Viitoria is mine ... no, someone else's 🙁 ...

Yes, perhaps, but Apple has a longer tradition of being for the wealthier snobbish crowd 🙂

OK, Vittoria is not mine, I am afraid to even know what they cost, but I want my eventual DIY Unity Synergy clone to have as nice wood finish. In my price range, I will have to try my "decorative painting" hobby upon the coroplast 😀

Yes, perhaps, but Apple has a longer tradition of being for the wealthier snobbish crowd 🙂

OK, Vittoria is not mine, I am afraid to even know what they cost, but I want my eventual DIY Unity Synergy clone to have as nice wood finish. In my price range, I will have to try my "decorative painting" hobby upon the coroplast 😀

Attachments

I have heard those. They are wonderful.

Poor man's upgdaded version = Peavey SP-1 with a high end co-ax HF driver and DSP Xover. Much nicer horns in general and crossover @ 400 hz is more than possible giving you all od the bennies of point source from 400 to 20k from point source. Those are found easily for 150 to 300 per pair. Comp divers will be less than 800 (you can sell your Peavey units for about 150 of that. DSP crossover anywhere from free with an old computer and a good multi out soundblaster (114 to 120 db snr + noise people!) To a Behringer or mini dsp for 200 to 300 at most. You will have a very ugly state of the art speaker system that needs only a few watts of any power for 1000 to 1500 at most much less if you find a deal on drivers (hf) Whatever peavey woofers that are in the sp1s are more tgan adaquate. It is truly all in the horn and driver.

Poor man's upgdaded version = Peavey SP-1 with a high end co-ax HF driver and DSP Xover. Much nicer horns in general and crossover @ 400 hz is more than possible giving you all od the bennies of point source from 400 to 20k from point source. Those are found easily for 150 to 300 per pair. Comp divers will be less than 800 (you can sell your Peavey units for about 150 of that. DSP crossover anywhere from free with an old computer and a good multi out soundblaster (114 to 120 db snr + noise people!) To a Behringer or mini dsp for 200 to 300 at most. You will have a very ugly state of the art speaker system that needs only a few watts of any power for 1000 to 1500 at most much less if you find a deal on drivers (hf) Whatever peavey woofers that are in the sp1s are more tgan adaquate. It is truly all in the horn and driver.

Wonderful. Yet more ways to splash my cash

Thanks Pete. One more thing to research for my wish-list.

Another Brilliant Idea* that just occurred to me, even before reading your post. Why can't we make a Unity | Synergy type horn using only compression drivers (for the highs and mids, duh.)? Arguably it won't be a true Danley horn since all of his (or the more reasonably sized ones anyway) use cone mids after a fashion. Other than astronomical costs[1] for example, I know that BMS makes coaxial compression drivers that go down to mid 100s Hz, and I just looked and you can get pure midrange CD that looks flat down to 400 Hz easy. Is a coaxial CD truly a point source? If not, just use a regular HF cd on the apex and one or more mid-freq CD at the point(s) where you would normally have the injector ports, then it is closer to a true Unity.

So, why not regulation CD for the midrange?

* In general, the fact that an idea has entered my Brain Cell pretty much disqualifies it from being wise. But, still worth checking!

[1] Somewhat in jest. I know that BMS is one of several reputable makes, but looks like you would pay about :

BMS 4591 mids = $237 (w/o tax, based on UK pricing -- bluearan.com );

BMS 4524 highs = $ 39 " "

So pricewise, not out of the question per speaker. Of course you can go cheaper, for example the Store Whose Name Must Not Be Spoken but in Roman numerals, means 1900

I mean DIY is great. If you can make a Unity from an old thimble and the diaphram from the earphone from a 1972 Longines Symphonette clock radio, more power to you! 🙄

Thanks Pete. One more thing to research for my wish-list.

