Hi all,

I was wondering if there is an old thread to point me to about how to customise the Onken / Fonken / etc. cabinets for different drivers, or if not, if somebody familiar with these can run me through the tuning process in general terms to make sure I'm not missing any considerations. I've read through and searched within a few Onken-related threads but not found anything comprehensive, but that doesn't mean it isn't out there. I've also definitely seen a few threads asking for advice about specific drivers lead to comments about appropriate box sizing but suggest that tuning will need to be done for them but can't find anywhere saying what this would entail.

Additionally, I've seen other threads saying that some designs for these behave like traditional ported enclosures and others function like aperiodic ones, and I'm not sure which the spreadsheet is for (presumably not aperiodic) nor if the design considerations are different for the other type.

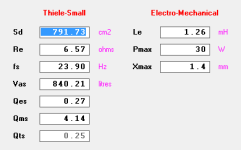

I've been looking at the 2011 thread by Togril on creating an Onken for the Tang Band W5-1611SA, who seemed pretty happy with how their build went. I have the SAF model of the same driver sitting unused at the moment, so I thought I'd see if I came to the same sort of parameters before I start building anything (and I've got some fairly hard space constraints where I'll be putting these speakers that would mean that if I can find a way to design it to be marginally shallower that would help too).

I'm aware that there is a spreadsheet by one of the gurus of these speakers out there - the one by Cyr-Marc Debien from 2000 - and have been playing around with it. As far as I can see, the goal is to figure out an enclosure of about the right volume that is a sensible shape (with the usual considerations around ratios of length/width/height as for any other box) for the driver parameters whilst keeping enough box depth to allow for the required vent length that the calculator spits out. Some drivers will basically be unsuitable, and others can easily be fit into these constraints.

Where I'm getting confused is around decisions to do with vent dimensions - obviously making these wider or longer or changing the total number of them will dramatically change the required vent length, but I'm assuming they also impact sound in other ways so have no idea what I should be picking here as a starting point or what changes are generally likely to be 'safe' vs causing other issues.

Assuming this spreadsheet is a good way for me to design a box, I was also hoping to clarify some parameters / outputs in the spreadsheet itself that have me confused:

Firstly, why there are separate fields for "effective vent length" and "corrected effective vent length" and what is being corrected for? I'm assuming the corrected one is what I should be aiming to use in the final design, but wanted to make sure I'm using the right one, as in the tests I've done it is usually 10-20% different to the 'effective' one.

Secondly, what is the impact of changes to the "n=" / "Onken alignment" parameter on the final result? I'm assuming the 6.34 was what the original bass cabinets 60+ years ago (presumably designed by trial and error) ended up having once more modern simulation/calculation methods were applied to the old designs, and the 5.7 is a better compromise that has since been identified mathematically, but I'm not sure what it is compromising on or what changes up or down from this 'ideal' value are likely to do.

Finally, what influences the tuning frequency for the box/vents that this spits out, aside from driver parameters? Fb is one of the calculated values and can't be set by the user. With other vented enclosure calculators (or at least subwoofer ones) this is something that I believe the designer usually decides on along with box size, target Q etc, and these then are used along with the (fixed) driver parameters to determine the vent parameters, both area and length. Here it seems we are coming at this from the other side - based on a given vent area and driver parameters, a fixed 'optimal' volume, Fb, and Q are set, and the required vent length to achieve this is output. Is this understanding correct?

Hopefully someone can set me straight or otherwise point me towards resources that will help me figure this out on my own!

I was wondering if there is an old thread to point me to about how to customise the Onken / Fonken / etc. cabinets for different drivers, or if not, if somebody familiar with these can run me through the tuning process in general terms to make sure I'm not missing any considerations. I've read through and searched within a few Onken-related threads but not found anything comprehensive, but that doesn't mean it isn't out there. I've also definitely seen a few threads asking for advice about specific drivers lead to comments about appropriate box sizing but suggest that tuning will need to be done for them but can't find anywhere saying what this would entail.

