HI,

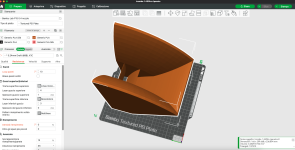

I bought a drawing of a Yuichi A-290 horn.

I know that the best solution would be to mill it in wood with a CNC, but the cost is very high..

I tried 3D printing them and they don't look bad, but I'm not sure I set good printing parameters.

Can good results be achieved with 3D printing?

I was thinking of trying to print them again, empty inside, with 10 wall shells, and then pouring some plaster inside...

could this be a good idea?

the drivers are jbl 375 and the printer is a bambulab

Thanks and sorry for my English..

I bought a drawing of a Yuichi A-290 horn.

I know that the best solution would be to mill it in wood with a CNC, but the cost is very high..

I tried 3D printing them and they don't look bad, but I'm not sure I set good printing parameters.

Can good results be achieved with 3D printing?

I was thinking of trying to print them again, empty inside, with 10 wall shells, and then pouring some plaster inside...

could this be a good idea?

the drivers are jbl 375 and the printer is a bambulab

Thanks and sorry for my English..

This approach shows a way to make it in wood without CNC:

https://www.araihorn.com/p/arai-290.html

Although more precise, it takes a long time to 3d print something like this. You have the right idea to print a low infill model, but I'm not sure plaster is the best filler material.

I'd go with the DIY wood approach. In the end it will also look more attractive. But it depends on your woodworking skills.

https://www.araihorn.com/p/arai-290.html

Although more precise, it takes a long time to 3d print something like this. You have the right idea to print a low infill model, but I'm not sure plaster is the best filler material.

I'd go with the DIY wood approach. In the end it will also look more attractive. But it depends on your woodworking skills.

Thanks for the replies, you are very kind 🙂

I printed them months ago, but I made them with 30% infill and I think something was wrong.

I would like to try to reprint them, it should take 2 days if I use 2 3D printers, otherwise 4 days.

I had thought about chalk, a very dampening material, but if there are suggestions I will gladly accept them.

I bought the project from Joseph Crowe and in the file there are 4 different sized horns with different cuts.

I chose to print at 450Hz, which was sufficient for my 500Hz cutting.

If I were to try to make them out of wood, I would probably make them bigger.

I'll try to look at the link you sent me, although unfortunately I'm not very good at woodworking.

I searched on Aliexpress, they seem very nice, but the shipping prices are very high...

I printed them months ago, but I made them with 30% infill and I think something was wrong.

I would like to try to reprint them, it should take 2 days if I use 2 3D printers, otherwise 4 days.

I had thought about chalk, a very dampening material, but if there are suggestions I will gladly accept them.

I bought the project from Joseph Crowe and in the file there are 4 different sized horns with different cuts.

I chose to print at 450Hz, which was sufficient for my 500Hz cutting.

If I were to try to make them out of wood, I would probably make them bigger.

I'll try to look at the link you sent me, although unfortunately I'm not very good at woodworking.

I searched on Aliexpress, they seem very nice, but the shipping prices are very high...

Attachments

Last edited:

Translation, please post in English

Hugo

Moderation team

Thanks for the replies, you are very kind 🙂

I printed them months ago, but I made them with 30% infill and I think something was wrong.

I would like to try to reprint them, it should take 2 days if I use 2 3D printers, otherwise 4 days.

I had thought about chalk, a very dampening material, but if there are suggestions I will gladly accept them.

I bought the project from Joseph Crowe and in the file there are 4 different sized horns with different cuts.

I chose to print at 450Hz, which was sufficient for my 500Hz cutting.

If I were to try to make them out of wood, I would probably make them bigger.

I'll try to look at the link you sent me, although unfortunately I'm not very good at woodworking.

I searched on Aliexpress, they seem very nice, but the shipping prices are very high...

Hugo

Moderation team

Thanks for the replies, you are very kind 🙂

I printed them months ago, but I made them with 30% infill and I think something was wrong.

I would like to try to reprint them, it should take 2 days if I use 2 3D printers, otherwise 4 days.

I had thought about chalk, a very dampening material, but if there are suggestions I will gladly accept them.

I bought the project from Joseph Crowe and in the file there are 4 different sized horns with different cuts.

I chose to print at 450Hz, which was sufficient for my 500Hz cutting.

If I were to try to make them out of wood, I would probably make them bigger.

I'll try to look at the link you sent me, although unfortunately I'm not very good at woodworking.

I searched on Aliexpress, they seem very nice, but the shipping prices are very high...

Grazie per le risposte, siete molto gentili 🙂

Li ho stampati mesi fa, ma li ho fatti con il 30% di riempimento e penso che fosse qualcosa di sbagliato.

Vorrei provare a ristamparli, ci dovrebbero volere 2 giorni se uso 2 stampanti 3D, altrimenti 4 giorni.

Avevo pensato al gesso, un materiale molto smorzante, ma se ci sono suggerimenti li accetto volentieri.

Ho comprato il progetto da Joseph Crowe e nel file ci sono 4 trombe di diverse dimensioni con tagli diversi.

Ho scelto di stampare a 450 Hz, che era sufficiente per il mio taglio a 500 Hz.

Se dovessi provare a farli in legno, probabilmente li farei più grandi.

Proverò a guardare il link che mi hai mandato, anche se purtroppo non sono molto bravo a lavorare il legno.

Ho cercato su Aliexpress, sembrano molto carini, ma i prezzi di spedizione sono molto alti...

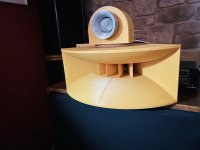

By your photo it looks like quality is okay. Can you detail the area you are not satisfied about?

I think printing them the way I printed them gives resonance problems... I was trying to understand how I could improve this with a new print🙂

yes, it is possible to print it with 0 filling,

but I think I made the wrong size of the trumpet..

the one I printed is the 450hz,

and with my 375 driver which is 2 inches with crossover at 500,

I think it's right to print the 300hz with 50x50 troath size...

I attach the link to Joseph Crowe, where I got the project.

Is what I say correct?

Thank you

https://josephcrowe.com/products/custom-yuichi-a-290-biradial-cad-model-make-any-size

but I think I made the wrong size of the trumpet..

the one I printed is the 450hz,

and with my 375 driver which is 2 inches with crossover at 500,

I think it's right to print the 300hz with 50x50 troath size...

I attach the link to Joseph Crowe, where I got the project.

Is what I say correct?

Thank you

https://josephcrowe.com/products/custom-yuichi-a-290-biradial-cad-model-make-any-size

- Home

- Loudspeakers

- Multi-Way

- Horn printed 3d