Another Brilliant Idea* that just occurred to me, even before reading your post. Why can't we make a Unity | Synergy type horn using only compression drivers (for the highs and mids, duh.)? Arguably it won't be a true Danley horn since all of his (or the more reasonably sized ones anyway) use cone mids after a fashion. Other than astronomical costs[1] for example, I know that BMS makes coaxial compression drivers that go down to mid 100s Hz, and I just looked and you can get pure midrange CD that looks flat down to 400 Hz easy. Is a coaxial CD truly a point source? If not, just use a regular HF cd on the apex and one or more mid-freq CD at the point(s) where you would normally have the injector ports, then it is closer to a true Unity.

So, why not regulation CD for the midrange?

* In general, the fact that an idea has entered my Brain Cell pretty much disqualifies it from being wise. But, still worth checking!

[1] Somewhat in jest. I know that BMS is one of several reputable makes, but looks like you would pay about :

BMS 4591 mids = $237 (w/o tax, based on UK pricing -- bluearan.com );

BMS 4524 highs = $ 39 " "

So pricewise, not out of the question per speaker. Of course you can go cheaper, for example the Store Whose Name Must Not Be Spoken but in Roman numerals, means 1900

I mean DIY is great. If you can make a Unity from an old thimble and the diaphram from the earphone from a 1972 Longines Symphonette clock radio, more power to you! 🙄

^ obviously holy grail. But makes no sense because multi drivers are needed and if within a quarter wavelength there is nothing

1) You could, using a coaxial compression driver.1)Why can't we make a Unity | Synergy type horn using only compression drivers (for the highs and mids, duh.)?

2)Is a coaxial CD truly a point source?

3)So, why not regulation CD for the midrange?

2) Yes, if time aligned.

3) Because cone mid drivers have far more excursion and output with less distortion for a fraction of the cost.

The small cone speakers available now sort of chang the game. Almost making compression drivers obsolete at small room levels.

[Isolation Ward] realism in audio system

I'm quite enjoying my pedigree driver (BMS 8" coax) in the dubious "synergy" horn of the month 🙂 The imaging is excellent. It is prety well dialed in with "new" active EQ using the (new to me) JRiver and balanced "DAC" for active EQ.

I wish I could trial the "ultimate": Patrick Bateman said he was able to rent a set of SH-50 (but I think he lives in Cali.) I should sniff around and see if anywhere near Tamper I could rent a pair. Failing that, I hope to arrange a visit to DSL's shop in the GA area enroute my next trip north.

I had this humorous (?) thought to share: stealing the idea from an ancient H.P. Lovecraft story (the man awake at night, aone, total darkness, wishing to light his bedside lamp, and the matches are handed to him):

I was listening to a live set* by the Grateful Dead, at home alone, and the experience was so realistic I swear that somebody passed me a joint.

*This is one of the few bands that left a legacy of many live recordings because they allowed private recording at their shows. If only more would do the same.

I'm quite enjoying my pedigree driver (BMS 8" coax) in the dubious "synergy" horn of the month 🙂 The imaging is excellent. It is prety well dialed in with "new" active EQ using the (new to me) JRiver and balanced "DAC" for active EQ.

I wish I could trial the "ultimate": Patrick Bateman said he was able to rent a set of SH-50 (but I think he lives in Cali.) I should sniff around and see if anywhere near Tamper I could rent a pair. Failing that, I hope to arrange a visit to DSL's shop in the GA area enroute my next trip north.

I had this humorous (?) thought to share: stealing the idea from an ancient H.P. Lovecraft story (the man awake at night, aone, total darkness, wishing to light his bedside lamp, and the matches are handed to him):

I was listening to a live set* by the Grateful Dead, at home alone, and the experience was so realistic I swear that somebody passed me a joint.

*This is one of the few bands that left a legacy of many live recordings because they allowed private recording at their shows. If only more would do the same.

Attachments

Happy May Day!

...to all you commie pro-union Europeans, and for everyone else, to dance around the May Pole or whatever

Ahem, returning to the topic of DIY, my next iteration of my Travesty will be a hornier horn. For the present, I have set aside my dreams of making a high-tech enclosure at the HackerSpace. I'm experimenting with casting (?) the waveguide out of fabric and covering it with various sticky compounds 🙂

Thanks to our own natehansen66 and many others who have posted in the past about making the waveguide out of fabric and (usually) fiber glass. I've bought some Bondo but so far my experimens are with Gorilla glue.