Additionally, I've seen other threads saying that some designs for these behave like traditional ported enclosures and others function like aperiodic ones, and I'm not sure which the spreadsheet is for (presumably not aperiodic) nor if the design considerations are different for the other type.

I've been looking at the 2011 thread by Togril on creating an Onken for the Tang Band W5-1611SA, who seemed pretty happy with how their build went. I have the SAF model of the same driver sitting unused at the moment, so I thought I'd see if I came to the same sort of parameters before I start building anything (and I've got some fairly hard space constraints where I'll be putting these speakers that would mean that if I can find a way to design it to be marginally shallower that would help too).

I'm aware that there is a spreadsheet by one of the gurus of these speakers out there - the one by Cyr-Marc Debien from 2000 - and have been playing around with it. As far as I can see, the goal is to figure out an enclosure of about the right volume that is a sensible shape (with the usual considerations around ratios of length/width/height as for any other box) for the driver parameters whilst keeping enough box depth to allow for the required vent length that the calculator spits out. Some drivers will basically be unsuitable, and others can easily be fit into these constraints.

Where I'm getting confused is around decisions to do with vent dimensions - obviously making these wider or longer or changing the total number of them will dramatically change the required vent length, but I'm assuming they also impact sound in other ways so have no idea what I should be picking here as a starting point or what changes are generally likely to be 'safe' vs causing other issues.

Assuming this spreadsheet is a good way for me to design a box, I was also hoping to clarify some parameters / outputs in the spreadsheet itself that have me confused:

Firstly, why there are separate fields for "effective vent length" and "corrected effective vent length" and what is being corrected for? I'm assuming the corrected one is what I should be aiming to use in the final design, but wanted to make sure I'm using the right one, as in the tests I've done it is usually 10-20% different to the 'effective' one.

Secondly, what is the impact of changes to the "n=" / "Onken alignment" parameter on the final result? I'm assuming the 6.34 was what the original bass cabinets 60+ years ago (presumably designed by trial and error) ended up having once more modern simulation/calculation methods were applied to the old designs, and the 5.7 is a better compromise that has since been identified mathematically, but I'm not sure what it is compromising on or what changes up or down from this 'ideal' value are likely to do.

Finally, what influences the tuning frequency for the box/vents that this spits out, aside from driver parameters? Fb is one of the calculated values and can't be set by the user. With other vented enclosure calculators (or at least subwoofer ones) this is something that I believe the designer usually decides on along with box size, target Q etc, and these then are used along with the (fixed) driver parameters to determine the vent parameters, both area and length. Here it seems we are coming at this from the other side - based on a given vent area and driver parameters, a fixed 'optimal' volume, Fb, and Q are set, and the required vent length to achieve this is output. Is this understanding correct?

Hopefully someone can set me straight or otherwise point me towards resources that will help me figure this out on my own!

An onken in original sense is a big ported cabinet with several small slotports on the side. The oldest i know is hte infamous HIagra Onken for the Altec 416. This works with older drivers with a higher Q and VAS to get more bass out of it compared to the design of that time (1960's - 1970's). You model that like a ported cabinet with a lot of smaller ports that are not ideal (Qp of 50 for instance).

Some use the look of that design but make the ports restricted or aperiodic, which can be an advantage. The Fonken series of Planet 10 are like that. That is very hard to model, as the damping that is needed is hard to model. There are some methods in Hornrsp, but I don't use that program, it's not easy to work with.

Some use the look of that design but make the ports restricted or aperiodic, which can be an advantage. The Fonken series of Planet 10 are like that. That is very hard to model, as the damping that is needed is hard to model. There are some methods in Hornrsp, but I don't use that program, it's not easy to work with.

The Onken calculator spreadsheet is based on the Snyder's "Simple formulas and graphs for design of vented loudspeaker systems" 1977 article (please find attached).Secondly, what is the impact of changes to the "n=" / "Onken alignment" parameter on the final result? I'm assuming the 6.34 was what the original bass cabinets 60+ years ago (presumably designed by trial and error) ended up having once more modern simulation/calculation methods were applied to the old designs, and the 5.7 is a better compromise that has since been identified mathematically, but I'm not sure what it is compromising on or what changes up or down from this 'ideal' value are likely to do.

