Hi guys,

I have broken a pcb track on a board in my xa5400es player whilst trying to upgrade some components.

Please bear with me, it is the first time i do smd soldering..

I use flux and have a very fine point on the iron.

I also have solder suck wire and a big magnifying glass with light.

So should be ok with this job, need to be more carefull though...

I have broken a pcb track on a board in my xa5400es player whilst trying to upgrade some components.

Please bear with me, it is the first time i do smd soldering..

I use flux and have a very fine point on the iron.

I also have solder suck wire and a big magnifying glass with light.

So should be ok with this job, need to be more carefull though...

Attachments

Last edited:

I can't positively identify the trace in the photo.

What I do for repair is take an exacto blade and scrape off the solder mask on each side of the break so I get to shiny copper. Then I take an appropriate size of solid wire (cut off component leads work well) and lay it across the break. Then apply fresh solder all along the wire so it bridges the break.

What I do for repair is take an exacto blade and scrape off the solder mask on each side of the break so I get to shiny copper. Then I take an appropriate size of solid wire (cut off component leads work well) and lay it across the break. Then apply fresh solder all along the wire so it bridges the break.

I have identified it in the page of the service manual, the red line is the part which came with the component and broke the tracks.

Attachments

Last edited:

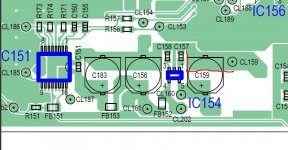

So maybe if you look at this picture there is no broken track?

The track came loose from the board and i thought i broke it.

Can someone see if the track is still intact?

If any pictures , sketches or pages from the service manual are needed, please ask!!

The track came loose from the board and i thought i broke it.

Can someone see if the track is still intact?

If any pictures , sketches or pages from the service manual are needed, please ask!!

Attachments

OK, there in the center of your photo. You can use the method I described above to repair the track. Then, when you reinsert the new component, verify that both its leads are connected in circuit. That may mean it will need a bit more solder, or even another small wire to jumper over to the previous bridge. This applies to thru-hole or SMT.

Before power-up, it's a good idea to use an ohmmeter to make sure what should be connected is, and what shouldn't be connected isn't.

Before power-up, it's a good idea to use an ohmmeter to make sure what should be connected is, and what shouldn't be connected isn't.

I can't positively identify the trace in the photo.

What I do for repair is take an exacto blade and scrape off the solder mask on each side of the break so I get to shiny copper. Then I take an appropriate size of solid wire (cut off component leads work well) and lay it across the break. Then apply fresh solder all along the wire so it bridges the break.

That is a good tip, thank you, however, now i am not certain that a track has broken, it came loose, and as it is the first time i work on a pcb, it scared me and i thought i had broke it, not so sure now, can i check for continuity?

With a multimeter (never done that too, but shouldn't be too hard i expect?)

It is an electrolytic capacitor. You can use a through hole component and using it's legs to complete the track.

Not hard at all. Set your multimeter to the lowest ohms scale (which may be the continuity beeper, or the next higher setting), then probe across each side of the possible break, at points that aren't covered with solder mask so you get reliable readings.That is a good tip, thank you, however, now i am not certain that a track has broken, it came loose, and as it is the first time i work on a pcb, it scared me and i thought i had broke it, not so sure now, can i check for continuity?

With a multimeter (never done that too, but shouldn't be too hard i expect?)

Practising this kind of work on a player that is currently advertised at nearly $6000 doesn't seem a good idea imo 🙂

Again, SMD repair takes skill... One would have to question also what improvements you expect to get from such a mod?

Yes, true, i found out..

But the other caps went good.

I am replacing the small caps for Elna Silmic.

I hope that it will be worthwile☺

And hope that the player works when i fire her up..

Keep you posted, hope to finish today.

But the other caps went good.

I am replacing the small caps for Elna Silmic.

I hope that it will be worthwile☺

And hope that the player works when i fire her up..

Keep you posted, hope to finish today.

Last edited:

The capacitors Sony use are organic and usually manufactured by Sanyo. They rarely change value but when very old tend to smell of fish as you remove them from the PCB. It is difficult to improve on a design by a manufacturer like Sony. I see people using gold plated mains IEC connectors ... makes me laugh. Is the household wiring gold plated? I think not so no improvement there then, just money in someone else's bulging pocket.

Always use plenty of flux and a hot iron. That will avoid track damage.

Always use plenty of flux and a hot iron. That will avoid track damage.

The capacitors Sony use are organic and usually manufactured by Sanyo. They rarely change value but when very old tend to smell of fish as you remove them from the PCB. It is difficult to improve on a design by a manufacturer like Sony. I see people using gold plated mains IEC connectors ... makes me laugh. Is the household wiring gold plated? I think not so no improvement there then, just money in someone else's bulging pocket.

Always use plenty of flux and a hot iron. That will avoid track damage.

Thanks Jon,

i have the iron at 480 Celcius when i remove the component and at 400 when i place it.

Should i always leave it at 480?

Different player i presume?

Bought mine 2nd hand for 390€

Dunno 🙂 I swiped it into Bing and this came up,

Brand New Sony SCD-XA5400ES SACD Super Audio CD Player SCDXA5400ES HATS Tech 0027242737075 | eBay

Dunno 🙂 I swiped it into Bing and this came up,

Brand New Sony SCD-XA5400ES SACD Super Audio CD Player SCDXA5400ES HATS Tech 0027242737075 | eBay

That's just crazy..

The retail price was 1600, i had luck with the 390, sure, but still you can buy a secondhand player here in the Netherlands for 450.

Thank you all guys, all went well, the player is still alive..

I made a repair by first scraping a portion of the track on each side of the broken track until shiny copper spots were created and secondly using some strings of wire with solder and flux to bridge these and that did the trick!

I made a repair by first scraping a portion of the track on each side of the broken track until shiny copper spots were created and secondly using some strings of wire with solder and flux to bridge these and that did the trick!

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- Help please, broke a pcb track on xa5400es sacd player