Diy 15" EOS waveguide in progress.... - Page 2 - AVS Forum | Home Theater Discussions And Reviews

Memo to self: if you're going to be using xylene as a solvent (gorilla glue) and Nitro lacquer, do it in open air

Questions: just how sturdy does the waveguide need to be? Is fiberglass even needed? If it will not be load-bearing (enclosed in a cubic box made of coroplast)...?

Is there an easy way to achieve a smooth (interior) waveguide surface, without sanding and whatever? (Did I mention that I am lazy?) The "default" surface is rough to the touch.

...to all you commie pro-union Europeans, and for everyone else, to dance around the May Pole or whatever

Ahem, returning to the topic of DIY, my next iteration of my Travesty will be a hornier horn. For the present, I have set aside my dreams of making a high-tech enclosure at the HackerSpace. I'm experimenting with casting (?) the waveguide out of fabric and covering it with various sticky compounds 🙂

Thanks to our own natehansen66 and many others who have posted in the past about making the waveguide out of fabric and (usually) fiber glass. I've bought some Bondo but so far my experimens are with Gorilla glue.

Diy 15" EOS waveguide in progress.... - Page 2 - AVS Forum | Home Theater Discussions And Reviews

Memo to self: if you're going to be using xylene as a solvent (gorilla glue) and Nitro lacquer, do it in open air

Questions: just how sturdy does the waveguide need to be? Is fiberglass even needed? If it will not be load-bearing (enclosed in a cubic box made of coroplast)...?

Is there an easy way to achieve a smooth (interior) waveguide surface, without sanding and whatever? (Did I mention that I am lazy?) The "default" surface is rough to the touch.

Last edited:

Wavering waveguides

Here is my innovative ("not") process to perpetrate a waveguide: (not shown) a 24" square wood frame to which the fabric is stapled. Paint can is very close to desired diameter and height of WG ( ~ 8 ") so it makes a good weight.

WG #1 is best so far: 1 coat Gorilla + xylene; 2 coats Nitro lacquer; backed with Great Stuff.

WG #2: only had one coat Nitro; at first looked OK but wrinkled like a prune after the Great Stuff dried. It is now a reject 🙁

Other than getting high off the fumes, the only downside yet is (1) the expanding foam "contracts" the horn if it is not stiff enough.

(2) even on the "good" WG, there is some wrinkling. It is not clear how this will affect the WG in use. My lazy instinct tells me it is not worth trying to sand or fill this.

(3) Still don't know if a mirror smooth surface is required.

A positive spin: "While at first it may appear that the waveguide was botched during its fabrication, the bumps and folds are actually sophisticated frequency and phase correction devices to correct for room anomalies. The sandpaper-like surface of the waveguide smooths the sound waves as they pass. Note that a 320 grit is used closer to the throat because highs have short wavelengths, while a 80 grit is used at the mouth to remove rough edges from lower mid frequencies."

Damn I'm good; maybe I should ditch DIY and see if an audio manufactuer needs an advertising writer 😀

Here is my innovative ("not") process to perpetrate a waveguide: (not shown) a 24" square wood frame to which the fabric is stapled. Paint can is very close to desired diameter and height of WG ( ~ 8 ") so it makes a good weight.

WG #1 is best so far: 1 coat Gorilla + xylene; 2 coats Nitro lacquer; backed with Great Stuff.

WG #2: only had one coat Nitro; at first looked OK but wrinkled like a prune after the Great Stuff dried. It is now a reject 🙁

Other than getting high off the fumes, the only downside yet is (1) the expanding foam "contracts" the horn if it is not stiff enough.

(2) even on the "good" WG, there is some wrinkling. It is not clear how this will affect the WG in use. My lazy instinct tells me it is not worth trying to sand or fill this.

(3) Still don't know if a mirror smooth surface is required.