There you can find some graphs for different Qts and different "n" which might be interesting to you.

Unfortunately though, this spreadsheet is just an attempt to reverse engineer the Onken design and has little to do with original Koizumi's approach.

Yes, you should use "corrected" length for the build. The correction is needed because real port is not just some theoretical "pipe", but is "half-flush" on the front and has walls adjacent to it on the rear, so it "appears" longer that it actually is.Firstly, why there are separate fields for "effective vent length" and "corrected effective vent length" and what is being corrected for? I'm assuming the corrected one is what I should be aiming to use in the final design, but wanted to make sure I'm using the right one, as in the tests I've done it is usually 10-20% different to the 'effective' one.

Attachments

Yes, that's roughly what I'd understood, and now that I've looked at the Planet10 page again, I've realised what I was actually asking about was Fonken / MiniOnken, so the title of this topic is a bit incorrect. Is what makes those resistive / aperiodic / near-aperiodic vs. the original Onkens just different proportions of vent size and length , or is something else done to add resistance?An onken in original sense is a big ported cabinet with several small slotports on the side. The oldest i know is hte infamous HIagra Onken for the Altec 416. This works with older drivers with a higher Q and VAS to get more bass out of it compared to the design of that time (1960's - 1970's). You model that like a ported cabinet with a lot of smaller ports that are not ideal (Qp of 50 for instance).

Some use the look of that design but make the ports restricted or aperiodic, which can be an advantage. The Fonken series of Planet 10 are like that. That is very hard to model, as the damping that is needed is hard to model. There are some methods in Hornrsp, but I don't use that program, it's not easy to work with.

At this stage I'm not clever enough to model even simpler enclosures myself in software (something on my long to-do list to figure out eventually, but this probably isn't the project to start with), which is why I'd looked for a "good enough" approach in the form of something like that calculator spreadsheet.

TG, thanks for the PDF of that article, looks like an interesting read for the weekend.

As mentioned in my reply to waxx, I'm probably not clever enough to do my own simulation at this stage, which is why I was hoping for an easy way to come up with a reasonable approximation. Thus, unfortunate to hear that the spreadsheet is an attempt at reverse-engineering. Do you know if it gets reasonably close to useful parameters despite this (particularly since we've now established I'm doing something in the Fonken/MiniOnken aperiodic style, not the original Onken design this is presumably working towards), and is there anything better / newer (given it is now 25 years old) that I could use instead that would do what I need without learning how to simulate an apparently complex enclosure myself?

Re: the vent length, if I go with the spreadsheet, I don't fully follow what the '"half-flush" on the front' bit means. Could you explain further? And re: the walls being adjacent at that back, are you referring to the outside wall running along the full length of the vent on one side and the back wall meeting it at right angles not far from where the slots start? That would make sense.

Also, on that note, is there any general rule about the minimum distance from the back the vents / inner side wall should start? With my Tang Band driver the spreadsheet is suggesting about 30cm vents for a 20L cabinet (which would ideally only be a bit over 30cm in depth to avoid ending up with a very odd overall box shape), and I note that the person who did the build for the same driver in 2011 here had the inner wall ending something like 2cm from the back panel, with another poster commenting that this was too short a distance, but I'm not certain if this feedback was correct / what the rationale would be. Certainly I've seen plenty of slot-loaded designs where a narrow slot goes around a 90 degree corner, so it doesn't seem like a hard-and-fast rule.

As mentioned in my reply to waxx, I'm probably not clever enough to do my own simulation at this stage, which is why I was hoping for an easy way to come up with a reasonable approximation. Thus, unfortunate to hear that the spreadsheet is an attempt at reverse-engineering. Do you know if it gets reasonably close to useful parameters despite this (particularly since we've now established I'm doing something in the Fonken/MiniOnken aperiodic style, not the original Onken design this is presumably working towards), and is there anything better / newer (given it is now 25 years old) that I could use instead that would do what I need without learning how to simulate an apparently complex enclosure myself?

