That sounds like a good idea. I was thinking about doing it with speaker in horizontal position, but gravity is (relatively, no pun intended) constant, so might as well use it..

I think vertical is the only way to correct the sag. Just don’t be in a hurry with the hairdryer. Patience is your friend. It took many years to sag, it won’t correct itself overnight.

Hi @Galu, I have recently acquired a pair identical to yours. Mind sharing how you use them (which enclosures). I am eager to do something with mine.Wharfedale components were shipped to the USA where loudspeaker versions different to those obtainable in the UK were manufactured.

We would need to find a US Wharfedale catalogue as the drivers illustrated do not appear in the UK catalogue.

This is what the RS12DD looks like for comparison purposes.

The RS12DD looks superior to your model and is still highly prized over here.

PS is anybody familiar with the open weave fabric surround? Seems like it isn’t an effective barrier between front and back, but there’s no sign that it was previously coated or doped or the like...

Yes, have you tried to blow/shoot air through them?

Regardless, I traced this product back to being Airflex's replacement for decades long toxic 5100 used on Altec, et al: Speaker Repair Adhesive, Sealer, Cloth Surrounds, Foam Surrunds, MI-1291

@ naboo123

Have just seen your request.

Bedtime here, will see what I can contribute tomorrow. 🙂

Have just seen your request.

Bedtime here, will see what I can contribute tomorrow. 🙂

Thanks @Galu@ naboo123

Have just seen your request.

Bedtime here, will see what I can contribute tomorrow. 🙂

I have te Briggs leaflet with the boxed design and slats at the back, that you refer to in another post. I was just wondering whether you use that design, or perhaps another. The Frugal Horn XL that @planet10 is involved in seems lovely, but I doubt that anyone has tried/designed it with this driver.

Not sure it can help, considering the stubborness of the so called "weak sex" minds BUT North and South Hemispheres have exact 180 degrees out of phase Seasons.The Chief Cook & Bottle Washer (CC&BW) has declared a "Spring Cleaning Emergency". In January. She says it's gotta be Springtime somewhere; says the same thing about 5 o'clock.

NO 45 - 60 - 90 degrees difference anywhere on the Planet.

So January is EITHER Winter (Northern Hemisphere, all around the World) OR Summer (Southern Hemisphere, again all around the World), NO SPRING ANYWHERE ON THE WHOLE WORLD.

Will it help you?

Dunno, lately a wave of anti-science and anti-logic is sweeping the World with extreme virulence but hey, you may try. 😛

EDIT: as of the speakers themselves:

If yours show canting, soft edges may have *some* influence but the main culprit is the spider/suspension which is harder.

Obviously deformed by gravity and age, you should try to restore its original shape and position.

Personally I would:

1) cut dustcap to have access to voice coil.

2) shim voice coil both to guarantee centering and keep it there while I work on the suspension (and cloth edge).

3) soften suspension and edge with solvents.

Suspension is made out of cotton cloth impregnated with phenolic varnish and cooked under pressure in proper shaped dies; it´s softened (not dissolved) by acetone, Ethyl Ether or nitro paint thinner, you can wet a ring around the suspension and then let it dry naturally, face up on a table.

Apply it with a small brush or wet Q-Tips but be careful not to wet the cone-suspension joints nor the suspension-frame ones to avoid softening their adhesives.

Do the same with the inverted cloth edge, but since impregation is some kind of (syntetic) latex preferred solvent is toluene - xylene - benzene or, easier to find for mere mortals 😉 , lighter fluid.

The idea is that the gravity (and weather and age) deformed part softes, takes the new shape and re-hardens keeping it.

I do NOT recommend heat, mainly because those parts are already dried and hardened, it´s better to partially resoften them.

Let them redry fully , undisturbed, face up, in a place away from Sun and drafts, for a couple days.

Then pull shims and reglue cut dustcap, you can use a bead of gel type Cyano adhesive, it will dry light and have minimal effect on sound.

If yours show canting, soft edges may have *some* influence but the main culprit is the spider/suspension which is harder.

Obviously deformed by gravity and age, you should try to restore its original shape and position.

Personally I would:

1) cut dustcap to have access to voice coil.

2) shim voice coil both to guarantee centering and keep it there while I work on the suspension (and cloth edge).

3) soften suspension and edge with solvents.

Suspension is made out of cotton cloth impregnated with phenolic varnish and cooked under pressure in proper shaped dies; it´s softened (not dissolved) by acetone, Ethyl Ether or nitro paint thinner, you can wet a ring around the suspension and then let it dry naturally, face up on a table.

Apply it with a small brush or wet Q-Tips but be careful not to wet the cone-suspension joints nor the suspension-frame ones to avoid softening their adhesives.

Do the same with the inverted cloth edge, but since impregation is some kind of (syntetic) latex preferred solvent is toluene - xylene - benzene or, easier to find for mere mortals 😉 , lighter fluid.

The idea is that the gravity (and weather and age) deformed part softes, takes the new shape and re-hardens keeping it.

I do NOT recommend heat, mainly because those parts are already dried and hardened, it´s better to partially resoften them.

Let them redry fully , undisturbed, face up, in a place away from Sun and drafts, for a couple days.

Then pull shims and reglue cut dustcap, you can use a bead of gel type Cyano adhesive, it will dry light and have minimal effect on sound.

The Wharfedale RS/12/DD works well in a variety of enclosure types of internal volume 2 cu ft and upwards.Hi @Galu, I have recently acquired a pair identical to yours. Mind sharing how you use them (which enclosures). I am eager to do something with mine.