A positive spin: "While at first it may appear that the waveguide was botched during its fabrication, the bumps and folds are actually sophisticated frequency and phase correction devices to correct for room anomalies. The sandpaper-like surface of the waveguide smooths the sound waves as they pass. Note that a 320 grit is used closer to the throat because highs have short wavelengths, while a 80 grit is used at the mouth to remove rough edges from lower mid frequencies."

Damn I'm good; maybe I should ditch DIY and see if an audio manufactuer needs an advertising writer 😀

Attachments

Cool! Kinda comes full circle because I got the idea from Danley. He mentioned it as a sort of rapid prototyping process.

You're getting wrinkles because the material probably isn't pulled tight enough and it's too thin. Pull that thin material tight and you lose the conical profile. The car audio guys turned me on to fleece which works well. It's really rough though so I sand the high spots and focus on getting the throat right for my prototypes. I like the idea of using Great Stuff to beef it up but it would be difficult to get it applied uniformly.

I'm actually about to start a large Synergy horn myself (prototype with the fleece stretch) pretty soon if my personal life stays out of the way....

You're getting wrinkles because the material probably isn't pulled tight enough and it's too thin. Pull that thin material tight and you lose the conical profile. The car audio guys turned me on to fleece which works well. It's really rough though so I sand the high spots and focus on getting the throat right for my prototypes. I like the idea of using Great Stuff to beef it up but it would be difficult to get it applied uniformly.

I'm actually about to start a large Synergy horn myself (prototype with the fleece stretch) pretty soon if my personal life stays out of the way....

Cool! Kinda comes full circle because I got the idea from Danley. He mentioned it as a sort of rapid prototyping process.

You're getting wrinkles because the material probably isn't pulled tight enough and it's too thin. Pull that thin material tight and you lose the conical profile. The car audio guys turned me on to fleece which works well. It's really rough though so I sand the high spots and focus on getting the throat right for my prototypes. I like the idea of using Great Stuff to beef it up but it would be difficult to get it applied uniformly.

I'm actually about to start a large Synergy horn myself (prototype with the fleece stretch) pretty soon if my personal life stays out of the way....

Fleece works really well.

Here's a center console subwoofer built out of mdf, fiberglass and fleece, to give you an idea of how good the results can be. Pics courtesy of teamaudionutz.com

Someone may chime in and prove me wrong, but I can't really see why the surface has to be smooth. Just thinking of the size of the wavelengths (1" and up), seems like it would take a pretty substantial glob to really affect things much. Sort of the opposite side of why it's not worth rounding the corners of cabinets unless using a radius of a couple of inches at least (though part of that is because directivity keeps hf away from the edges already).

Someone may chime in and prove me wrong, but I can't really see why the surface has to be smooth. Just thinking of the size of the wavelengths (1" and up), seems like it would take a pretty substantial glob to really affect things much. Sort of the opposite side of why it's not worth rounding the corners of cabinets unless using a radius of a couple of inches at least (though part of that is because directivity keeps hf away from the edges already).

Are you then saying that in a SEOS-12 / 12" woofer build, that if the biggest roundover bit I have is 3/4" that it's not really useful?

Last edited:

According to Dr. Geddes, it's not. I haven't seen any evidence of it helping in the builds I've used round-overs on (though it can look pretty nice), but YMMV

Build it, measure it, and see.

Build it, measure it, and see.

Mindsource,

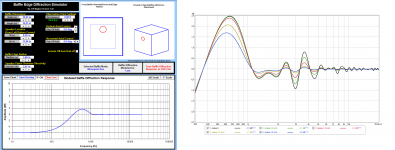

In Jeff Bagby calculator three inch edge radius looks as blue trace in left plot below, at right plot traces is 0/0.5/1.0/2.0/3.0 inch radius.

In Jeff Bagby calculator three inch edge radius looks as blue trace in left plot below, at right plot traces is 0/0.5/1.0/2.0/3.0 inch radius.

Attachments

Last edited:

Thanks guys!

