Go on, rub it in 🙂

Btw, just measured the phase shift with the manufacturer's recommended 4uF cap. It is spot on 60deg. Not sure what sense to make out of this. So this motor is not supposed to be driven at 90deg between the phases? With a more appropriate transformer power consumption in this connection dropped to 45W.

90 degrees phase shift with a capacitor into a resistive load is asymptotic. Into a reactive load, who knows, but 60 degrees sounds feasible. Papst will have shifted the physical location of the windings to correspond to the expected phase shift. It's still a delta connected 3 phase motor, just designed to run a little differently and the power sum will no longer be constant.

Is this motor even synchronous? It displays some very strange behaviour. By changing the frequency i can get very accurate adjustments up to about 33.23rpm after which there is a jump to 33.9. By reducing the frequency the same jump happens on the way down with some hysteresis. This is at roughly 58Hz, so pretty close to its intended operational frequency.

Is this motor even synchronous? It displays some very strange behaviour. By changing the frequency i can get very accurate adjustments up to about 33.23rpm after which there is a jump to 33.9. By reducing the frequency the same jump happens on the way down with some hysteresis. This is at roughly 58Hz, so pretty close to its intended operational frequency.

It's not a permanent magnet motor, it's an "Outer rotor eddy current motor" think of the outer shell as the eddy current part of a linear eddy current motor in a ring. Anyway, the optimal phase will be only approximately what you measure with a cap hookup.

As soon as you stray far from the design frequency you end up with issues. I don't think mine liked working at around 67.5Hz (45rpm), but it's been at least 10 years since I was experimenting with it.

Do not want to add to the confusion but how many wires are coming out of the motor. Did you measure them and are they equal. The papst motor both Ralph and I have have caps listed on them. But running it 3 phase for years.

On a different note it would be interesting if you shared how you went about using a Arduino for frequency generator and other things. Can you do slow ramp up on voltage?

Would be fun to see this vs the Phoenix stuff.

Enjoy the ride

Tom

On a different note it would be interesting if you shared how you went about using a Arduino for frequency generator and other things. Can you do slow ramp up on voltage?

Would be fun to see this vs the Phoenix stuff.

Enjoy the ride

Tom

Spin it with a power drill, somewhat below design speed, and look at the waveforms on all windings.

It may do nothing. It may go to HIGH voltage.

If it comes to near nominal voltage, those generator phases are the optimum phases for the motor.

Note that a motor can be wound 3-phase or 2-phase. Note that a phase cap may not give "perfect angle" if it is used mostly for starting and getting up near sync speed where a motor can work 1-winding, or where a heavy load must be pulled and a larger frame must be picked to handle the heat.

It may do nothing. It may go to HIGH voltage.

If it comes to near nominal voltage, those generator phases are the optimum phases for the motor.

Note that a motor can be wound 3-phase or 2-phase. Note that a phase cap may not give "perfect angle" if it is used mostly for starting and getting up near sync speed where a motor can work 1-winding, or where a heavy load must be pulled and a larger frame must be picked to handle the heat.

Do not want to add to the confusion but how many wires are coming out of the motor. Did you measure them and are they equal.

3 wires. Both inductance and resistance between any two are identical.

The generation uses an 8-bit lookup table for the sine and PWM. Nearly 20 years ago i did the same but using 8-bit dacs at the output and that worked out just as well. It is amazing how time flies.

If it comes to near nominal voltage, those generator phases are the optimum phases for the motor.

That's a great idea! Will have to wait for next month as i have no one reliable to hold the hand drill at the moment 🙂

Unfortunately I don't think you will generate a significant output from one of these motors as there's little or no residual magnetic field in the rotor.

I would suggest you check out some discussions started by member Pyramid:

1. DIY 4 Phase Sinewave Generator for Turntable Motor Drive

2. 3 Phase BLDC motor for turntable use?

Pyramid was the power behind the Roadrunner and Eagle which together provided a tremendous upgrade to turntables using a hysteresis synchronous motor (? I could be wrong on this nomenclature) the type of motor found in many belt driven turntables.

The first of these two threads presents a very sophisticated signal generating project which can provide 2 or 3 phase signals with adjustable frequency and phase, links to OSH for circuit boards and possible firmware. Total cost to build is around $100. It requires only some power amplification and possibly a step-up transformer to run a motor.

The second thread is a great discussion of a much more sophisticated three phase motor drive although Pyramid's circuit in this case is designed around a specific BLDC motor from Anaheim Automation. You may be able to modify it to drive other motors but he makes it fairly clear that you will be on your own.

Hal (Frogeye)

1. DIY 4 Phase Sinewave Generator for Turntable Motor Drive

2. 3 Phase BLDC motor for turntable use?

Pyramid was the power behind the Roadrunner and Eagle which together provided a tremendous upgrade to turntables using a hysteresis synchronous motor (? I could be wrong on this nomenclature) the type of motor found in many belt driven turntables.