Re: the vent length, if I go with the spreadsheet, I don't fully follow what the '"half-flush" on the front' bit means. Could you explain further? And re: the walls being adjacent at that back, are you referring to the outside wall running along the full length of the vent on one side and the back wall meeting it at right angles not far from where the slots start? That would make sense.

Also, on that note, is there any general rule about the minimum distance from the back the vents / inner side wall should start? With my Tang Band driver the spreadsheet is suggesting about 30cm vents for a 20L cabinet (which would ideally only be a bit over 30cm in depth to avoid ending up with a very odd overall box shape), and I note that the person who did the build for the same driver in 2011 here had the inner wall ending something like 2cm from the back panel, with another poster commenting that this was too short a distance, but I'm not certain if this feedback was correct / what the rationale would be. Certainly I've seen plenty of slot-loaded designs where a narrow slot goes around a 90 degree corner, so it doesn't seem like a hard-and-fast rule.

Dave's xyx-Ken designs have very little connection to Onkens [which themselves are a quasi-T/S descendent of the Jensen Ultraflex]. An Onken as usually termed is just a large vented box with a massive distributed vent system up each side. The original, like the Ultraflex and trad. vented boxes was targeting maximum efficiency at Fb; Dave's full xyz-Ken enclosures only share the visuals -as has been noted, he targets almost the polar opposite in alignment terms, where he's selected a well-damped alignment & is using a high aspect ratio for the vents to increase frictional losses & push the response toward aperiodic / leaky sealed behaviour. If you can't simulate it, you can't really recreate them unless you've a load of test data available & want to spend a long time working out empirical equations to match that data & then modify & repeat as desired.

For whatever it's worth, I generally [certain exceptions] work on a basis of a minimum vent distance to a facing internal baffle of Dv*1.414, where Dv = duct diameter.

One issue that regularly crops up with regular Onkens & is one reason for their characteristic sound is the length of the ducts. Ducts being pipes that are open at both ends are 1/2 wave resonators, i.e. they have their own independent resonant modes at lambda/2 [ignoring end correction] and since with low-tuned Onkens this tends to result in quite lengthy ducting, their resonant modes can comb with the direct output of the driver in the lower midrange. Some like the effect some don't; it doesn't really apply to the type Dave designs though.

For whatever it's worth, I generally [certain exceptions] work on a basis of a minimum vent distance to a facing internal baffle of Dv*1.414, where Dv = duct diameter.

One issue that regularly crops up with regular Onkens & is one reason for their characteristic sound is the length of the ducts. Ducts being pipes that are open at both ends are 1/2 wave resonators, i.e. they have their own independent resonant modes at lambda/2 [ignoring end correction] and since with low-tuned Onkens this tends to result in quite lengthy ducting, their resonant modes can comb with the direct output of the driver in the lower midrange. Some like the effect some don't; it doesn't really apply to the type Dave designs though.

The Onken, despite numerous esoteric claims, is just a bass reflex design. Slightly unconventional in terms of construction and port area, but still. Of course, we should give credits to Eijiro Koizumi, who developed the system long before Thiele-Small theory was a thing.As mentioned in my reply to waxx, I'm probably not clever enough to do my own simulation at this stage, which is why I was hoping for an easy way to come up with a reasonable approximation. Thus, unfortunate to hear that the spreadsheet is an attempt at reverse-engineering. Do you know if it gets reasonably close to useful parameters despite this (particularly since we've now established I'm doing something in the Fonken/MiniOnken aperiodic style, not the original Onken design this is presumably working towards), and is there anything better / newer (given it is now 25 years old) that I could use instead that would do what I need without learning how to simulate an apparently complex enclosure myself?

Below is my quick Unibox sim of the Hiraga's 1977 published Onken design (with Altec 416-8B, can't find the TS parameters for the 416-8A):

And then the screenshot of the Snyder's article mentioned before:

Given all that, you can use any enclosure calculator software you want.

I meant that the whole front panel is next to one side of the port output (and relatively thin wall and then empty space is next to the other).Re: the vent length, if I go with the spreadsheet, I don't fully follow what the '"half-flush" on the front' bit means. Could you explain further?