Many good suggestions. Of course I don't expect a fine smooth perfectly formed waveguide, and so far I have not been disapointed 😛

Although what I'm doing is not at all original, it is kind of fun, not at all difficult, and quickly (1-2 days) produces a usable larger waveguide. The thought has occurred to me to make a tutorial with photos, something I've not yet seen anywhere. Foamcore board may be best for normal-ish rectangualr boxes, with the occasional tractrix bend thrown in for fun, but making odd hammocks with stretchy fibers and then applying sticky chemicas has a certain allure too 🙂

Beyond just making the waveguide, expanding foam also is a most versatile and inexpensive tool. Unlike fiberglass, at least Gorilla Glue and "Great Stuff" are polyurethane based and much less stinky if used indoors (although the aerosol does say to ventilate.) Foam(s) is used in all kinds of hobbies, not just nutso speaker building, such as for props or scenery for cosplay.

Design note: hot melt glue alone will hold the heavy 8" coax in place. For about 8 hours I am currently trying different methods to support said driver. If I could figure out a way to not gum up the driver, I would consider sealing th whole thing with foam.

I am currently trying different methods to support said driver. If I could figure out a way to not gum up the driver, I would consider sealing th whole thing with foam.

Quality control is lacking. 2nd "good" waveguide appears a few inches deeper than its mate. oops. In any case, I expect to hear a change with two "horns" that are closer to 90x90 degrees instead of (eyeballing it...) 45x45 of the Travesty 2.x they will replace.

It's amazing how easy it is to fashion a wave guide, with probably no more than $10-20 in parts per speaker (couple cans "Great Stuff" + unknown amount of Gorilla Glue + xylene + scrap wood + pilfered coroplast).

I now leave you with a video for making foam. I'd like to see if their method could be adapted to foaming (say) varnish or some plastic compound that would (duh) air-cure into a hard foam. I'll experiment outside....! Ah those crazy Norwegians. 🙂

Putting Exploding Expanding Foam Inside a House Is Totally Crazy

Many good suggestions. Of course I don't expect a fine smooth perfectly formed waveguide, and so far I have not been disapointed 😛

Although what I'm doing is not at all original, it is kind of fun, not at all difficult, and quickly (1-2 days) produces a usable larger waveguide. The thought has occurred to me to make a tutorial with photos, something I've not yet seen anywhere. Foamcore board may be best for normal-ish rectangualr boxes, with the occasional tractrix bend thrown in for fun, but making odd hammocks with stretchy fibers and then applying sticky chemicas has a certain allure too 🙂

Beyond just making the waveguide, expanding foam also is a most versatile and inexpensive tool. Unlike fiberglass, at least Gorilla Glue and "Great Stuff" are polyurethane based and much less stinky if used indoors (although the aerosol does say to ventilate.) Foam(s) is used in all kinds of hobbies, not just nutso speaker building, such as for props or scenery for cosplay.

Design note: hot melt glue alone will hold the heavy 8" coax in place. For about 8 hours

I am currently trying different methods to support said driver. If I could figure out a way to not gum up the driver, I would consider sealing th whole thing with foam.

I am currently trying different methods to support said driver. If I could figure out a way to not gum up the driver, I would consider sealing th whole thing with foam.Quality control is lacking. 2nd "good" waveguide appears a few inches deeper than its mate. oops. In any case, I expect to hear a change with two "horns" that are closer to 90x90 degrees instead of (eyeballing it...) 45x45 of the Travesty 2.x they will replace.

It's amazing how easy it is to fashion a wave guide, with probably no more than $10-20 in parts per speaker (couple cans "Great Stuff" + unknown amount of Gorilla Glue + xylene + scrap wood + pilfered coroplast).

I now leave you with a video for making foam. I'd like to see if their method could be adapted to foaming (say) varnish or some plastic compound that would (duh) air-cure into a hard foam. I'll experiment outside....! Ah those crazy Norwegians. 🙂

Putting Exploding Expanding Foam Inside a House Is Totally Crazy

Working ok, few bugs to swat...