I've had mine from new in the late 1960s and I originally fitted them in a 3 cu ft slotted back enclosure as per Wharfedale's Cabinet Construction Sheet. The result was a clear, open and resonant free sound reproduction.

However, I felt I wanted more 'oomph' in the bass, as well as a more modern appearance, so I designed a new taller and narrower enclosure. I stayed with the 3 cu ft internal volume, but reflex tuned the enclosure to 40Hz in the traditional manner à la Briggs and was pleased with the improvement in the bass.

I'm not at home at the moment or I could give you the exact dimensions of the small circular port I used. I made an impedance versus frequency plot at the time (we're talking the 1970s here!) which showed the expected two impedance peaks to be symmetrically arranged around the 40 Hz tuning frequency dip in the traditional reflex manner.

I'm afraid I've never experimented with more sophisticated enclosures. Suffice it to say that it's a case of the bigger the better for the RS/12/DD.

preferred solvent is toluene - xylene - benzene or, easier to find for mere mortals 😉 , lighter fluid.

In the states, xylene is readily available in the paint section at hardware stores.

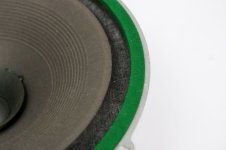

A wee word on Wharfedale roll surrounds:

The doped fabric roll surrounds of my RS/12/DD speakers were 'see-through' (as seen in the attachment) on the day I bought them over 50 years ago - and they look exactly the same today. I see no need to re-dope them as I don't consider them to be faulty.

The 12⅜" frame diameter drivers were intended to be rear mounted with a baffle cut out of 10⅞" in diameter.

The doped fabric roll surrounds of my RS/12/DD speakers were 'see-through' (as seen in the attachment) on the day I bought them over 50 years ago - and they look exactly the same today. I see no need to re-dope them as I don't consider them to be faulty.

The 12⅜" frame diameter drivers were intended to be rear mounted with a baffle cut out of 10⅞" in diameter.

Attachments

Thanks for taking the time to respond @Galu. What you're saying makes sense, and perhaps I should try to determine T/S parameters and go with a normal ported enclosure, seems like that is what you have at the moment.The Wharfedale RS/12/DD works well in a variety of enclosure types of internal volume 2 cu ft and upwards.

I've had mine from new in the late 1960s and I originally fitted them in a 3 cu ft slotted back enclosure as per Wharfedale's Cabinet Construction Sheet. The result was a clear, open and resonant free sound reproduction.

However, I felt I wanted more 'oomph' in the bass, as well as a more modern appearance, so I designed a new taller and narrower enclosure. I stayed with the 3 cu ft internal volume, but reflex tuned the enclosure to 40Hz in the traditional manner à la Briggs and was pleased with the improvement in the bass.

I'm not at home at the moment or I could give you the exact dimensions of the small circular port I used. I made an impedance versus frequency plot at the time (we're talking the 1970s here!) which showed the expected two impedance peaks to be symmetrically arranged around the 40 Hz tuning frequency dip in the traditional reflex manner.

I'm afraid I've never experimented with more sophisticated enclosures. Suffice it to say that it's a case of the bigger the better for the RS/12/DD.

I have built that design on other speakers and I think I would like to try something new. I am considering a Tqwt design, or a horn similar to the Frugal Horn XL. I lack the crossover skills to tune the Frugal Horn, though. Still trying to figure out which design would tick the most boxes. Once done I will send you a pic 😉

If you do get round to measuring the T/S parameters of your particular RS/12/DDs, I'd be interested in seeing them.

Good luck with your project. I'm holding you to that promise of a pic!

Good luck with your project. I'm holding you to that promise of a pic!

Hi

I promised I'd post the driver parameters. The two drivers measured differently. There are two things that I think might account for the difference: 1)The second driver had been running for a week and the first probably hasn't seen action for some time. 2)There seems to be two small abnormalities in the surround of the second driver, but I can't think that it could have an influence, looks benign to me.

Driver 1 Driver 2

R(e) 11.28 12.39

F(s) 34.99 29.61

Q(ts) 0.3863 0.2816

Q(es) 0.4415 0.326

Q(ms) 3.095 2.07

L(e) mH(10k) 0.4835 0.5162

R(t) 0.3608

I am now seriously considering building mini-onkens from these drivers. The best setup I have heard in my limited exposure to hi-fi have been Onkens with Altec 406's in them - the sound really worked for me. Sure, these aren't Altecs but I can't lose much by trying 🙂

Anyone with knowledge on whether these would work in mini-onkens?

I promised I'd post the driver parameters. The two drivers measured differently. There are two things that I think might account for the difference: 1)The second driver had been running for a week and the first probably hasn't seen action for some time. 2)There seems to be two small abnormalities in the surround of the second driver, but I can't think that it could have an influence, looks benign to me.

Driver 1 Driver 2

R(e) 11.28 12.39

F(s) 34.99 29.61

Q(ts) 0.3863 0.2816

Q(es) 0.4415 0.326

Q(ms) 3.095 2.07

L(e) mH(10k) 0.4835 0.5162

R(t) 0.3608

I am now seriously considering building mini-onkens from these drivers. The best setup I have heard in my limited exposure to hi-fi have been Onkens with Altec 406's in them - the sound really worked for me. Sure, these aren't Altecs but I can't lose much by trying 🙂

Anyone with knowledge on whether these would work in mini-onkens?

- Home

- Loudspeakers

- Full Range

- HELP, please, ID'ing these 12" speakers