I picked up pair of Pioneer CS-V935 floorstanders for 20 bucks. The old man said he bought them back in 1991:

The paper tweeter and midranges are damaged so I ordered new components for the pair instead of bothering to repair them.

Midrange:

https://www.lavocespeakers.com/lavoce/assets/datasheets/LAVOCE_MSF051.22_5in_MIDRANGE_A.a.pdf

Tweeter:

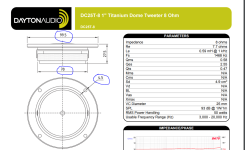

https://www.parts-express.com/pedocs/specs/275-045-dayton-audio-dc25t-8-specifications-46190.pdf

I realize that there will be wave interference using non-sealed midrange in the enclosure where there is no physical isolation provisioned. The original midrange is "semi-sealed" but here are a couple photos of the original Pioneer midrange FWIW:

My main question is what volume of isolation chamber cup should I be designing for? I chose to make it 7 inch (177.80mm) deep and around (122mm) 4.72" OD just for safe numbers that are plug and play but I can go a little more deeper (max is about 9 inch deep) and a little wider if it matters. As above I chose the Lavoce 5" MSF051.22 midrange speaker replacement as it aligns with the original speaker bolt pattern. I have a rough drawing to show my idea for 3d printing using carbon fiber or similar material:

Also, I assume I stuff it with 1/2-3/4 full of insulation? Whats the right way to do this? I read some old speaker design books but haven't designed my own speaker enclosures or fitting before. I think I need some advice from experts on here to move forward.

Thanks for any pointers!

Jeff

The paper tweeter and midranges are damaged so I ordered new components for the pair instead of bothering to repair them.

Midrange:

https://www.lavocespeakers.com/lavoce/assets/datasheets/LAVOCE_MSF051.22_5in_MIDRANGE_A.a.pdf

Tweeter:

https://www.parts-express.com/pedocs/specs/275-045-dayton-audio-dc25t-8-specifications-46190.pdf

I realize that there will be wave interference using non-sealed midrange in the enclosure where there is no physical isolation provisioned. The original midrange is "semi-sealed" but here are a couple photos of the original Pioneer midrange FWIW:

My main question is what volume of isolation chamber cup should I be designing for? I chose to make it 7 inch (177.80mm) deep and around (122mm) 4.72" OD just for safe numbers that are plug and play but I can go a little more deeper (max is about 9 inch deep) and a little wider if it matters. As above I chose the Lavoce 5" MSF051.22 midrange speaker replacement as it aligns with the original speaker bolt pattern. I have a rough drawing to show my idea for 3d printing using carbon fiber or similar material:

Also, I assume I stuff it with 1/2-3/4 full of insulation? Whats the right way to do this? I read some old speaker design books but haven't designed my own speaker enclosures or fitting before. I think I need some advice from experts on here to move forward.

Thanks for any pointers!

Jeff

Last edited:

Hi, are you looking to 3D print these ?. Not an expert here by any means . Tho , I would suggest making them thicker , maybe 8mm if you can. And add some reinforcements ( stripes, lines , not a smooth surface , on the exterior. ) Less vibrations. Building from wood would be even better , a square box is easiest but your Ports might get in the way. You could cut rings out of MDF , stack them to make an enclosure for the mid range.

For the tweeter I personally think it won't matter how big the enclosure is. Only so the tweeter is separated from the rest of the drivers. ( I would separate the tweeter as well, even if it's self closed, some air can escape.

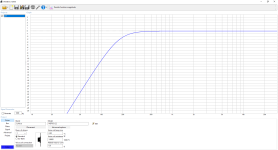

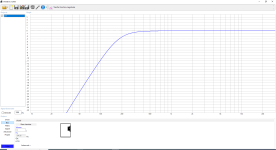

Simulated your mid range driver in WinISD , with a minimum of 2 Liters it would give you a flat response with no peaks .

Size for the enclosure will depend on how low frequency you want your mid driver to play. The size of the box I don't think it would matter that much for a mid range driver.

I have my 3.5 inch mid drivers in a 1.5 liter cabinet, and they sound great. tested them in a 4 liter box , the bass is better, but used as a mid range, I couldn't hear a difference in the mid range.

Most mid range drivers don't have an enclosure, their back is just closed.

Main reason so the woofers don't move the mid range cone ( being in the same enclosure ) . making the mids sound bad and also it could damage them ( mechanically , exceeding their x-max ).

For the tweeter I personally think it won't matter how big the enclosure is. Only so the tweeter is separated from the rest of the drivers. ( I would separate the tweeter as well, even if it's self closed, some air can escape.

Simulated your mid range driver in WinISD , with a minimum of 2 Liters it would give you a flat response with no peaks .

Size for the enclosure will depend on how low frequency you want your mid driver to play. The size of the box I don't think it would matter that much for a mid range driver.

I have my 3.5 inch mid drivers in a 1.5 liter cabinet, and they sound great. tested them in a 4 liter box , the bass is better, but used as a mid range, I couldn't hear a difference in the mid range.

Most mid range drivers don't have an enclosure, their back is just closed.

Main reason so the woofers don't move the mid range cone ( being in the same enclosure ) . making the mids sound bad and also it could damage them ( mechanically , exceeding their x-max ).

Attachments

Also , the new tweeter seems to be bigger than the original , will it fit?.

That's the frequency response of the Lavoce. The 7dB steep step at 1,5kHz is not that easy to handle, it would be a lot easier and cheaper to get a driver that behaves better. Did you buy it already?

Yes, I need to cut out the hole to 100mm?Also , the new tweeter seems to be bigger than the original , will it fit?.