Two pairs of speakers up and running. I did a quick paint job of the horns when they were dried, this is just black india ink and then a linseed oil & turpentine glaze with raw umber (I think) for a color. Looks leather-ish with my wavy horn; I am calling it a "Tiger Lily" as the colors remind me of said flower. this is a photo of the nicer one with less foam squeeze out 🙂

Biggest problem is how to mount the driver properly? Lacking anything resembling precision tools, it's mostly cut, fit, cut, etc. I may be getting some surround hitting the baffle, there are some buzzes on a sine sweep. Yet music sounds fine 🙂

Latest idiotic idea: since 24" cubes seems to be my format due to coroplast sizing, why can't I stick one or more huge woofers on the sides or top? I am running the coax 100 Hz > ... Other than losing my sub woofer as a base for the "tops", are there any other issues in having big woofers in a cube? There should be plenty of internal space (8 ft^3) less horn, less volume for coax (only needs a few liters)... but probably can't build it out of coroplast 🙁

Two pairs of speakers up and running. I did a quick paint job of the horns when they were dried, this is just black india ink and then a linseed oil & turpentine glaze with raw umber (I think) for a color. Looks leather-ish with my wavy horn; I am calling it a "Tiger Lily" as the colors remind me of said flower. this is a photo of the nicer one with less foam squeeze out 🙂

Biggest problem is how to mount the driver properly? Lacking anything resembling precision tools, it's mostly cut, fit, cut, etc. I may be getting some surround hitting the baffle, there are some buzzes on a sine sweep. Yet music sounds fine 🙂

Latest idiotic idea: since 24" cubes seems to be my format due to coroplast sizing, why can't I stick one or more huge woofers on the sides or top? I am running the coax 100 Hz > ... Other than losing my sub woofer as a base for the "tops", are there any other issues in having big woofers in a cube? There should be plenty of internal space (8 ft^3) less horn, less volume for coax (only needs a few liters)... but probably can't build it out of coroplast 🙁

Attachments

Content (for now!)

I did some more sweeps of them today. As far as I can tell the surround is not hitting the baffle ("a good thing"!). Still some minor buzzes just like with my Bose 901s when a sweep is run. Still I expect better of a premium German coax, but then I recall what enclosure it is in 😡

Latest annoyance is the occasional "glitch" (pop or click) in the playback. Right now I am committed to JRiver, which rarely has this problem except when playing using the "WDM" (to play audio from other Windows apps.) I can't run a reliable REW sweep.

This is what happens when you use an ancient (2010) Intel Atom netbook for your music server...plus email server....plus file server 😀

I think I have reached my optimum, sound wise. No, it's not a true Synergy*, but neither is Danley's SM100 🙂 Future efforts should be on a more permanent cabinet, perhaps some that (God forbid) might not be made out of coroplast

* I took the easy way out with a coax. I shall leave it to the ardent hobbyist with skills and tools to tweak those designs for the right HF and midrange drivers, etc. Those lucky few who have hit upon a working Synergy clone have achieved the acoustic equivalent of the legendary female who could suck the golf ball through the garden hose 😀

I did some more sweeps of them today. As far as I can tell the surround is not hitting the baffle ("a good thing"!). Still some minor buzzes just like with my Bose 901s when a sweep is run. Still I expect better of a premium German coax, but then I recall what enclosure it is in 😡

Latest annoyance is the occasional "glitch" (pop or click) in the playback. Right now I am committed to JRiver, which rarely has this problem except when playing using the "WDM" (to play audio from other Windows apps.) I can't run a reliable REW sweep.

This is what happens when you use an ancient (2010) Intel Atom netbook for your music server...plus email server....plus file server 😀

I think I have reached my optimum, sound wise. No, it's not a true Synergy*, but neither is Danley's SM100 🙂 Future efforts should be on a more permanent cabinet, perhaps some that (God forbid) might not be made out of coroplast

* I took the easy way out with a coax. I shall leave it to the ardent hobbyist with skills and tools to tweak those designs for the right HF and midrange drivers, etc. Those lucky few who have hit upon a working Synergy clone have achieved the acoustic equivalent of the legendary female who could suck the golf ball through the garden hose 😀

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Help the Ijit write Ijit's guide to Danley tech