Hi Gents.

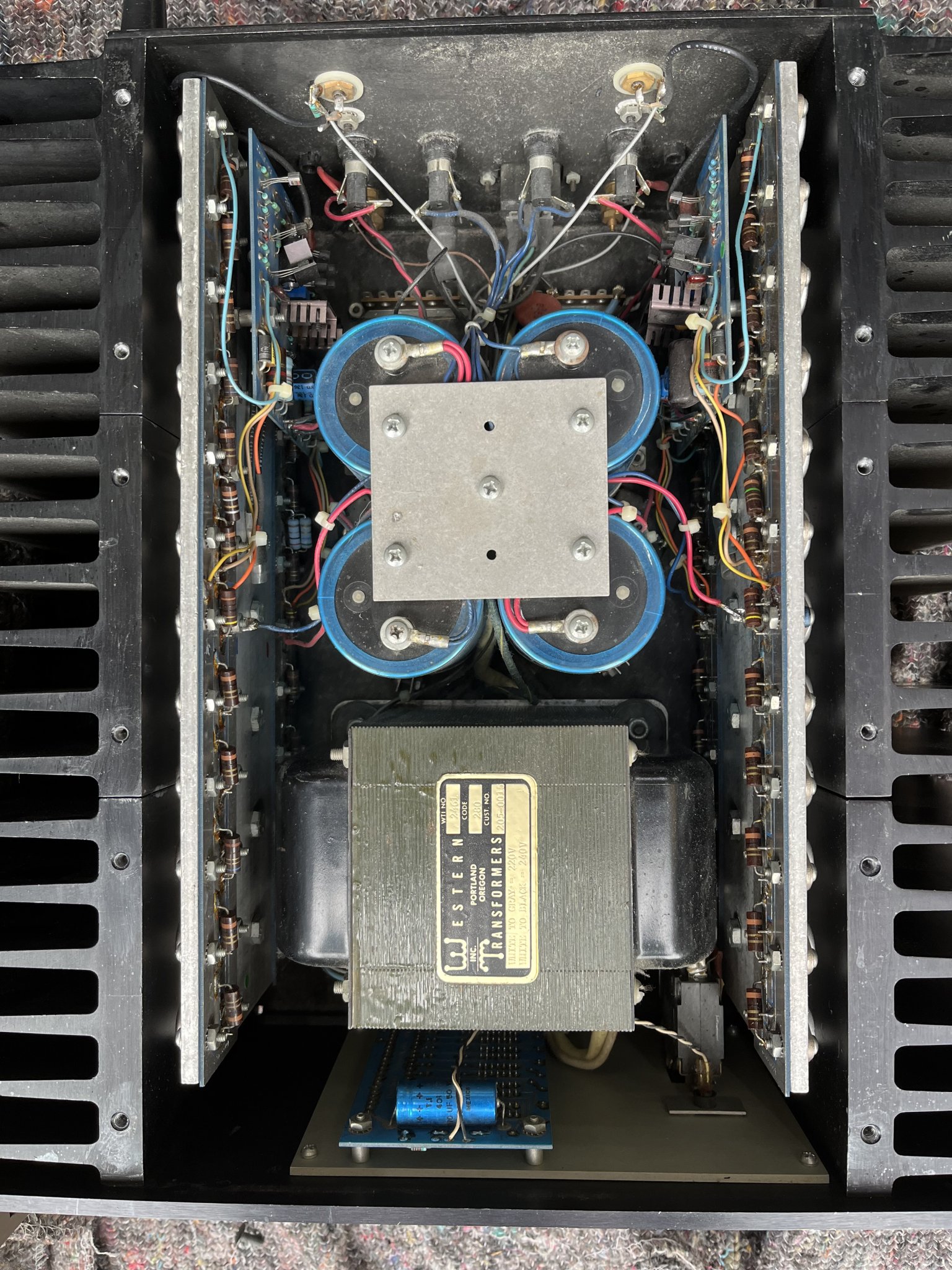

Recently bought this Stasis 2 as faulty ( the only way I could ever afford one )

Symptoms were : slowly over time was brought up to 240v using a variac , then used for a week until smoke was seen and then the left channel went down.

