Hi, i want to start winding some transformers from 100VA to 600VA.

want to know where can i get info about how many windings i need to use and the thickness of the copper, i want to know that because i want to purchase an machine to do the job, but need to know the thickness of the copper and the amount of turns first 🙂

Regards

want to know where can i get info about how many windings i need to use and the thickness of the copper, i want to know that because i want to purchase an machine to do the job, but need to know the thickness of the copper and the amount of turns first 🙂

Regards

If you have to ask those questions I would seriously suggest purchasing a transformer made by a reputable manufacturer. In the end, it will be cheaper and safer.

Hi,

the primary and the secondary windings run at between 1.6A/sqmm and 3.1A/sqmm.

The lower current gives a better regulation and lower heat dissipation.

The ampere turns in the primary controls the core flux, but I have no guidance on what values to use nor the type and thickness of steels available to wind the core.

Where can you source the insulation tape? Is it mylar? What overlap is minimum for perfect taping? How big a factor of safety will be appropriate for imperfect taping?

How will you test the enamel and tape insulation? What voltage should it be tested to? and for how long? How can you measure core and winding temperature? What will be an acceptable maximum ambient temperature.

I solve those questions by avoiding them (bury my head in the sand method!). I use an existing transformer and alter it slightly.

the primary and the secondary windings run at between 1.6A/sqmm and 3.1A/sqmm.

The lower current gives a better regulation and lower heat dissipation.

The ampere turns in the primary controls the core flux, but I have no guidance on what values to use nor the type and thickness of steels available to wind the core.

Where can you source the insulation tape? Is it mylar? What overlap is minimum for perfect taping? How big a factor of safety will be appropriate for imperfect taping?

How will you test the enamel and tape insulation? What voltage should it be tested to? and for how long? How can you measure core and winding temperature? What will be an acceptable maximum ambient temperature.

I solve those questions by avoiding them (bury my head in the sand method!). I use an existing transformer and alter it slightly.

How many units do you want to produce? You would have to produce 100+ units to start to be worthwhile.

I have to agree with BWRX. By the time you have bought the machine and the materials, and the test equipment, and wasted a lot of materials because you didn't set the machine up properly a lot of times, you might have well just bought proper ones in the first place.

I have to agree with BWRX. By the time you have bought the machine and the materials, and the test equipment, and wasted a lot of materials because you didn't set the machine up properly a lot of times, you might have well just bought proper ones in the first place.

I would be more concerned about the safety aspect of making your own transformer, especially a larger one (>50VA). In fact it may be illegal to connect a non-certified piece of equipment to your power grid.

Andrew and Richie brought up other good points too. A lot more goes into making, testing, and certifying a transformer than you might think. I'd hate to hear that someone's house burned down due to a faulty transformer in a DIY amp.

Andrew and Richie brought up other good points too. A lot more goes into making, testing, and certifying a transformer than you might think. I'd hate to hear that someone's house burned down due to a faulty transformer in a DIY amp.

This is not a casual undertaking

Please note, poorly designed and constructed transformers KILL people. These simple looking devices are actually very subtle and the kind of error that is acceptable in, perhaps, constructing an amplifier chassis and having the dimensions wrong by a few thousandths of an inch, will KILL people.

If you are seriously interested in learning how to design and then how to build power transformers you have only one real course. Find a local manufacturer, talk your way into working for the designer and use their materials and test equipment to learn what is a subtle and complex electromechanical art form.

As an added negative to your plans you cannot build toroids as cheaply as do the people in China and India. Buy from them and spend your time more wisely...

Unless, of course, you are simply fascinated by these lumps that take the basic force that the reality we live in is constructed of, tear it in two, rotate it 90 degrees, force it back together again and then make it do work. I am and have been for 35 years.

Bud

Please note, poorly designed and constructed transformers KILL people. These simple looking devices are actually very subtle and the kind of error that is acceptable in, perhaps, constructing an amplifier chassis and having the dimensions wrong by a few thousandths of an inch, will KILL people.

If you are seriously interested in learning how to design and then how to build power transformers you have only one real course. Find a local manufacturer, talk your way into working for the designer and use their materials and test equipment to learn what is a subtle and complex electromechanical art form.

As an added negative to your plans you cannot build toroids as cheaply as do the people in China and India. Buy from them and spend your time more wisely...

Unless, of course, you are simply fascinated by these lumps that take the basic force that the reality we live in is constructed of, tear it in two, rotate it 90 degrees, force it back together again and then make it do work. I am and have been for 35 years.

Bud

Hello,Hi, i want to start winding some transformers from 100VA to 600VA.

want to know where can i get info about how many windings i need to use and the thickness of the copper, i want to know that because i want to purchase an machine to do the job, but need to know the thickness of the copper and the amount of turns first 🙂

Regards

Now there is an App for the design/manufacture of toroid transformers.

Downloads:

https://play.google.com/store/apps/details?id=com.nano.rumuslengkaptrafotoroidor you can download it directly from playstore (key = "trafo toroid").

Videos :

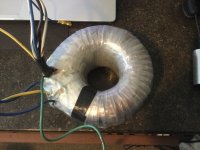

Winding machines are too rich for my blood, but I’ve never had problems just using a hand shuttle. Even with two #10 or up to four #12 at once on the largest cores. I don‘t wind my own primaries for toroids - I’ve always left that job to someone else. Toroid Corp (Maryland, USA) still sells the prewound primaries, and I’ve used their 1400 VA units. And pulled secondaries I can’t use off existing ones and put on the secondary I want. And added tertiary windings to off the shelf units. Something bought for $25 on the surplus market that’s too low a voltage to be useful (THE most common scenario) can easily be turned into a suitable power trafo for 100 to 200 watts per channel, with just a roll of #13 or 15 and some elbow grease.

Attachments

Kits with pre-made primaries are a great idea - you don't have to worry about the safety-critical part of the design.

- Home

- Design & Build

- Parts

- How Build Toroidal Transformer