance, I "de-chinese'd" a portable space heater for a friend - the original cheap plastic rotary switch crapped out, and now its got a pair of heavy-duty 20a rated toggle switches that will last a long time.

As for American-made, vintage stuff, I've done some "upgrading", mostly to bring things into the 21st century and enhance their performance, usefulness, as well as reliability.

As to Burnedfingers original post mentioning the chinese products, I've had to "de-chinese" many things in order to make them more reliable for my own use, safety, and pleasure.

And that's because of the cheapening and cutbacks of those products, of course.

For instance, I "de-chinese'd" a portable space heater for a friend - the original cheap plastic rotary switch crapped out, and now its got a pair of heavy-duty 20a rated toggle switches that will last a long time.

As for American-made, vintage stuff, I've done some "upgrading", mostly to bring things into the 21st century and enhance their performance, usefulness, as well as reliability.

Since you mentioned three bearing crankshaft being a challenge, here's one on my live steam Shay locomotive...Machine every part of a car, that's ambitious, maching a crank from solid, even a " bent wire " Austin 7 three bearing crank would be a challenge. When younger I was interested in model engineering, old men in sheds making working live steam locomotives, some would make their own lathe ( no cheep Chinese tools back then ). I buy Chinese DAC and amp boards, but I make auxiliary boards from strip ( verio? ) boards. I also try and use as much " found " ( discarded ) materials as I can find. I'd say "diy audio " encompasses a broad church, from simple repair/assembling kits to starting with raw materials. We all share the same interest, and willing to pass on knowledge and, erm, " opinions".

Attachments

Anyone remember the Lindberg "Motorized" plastic model car kits, from the 60's, with the electric motor that you had to build yourself? Wasn't easy for some kids, but super cool when you got it working.

Probably the first electric kit for me. Before that it was clockwork and Meccano.

Probably the first electric kit for me. Before that it was clockwork and Meccano.

Ah, beautiful but did you mine the brass (yes I know brass isn't a mineral found in mines) and smelt/cast the thing? Where does one draw the line?Since you mentioned three bearing crankshaft being a challenge, here's one on my live steam Shay locomotive...

Ultimately, does it really matter? After all, isn't the purpose of a hobby is to spend your time and money doing something that you derive enjoyment or meaning from?

Some may derive more meaning or enjoyment if they design the circuit from scratch. They might only complete one build in a year, though. Others, might enjoy the process of putting preassembled boards together in a chassis. The can probably complete more projects that way. Maybe that leads to greater enjoyment for them.

Tom

Some may derive more meaning or enjoyment if they design the circuit from scratch. They might only complete one build in a year, though. Others, might enjoy the process of putting preassembled boards together in a chassis. The can probably complete more projects that way. Maybe that leads to greater enjoyment for them.

Tom

I made a mistake, the original Austin 7 had a two bearing crank, with " spit and hope " lubrication to the big ends. I believe the first car to have conventional controls ( accelerator/brake/clutch peddles, transmission tunnel mount gear change).

I thought about making my own copper foil + bees wax caps, but the size required to get the right value put me off.

I did have a go at making my own air core toridal chokes, but to make them I had to make the formers, but to make the formers I had to make a rotory tool, to make the rotory tool I had to grind a form tool. Perhaps I should have made a gig to grind to form tool...

I thought about making my own copper foil + bees wax caps, but the size required to get the right value put me off.

I did have a go at making my own air core toridal chokes, but to make them I had to make the formers, but to make the formers I had to make a rotory tool, to make the rotory tool I had to grind a form tool. Perhaps I should have made a gig to grind to form tool...

In virtually every other hobby, DIY simply means to build it yourself regardless of who did the design. You might also be the designer, but that is not a requirement for a DIY project.

An example that I have cited on other pages is DIY airplanes. Not models, but real airplanes that people fly in. The people who build these are not aeronautical engineers and don't design them. Nevertheless, they consider their hobby to be fully DIY.

However, there appears to be a certain amount of snobbery in the audio sector, and particularly here on this forum, by people who do their own designs as well as builds. But I'm not willing to accept that as the last word.

Building amplifiers, speakers or anything else yourself IS DIY regardless of where the design came from. There is no reason that audio should be any different from the rest of the world.

An example that I have cited on other pages is DIY airplanes. Not models, but real airplanes that people fly in. The people who build these are not aeronautical engineers and don't design them. Nevertheless, they consider their hobby to be fully DIY.

However, there appears to be a certain amount of snobbery in the audio sector, and particularly here on this forum, by people who do their own designs as well as builds. But I'm not willing to accept that as the last word.

Building amplifiers, speakers or anything else yourself IS DIY regardless of where the design came from. There is no reason that audio should be any different from the rest of the world.

Last edited:

No need to fully design the product, think building a Linsley Hood amplifier in the 60´s or early 70´s, following a schematic published in Wireless World, maybe even using a PCB sold through the same magazine.

Power transformer would also be bought ready made or best case, custom wound following a published "recipe".

In general chassis would be drilled at home as needed and cabinet could be made in a garage woodshop but that´s not indispensable either.

Do you consider that NOT "Diy"?

Gimme a break!!!!

Personally I consider it DIY if it includes a significant portion (say above 10%) of the total work or maybe 20-30% of the assembly work needed to make it working/usable, and such work being functional, amp or product would not work without it, work done should not be just "cosmetic".

