I am designing an exponential midbass horn for 70Hz to 250Hz.

I am using this horn calculator:

Single Driver Website

One thing I am not sure about is the cutoff frequency (flare frequency).

I choose 1 for M, and 2 for "size factor"

What should the "flare frequency" be if I plan to crossover at 70Hz with 24dB slope ?

I am using this horn calculator:

Single Driver Website

One thing I am not sure about is the cutoff frequency (flare frequency).

I choose 1 for M, and 2 for "size factor"

What should the "flare frequency" be if I plan to crossover at 70Hz with 24dB slope ?

Last edited:

Alternative Design Tool

[fc] < 50 Hz.

Study and use this program instead.

Hornresp

For best results a large horn is required. The Length & Mouth Size chosen will be the primary determinants of the horn load the driver sees and system frequency response, assuming a driver of appropriate parameters is used

Regards,

WHG

P.S., See Attachment from Beranek

[fc] < 50 Hz.

Study and use this program instead.

Hornresp

For best results a large horn is required. The Length & Mouth Size chosen will be the primary determinants of the horn load the driver sees and system frequency response, assuming a driver of appropriate parameters is used

Regards,

WHG

P.S., See Attachment from Beranek

Attachments

Last edited:

Thank you for the input.

50Hz is very difficult.

I was hoping I could achieve 70Hz cutoff with 57Hz horn.

50Hz is very difficult.

I was hoping I could achieve 70Hz cutoff with 57Hz horn.

Simulation

Run some simulations and adjust accordingly. Below 60Hz. may be sufficient.

The differences in this frequency range are nominal.

Regards,

WHG

Run some simulations and adjust accordingly. Below 60Hz. may be sufficient.

The differences in this frequency range are nominal.

Regards,

WHG

Last edited:

I do not have the driver's T-S parameters.

Do you know another way to determine (or extimate) the horn's Fc for 70Hz crossover ?

Do you know another way to determine (or extimate) the horn's Fc for 70Hz crossover ?

Last edited:

Essentials

Driver Mfg.? Model?

or

Measure it?

A horn build is a non-trivial project.

A good driver is essential to success.

For tweaking the system you will need to measure it (driver included).

Regards,

WHG

Driver Mfg.? Model?

or

Measure it?

A horn build is a non-trivial project.

A good driver is essential to success.

For tweaking the system you will need to measure it (driver included).

Regards,

WHG

Thank you David

I see that you are the author of Hornresp.

It is members like you and whgeiger that make DIYAudio THE BEST audio site.

Hornresp has a steep learning curve. That is why I haven't learn to use it.

Also because I do not have the TS parameter of my drivers.

I see that you are the author of Hornresp.

It is members like you and whgeiger that make DIYAudio THE BEST audio site.

Hornresp has a steep learning curve. That is why I haven't learn to use it.

Also because I do not have the TS parameter of my drivers.

Hello,

If you don't have the T&S parameters of your bass loudspeaker, simply put Eg = 0 in the data input screen of Hornresp.

This will simulate the horn only on a theorically perfect loudspeaker.

Best regards from Paris, France

Jean-Michel Le Cléac'h

If you don't have the T&S parameters of your bass loudspeaker, simply put Eg = 0 in the data input screen of Hornresp.

This will simulate the horn only on a theorically perfect loudspeaker.

Best regards from Paris, France

Jean-Michel Le Cléac'h

David mentioned that a general rule of thumb for an exponential horn is:

Fc = Fx / 1.25

So 56Hz cutoff for 70Hz crossover.

What do you think of this ?

Fc = Fx / 1.25

So 56Hz cutoff for 70Hz crossover.

What do you think of this ?

That is strange; David's post is completely gone.

Hi HP8903B,

You were too quick for me 🙂.

I deleted my response shortly after posting it because on reflection I became concerned that the "rule of thumb" I quoted might give you a false sense of security. If you do decide to adopt the rule however, please note that the final performance cannot guaranteed and that it will depend greatly on the actual driver used and the dimensions of the horn. This is why simulation programs can be so useful.

Just for the record, in case others are interested, the "rule of thumb" I quoted for an exponential horn was:

fc = fxo / 1.25

The value of fc so calculated should be considered the maximum permissible cutoff frequency, with a lower value preferable if possible.