I’m no engineer but I can replace parts so I’m hoping someone can steer me in the right direction.

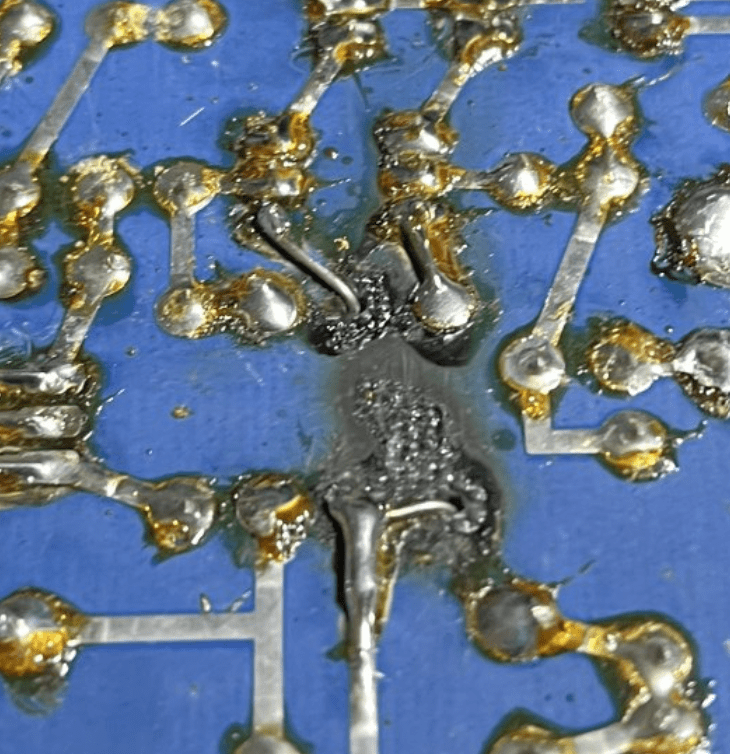

Any idea which component(s) have failed and caused the burn ? ( see photo also )

Any assistance would be greatly appreciated.

Recently bought this Stasis 2 as faulty ( the only way I could ever afford one )

Symptoms were : slowly over time was brought up to 240v using a variac , then used for a week until smoke was seen and then the left channel went down.

I’m no engineer but I can replace parts so I’m hoping someone can steer me in the right direction.

Any idea which component(s) have failed and caused the burn ? ( see photo also )

Any assistance would be greatly appreciated.

I would start by looking for a schematic and posting it here. Then I would clean the bulk of that smoke residue off of the board to try to decipher where it originated. Could be the 25/470 cap, could be a resistor.

To clean the board, you can use a Q tip and isopropyl alcohol. Also, make sure it is unplugged and confirm that the voltage has left the caps in the power supply.

How was the amp considered faulty when you purchased it?

To clean the board, you can use a Q tip and isopropyl alcohol. Also, make sure it is unplugged and confirm that the voltage has left the caps in the power supply.

How was the amp considered faulty when you purchased it?

Last edited:

The failure was as I wrote in the original post, after the sight of smoke and left channel going down the amp was switched off and now I have it .

Interesting. I suppose it is time to start idendifying the culprits.