The "effective port length" is the length of the theoretical tube with zero thickness walls sticking "far enough" of the both sides of the panel. In practical design there's always something near the port end (or ends) and that something affects the port behavior. Thats why the thing called "port end correction" exists (just about any software is able to take these effects into account).

And re: the walls being adjacent at that back, are you referring to the outside wall running along the full length of the vent on one side and the back wall meeting it at right angles not far from where the slots start?

That's correct.

Also, on that note, is there any general rule about the minimum distance from the back the vents / inner side wall should start?

Generally the distance that is equal or greater than the port diameter (or the diameter of the equal area sircle for non-round ports) is considered acceptable.

Got it re: all the port end correction stuff, makes sense.

Interesting to hear that the trick to Dave's designs being semi-aperiodic is to do with frictional losses from a different aspect ratio - I previously was thinking purely in terms of vent areas and couldn't really see why those designs would be different in terms of alignment since as you mentioned they are visually similar. But now that you've mentioned it it makes sense to me too.

Similarly, good to know that the old/original type of Onken are not complex to simulate and are basically just ported boxes. However, I'm assuming that that isn't the case for Dave's designs since as mentioned they apparently work quite differently, have the quasi-aperiodic thing going on, etc. Similarly, I would imagine design/tuning rules of thumb for the traditional Onkens probably wouldn't apply well to Dave's designs (and presumably the spreadsheet I was previously referring to probably also won't work terribly well for this purpose).

It appears that the previous build in the other thread I was looking at (using the same driver as I have available with apparently good results) was one of Dave's style, using a smaller, modern, full-range driver, and not a traditional Onken. Thus, in some ways I'm now back at square one trying to figure out how to tune the enclosure/vent parameters for the driver I have to hand. I've previously seen other posts where people have asked for advice about using a given driver in a Fonken / MiniOnken style design and Dave has suggested one of the existing cabinet designs that were made for another driver with similar parameters but advised that the person doing the build would need to redo the tuning for the driver they wanted to use. However, I don't think I've seen anywhere that anybody has proceeded on past this sort of comment and don't know what that tuning would actually entail - applying some mathematical formulas I'm not aware of to the driver and box parameters, simulating the whole thing in software, or doing something else I'm not thinking of.

I'm not sure how much of the stuff to do with Dave's designs is a trade secret as opposed to something that other users can explain so this might be a question for Dave himself. Not sure how to tag him if he hasn't seen this thread already - I might need to PM him at some point and see if he can give further advice.

Interesting to hear that the trick to Dave's designs being semi-aperiodic is to do with frictional losses from a different aspect ratio - I previously was thinking purely in terms of vent areas and couldn't really see why those designs would be different in terms of alignment since as you mentioned they are visually similar. But now that you've mentioned it it makes sense to me too.

Similarly, good to know that the old/original type of Onken are not complex to simulate and are basically just ported boxes. However, I'm assuming that that isn't the case for Dave's designs since as mentioned they apparently work quite differently, have the quasi-aperiodic thing going on, etc. Similarly, I would imagine design/tuning rules of thumb for the traditional Onkens probably wouldn't apply well to Dave's designs (and presumably the spreadsheet I was previously referring to probably also won't work terribly well for this purpose).

It appears that the previous build in the other thread I was looking at (using the same driver as I have available with apparently good results) was one of Dave's style, using a smaller, modern, full-range driver, and not a traditional Onken. Thus, in some ways I'm now back at square one trying to figure out how to tune the enclosure/vent parameters for the driver I have to hand. I've previously seen other posts where people have asked for advice about using a given driver in a Fonken / MiniOnken style design and Dave has suggested one of the existing cabinet designs that were made for another driver with similar parameters but advised that the person doing the build would need to redo the tuning for the driver they wanted to use. However, I don't think I've seen anywhere that anybody has proceeded on past this sort of comment and don't know what that tuning would actually entail - applying some mathematical formulas I'm not aware of to the driver and box parameters, simulating the whole thing in software, or doing something else I'm not thinking of.