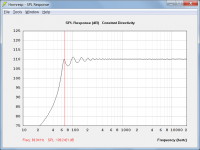

I have attached a screenprint showing the response of a sample 56Hz cutoff exponential horn with Eg = 0 as mentioned by Jean-Michel.

EDIT - You beat me again!

Kind regards,

David

Attachments

David,

Thanks for the clarification and the graph.

Yes I understand. There are other factors involved in the actual performance.

From looking at the graph, 70Hz crossover point with 24dB slope loosely follows the horn's slope.

The horn's slope doesn't effect the filter's slope (crossover slope) much.

What did you enter for the drivers parameters to get that graph ?

Thanks for the clarification and the graph.

Yes I understand. There are other factors involved in the actual performance.

From looking at the graph, 70Hz crossover point with 24dB slope loosely follows the horn's slope.

The horn's slope doesn't effect the filter's slope (crossover slope) much.

What did you enter for the drivers parameters to get that graph ?

Last edited:

From looking at the graph, 70Hz crossover point with 24dB slope loosely follows the horn's slope.

The horn's slope doesn't effect the filter's slope (crossover slope) much.

What did you enter for the drivers parameters to get that graph ?

Hi HP8903B,

Setting Eg equal to zero in Hornresp gives the driver diaphragm a constant rms velocity of 10 cm/sec. The only driver parameter value that then affects the response is Sd, and all it does is to change the absolute level, not the shape. In my example, the driver parameters were left at the default values. Note that the response shown is that of the horn only - the 70Hz crossover filter has not been applied to the response.

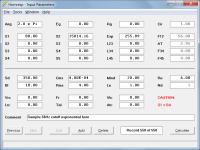

The input parameters I used in my example are shown in the attached screenprint.

Kind regards,

David

Attachments

Last edited:

Thank you

Could you clarify what "Cir" and "AT" are ?

I don't understand the description.

Also, what does 1 for "Cir" and "2.2" for "AT" mean ?

Could you clarify what "Cir" and "AT" are ?

I don't understand the description.

Also, what does 1 for "Cir" and "2.2" for "AT" mean ?

Let's say I have the driver's TS parameters and want a more accurate simulation.

If I use a compression driver, do I enter "0" for all chamber parameters ?

If I use a compression driver, do I enter "0" for all chamber parameters ?

Could you clarify what "Cir" and "AT" are ?

Also, what does 1 for "Cir" and "2.2" for "AT" mean ?

Hi HP8903B,

Cir = 1 means that the axisymmetric (circular) horn mouth has a circumference equal to one wavelength at the horn cutoff frequency, when the mouth area is normalised to free space conditions. If this still doesn't mean anything to you then simply remember that ideally Cir should have a value of 1 or greater, to reduce the impedance mismatch at the mouth. The horn will still work with smaller values of Cir, but the amplitude of the ripples in the response will be greater. Horn design is all about compromise 🙂.

AT = 2.2 means that the flare tangent half-angle at the horn throat is 2.2 degrees. This information is useful when wanting to exactly match a horn to a compression driver.

Kind regards,

David

If I use a compression driver, do I enter "0" for all chamber parameters ?

Hi HP8903B,

Ideally the air chambers on each side of the compression driver diaphragm should be specified in the design - you may need to make "educated guesses" on the dimensions.

Perhaps try simulating with and without chambers, to see what difference they make.

Kind regards,

David

I understand now.

Thank you very much for your help.

How can I convert the dimensions in Hornresp to make a horn with rectangular mouth, say 40" x 58" ?

From the horn calculator, the single curve is for a circular horn. But I need two curves, one for the top/bottom, and one for the 2 sides.

Thank you very much for your help.

How can I convert the dimensions in Hornresp to make a horn with rectangular mouth, say 40" x 58" ?

From the horn calculator, the single curve is for a circular horn. But I need two curves, one for the top/bottom, and one for the 2 sides.

How can I convert the dimensions in Hornresp to make a horn with rectangular mouth, say 40" x 58" ?

Hi HP8903B,

With the schematic diagram displayed, select the File > Export > Horn Data... menu command.

See the Export Horn Data section of the Hornresp Help file for further details.

Kind regards,

David

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Horn Cut Off Frequency Question ?