The second channel looks as though it had never been repaired before. It looks like this resistor was pulling some serious current:

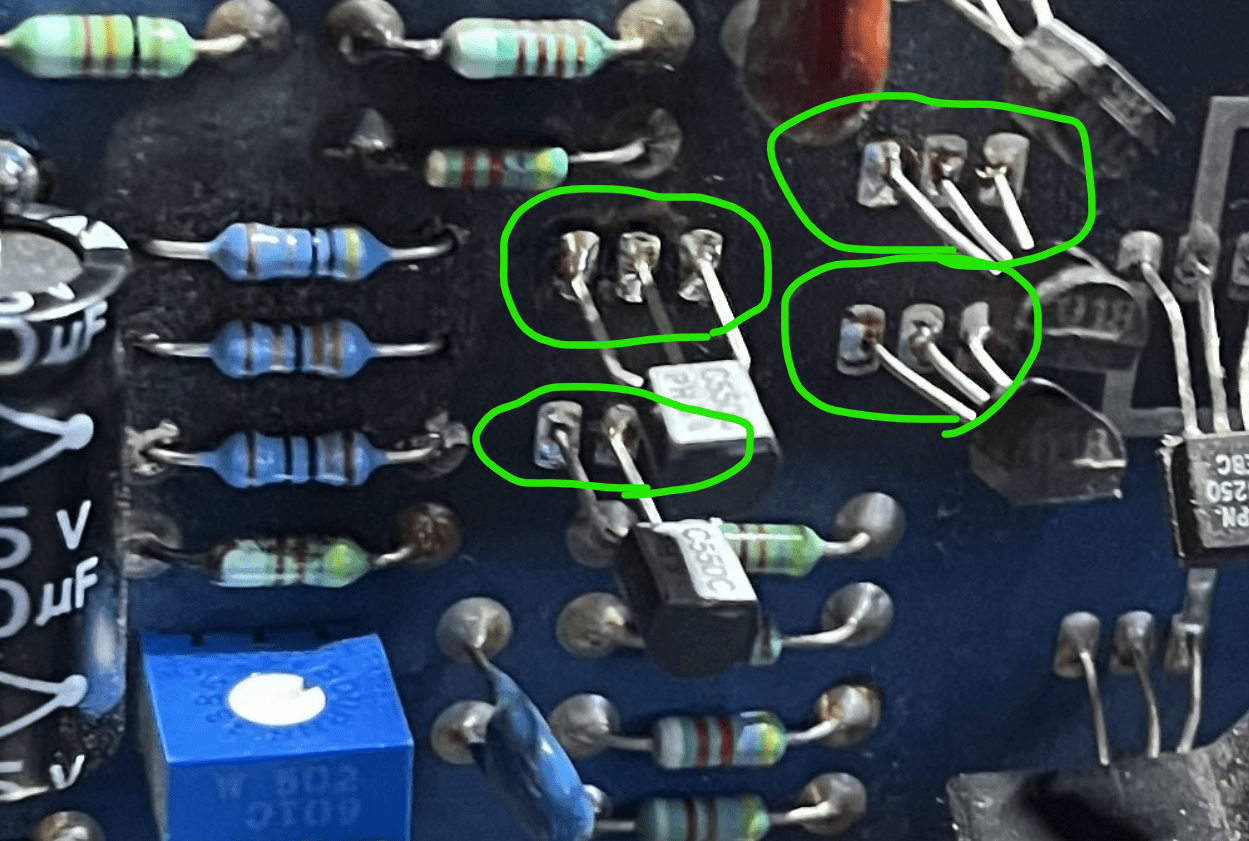

The first channel you posted looks to have been repaired after a part had blown:

The solder joints look to be shiney and new'er' on the first channel:

so the first channel may work. You can get a dim bulb tester or a variac and try to bring that channel up by itself slowly. The first thing that I would do is to start identifying the componants in the circuit and where they are. These old boards do not have a silkscreen which makes things a bit more difficult.

You can use the color codes as well as a multimeter to check the resistors. If a multimeter is slow to give you a ohm reading, you may have to lift one lead and retest. So to start off with, identify the resistors usign the resistor calculator I linked to and confirm that the resistors are within say 5% of that.

Once we know what is blown as far as resistors, we can see what active devices they are tied to and test those devices seperately.