Manufacturing huge parts of an amp (or cabinet or speaker or digital thingie) typically means heavy spending in expensive machinery, absolutely NOT justified in making a small quantity, even less in ones or twos.

EDIT:

Unless youused some NOS/junkbox ones you had lying around.

Power transformer would also be bought ready made or best case, custom wound following a published "recipe".

In general chassis would be drilled at home as needed and cabinet could be made in a garage woodshop but that´s not indispensable either.

Do you consider that NOT "Diy"?

Gimme a break!!!!

Personally I consider it DIY if it includes a significant portion (say above 10%) of the total work or maybe 20-30% of the assembly work needed to make it working/usable, and such work being functional, amp or product would not work without it, work done should not be just "cosmetic".

Manufacturing huge parts of an amp (or cabinet or speaker or digital thingie) typically means heavy spending in expensive machinery, absolutely NOT justified in making a small quantity, even less in ones or twos.

EDIT:

Not sure you de-chinesed anything 😉 since I highly suspect those toggle switches are also Chinese.I "de-chinese'd" a portable space heater for a friend - the original cheap plastic rotary switch crapped out, and now its got a pair of heavy-duty 20a rated toggle switches that will last a long time.

Unless youused some NOS/junkbox ones you had lying around.

Last edited:

I am a pretty serious woodworker, after this I think I'm gonna need to start growing trees from seed, cutting them down and milling the lumber myself, I'll need a kiln to dry the wood oh and a I'll need a foundry and machine shop to make my tools. But wait...is it fair to use seeds to plant the trees? I could learn to use CRISPER and jigsaw up my own custom tree DNA molecules. Wait, for it to be real DIY I should invent my own version of CRISPER or it won't really be my trees. Crap this DIY is complicated.

Snobbery in the audio world? NOOOOO!!!!! NEVER!!!!! 🙂However, there appears to be a certain amount of snobbery in the audio sector, and particularly here on this forum, by people who do their own designs as well as builds. But I'm not willing to accept that as the last word.

From a social psychology perspective the snobbery could be seen as downward social comparisons. It's part of how humans perceive themselves.

Tom

DIY is about the need to be creative, having fun, its like a complex game for some, its about thinking and overthinking, revising then revising, then revising again, its about daring to make mistakes by trying out something anyway you're not sure of, its about reading and studying, its about collecting endless schematics, its about buying parts you think you need but fining out you didn't, its about scouring over tables at ham swap meets for that guy that has a caddy full of NOS 01A tubes he had in his basement since 1966, its about this forum, its about buying books. Its about doing the best you can with the knowledge you have now. Its about admiring pillars like Norman Crowhurst or modern ones like John Broskie, and of course the amazing minds here and realizing how many holes you have in your own knowledge. Its about your wife asking you what you're reading and you answer that you are trying to figure out what brand of capacitor you should use as C1 in your power supply. And she rolls her eyes.

Ultimately I see the break as between "kit building" or actually trying to import some of your own design. So for me that break is distinguished by if the diy'er is doing one of two things or not. If the diy'er is using spice or doing breadboarding, then they are in the camp of designing, if they are not doing either of these, then they are merely in the camp of "kit building". The latter camp is someone who grabs a schematic, and simply builds it, and that is just fine. when I started this hobby my desire was to breadboard, experiment, listen, then build. I've built many kits or exact schema builds in the past, this time I want to make mistakes lots of them, by experimenting via the breadboard, to learn. Then do up a nice chassis for something I like and can execute. Ultimately diy is about a journey you enjoy.

Ultimately I see the break as between "kit building" or actually trying to import some of your own design. So for me that break is distinguished by if the diy'er is doing one of two things or not. If the diy'er is using spice or doing breadboarding, then they are in the camp of designing, if they are not doing either of these, then they are merely in the camp of "kit building". The latter camp is someone who grabs a schematic, and simply builds it, and that is just fine. when I started this hobby my desire was to breadboard, experiment, listen, then build. I've built many kits or exact schema builds in the past, this time I want to make mistakes lots of them, by experimenting via the breadboard, to learn. Then do up a nice chassis for something I like and can execute. Ultimately diy is about a journey you enjoy.

So, based on your definition of DIY, should those of us who build from other people's designs not be involved in this forum? Should we perhaps be banned, because we don't belong here?

My last take on the Op's post.

It is sort of like the response to COVID. Those that are doing less than me are foolish and those that are doing more are wasting their efforts.

Audio parts purchases are similar. The price point that I choose to spend on a cartridge, for instance, is the "sweet" spot. More, and you are wasting your money and less must mean you are leaving performance on the "table".

It is sort of like the response to COVID. Those that are doing less than me are foolish and those that are doing more are wasting their efforts.

Audio parts purchases are similar. The price point that I choose to spend on a cartridge, for instance, is the "sweet" spot. More, and you are wasting your money and less must mean you are leaving performance on the "table".

I'm curious where that sort of extremist thought comes from. Why the dichotomy?So, based on your definition of DIY, should those of us who build from other people's designs not be involved in this forum? Should we perhaps be banned, because we don't belong here?

I see DIY audio (lower case A) as a spectrum. One one end, there's someone with significant design and build skills (both electrical and mechanical). At the other end may be someone who buys commercial gear and swaps a couple of capacitors. There's an infinite number of possibilities between those two ends (and nobody says those have to be the end points or that there has to be end points at all). Nobody says the spectrum has to be limited to two dimensions either.

We can coexist, I think.

Tom

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- How do you classify a project a DIY?