Hi. I'd like help understanding the center frequency of an existing parallel notch filter.

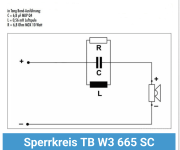

I'm just finishing some small full-range speakers, using the Tang Band W3-665sc I scavenged from some Logitech media speakers, Googling the driver model # when I saw the following Parallel notch filter posted by a German DIYer.

I tried to translate the caption, and it said the filter was to compensate for a driver basket resonance in the W3-665sc.

I am curious as to what frequency this is reputed to be.

I tried to reverse-engineer using the notch filter calculators online, but got conflicting results.

Can someone please tell me what the center frequency of this filter is? Thanks 🙏

and Happy New Year!

I'm just finishing some small full-range speakers, using the Tang Band W3-665sc I scavenged from some Logitech media speakers, Googling the driver model # when I saw the following Parallel notch filter posted by a German DIYer.

I tried to translate the caption, and it said the filter was to compensate for a driver basket resonance in the W3-665sc.

I am curious as to what frequency this is reputed to be.

I tried to reverse-engineer using the notch filter calculators online, but got conflicting results.

Can someone please tell me what the center frequency of this filter is? Thanks 🙏

and Happy New Year!

Attachments

Hey-

Thanks!

Seems a little high for a basket resonance(but it is a 3" driver).

I wonder if a more acoustically benign solution would be to damp the metal basket with hot glue, mortite, or other viscoelastic material, eliminating the very caps & coils a full-range design avoids?

Cheers 🍻

Thanks!

Seems a little high for a basket resonance(but it is a 3" driver).

I wonder if a more acoustically benign solution would be to damp the metal basket with hot glue, mortite, or other viscoelastic material, eliminating the very caps & coils a full-range design avoids?

Cheers 🍻

Right, 'acoustic solutions to acoustic problems' was the pioneer's motto. 👍 😎

So, you recommend I use mechanical damping of the steel driver basket, rather than using a notch filter, right?

Any other recommendations for good chassis damping compounds, that won't get loose or outgas and affect the cone, surround, spider or coil?

🙏

Any other recommendations for good chassis damping compounds, that won't get loose or outgas and affect the cone, surround, spider or coil?

🙏

Correct.

Mortite or similar with some added mass is probably most common, but I just cut pieces of roofing lead flashing.

Mortite or similar with some added mass is probably most common, but I just cut pieces of roofing lead flashing.

Go to a local machine shop and get a bag of heavy metal shavings and/or grinding 'dust' to mix into the mortite.

Think of it as 1st-order XO on a single driver, LPF and HPF connected to the driver + in parallel. Center frequency ~ 5khz/sqrt (mH*uF) because (the same) impedance cancels out from the formulae for LPF=HPF.Hi. I'd like help understanding the center frequency of an existing parallel notch filter.

LPF ~ (160hz*ohm) /mH

HPF ~ (160khz/ohm)/uF

See also https://www.diyaudio.com/community/...ullrange-and-4-ohm-woofer.407256/post-7553230

For the pictured notch filter 6.8uF | 0.56mH | 6.8ohm the center frequency ~ 5khz/sqrt (3.81) ~ 2.6khz (checks).

Last edited:

Cool-Thanks for the info.

I would like to avoid sand grains might possibly get into the motor system. There is no dust cover (aluminum phase plug= exposed voice coil gap).

I tried using Mortite and hot glue on the basket. The 2.6khz ring was attenuated, but still rang when tapped.

I finally tried 5min epoxy where the basket meets the magnet/shield cup assembly, This damped the "ring" more than all that Mortite, indicating the main problem was small area supporting the basket. I will use the epoxy, plus a small amount of Moretite(or even hot glue) on each spoke.

Thanks again for all the help.

and Happy New Year! 🥂

I would like to avoid sand grains might possibly get into the motor system. There is no dust cover (aluminum phase plug= exposed voice coil gap).

I tried using Mortite and hot glue on the basket. The 2.6khz ring was attenuated, but still rang when tapped.

I finally tried 5min epoxy where the basket meets the magnet/shield cup assembly, This damped the "ring" more than all that Mortite, indicating the main problem was small area supporting the basket. I will use the epoxy, plus a small amount of Moretite(or even hot glue) on each spoke.

Thanks again for all the help.

and Happy New Year! 🥂

Attachments

Finished the small Tang Band towers last night. I'm surprised that they sound better than they "should", considering their pedigree. Soundstage is well outside and behind the speaker, and imaging is pinpoint. The bright top end was tamed by use of dual drivers; likewise, the dynamic range and power handling have been increased. The actual enclosures are generic (China) MDF "speaker stands", port is tuned to 80hz.

Total cost of materials was about the same as I spent for pizzas on New Year's Eve.

Thanks again to all.

I love DIY! 😍

Total cost of materials was about the same as I spent for pizzas on New Year's Eve.

Thanks again to all.

I love DIY! 😍

Attachments

I've used High Temp Silicone on the joint between the basket & magnet.

For the basket legs/spokes,

Step 1) cut narrow strips of wax paper, apply silicone on strips.

Step 2) Carefully wrap around the basket leg- may need to secure with paper clip, etc ,. Let dry- a few days.

I learned many years ago from a speaker designer, he mixed some epoxy in a container & placed the speaker magnet (up to the frame/magnet)- encapsulating it.

For the basket legs/spokes,

Step 1) cut narrow strips of wax paper, apply silicone on strips.

Step 2) Carefully wrap around the basket leg- may need to secure with paper clip, etc ,. Let dry- a few days.

I learned many years ago from a speaker designer, he mixed some epoxy in a container & placed the speaker magnet (up to the frame/magnet)- encapsulating it.

- Home

- Loudspeakers

- Full Range

- Help with Parallel notch filter for small full-range speaker