Your tweeter dimension is 99.5mm . Magnet size 70mm . You need to cut 70mm ( a tiny bit more so it can easily fit , cut 70 and use sandpaper until the tweeter goes in , or cut 72mm or so. ) . so the driver fits and can be screwed in. The edge ring is 4.5mm ( where the holes are ) .Yes, I need to cut out the hole to 100mm?

Attachments

Are you sure ? . from the looks of it it might not.

Green lines is where you want to put the 5 inch mid ?. and Red lines where the tweeter ?.

Attachments

@xXBrunoXx The replacement speakers are same OD as the originals but I need to expand the tweeter hole a little but OD is still retained.

I'll keep it in mind. I am not going to be super picky about the sound knowing my room needs a lot of work too but if it is a drop in replacement I will put it on my wish list. I already ordered the other components and shipping is crazy to here from Parts Express. I am saving some cash for a measurement microphone so I can try to make some plots and try to better EQ the room.The Dayton Audio DC130B-4 is a lot easier to handle and not expensive either.

View attachment 1360577

Hi, are you looking to 3D print these ?. Not an expert here by any means . Tho , I would suggest making them thicker , maybe 8mm if you can. And add some reinforcements ( stripes, lines , not a smooth surface , on the exterior. ) Less vibrations. Building from wood would be even better , a square box is easiest but your Ports might get in the way. You could cut rings out of MDF , stack them to make an enclosure for the mid range.

For the tweeter I personally think it won't matter how big the enclosure is. Only so the tweeter is separated from the rest of the drivers. ( I would separate the tweeter as well, even if it's self closed, some air can escape.

Simulated your mid range driver in WinISD , with a minimum of 2 Liters it would give you a flat response with no peaks .

Size for the enclosure will depend on how low frequency you want your mid driver to play. The size of the box I don't think it would matter that much for a mid range driver.

I have my 3.5 inch mid drivers in a 1.5 liter cabinet, and they sound great. tested them in a 4 liter box , the bass is better, but used as a mid range, I couldn't hear a difference in the mid range.

Most mid range drivers don't have an enclosure, their back is just closed.

Main reason so the woofers don't move the mid range cone ( being in the same enclosure ) . making the mids sound bad and also it could damage them ( mechanically , exceeding their x-max ).

Based on what you calculated I increased the size of the isolation chamber cup as much as I could. I will 3D print it using carbon fibre PLA or PETG:

Pioneer Monkey Coffin ⚰️ speaker update:

I was able to make a little double hole 🕳️ saw jig to be able to cut the tweeter hole to 70MM dia centre without too much trouble. However, maybe the drawing doesn’t show it or I missed it —the speaker wire terminal lugs are offset outside the 70mm dia by about maybe 5mm or so on each side which complicates the install a little more than originally planned. I can maybe able to drill out a pilot hole on each side to let them seat properly but the magnet for the new Dayton DC25T-8 tweeter fits inside the modified hole now.

Custom hole saw expander:

Setting up the drill:

After the rip:

Measurement of speaker terminal offset from magnet:

I was able to make a little double hole 🕳️ saw jig to be able to cut the tweeter hole to 70MM dia centre without too much trouble. However, maybe the drawing doesn’t show it or I missed it —the speaker wire terminal lugs are offset outside the 70mm dia by about maybe 5mm or so on each side which complicates the install a little more than originally planned. I can maybe able to drill out a pilot hole on each side to let them seat properly but the magnet for the new Dayton DC25T-8 tweeter fits inside the modified hole now.

Custom hole saw expander:

Setting up the drill:

After the rip:

Measurement of speaker terminal offset from magnet:

Attachments

Last edited:

Not too much action or love in this thread but I made a couple crude cutouts for the tweeters terminal lugs and wired them up to the original female socket blades within the original crossover wiring, amazingly they are perfect fit for the factory 🏭 wiring which made the job a bit easier plug and play🤗

How does it sound?

Personally I'd have gone for the smoother Dayton driver but if needed that should be a reasonably easy upgrade

Personally I'd have gone for the smoother Dayton driver but if needed that should be a reasonably easy upgrade

These simple things are always more trouble than imaginable from first glance. I would say that all things considered you did just fine. I would consider protecting the woofer driver cones next time around. Getting saw dust out of surrounds can be a challenge after the fact.

Yes, the integration is done. I had several challenges associated with the fit of the drivers and resulting space around them. I could not have the opportunity of "pick of the litter" for this job. I did my best to chose aftermarket drivers that were close or identical to the OD of the originals to try and make things easier on myself. I also had to design an isolation chamber for the new midrange speaker as the original factory speaker had a semi-sealed insulated design. I will try and take some measurements of the current setup.View attachment 1360575

That's the frequency response of the Lavoce. The 7dB steep step at 1,5kHz is not that easy to handle, it would be a lot easier and cheaper to get a driver that behaves better. Did you buy it already?

which one? I figured I would wait a day for the sealant to set before I take a listen.How does it sound?

Personally I'd have gone for the smoother Dayton driver but if needed that should be a reasonably easy upgrade

The 130mm Midrange

Either the 4R or the 8R

https://www.parts-express.com/Dayton-Audio-DC130B-8-5-1-4-Classic-Woofer-Speaker-295-304?quantity=1

Good bang for the buck even here in Oz

Either the 4R or the 8R

https://www.parts-express.com/Dayton-Audio-DC130B-8-5-1-4-Classic-Woofer-Speaker-295-304?quantity=1

Good bang for the buck even here in Oz

- Home

- Loudspeakers

- Multi-Way

- Help with sealed chamber size for 5" Lavoce Midrange driver for Pioneer CS-V935