I'm not sure how much of the stuff to do with Dave's designs is a trade secret as opposed to something that other users can explain so this might be a question for Dave himself. Not sure how to tag him if he hasn't seen this thread already - I might need to PM him at some point and see if he can give further advice.

Fonken-style cabinets are BRs too 🙂

What you have to adjust to simulate very lossy ports is Qp parameter (port quality factor).

The default Qp value in most enclosure simulators is 50-100, and you have to lower it to 5 and below.

Here's the impedance plot for Dave's Fostex FE127E Fonken speaker with dampened lower peak:

And here's my quick sim with Qp set to 3:

What you have to adjust to simulate very lossy ports is Qp parameter (port quality factor).

The default Qp value in most enclosure simulators is 50-100, and you have to lower it to 5 and below.

Here's the impedance plot for Dave's Fostex FE127E Fonken speaker with dampened lower peak:

And here's my quick sim with Qp set to 3:

This is true -unfortunately, the Qp factor, being a lumped value, does not provide any hard data on how best to accurately determine & provide the target level of frictional losses / resistance in the vent structure. So while you can certainly get a reasonable approximation of them in lumped element simulations, ideally you need a variety of concrete examples with measurements [acoustic / electrical & physical] to analyse & then establish the necessary dimensions to hit whatever your target alignment happens to be.

how to customise the Onken / Fonken / etc. cabinets for different driver

A Fonken/miniOnken is not the same tuning as a traditional Onken, they normally using a bass-shelf alignment, althou more recently people have tuned them for max flat.

miniOnken takes the slots to extremes purposely to gain an aperiodic effect from the long, high aspect bratio slots. No BR modeler can simulate nit, one has to tune a specific way and then extrapolate.

Thanx to Scott for his miniOnken comments.

What you are really asking is about 3ndirrerent enclosures with asimilar cosmetioc \ aspect.

Take into consideration the Rout,ofmyour amplifier when designing the box.

Dave's designs is a trade secret

Not really, but i won’t walk you thru the proces, more than a few people have figured it out from the clues dropped over the years. Basically you add a bump to the sim which is attenuated by the high-R vents. I haveenuff experience to usually nail it, but if you don’t, open cel foam can be added to the vents to push it fuirther aperiodic.

dave

Jean-Michel LeCléac'h hypothesised that the main volume of an Onken enclosure did double duty as an acoustic filter. Like the compression chamber of an acoustic horn. Because he didn't see nearly the comb filtering he would expect from Onkens. I think in his French DIY audio circles, they lined the inside of the enclosure with a thick layer of Rockwool or fiberglass, which may already have absorbed a fair amount of the frequencies at play.

I like the form factor (I am Dutch and Rietveld and Mondriaan etc are in my cultural idiom), but it's a very specific alignment for a very specific type of driver. There was never a good reason for me to try.

I like the form factor (I am Dutch and Rietveld and Mondriaan etc are in my cultural idiom), but it's a very specific alignment for a very specific type of driver. There was never a good reason for me to try.

Hmm. Since all types of vented back loads form acoustic LP filters, the late Jean-Michel was certainly correct on that front. Most vented boxes, [which is all an Onken is, no more, no less] are lagged in some way, so again, 'nothing to see here' either.

As noted, the main potential issue with this type of enclosure, especially if tuned low, is the duct length which can often become long enough to have their own resonant modes excited. These are independent of the box tuning itself & the amount of excitation ultimately depends on how much energy you put into them. Drivers requiring acoustically large enclosures can help avoid this since the higher Vb means you can keep the duct length down a bit for a given target alignment & total CSA.

As noted, the main potential issue with this type of enclosure, especially if tuned low, is the duct length which can often become long enough to have their own resonant modes excited. These are independent of the box tuning itself & the amount of excitation ultimately depends on how much energy you put into them. Drivers requiring acoustically large enclosures can help avoid this since the higher Vb means you can keep the duct length down a bit for a given target alignment & total CSA.

Hence easiest for the typical DIYer to critically damp a 'textbook'/simmed vent.This is true -unfortunately, the Qp factor, being a lumped value, does not provide any hard data on how best to accurately determine & provide the target level of frictional losses / resistance in the vent structure.