The second channel looks as though it had never been repaired before. It looks like this resistor was pulling some serious current:

The first channel you posted looks to have been repaired after a part had blown:

The solder joints look to be shiney and new'er' on the first channel:

so the first channel may work. You can get a dim bulb tester or a variac and try to bring that channel up by itself slowly. The first thing that I would do is to start identifying the componants in the circuit and where they are. These old boards do not have a silkscreen which makes things a bit more difficult.

You can use the color codes as well as a multimeter to check the resistors. If a multimeter is slow to give you a ohm reading, you may have to lift one lead and retest. So to start off with, identify the resistors usign the resistor calculator I linked to and confirm that the resistors are within say 5% of that.

Once we know what is blown as far as resistors, we can see what active devices they are tied to and test those devices seperately.

Thanks mate ,

I will get the brain into gear in the morning and research what the values are of those components.

Cheers

I will get the brain into gear in the morning and research what the values are of those components.

Cheers

Sorry Mike , forgive my ignorance. Do I count all the bands on the resistors? There are silver bands that are not in the calculator?Interesting. I suppose it is time to start idendifying the culprits.

The second channel looks as though it had never been repaired before. It looks like this resistor was pulling some serious current:

View attachment 1267946

The first channel you posted looks to have been repaired after a part had blown:

View attachment 1267947

The solder joints look to be shiney and new'er' on the first channel:

View attachment 1267948

so the first channel may work. You can get a dim bulb tester or a variac and try to bring that channel up by itself slowly. The first thing that I would do is to start identifying the componants in the circuit and where they are. These old boards do not have a silkscreen which makes things a bit more difficult.

You can use the color codes as well as a multimeter to check the resistors. If a multimeter is slow to give you a ohm reading, you may have to lift one lead and retest. So to start off with, identify the resistors usign the resistor calculator I linked to and confirm that the resistors are within say 5% of that.

Once we know what is blown as far as resistors, we can see what active devices they are tied to and test those devices seperately.

the blue resistors are 5 band resistors with the brown being the tolerance.

Another thing to consider playing with at some point is this:

https://www.diyaudio.com/community/threads/new-stasis-front-end.363701/

When you get the amp working and confirm that the output stage is good to go, this new front end that Mr Pass designed does sound very nice. But save that in the back of your head for later 🙂

https://www.diyaudio.com/community/threads/new-stasis-front-end.363701/

When you get the amp working and confirm that the output stage is good to go, this new front end that Mr Pass designed does sound very nice. But save that in the back of your head for later 🙂

Okay cool. Worst case scenario, Jon Soderberg should be able to get it sorted out for you. If the issue lies in the front end, then you could probably even just send that piece in. But hopefully, it was just hooked up to a deadly source that did it in. If you can get the actives for pretty cheap, it may be handy to get them as well.

Thanks again Mike . Having now slept on it I think this is beyond my skill set so I’m going to get it repaired by someone who knows what they’re doing. This has the potential to be the best amp I’ve ever had and I’m not able to diagnose what happened to it so even if I did get it working it could just do it again or worse.

I take it that Jon is in the USA ?

I take it that Jon is in the USA ?

He sure is, see post #12 in the thread below. Jon was at Threshold in the good old days.

https://www.diyaudio.com/community/threads/vintage-amp-repair-closed.392033/

https://www.diyaudio.com/community/threads/vintage-amp-repair-closed.392033/

That sounds fair. Circle back here with some listening impressions when you get the amp sorted out 🙂

Have a look at this thread - https://www.diyaudio.com/community/threads/new-stasis-front-end.363701/

Nelson designed this new front end pcb for a member who was exactly in the same situation you are in now. It might be cheaper to update to this FE rather than send boards to the US with associated repair costs. NP has supplied the gerbers in the thread, so not too hard to get new replacement boards made.

Just a thought.

Nelson designed this new front end pcb for a member who was exactly in the same situation you are in now. It might be cheaper to update to this FE rather than send boards to the US with associated repair costs. NP has supplied the gerbers in the thread, so not too hard to get new replacement boards made.

Just a thought.

- Home

- Amplifiers

- Pass Labs

- Help please with my poorly Stasis 2