I had some problem with arcing with a regular bolt and insulator with my HV supply regulator. I used a nylon bolt and no further issue.

That is why I would use the clip solution. Maybe it was yout comment I read somewhere?

I had some problem with arcing with a regular bolt and insulator with my HV supply regulator. I used a nylon bolt and no further issue.

Where did the arcing take place; e.g. through the shoulder washer or from the bolthead to the TO-220 metal flange?

I haven't had arcing occur below 500V but maybe I've been lucky.

For higher voltages I use the TO-247 or TO-3P case devices which have an insulated hole for the mounting bolt. For a regulator circuit these are fine e.g. FQA7N80 or IXGH6N170.

The aluminum oxide pads rock. I haven't checked the breakdown voltage but they are hard to damage. For PC work they need extra clearance for the thickness of the pad itself.

For dissipation under 2-3 watts sometimes the metal chassis itself can be an adequate heat sink.

+1 on the heatsink sandwich, device inside and heatsink outside.

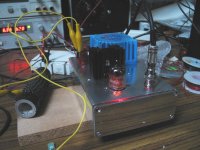

Here's another way. I use a vertical PC mount heatsink as pictured and remove the solder posts. I then drill 2 small holes in the chassis to fasten the heatsink using self tapping screws, and a large 1/2" hole in the center for the device leads to go through the top. I then connect to the device leads underneath using a 3 pin Molex connector. Cheep and cheerful!

Michael

Attachments

Last edited:

From what I could see from the tracking, and the odd occasion I saw a spark, I am assuming that the arcing was happening between the bolt head and the metal flange of the 220 package. I was getting it on the IRF840 pass device of a MAIDA style regulator. The regulated voltage was 400 volts, so the pass device must have been getting 450 or so, maybe higher for the turn-on spike.

This was causing me a whole lot of problems on my latest amp build (due to my general lack of experience). Took me a while to work out what was going on and come up with a solution that worked.

Chris

This was causing me a whole lot of problems on my latest amp build (due to my general lack of experience). Took me a while to work out what was going on and come up with a solution that worked.

Chris

I had some problem with arcing with a regular bolt and insulator with my HV supply regulator. I used a nylon bolt and no further issue.

I've had the same issue. Also on a Maida-style regulator. Though, I think it was the LM317 that threw the spark. I traced it down to a burr on the heat sink and a shoulder washer that had a nick in it from being pinched during mounting.

Of course one could use an LM317P (isolated TO220FP package).

~Tom

Last edited:

- Status

- Not open for further replies.