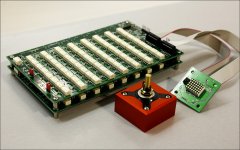

I'm planning a preamp utilizing a pair of these controllers (remote function as well as the knobs). I'm trying to figure out how to create the front panel. Either the panel with the inset screen or better, the arrangement of holes for the individual lights to shine through. Front Panel Express is a possibility but I want additional ideas. The chassis has a lip on the inside which means that all machining has to be done from the front if FPE does it. The circuit board is not exactly what the unit looks like but is similar. BTW, what is that type of light emitting chip called and is there a standard light pattern?

TIA

Dave

TIA

Dave

Attachments

HP made some of the first dot matrix LED displays for use in calculators in the 70s.

https://www.hpl.hp.com/hpjournal/pdfs/IssuePDFs/1977-04.pdf

LED Dot Matrix Display Systems - Forge Europa

https://www.hpl.hp.com/hpjournal/pdfs/IssuePDFs/1977-04.pdf

LED Dot Matrix Display Systems - Forge Europa

Last edited:

You draw what you want and give it to a machinist.

Or you cut & file the hole but if you were capable of that to the required precision you wouldn't be asking how to do it.

Individual holes would only work well with a very thin panel otherwise no viewing angle.

It gets even more complicated if you don't want screws showing on the panel.

Or you cut & file the hole but if you were capable of that to the required precision you wouldn't be asking how to do it.

Individual holes would only work well with a very thin panel otherwise no viewing angle.

It gets even more complicated if you don't want screws showing on the panel.

I've used sometime 16*2 LCD displays for DMX stuff and they had a frame which You could glue to the front panel, so Your cutting imperfections would remain hidden.

Drilled holes in aluminium make reasonable light-pipes, so not a big issue.Individual holes would only work well with a very thin panel otherwise no viewing angle.

Makes me think of the MacBook Pro unibody‘s stand-by led: it glows, but you don’t see no hole... [emoji2955]

The picture was just an example that showed the screens the best.128 signal relays? What? Really? NO!

There's got to be a better way.

I've used sometime 16*2 LCD displays for DMX stuff and they had a frame which You could glue to the front panel, so Your cutting imperfections would remain hidden.

Any help with locating such a part?+

People overestimate the difficulty of cutting a square hole in sheet metal. It's important to scribe the outline accurately. Clamp the panel securely to a workbench and use good lighting. Drill a starting hole, and then cut undersize with a sabre saw with an appropriate blade. Finally, file to the line with flat files of various coarseness.

Last edited:

I agree, I cut holes for IEC connectirs frequently. The difference is that there is a small bezel for the IEC where there is nothing to hide imperfection with the LED panel installed from the back.

- Home

- Design & Build

- Construction Tips

- How Do I Mount Screen?