Last edited by a moderator:

My fave pen pal, starting with the Onken. Sorely miss him.Jean-Michel LeCléac'h hypothesised that the main volume of an Onken enclosure did double duty as an acoustic filter. Like the compression chamber of an acoustic horn. Because he didn't see nearly the comb filtering he would expect from Onkens. I think in his French DIY audio circles, they lined the inside of the enclosure with a thick layer of Rockwool or fiberglass, which may already have absorbed a fair amount of the frequencies at play.

I like the form factor (I am Dutch and Rietveld and Mondriaan etc are in my cultural idiom), but it's a very specific alignment for a very specific type of driver. There was never a good reason for me to try.

Yeah, we agreed that fundamentally it was a huge compression driver and yes, the pics he sent of some builds were heavily damped.

Yeah, we agreed that fundamentally it was a huge compression driver and yes, the pics he sent of some builds were heavily damped.Not really, the basic concept is quite flexible........Note that Altec, etc., CDs that I've seen measurements of have a mid 0.7 Qt and IIRC this Onken was being driven with some type of matching impedance tube system, hence the need for low Qt Altec 416, etc., drivers, ergo higher Qt drivers are fine and of course can be fine tuned with a bit of series resistance.

As for vents, sim them to driver Sd per Thuras' reflex patent (original 'Onken') and if too long, then make them as long as practical and critically damp to 'taste'.😉

Last edited:

I will admit a lot of this discussion is now going somewhat above my head, but I think I've figured out what I need to go and read up on, and I probably also need to bite the bullet and learn how to properly simulate enclosures in software and then figure out how things work through trial and error - whilst I've built a fair few enclosures in the past, with one exception (which admittedly didn't end up sounding fantastic) they've been either directly made from other people's plans for a given driver, or minor adjustments from known good designs targeting very specific things or to adjust for a similar but not identical driver to the one that had originally been used, parameter-wise. And a few sealed boxes, but those are fairly straightforward.

Originally when starting this thread, I was hoping for someone to lay out a series of steps to go from having a driver that I understand should be workable in a given design (in this case, one of the Onken derivatives) to coming up with a workable enclosure - e.g. first figure out appropriate enclosure volume/dimensions for the driver parameters, then figure out apprpriate porting for that volume and whether they will physically fit (and if not, compromise on length, change the dimensions, or change the driver), then presumably simulate whatever has been calculated and see if it looks like the response will behave, then build it, so that I could then go on to read up on whatever was needed for each step and also make sure I didn't do them in an incorrect order or unintentionally compromise something that shouldn't be compromised, design-wise. And I came into this thinking that there would be a lot of unique considerations or methodologies for this particular style of enclosure whereas it appears from several subsequent posts that I was incorrect, and in large part all of them still follow the basic design rules for bass reflex systems, which obviously are easy to find in many places. Part of the reason I came to my original conclusion was that (unless I've been doing pretty basic caclulations wrong) it looked like the known working designs I could find online (whether traditional Onkens, or Dave's variations) seemd to have quite different total port dimensions to what I would come to if I'd converted the area of a round port for the same size enclosure into a bunch of rectangles.

Anyway, starting from that (incorrect) assumption, I thought there would be lots of information unique to designing these required, and had also figured that getting that sort of stepwise plan in one place would be helpful for others of limited experience embarking on the same sort of project down the track, as when I'd hunted through prior threads about Onken-derivatives, I couldn't really find anywhere that someone had pulled together a lot of existing information or links to prior threads into one summary, which is something I've seen done in some depth for popular designs on here.

That said, even if it is just a bass reflex design, if anyone still wants to do the 'explain like I'm 5' thing for what I should do next, that would be much appreciated! (Hopefully it isn't "go build something simpler")

And similarly, if there are recommendations about what the best software to learn as a beginner to simulating enclosures would be, that would be great - I've seen plenty of suggestions over the years and imagine that things change over time and what was optimal in 2010 is probably no longer the best in 2025.