The first of these two threads presents a very sophisticated signal generating project which can provide 2 or 3 phase signals with adjustable frequency and phase, links to OSH for circuit boards and possible firmware. Total cost to build is around $100. It requires only some power amplification and possibly a step-up transformer to run a motor.

The second thread is a great discussion of a much more sophisticated three phase motor drive although Pyramid's circuit in this case is designed around a specific BLDC motor from Anaheim Automation. You may be able to modify it to drive other motors but he makes it fairly clear that you will be on your own.

Hal (Frogeye)

It seems the OP is already at this level. Point is that his specific motor just needs single phase 230 V mains with a 4 uF capacitor to run fine @ 35W power consumption. A bit just like the motor was designed for.

Last edited:

Perhaps the only part i need no help with is the signal generator, which works very well, thank you and is based on code i have in front of me and can modify in any way i see fit.

Which for me is more important than having something, perhaps engineered to a much higher standard but being a proprietary commercial solution.

In short none of what you suggest can have the slightest effect on making this motor run on 3-phase 🙂

From my POV this thread has pretty much run its course. It has really helped me understand the issue of driving this particular motor simply cannot be resolved with a 3-phase driving system. Driven from a single phase with a cap the motor is too noisy for any serious consideration. It is more fitting for some agricultural attachment than for a turntable 🙂

Which for me is more important than having something, perhaps engineered to a much higher standard but being a proprietary commercial solution.

In short none of what you suggest can have the slightest effect on making this motor run on 3-phase 🙂

From my POV this thread has pretty much run its course. It has really helped me understand the issue of driving this particular motor simply cannot be resolved with a 3-phase driving system. Driven from a single phase with a cap the motor is too noisy for any serious consideration. It is more fitting for some agricultural attachment than for a turntable 🙂

Have you had a look at this thread:-

Optimally driving a (VPI) synchronous turntable motor

Ignore the title, there's a lot of info regarding driving 120 and 220V Papst motors as 3 phase units, using different amplifiers, transformers, and how to avoid startup problems.

Optimally driving a (VPI) synchronous turntable motor

Ignore the title, there's a lot of info regarding driving 120 and 220V Papst motors as 3 phase units, using different amplifiers, transformers, and how to avoid startup problems.

From my POV this thread has pretty much run its course. It has really helped me understand the issue of driving this particular motor simply cannot be resolved with a 3-phase driving system. Driven from a single phase with a cap the motor is too noisy for any serious consideration. It is more fitting for some agricultural attachment than for a turntable 🙂

The cold world of hard facts 🙂 Anyway I wish you luck in finding a decent 3 (or even 4) phase motor that works ok in your setup.

Last edited:

🙄Sadly too many people give up too easily, the thread I referred to above went to 42 pages, and out of it came Pyramid's 4 phase generator, and a lot of other good ideas along the way

He already has a 3 phase motor! What he needs is a good amplifier/transformer setup.

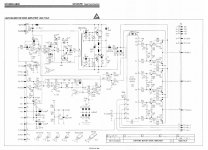

Here is a page from a Studer Tape recorder service manual, showing the Papst motor driven by a 3 phase supply:-

He already has a 3 phase motor! What he needs is a good amplifier/transformer setup.

Here is a page from a Studer Tape recorder service manual, showing the Papst motor driven by a 3 phase supply:-

Attachments

Last edited:

4 phase will be hard with only 3 wires. I guess it is possible to use airplanes on railtracks but it is more simple to fly with airplanes and use trains on railtracks.

If you would read the posts you would learn OP already has the described setup but unfortunately an unsuitable motor. Not all Aussenläufer are equal.

If you would read the posts you would learn OP already has the described setup but unfortunately an unsuitable motor. Not all Aussenläufer are equal.

Last edited:

Now you're just being silly!

The 4 phase generator allows 0, 90 120 and 240 degree outputs. suitable for driving either a 2 phase motor, eg Hurst or Premotec, or a 3 phase motor such as the Papst or BLDC motor that Pyramid developed

The 4 phase generator allows 0, 90 120 and 240 degree outputs. suitable for driving either a 2 phase motor, eg Hurst or Premotec, or a 3 phase motor such as the Papst or BLDC motor that Pyramid developed

You are probably right (I haven’t read the links yet) and I was thinking of true 4 phase motors but it does not change the fact that this specific motor is very likely not suitable. Everything else may be layed out in details in fantastic designed electronic contraptions described in endless threads costing many hours and probably also much energy but in this case OP must look for another motor.

Last edited:

but in this case OP must look for another motor.

Yup.

The motor issue is not trivial. Seems like most manufacturers choose BLDC motors for new designs and i really don't like the way these sound. Even commercial examples costing thousands.

My old Maxon dc brushed motor from the Teres project is very quiet but the short term speed stability is atrocious no matter how it is driven. It seems running a dc motor at 10% of its rated voltage is not a brilliant idea.

The more expensive Maxon motors and the old Papst capstan motors are probably great, provided one has the means of having a pulley manufactured. It is certainly worth looking into.

- Home

- Source & Line

- Analogue Source

- Help driving a 3-phase Papst ausenlaufer