Originally when starting this thread, I was hoping for someone to lay out a series of steps to go from having a driver that I understand should be workable in a given design (in this case, one of the Onken derivatives) to coming up with a workable enclosure - e.g. first figure out appropriate enclosure volume/dimensions for the driver parameters, then figure out apprpriate porting for that volume and whether they will physically fit (and if not, compromise on length, change the dimensions, or change the driver), then presumably simulate whatever has been calculated and see if it looks like the response will behave, then build it, so that I could then go on to read up on whatever was needed for each step and also make sure I didn't do them in an incorrect order or unintentionally compromise something that shouldn't be compromised, design-wise. And I came into this thinking that there would be a lot of unique considerations or methodologies for this particular style of enclosure whereas it appears from several subsequent posts that I was incorrect, and in large part all of them still follow the basic design rules for bass reflex systems, which obviously are easy to find in many places. Part of the reason I came to my original conclusion was that (unless I've been doing pretty basic caclulations wrong) it looked like the known working designs I could find online (whether traditional Onkens, or Dave's variations) seemd to have quite different total port dimensions to what I would come to if I'd converted the area of a round port for the same size enclosure into a bunch of rectangles.

Anyway, starting from that (incorrect) assumption, I thought there would be lots of information unique to designing these required, and had also figured that getting that sort of stepwise plan in one place would be helpful for others of limited experience embarking on the same sort of project down the track, as when I'd hunted through prior threads about Onken-derivatives, I couldn't really find anywhere that someone had pulled together a lot of existing information or links to prior threads into one summary, which is something I've seen done in some depth for popular designs on here.

That said, even if it is just a bass reflex design, if anyone still wants to do the 'explain like I'm 5' thing for what I should do next, that would be much appreciated! (Hopefully it isn't "go build something simpler")

And similarly, if there are recommendations about what the best software to learn as a beginner to simulating enclosures would be, that would be great - I've seen plenty of suggestions over the years and imagine that things change over time and what was optimal in 2010 is probably no longer the best in 2025.

Sorry, but I prefer to just educate as best I can, so in general; if seriously interested in designing speakers, horns beyond doodling with design programs till you get what seems suits the needs of your app, then you must understand these fundamentals of acoustics:

T/S theory peters out at the driver's effective upper [Fhm], lower [Flc] mass corners, so any bandwidth response plot beyond these points are strictly due to [inputted] inductance [mH] and/or voice coil mass roll off [Fhvc], with on-line freeware generally just flatlining it:

Fhm = 2*Fs/Qts' end of acceleration BW

Flc = Fs*Qts'/2 end of LF BW roll off

Fhvc = Re/(pi*Le)

Qts' = 2*Fs/Fhm

(Qts'): (Qts) + any added series resistance (Rs)

Maybe more easily understood from a horn loading POV along with all the extra math, pg. 7.

Reference material:

T/S Explained

T/S Equations and how each one affects the others

Using eff/n0 to compare drivers

Re software: 'best' depends on what you're wanting to design with AKABAK best overall AFAIK, but has a steep learning curve, so I use Hornresp, but there's been a lot of new programs in recent years, so will 'pass the buck' to others much more current.

T/S theory peters out at the driver's effective upper [Fhm], lower [Flc] mass corners, so any bandwidth response plot beyond these points are strictly due to [inputted] inductance [mH] and/or voice coil mass roll off [Fhvc], with on-line freeware generally just flatlining it:

Fhm = 2*Fs/Qts' end of acceleration BW

Flc = Fs*Qts'/2 end of LF BW roll off

Fhvc = Re/(pi*Le)

Qts' = 2*Fs/Fhm

(Qts'): (Qts) + any added series resistance (Rs)

Maybe more easily understood from a horn loading POV along with all the extra math, pg. 7.

Reference material:

T/S Explained

T/S Equations and how each one affects the others

Using eff/n0 to compare drivers

Re software: 'best' depends on what you're wanting to design with AKABAK best overall AFAIK, but has a steep learning curve, so I use Hornresp, but there's been a lot of new programs in recent years, so will 'pass the buck' to others much more current.

- Home

- Loudspeakers

- Full Range

- Help with tuning Onken enclosures